turn signal bulb PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 132 of 1825

STEERING, SUSPENSION, TIRES AND WHEELS DIAGNOSIS 3-7

e To determine if turn signal switch is inoperative,

substitute new turn signal switch into circuit and

operate switch by hand.

If the car's lights operate

normally, turn signal switch is inoperative.

Front Or Rear Turn Signal Lights Not Flashing

Inspect

s Burned-out or damaged turn signal bulb

e High resistance conection to ground at bulb

socket

s Loose chassis-to-column connector. Disconnect

column-to-chassis connector and connect new

turn signal switch into system and operate switch

by hand.

A. If turn signal lights are now on and flashing,

turn signal switch is inoperative.

B. If car lights do not operate, refer to Section

8A

for electrical diagnosis.

Turn Indicator Panel Lights

Inspect

Burned out bulbs or opens, grounds in the wiring

harness from the front turn signal bulb socket to the

indicator lights. Refer to Section

8A for electrical

diagnosis.

Stop Light Mot On When Turn Indicated

Inspect

s Loose column-to-chassis connection

e Disconnect the column-to-chassis connector and

connect the new turn signal switch into the

system and operate the switch by hand.

A. If the brake lights work when the switch is

in the turn position, the turn signal switch

is inoperative.

B. If the brake lights do not work, refer to Section

8A for electrical diagnosis.

Turn Signal Lights Flash Very Slowly

e Loose chassis-to-column connection

a Disconnect the column-to-chassis connector and

connect a new turn signal switch into the system

and operate the switch by hand.

A. If the lights flash at a normal rate, the turn

signal switch is inoperative.

B. If the Lights still flash very slowly, refer to

Section

8A for electrical diagnosis.

Hazard Signal Lights Will Not Flash - Turn

Signal Functions Normally

~"SPBC~

a Blown fuse

Inoperative hazard warning flasher

e Loose chassis-to-column connection

s Disconnect the column-to-chassis connector and

connect a new turn signal switch into the system,

then press in the hazard warning button and

watch the hazard warning lights.

A. If the lights now work normally, the turn

signal switch is inoperative.

B. If the lights do not flash, check the wiring

harness. Refer to Section

8A for electrical

diagnosis.

IGNITION SWITCH

Electrical System Will Not Function

Damaged ign~rion switch

e Ignition switch not adjusted properly

e Loose connector at the ignition switch

Switch Will Not Turn

Inspect

Damaged ignition switch

Switch Cannot Be Set Correctly

Inspect

Switch actuator rod deformed

e Sector to rack engaged in wrong tooth

KEY REMINDER

Figs. 1 through 11 ,

Weminder Continues To Operate With Key Out,

But Stops When Driver's Door Is Closed

e Chips, foreign material in lock cylinder bore

Sticky lock cylinder actuator tip

Damaged or broken reminder switch

Reminder Does Not Sound With Key Fully

Inserted In Lock Cylinder And The Driver's Door

Open

Inspect

1. Power not available to reminder. Refer to Sec-

tion

8A for electrical diagnosis.

2. Open in chassis wiring. Check by separating

chassis-to-column connector. Connect terminals

"E" and "F" female contacts on the chassis

connector (a bent paper clip will work). If the

reminder sounds, repair chassis wiring. If the

reminder does not sound, go to Step

A.

A. Connect a continuity meter (light) to the

male

"E" and "F" column connector

contacts. Push the key all the way into the

lock cylinder. If the light is on when the key

Page 786 of 1825

DRIVEABILITY AND EMlSSlONS 2.8L (VIN %I 6E3-C8-1

TRANSMISSION CONVERTER CLUTCH (KC) SYSTEM

AND MANUAL

TRANSMISSION SHIFT LIGHT

CONTENTS

GENERAL DESCRIPTION ................ C8-1 DIAGNOSIS ..........ee...ee....e.e. C8-1

PURPOSE ......................... C8-1 SHIFT LIGHT (MIT) DESCRIPTION ........ C8-1

OPERATION ....................... C8-1 DIAGNOSIS ....................... .. C8-1

ON-CAR SERVICE ...................*. C8-1

GENERAL DESCRIPTION

PURPOSE

The transmission converter clutch (TCC) svstem

uses a solenoid operated valve in the automatic

transmission to couple the engine flywheel to the

output shaft of the transmission thru the torque

converter. This reduces the slippage losses in the

converter, which increases fuel economy.

OPERATION

For the converter clutch to apply, two conditions

must be met:

o Internal transmission fluid pressure must be

correct. For information on internal transmission

operation, see Section

"7A". This section will cover

only the electrical operation of the TCC system.

@ The ECM grounds a switch internally to turn on a

solenoid in the transmission. This moves a check

ball, which will allow the converter clutch to

apply, if the hydraulic pressure is correct, as

described above.

The ECM controls the TCC apply solenoid by

looking at several sensors:

@ Speedo Buffer Sensor (also called vehicle speed

sensor

(VSS). Speed must be above a certain value

before the clutch can apply.

@ Coolant Temperature Sensor. Engine must be

warmed up before clutch can apply about

65OC

(149°F').

Throttle position sensor ('I'PS). After the

converter clutch applies, the

HCM uses the

information from the TPS to release thc clutch

when the car is accelerating or decelerating at a

certain rate.

@ 'I'he brake switch is also part of the 'I'CC circuit as

it will remove battery voltage to the 'KC solenoid

when the brake pedal is depressed.

@ Gear Select Switch. The 4th gear switch is used to

send a signal to the

ECM telling it when the

transmission is in 4th gear. The ECM uses this

information to vary the conditions under which

the clutch applies or releases.

IIowever, the

transmission does not have to be in fourth gear in

order for the ECM to turn the clutch on.

If the converter clutch is applied at all times. the

engine will stall immediately, just as in

u manual

transmission with the clutch applied.

If the converter clutch does not apply, fuel

ecomony

may be lower than expected. If the vehicle

speed sensor fails, the TCC will not apply. If the 4th

gear switch does not operate, the TCC may not apply

at the right time.

DIAGNOSIS

The diagnosis of the TCC system is covered in

CHART C-8

. If the ECM detects a problem in the

system,

a Code 24 should set. In this case see Code 24

CHART.

SHIFT LIGHT (MiT) DESCRIPTION

'The purpose of the shift light is to provide a

display which indicates the optimum fuel economy

point for up

shifling the manual transmission based

on engine speed

and load. 'I'he display is a lamp on the

instrument panel. Activation of the ECM driver turns

the lamp

on.

'I'he shift light circuit can he checlted using

CHAR?' C-8C.

ON-CAR SERVICE

@ See Section "8B" if the shift light bulb needs

replacement.

@ See Section "6E" to repair wiring problem.

@ See Section "6C" if ECM is to be replaced.

Page 942 of 1825

DWlVEABlLlTV AND EMISSIONS 5.01, QVIN F) & 5.71 (VIN 8) 6E3-C8-1

TRANSMISSION CONVERTER CLUTCH (KC) SYSTEM

AND MANUAL "TRANSMISSION SHlFT LBGH"O"=Ob ONLY

CONTENTS

................ GENERAL DESCRIPTION C8-1 DIAGNOSIS ....................... .. C8-1

........ PURPOSE ......................... CS-1 SHIFT LIGHT (MIT) DESCRIPTION C8-1

....................... OPERATION C8-1 DIAGNOSIS ......................... CS-1

OM-CAR SERVICE ..................... C8-1

GENERAL DESCRIPTION

PURPOSE

The transmission converter clutch (TCC) system

uses

a solenoid operated valve in the automatic

transmission to couple the engine flywheel to the

output shaft of the transmission thru the torque

converter. This reduces the slippage losses in the

converter, which increases fuel economy.

OPERATION

For the converter clutch to apply, two conditions

must be met:

e Internal transmission fluid pressure must be

correct. For information on internal transmission

operation, see Section

"7A". This section will

cover only the electrical operation of the TCC

system.

@ The ECM grounds a switch internally to turn

"ON" a solenoid in the transmission. This moves a

check ball, which will allow the converter clutch

to apply, if the hydraulic pressure is correct, as

described above.

The ECM controls the TCC apply solenoid by

looking at several sensors:

@ Speedo Buffer Sensor (also called Vehicle Speed

Sensor

(VSS) Speed must be above a certain value

before the clutch can apply.

@ Coolant Temperature Sensor Engine must be

warmed

LIP before clutch can apply about 65" C

(149°F).

Throttle Position Sensor (TPS) After the

converter clutch applies, the ECM uses the

information

from the TPS to release the clutch

when the car is accelerating or decelerating at

a

certain rate.

The brake switch

is also part of the 'I'CC circuit as

it will remove battery voltage to the

'FCC solenoid

when the brake pedal is depressed.

@ Gear Select Switch The 4th gear switch is used to

send a signal to the ECM telling it when the

transmission is in 4th

gear

The ECM uses this information to vary the conditions

under which the clutch applies or releases. However,

the transmission does not have to be in fourth gear in

order for the ECM to turn the clutch "ON".

If the converter clutch is applied at all times, the

engine will stall immediately, just as in a manual

transmission with the clutch applied.

If the converter

clutch does not apply, fuel

ecomony may be lower than expected. If the vehicle

speed sensor fails, the TCC will not apply. If the 4th

gear switch does not operate, the TCC may not apply

at the right time.

DIAGNOSIS

The diagnosis of the TCC system is covered in

CHART C-$A. If the ECM detects a problem in the

system, a Code 24 should set. In this case, see Code 24

CHART.

SHIFT LIGHT (MR) DESCRIPTION

The purpose of the shift light is to provide a

display which indicates the optimum fuel economy

point for up shifting the manual transmission based

on engine speed and load. The display is

a lamp on the

instrument panel. Activation

of the ECM driver turns

the lamp "ON".

DIAGNOSIS

The shift light circuit can be checked using

CEIAR'I' C-8B.

ON-CAR SERVICE

See Section "8B" if the shift light bulb needs

replacement.

See Section

"GE" to repair wiring problem.

@ See Section "C- 1" if ECM is to be replaced.

Page 1477 of 1825

EXTERIOR LIGHTS I$

(Continued from previous page)

Front Park Lights

The Front Park Lights can be lit by putting the

Light Switch either in

PARK or in HEAD.

With the Park Lights or Headlights on, battery

voltage is provided through the BRN wires to

both Park Lights. The path to ground for the Park

Lights is

6103 (LH) or 6104 (RN).

The Park Lights will not flash when the turn

signal is on, they will have a steady glow.

Front Marker Lights

The Front Marker Lights can be lit by the Park

Lights or the Turn Lights. Neither of the two

wires to each of the marker bulbs is

a ground

wire.

With the Park Lights on, battery voltage is sup-

plied through the BRN wires to both Marker

Lights. The path

to ground for the marker bulbs

is through the

Turn Lights. The small Marker

Light bulbs light up, but not the larger turn

bulbs.

Lights are on, but not the Park

Lights, battery voltage is applied through the

BLU wires

to the Marker Lights. They glow since

they are grounded through the entire Park Light

system. As before, the small marker bulbs light

up, but not all the parking bulbs. If

both the Park Lights and a set of

lights are on at the same time, the marker

for that side

will not light up. With battery

voltage on both sides of

a bulb, it will not glow.

When the Lights flash off, however, the

marker bulb on that side will come on since

it is

now grounded through the Lights. This

circuit

makes the turn and marker bulbs flash

out of step with each other when the Park

Lights are on.

License, Tail, or Rear Marker Lights

Voltage is applied through the Tail Fuse to the

Light Switch at all times. With the Light Switch

in PARK or

HEAD, voltage is applied through the

fuse and the Light Switch to all of the lights in

this circuit.

Page 1516 of 1825

THEFT DETERRENT SYSTEM: PASSKEY

3. A number from 1 to 15 will appear in the

window designating the electrical code of

the key.

4. Cut a new key having the electrical code

ed from the 535628 Interrogator.

5. Start the engine using the new key to insure

that the key is correct both mechanically

and electrically.

Key Replacement (No Spare Key Available)

1. If the Ignition Key is lost and there is no

spare key, determine the mechanical code

from the code on the Ignition Key Lock

CyE

inder. The code may also be det

the dealer invoice for the car, or from the

Chewolet Zone Office.

2. Cut anew key to this mechanical code. Use a

blank PASSKEY test key which has no

resistance pellet. This key will be used to

operate the Ignition Switch for the remain-

ing steps.

3. Remove the hush panel under the steering

column and disconnect

C281 (two-cavity

connector leading into the steering column).

4. Insert the male half of the connector into the

female

pigtail connector from the 535628

Interrogator.

5. Set the Key Code Selector on the

Hnter-

rogator (535628 or equivalent) to "1 ".

6. Attempt to start engine using the key made

in step 2.

r If engine starts, the Key Code Selector is set

to the correct electrical code. Cut a new key

having this electrical code. The new key will

be customer's replacement key.

If engine does not start, turn Ignition

Switch to OFF, then turn the Key Code

Selector to the next higher position. Wait

four minutes and attempt to start the engine

using the new electrical code. Use the 4-min-

ute Timer on the 535628 Interrogator to

indicate the 4-minute interval. Start the

Timer by depressing the "Start" rocker

switch. The red indicator

will turn off at the

end of a four minute interval.

CIRCUIT OPERATION

Resistor senshg contacts are located in the

Ignition Key Lock Cylinder. These contact the

Key Resistor Pellet on the key when it is

inserted. When the lock is rotated, battery is

applied through the

CIH Fuse to the PASSKEY

Decoder Module. The Pellet resistance is then

colnpared against a fixed resistance in the Mod-

ule.

If the Key Pellet is the proper resistance, ter-

minal A3 is grounded, energizing the Starter

Enable Relay. At the

same time, a signal is

appfied at terminal A2 to enable the Electronic

Control Module

(ECM). When this signal is

received by the Electronic Control Module

(ECM), it allows fuel injector pulses to begin.

If the Key Resistor Pellet is the wrong

value,

the PASSKEY Decoder Module will shut down

tes. During this interval there

will be no output at terminals A3 or

A2.

If the Ignition Switch is turned on again dur-

ing this interval, the Timer will begin over

again and the PASSKEY Decoder Module

will

remain shut down for another 2 to 4 minutes.

The PASSKEY Decoder Module will continue

this process even if a key with the correct pellet

is used to turn the ignition back on. The Timer

is restarted by the ignition voltage at

t

A1 when Ignition Switch is turned to RUN.

Once the Timer has completed its

2 to 4 min-

ute cycle with the ignition off, the PASSKEY

Decoder Module and Timer are reset. A key

having the correct code can then be used to

start the engine.

The Security Indicator is controlled directly

by the PASSKEY Decoder Module. If there is a

PASSKEY Failure this indicator will be

grounded by the PASSKEY

Decoder Module

with the ignition in RUN,

BULB TEST or

START. When the Ignition Switch is first

placed in

RUN, BULB TEST or START the

Indicator lights for about 2 seconds as a bulb

check.

Page 1600 of 1825

LIGHTING SYSTEMS AND HORNS 8B-I

SECTION 8B

NG SYSTEMS AND HORNS

CONTENTS

........................... GENERAL DESCRIPTION 8B-1

Exterior Lights

....................... ................... Back-up Lights .. 8B- 1

Center High-Mounted Stoplight .................... 8B-1

Exterior Light Monitor .................................. 8B-1

............................ .................... Fog Lights .. 8B-1

Front Parking/Turn Signal Lights ................ 8B-2

............................... Hazard Flashers .. ........ 8B-2 .................................................... Headlights 8B-2

License Plate Lights ..................................... 8B-2

Light Switch ............................................... 8B-2

............... Rear Tail/Stop/Turn Signal Lights 8B-2

Sidemarker Lights ........................................ 8B-2

Turn Signals .......................................... 8B-2

......................... Underhood Light ... ........ 8B-2

Horns .......................................................... 8B-3

....................................... ON-CAR SERVICE 8B-3

Exterior Lights

............................................. Back-up Lights 8B-3

Center High-Mounted Stoplight .................... 8B-3

Fog Lights .................................................... 8B-4

Front Parking/Turn Signal Lights ................ 8B-4

Hazard Flasher .............................................. 8B-5

....................................................... Headlights 8B-5

License Plate Lights ..................................... 8B-7

............... Rear Tail/Stop/Turn Signal Lights 8B-8

.......................................... Sidemarker Lights 8B-8

................... ............... Turn Signal Flasher .. 8B-9

......................................... Underhood Light 8B-9

Horns ................................................................. 8B-9

REPLACEMENT BULB

.................................... SPECIFICATIONS 8B- 10

The following information, previously shown in this section,

has been moved to the sections shown.

Back-up Lights Switch

............................. ... ............................................................................ 7

................................................................................................................................. Fuse Block 8A

Ignition Switch ........................................................................................................................... 3B

Interior Lights

................................................................................................................... 8A, 8C

Neutral Start Switch ..................................................................................................................... 7

Parking Brake Warning Switch

......................... ... .................................................................... 5

........................................................................ Seat Belt, Key and Headlight Warning Alarm 8A

Stoplight Switch .......................... .. ............................................................................................... 5

Windshield

Wipers/Washers .................................................................................................... 8E

GENERAL DESCRIPTION

The exterior lighting system includes the

headlights (and headlight motors to raise or lower the

headlights), front

parkinghurn signal lights, front

cornering lights, fog lights, rear

tail/stop/turn signal

lights, back-up lights, license plate lights, center

high-mounted stoplight, and the underhood light; it

also includes all associated wiring, controls and related

hardware for these lights.

BACK-UP LIGHTS - The back-up lights are

next to the rear license plate. They will come on when

the transmission is shifted to Reverse. On cars with an

automatic transmission, the back-up lights are

activated by the neutral start switch. On cars with a

manual transmission, they are activated by a separate

back-up light switch on the transmission. For more

information, see Section 7.

CENTER HIGH-MOUNTED STOPLIGHT-

The center high-mounted stoplight, in the center of the

rear spoiler, will come on whenever the brake pedal is

pushed down. The light is powered separately from the rear

tail/stop/turn signal

lights through a separate

circuit in the stoplight switch (see Section

8A).

EXTERIOR LIGHT MONITOR - The Driver

Information Center, on cars so equipped, also monitors

certain front and rear lights. When a bulb burns out,

the message

"FRONT LAMP" or "REAR LAMP"

will appear in the DIC display, and a light will come

on to indicate which bulb has burned out. For more

information, see Section

8A.

FOG LIGHTS -The fog light switches are to the

left of the steering column on the edge of the

instrument panel. To use the fog lights, first turn on the

headlights or parking lights. Then, push the middle

switch (with the fog light symbol) to turn on the fog

lights. Push the left

("OFF") switch to turn off the fog

lights.

The fog lights should not be used as a substitute

for the headlights.

Switching to high-beam headlights will turn off

the fog lights; switching back to low-beams will turn

the fog lights on again.

Page 1601 of 1825

88-2 LIGHTING SYSTEMS AND HORNS

The fog lights must be aimed for proper

illumination of the road. Fog light

aim should be

checked: at least once a year; when a new light housing

is installed; or if service or repairs in the front end area

have (or may have) disturbed the fog light mountings.

FRONT PARKING/TURM SIGNAL

LIGHTS - Pushing either side of the instrument panel

switch will turn on the front parking lights. (Pushing

the left side of the switch will also turn on the

headlights.) When the ignition is on and the turn signal

lever is moved, the appropriate front parking light

flashes to signal a turn. Both lights will flash when the

hazard flashers are on.

If the driver's door is opened when the parking

lights are on, a warning tone will sound. For more

information, see Section

8A-77.

HAZARD FLASHERS - The hazard warning

flasher is part of the turn signal circuit. Pushing in the

button (on the right side of the steering column) will

cause the front and rear turn signal lights, and the front

sidemarker lights, to flash. Pull out the collar around

the button to turn off the hazard flashers.

The hazard flashers will work with the ignition

either off or on. When the hazard flashers are on, the

turn signals do not

work.

The hazard flashers will stop flashing and stay on

brightly if the brake pedal is pushed down.

HEADLIGHTS - The headlights are controlled

by the switch on the instrument panel (to the left of the

speedometer). They will come on whether or not the

ignition is turned on. Pushing the upper left side of the

switch turns on the headlights and causes the headlight

motors to raise the headlights. Pushing the bottom part

of the switch turns off the headlights, and they should

lower.

If the driver's door is opened when the ignition

is off and the headlights are on, a warning tone will

sound. For more information, see Section

8A-77.

Headlight low-beam and high-beam are

controlled by the turn

signal/multifunction lever on

the left side of the steering column. When the

headlights are on, pull the lever toward the steering

wheel until the switch clicks; the lights will change

from low-beam to high-beam, or from high-beam to

low-beam. An indicator light on the center instrument

cluster will come on when the high-beam headlights

are on.

The headlights must be aimed for proper

illumination of the road. Headlight aim should be

checked: at least once a year; when a new headlight

bulb is installed; or if service or repairs in the front end

area have (or may have) disturbed the headlights or

their mountings. The headlight bezels do not need to

be removed to aim the headlights.

Headlight focus is set when the sealed-beam unit

is made; no adjustment for focus is necessary or

possible.

Some state and local laws specify

requirements for headlight aim; these laws

must be followed.

LICENSE PLATE LBGHTS -A light above the

rear license plate will come on when the headlights or

parking lights are on.

LIGHT SWITCH - Most exterior lights are

controlled by the switch on the instrument panel, to the

left of the speedometer. Pushing the upper right part

of the switch turns on the front parking lights, the

taillights and the sidemarker lights. (It also turns on

the instrument panel lights.) Pushing the upper left

part of the switch turns on all these lights plus the

headlights. Pushing the bottom part of the switch turns

off all lights.

In some cases (such as going through a car wash),

it may be desirable to raise the headlights without

leaving the headlights on. To do so, push the upper

right part of the switch to turn on the parking lights.

Then, lightly push the upper right part of the switch;

the headlights will raise but will not turn on.

(Remember that the parking lights and taillights will

stay on.)

For more information on this switch (including

on-car service), see Section

8C. Also see Section 8C for

information on interior lights.

REAR TAlL/STOP/TURN SIGNAL

LIGHTS - The rear tail/stop/turn signal lights are

part of the same light assembly. Pushing either side of

the instrument panel switch turns on the taillights.

When the brake pedal is pushed down, the lights glow

brighter to serve as stoplights.

Moving the turn signal lever when the ignition is

on causes the appropriate rear lights to flash. (If the

brake pedal is held down and a turn is signalled, one

side will flash and the other will stay on brightly.)

All lights will flash when the hazard flashers are

on. However, if the brake pedal is pushed while the

hazard flashers are on, the lights will stop flashing and

stay on brightly.

SIDEMARKER LIGHTS -The front and rear

sidemarker lights will come on when the headlights or

parking lights are on. Both front and rear sidemarker

lights also have reflectors; they will shine when struck

by light, whether or not the car's lights are on.

If the headlights or parking lights are off when a

turn is signalled, the front sidemarker light will flash

in unison with the front turn signal light on the same

side. If the lights are on when a turn is signalled, the

front

sidemarker light and front turn signal light flash

alternately.

TURN SlG N ALS - The front turn signals are

combined with the front parking lights. The rear turn

signals are part of the rear

tail/stop/turn signal lights.

The turn signals work only when the ignition is on, and

the hazard flashers are turned off.

The turn signals are controlled by the turn

signal/multifunction lever on the left side of the

steering column. Moving the lever all the way up or

down (past the detent) will turn on the turn signals.

When the turn is completed, the lever will return to

neutral and the turn signals will stop flashing.

For changing lanes or shallow turns where the

steering wheel does not move far enough to cancel the

signal, move the turn signal lever only to the first

detent. When the lever is released, it will return to

neutral and the turn signals will cancel.

UNDERHOOD LIGHT - The underhood light

will come on when the hood is raised.

Page 1602 of 1825

LIGHTING SYSTEMS AND HORNS 8B-3

HORNS the steering wheel sounds the horn by closing the horn

relay (in the convenience center behind the instrument

panel, to the right of the steering column). The horns

The holm(§) are mounted behind the front fascia use a solenoid-operated diaphragm to generate sound.

on the driver's side. $ushing the pad in the center of See Section 8A-40 for wiring and circuit information.

ON-CAR SERVICE

Wiring diagrams and other diagnosis information

is given in Section

8A. Information on properly

repairing wiring harnesses, connectors, etc., is on

8A-5.

Most lighting problems are caused by loose

connectors, open or shorted wiring, burned-out bulbs,

bad switches, inadequate ground or blown fuses. Many

of these require only replacement of a defective part.

When replacing a part that requires a special procedure

(such as a lens and housing assembly sealed together),

follow the instructions normally included in the

replacement parts package.

When removing a part that requires special

sealing items (such as sealing washers), be sure to

reinstall those items when replacing the part. Also, if

any body sealing items (grommets, etc.) are disturbed,

be sure to repair them so the passenger compartment

remains properly sealed.

EXTERlOR LIGHTS

BACK-UP LIGHTS

Fig. 8B-8

Replacement Bulb: Trade No. 1156, 32

Candlepower

To replace a back-up light bulb, see "Rear

Tail/Stop/Turn Signal Lights9' in this section. For

information on the back-up light switch on the

transmission, see Section

7.

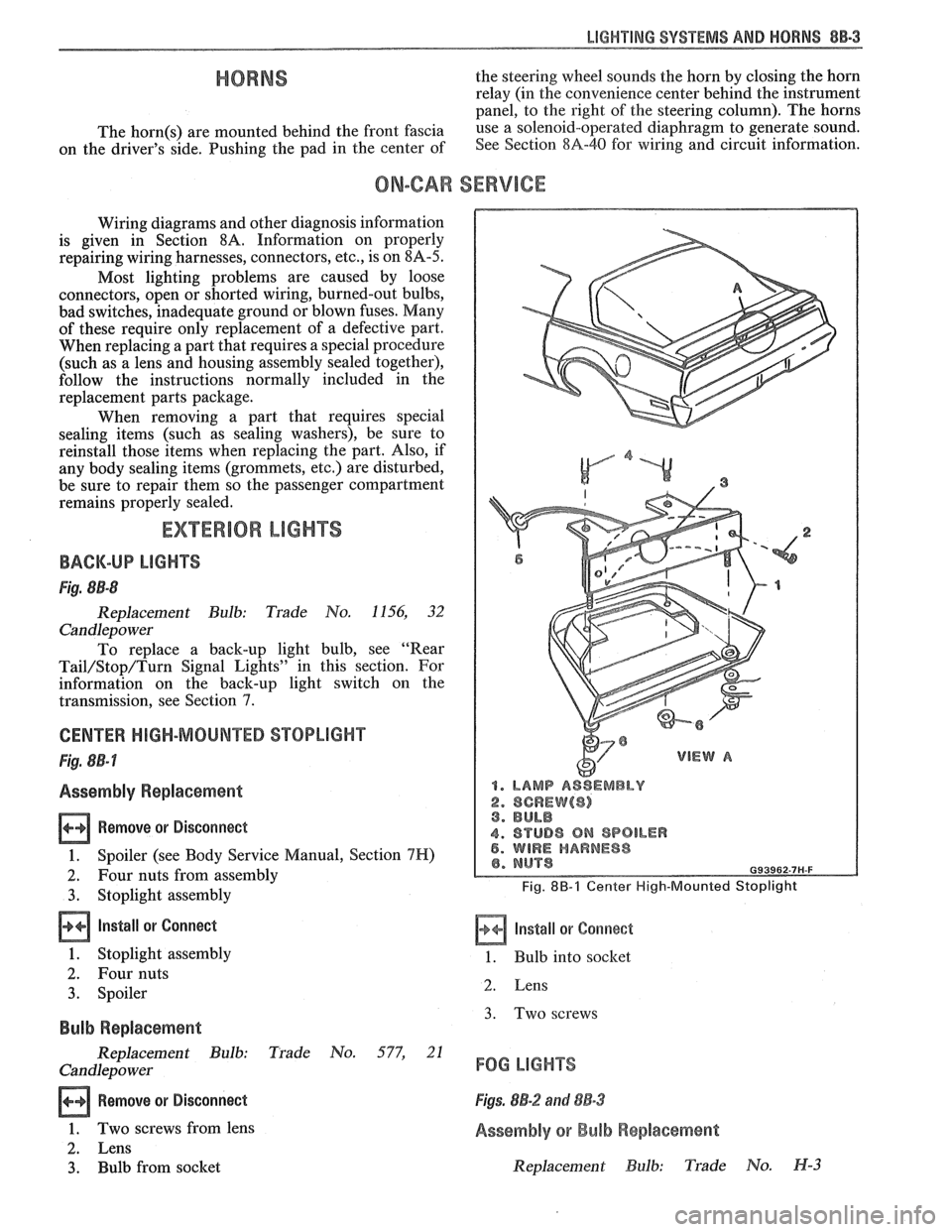

CENTER HIGH-MOUNTED STOPLIGHT

Fig. 8B-7

Assembly Replacement

Remove or Disconnect

1. Spoiler (see Body Service Manual, Section 7H)

2. Four nuts from assembly

3. Stoplight assembly

Install or Connect

1. Stoplight assembly

2. Four nuts

3. Spoiler

Bulb Replacement

Replacement Bulb: Trade No. 577, 21

Candlepo wer

Remove or Disconnect

1. Two screws from lens

2. Lens

3. Bulb from socket

1. LAMP ASSEMBLY

2. SCREW($) 3. BULB

4. STUD8 ON SPOILER 5. WIRE HARNESS

Fig. 8B-1 Center High-Mounted Stoplight

Install or Corrnect

1. Bulb into socket

2. Lens

3. Two screws

FOG LIGHTS

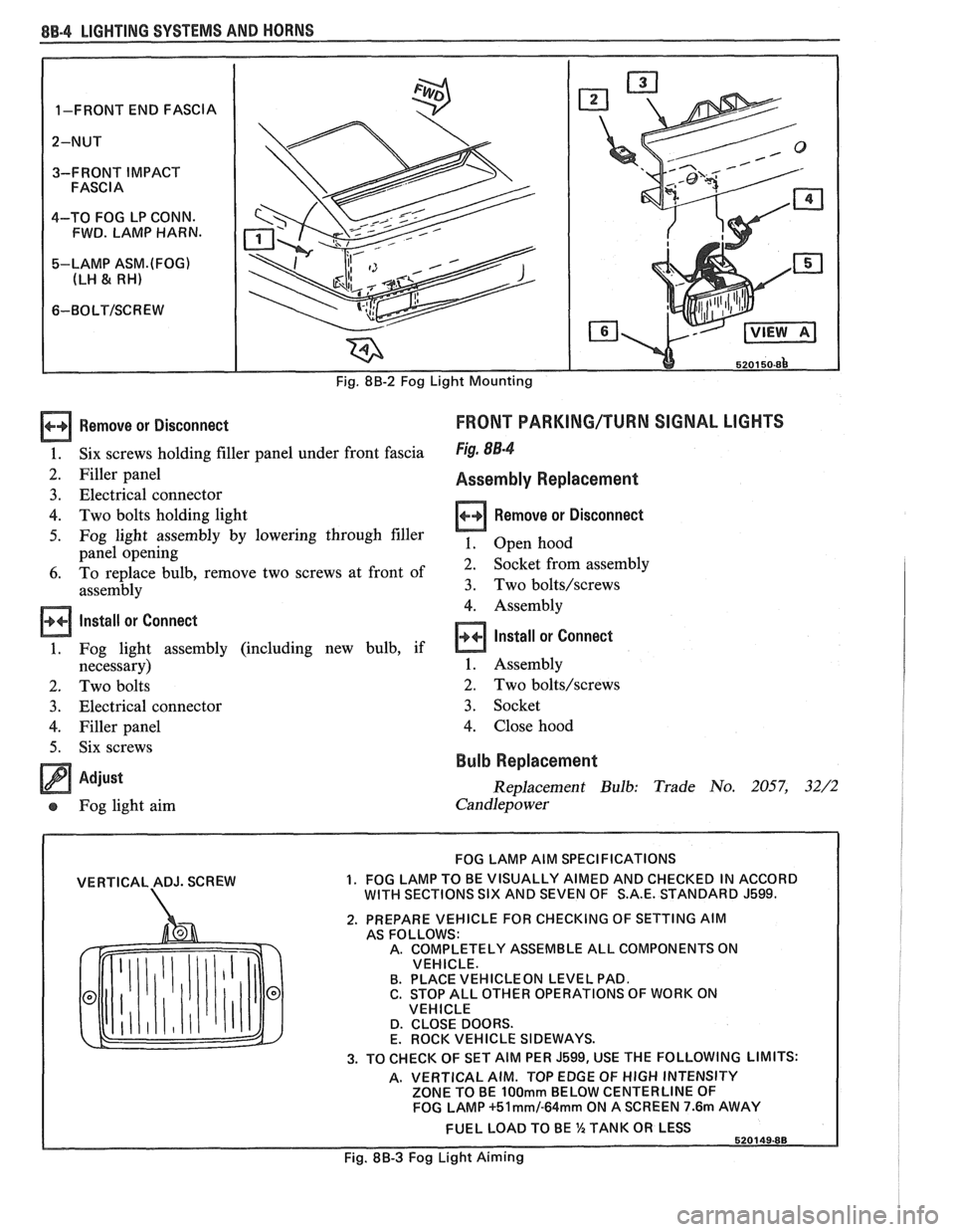

Figs. 8B-2 and 88-3

Assembly or Bulb Replacement

Replacement Bulb: Trade No. H-3

Page 1603 of 1825

8B-4 LIGHTING SYSTEMS AND HORNS

Remove or Disconnect

Six screws holding filler panel under front fascia

Filler panel

Electrical connector

Two bolts holding light

Fog light assembly by lowering through filler

panel opening

To replace bulb, remove two screws at front of

assembly

Install or Connect

Fog light assembly (including new bulb, if

necessary)

Two bolts

Electrical connector

Filler panel Six screws

Adjust

Fog light aim

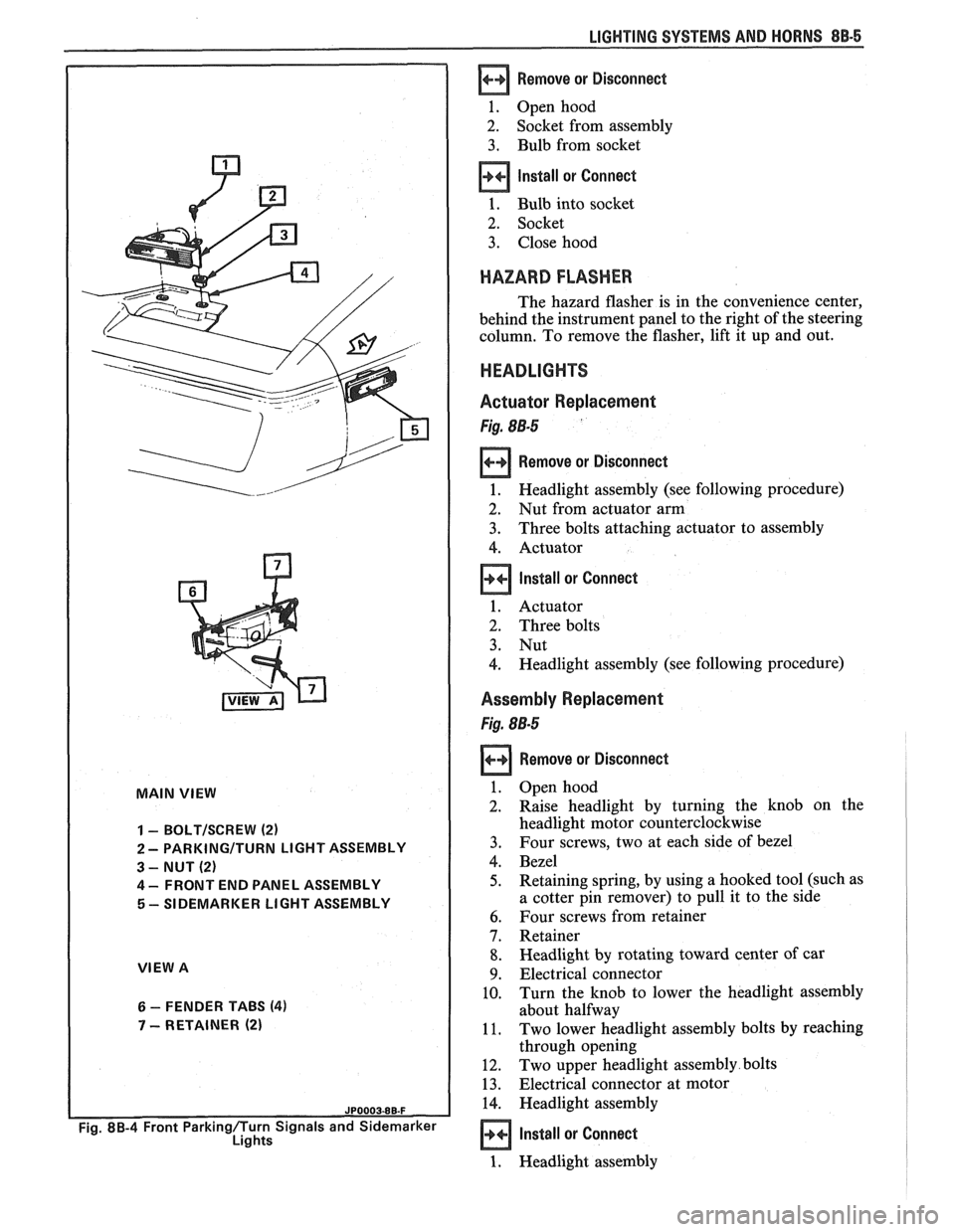

FRONT PARKING/TURN SIGNAL LIGHTS

Fig. 88-4

Assembly Replacement

Remove or Disconnect

1. Open hood

2. Socket from assembly

3. Two bolts/screws

4. Assembly

Install or Connect

1. Assembly

2. Two bolts/screws

3. Socket

4. Close hood

Bulb Replacement

Replacement Bulb: Trade No. 2057, 32/2

Candlepower

VERTICAL ADJ. SCREW

FOG LAMP AIM SPECIFICATIONS

1. FOG LAMP TO BE VISUALLY AIMED AND CHECKED IN ACCORD WITH SECTIONS SIX AND SEVEN OF S.A.E. STANDARD J599.

2. PREPARE VEHICLE FOR CHECKING OF SETTING AIM

AS FOLLOWS:

A. COMPLETELY ASSEMBLE ALL COMPONENTS ON

VEHICLE.

B. PLACE

VEHICLEON LEVEL PAD.

C. STOP ALL OTHER OPERATIONS OF WORK ON

VEHICLE

D. CLOSE DOORS.

E. ROCK VEHICLE SIDEWAYS.

3. TO CHECK OF SET AIM PER J599, USE THE FOLLOWING LIMITS:

A. VERTICAL AIM. TOP EDGE OF

HIGH INTENSITY

ZONE TO BE 100mm BELOW CENTERLINE OF

FOG LAMP +51mm/-64mm ON A SCREEN 7.6m AWAY

FUEL LOAD TO BE %TANK OR LESS

Fig. 88-3 Fog Light Aiming

Page 1604 of 1825

I

MAIN VIEW

I

1 - BOLTISCREW (2)

2 - PARKINGITURN LIGHT ASSEMBLY

3 - NUT (2)

4 - FRONT END PANEL ASSEMBLY

5 - SIDEMARKER LIGHT ASSEMBLY

VIEW A

6 - FENDER TABS (4)

7 - RETAINER (2)

Fig. 8B-4 Front Parkingflurn Signals and Sidemarker

Lights

LIGHTING SYSTEMS AND HORNS 88-5

Remove or Disconnect

1. Open hood

2. Socket from assembly

3. Bulb from socket

Install or Connect

1. Bulb into socket

2. Socket

3. Close hood

HAZARD FLASHER

The hazard flasher is in the convenience center,

behind the instrument panel to the right of the steering

column. To remove the flasher, lift it up and out.

HEADLIGHTS

Actuator Replacement

Fig. 88-5

Remove or Disconnect

1. Headlight assembly (see following procedure)

2. Nut from actuator arm

3. Three bolts attaching actuator to assembly

4. Actuator

Install or Connect

1. Actuator

2. Three bolts

3. Nut

4. Headlight assembly (see following procedure)

Assembly Replacement

Fig. 88-5

Remove or Disconnect

Open hood

Raise headlight by turning the knob on the

headlight motor counterclockwise

Four screws, two at each side of bezel

Bezel

Retaining spring, by using a hooked tool (such as

a cotter pin remover) to pull it to the side

Four screws from retainer

Retainer

Headlight by rotating toward center of car

Electrical connector

Turn the knob to lower the headlight assembly

about halfway

Two lower headlight assembly bolts by reaching

through opening

Two upper headlight assembly bolts

Electrical connector at motor

Headlight assembly

Install or Connect

1. Headlight assembly