wheel bolt torque PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 18 of 1825

MAINTENANCE AND LUBRICATION OB-1

SECTION OB

NTENANCE AND LUBR

CONTENTS

Maintenance Schedule, Gasoline .............................................. OB-l

Maintenance Schedules I and 11 .............................................. OB-2

Owner Inspections

......................................................... OB-3

Recommended Fluids and Lubricants ......................................... OB-6

PASSENGER CAR MAINTENANCE SCHEDULE

VEHICLES

WITH GASOLINE ENGINE

NORMAL CAR USE ITEM 4

The maintenance services contained in Schedules I Carburetor or Throttle Body Mounting Bolt

and 11 are based on the assumption that your car will be Torque* used as designed:

Check torque of mounting bolts and/or nuts. @ To carry passengers and cargo within the limits

shown on the Tire Placard located on the edge of the ITEM 5 driver's door.

@ On reasonable road surfaces within legal driving Engine Idle Speed Adjustment*

limits. (Engines

without Idle Speed Control or Idle Air

Control) - Adjust to specifications shown on the under- @ On unleaded gasoline.

hood label. If no specifications are shown on the label, no

adjustment is necessary. Calibrated test equipment must

EXPLANATION OF SCHEDULED MAINTENANCE be used. SERVICES

The services listed in Maintenance Scheduies I and ITEM 6

11 are further explained below. When the following main- ~i~~ and wheel aotation tenance services are performed, make sure all parts are

replaced and all necessary repairs are done before driving To equalize wear and obtain maximum tire life,

your car. Be sure to use the proper fluid and lubricants as rotate in accordance with patterns shown in Owner's

shown in Figure OB-2. Manual.

ITEM 1

Engine Oil and Oil Filter Change*

ALWAYS USE SFICC OR SF/CD ENERGY CON-

SERVING OILS OF PROPER VISCOSITY

- Also.

always change oil and filter as soon as possible after

driving in a dust storm. See your Owner's Manual for

further details.

ITEM 2

Chassis Lubrication

Lubricate all grease fittings in suspension and steer-

ing linkage. Lubricate

transmissionltransaxle shift

linkage, parking brake cable guides, underbody contact

points and linkage. Also lubricate clutch cross shaft lever

every

30,000 miles (50 000 km) on rear-wheel-drive cars

only.

ITEM 3

Carburetor Choke and Hoses*

If your car is equipped with a carburetor, verify that

choke and vacuum break work properly and are within

specifications. Correct any binding caused by damage or

gum on the choke shaft. Inspect hoses for proper hookup,

cracks, chafing or decay. Correct as necessary.

Vacuum or A.I.R. Pump Drive Belt Inspection*

When a separate belt is used to drive the vacuum or

A.I.R.

pump, inspect it for cracks, fraying, wear and

proper tension. Adjust or replace as needed.

ITEM 8

Cooling System Service*

Drain, flush and refill system with new coolant. See

your Owner's Manual

for further details.

ITEM 9

Wheel Bearing Repack (Rear-Wheel-Drive Cars

Only Except Corvette)

Clean and repack front wheel bearings at each brake

relining or 15,000 miles

(25 000 km), whichever comes

first, when car is used in such service as police, taxi or

door-to-door delivery. If you do not use your car in such

service, clean and repack bearings at each brake relining

or 30,000 miles

(50 000 km), whichever comes first.

Corvette models do not require wheel bearing repack.

Page 135 of 1825

3-10 STEERING, SUSPENSION, TIRES AND WHEELS DIAGNOSIS

Reminder Keeps Operating With Key In Lock

Cylinder, Driver's Door Open Or Closed; Ceases

When Key Is Removed

Inspect

s Door jamb switch on driver's side misadjusted or

inoperative.

e Wire from signal switch to door jamb switch

shorted.

A. This condition indicates the lock cylinder or

the reminder switch is at fault. To verify,

check for continuity at the

"E" and "F"

male column connector contacts, with the

key removed from the lock cylinder. If

continuity exists, the fault is in the column.

B. Insert the key into the lock, then turn the

lock toward the "Start" position. If the

reminder stops when the key is in the

"Run" position or when it is turned past

"Run" toward "Start," the problem is a

sticky lock cylinder actuator.

COLUMN-MOUNTED DIMMER SWITCH

No "Low" or "High" Beam

Inspect

e Loose connector at dimmer switch

e Improper adjustment

e Internally damaged or worn switch. Check the

continuity on the switch at the It. green and at the

tan switch terminals by pushing in the plunger all

the way.

A click should be heard. If there is no

continuity, replace the dimmer switch. If there is

continuity, refer

to'section 8A for electricaldiag-

nosis.

PIVOT AND SWITCH ASSEMBLY

Switch Inoperative: No "Low," "High" and/or

"Wash"

e Loose body-to-switch connector

a Broken or damaged switch

Internally damaged or worn switch. Connect a

new switch without removing the old one. If the

system functions, replace the switch. If the

system doesn't function, refer to Section

8A for

electrical diagnosis.

STEERING GEAR AND PUMP LEAKS

General Procedure

Inspect

s Overfilled reservoir

s Fluid aeration and overflow

e , Hose connections

Verify exact point of leakage Example:

Torsion bar, stub shaft and

adjuster seals are close together; the exact

spot where the system is leaking may not be

clear.

Example: The point from which the fluid is

dripping is not necessarily the point where

the system is leaking; fluid overflowing from

the reservoir, for instance.

e When service is required:

A. Clean leakage area upon disassembly.

B. Replace leaking seal.

C. Check component sealing surfaces for

damage.

D. Reset bolt torque to specifications, where

required.

Some complaints about the power steering system

may be reported as:

A. Fluid leakage on garage floor

B. Fluid leaks visible on steering gear or pump

C. Growling noise, especially when parking or

when engine is cold

D. Loss of power steering when parking

E. Heavy steering effort

When troubleshooting these kinds of complaints,

check for an external leak in the power steering system.

For further diagnosis of leaks, refer to External

Leakage Check in this section.

External Leakage Check

Fig. 12

The purpose of this procedure is to pinpoint the

location of the leak.

In some cases, the leak can easily be located. But,

seepage-type leaks may be more difficult to isolate. To

locate seepage leaks, use the following method.

1. With the engine off, wipe dry the complete power

steering system.

2. Check the fluid level in the pump's reservoir. Add

fluid if necessary.

3. Start the engine, then turn the steering wheel

from stop to stop several times. Do not hold it at

a stop for any length of time, as this can damage

the power steering pump. It is easier if someone

else operates the steering wheel while you search

for the seepage.

4. Find the exact area of the leak and repair leak.

SEAL REPLACEMENT

RECOMMENDATIONS

Lip seals, which seal rotating shafts, require

special treatment. This type of seal is used on the

steering gear and on the drive shaft of the pump. When

there is a leak in one of these areas, always replace the

seal(s), after inspecting and thoroughly cleaning the

sealing surfaces. Replace the shaft only if very severe

pitting is found. If the corrosion in the lip seal contact

zone is slight, clean the surface of the shaft with crocus

cloth. Replace the shaft only if the leakage cannot be

stopped by first smoothing with crocus cloth.

Page 148 of 1825

-

WHEEL. ALIGNMENT 3A-1

SECTION 3A

WHEEL AL GNMENT

NOTICE: These fasteners are important attaching Do not use a replacement part of lesser quality or

parts, in that they could affect the performance of substitute

design. Torque values must be used as

vital components and systems, and/or could result specified during reassembly to assure proper

in major repair expense. They must be replaced retention of these parts. For prevailing torque

with one of the same part number or with an

nut(s) and bolt(s), refer to the "Reuse of Prevailing

equivalent part if replacement becomes necessary. torque

Nut(s) and Bolt(s)" chart in Section 0.

General Description ...................... .. ...... 3A- 1 On-Car Service ........................ .. ........... 3A-2

Caster .................... .. ............................ 3A- 1 Caster and Camber Adjustment .................. 3A-2

..................................... Camber ................... .. .............................. 3A-I Toe-In Adjustment 3A-2

Toe.. ................................................. 3A- 1 Axle Housing Alignment ......................... .... 3A-4

Preliminary Checks Prior to Specifications ....................... ... ............... 3A-4

Adjusting Alignment ..................... ...... 3A- 1

GENERAL DESCRIPmIOMI

Wheel alignment refers to the angular they tend to roll parallel on the road when the car is

relationship between the wheels, the suspension moving.

attaching parts and the ground.

PRELIMINARY CHECKS PRIOR TO ADJUSTING

CASTER ALIGNMENT

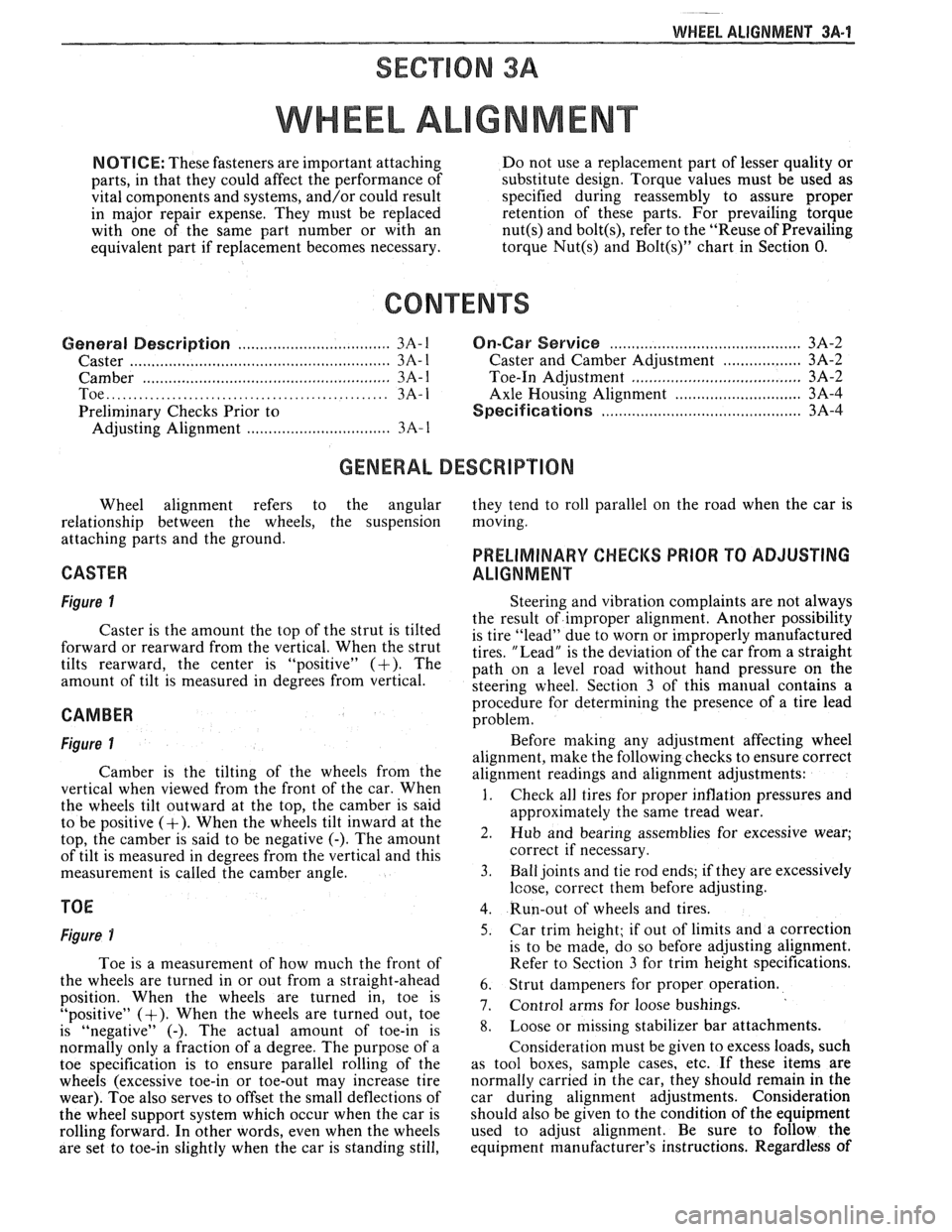

Figure 1

Caster is the amount the top of the strut is tilted

forward or rearward from the vertical. When the strut

tilts rearward, the center is "positive"

(+). The

amount of tilt is measured in degrees from vertical.

CAMBER

Figure 1

Camber is the tilting of the wheels from the

vertical when viewed from the front of the car. When

the wheels tilt outward at the top, the camber is said

to be positive

(+). When the wheels tilt inward at the

top, the camber is said to be negative

(-). The amount

of tilt is measured in degrees from the vertical and this

measurement is called the camber angle.

TOE

Figure i

Toe is a measurement of how much the front of

the wheels are turned in or out from a straight-ahead

position. When the wheels are turned in, toe is

"positive"

(+). When the wheels are turned out, toe

is "negative"

(-). The actual amount of toe-in is

normally only a fraction of a degree. The purpose of a

toe specification is to ensure parallel rolling of the

wheels (excessive toe-in or toe-out may increase tire

wear). Toe also serves to offset the small deflections of

the wheel support system which occur when the car is

rolling forward. In other words, even when the wheels

are set to toe-in slightly when the car is standing still, Steering

and vibration complaints are not always

the result of improper alignment. Another possibility

is tire "lead" due to worn or improperly manufactured

tires. "Lead" is the deviation of the car from a straight

path on a level road without hand pressure on the

steering wheel. Section

3 of this manual contains a

procedure for determining the presence of a tire lead

problem.

Before making any adjustment affecting wheel

alignment, make the following checks to ensure correct

alignment readings and alignment adjustments:

1. Check all tires for proper inflation pressures and

approximately the same tread wear.

2. Hub and bearing assemblies for excessive wear;

correct if necessary.

3. Ball joints and tie rod ends; if they are excessively

lcose, correct them before adjusting.

4. Run-out of wheels and tires.

5. Car trim height; if out of limits and a correction

is to be made, do so before adjusting alignment.

Refer to Section

3 for trim height specifications.

6. Strut dampeners for proper operation.

7. Control arms for loose bushings.

8. Loose or missing stabilizer bar attachments.

Consideration must be given to excess loads, such

as tool boxes, sample cases, etc. If these items are

normally carried in the car, they should remain in the

car during alignment adjustments. Consideration

should also be given to the condition of the equipment

used to adjust alignment. Be sure to follow the

equipment manufacturer's instructions. Regardless

of

Page 149 of 1825

3A-2 WHEEL ALIGNMENT

0 FRONT

& OF WHEEL

CASTER ANGLE

LEFT SIDE

VIEW

CAMBER

I

Fig. 1 Alignment Angles

the equipment used to adjust alignment, the car must

be on a

level surface, both fore-and-aft and sideways.

ON-CAR SERVICE

CASTER AND CAMBER ADJUSTMENT nuts and bolts. Apply penetrating oil between the

clamp and tube and rotate the clamps until they move

Before adjusting caster and camber the freely. Install new bolts and nuts having the same part front be 'aised and twice to number to assure proper at the specified nut allow vehicle to return to its normal height. See "Trim torque. Heights."

Caster and camber can be adjusted by moving the

position of the upper strut mount assembly, as shown

in Fig. 601. Moving

the mount forward/rearward

adjusts caster; 'movement inboard/outboard adjusts

camber.

The position of the mount can be changed after

loosening the three nuts shown in Fig.

601. The weight

of the vehicle will normally cause the strut assembly to

move to the full inboard position.

Install Tool

5-29724 and tighten the turnbuckle

until the proper camber reading is obtained. Then, if

an adjustment in caster is required, the mount can be

tapped forward or rearward with a rubber mallet.

Tighten the three

(3) nuts to specifications.

TOE-IN ADJUSTMENT

Toe-in can be increased or decreased by changing

the length of the tie rods.

A threaded sleeve is provided

for this purpose.

When the tie rods are mounted ahead of the

steering knuckle they must be decreased in length in

order to increase toe-in.

1. Loosen the clamp bolts at each end of the steering

tie rod adjustable sleeves.

2. With steering wheel set in straight ahead position,

turn tie rod adjusting sleeves to obtain the proper

toe-in

adjustrne~t.

3. When adjustment has been completed according

to the recommended snecifications. check to see

Tie rod adjuster parts often become rusted in

that the number of thrkads showing on each end

service. In such cases, it is recommended that if the

of sleeve are equal and that the tie rod end

torque required to remove the nut from the bolt after housings are at the right angles to steering arm.

breakaway exceeds 9.0

Nam (80 lb. in.), discard the

Position tie rod clamps and sleeves. Torque nuts.

Page 152 of 1825

STEERING WHEELS AND COLUMNS 385.1

SECTION 3B5

STEER NG WHEELS AND COLUMNS

NOTICE: All steering wheel and column fasteners are important attaching parts in that they could affect

the performance of vital parts and systems, and/or could result in major repair expense. They

must be replaced

with one of the same part number or with an equivalent part if

replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. 'Torque values must be used as specified during reassembly

to assure proper retention of all parts. There is to be no welding as

it may result in extensive damage and weakening

of the metal.

For prevailing torque

nut(s) and bolts(s), refer to the "Reuse of Prevailing Torque Nut(<) and Bolt(s) " chart

in Section OA.

CONTENTS

..................... ................................................................... GENERAL DESCRIPTION .. 3B5-1 ............................................. ........................ MAINTENANCE AND ADJUSTMENTS .. 3B5-1 ON-CAR SERVICE ........................................................................................................ 3B5-2

Steering Column ............................................................................................................ 3B5-2 ......................................................................................................... Intermediateshaft 3B5-3

Park Lock Cable .................................................................... 3B54 ......................................................................................... Checking For Accident Damage 3B5-5 ............................................................................ Unit Repair Intermediate Shaft Assembly 3B5-6

..................................................................................... Standard Column @lanual Trans) 3B5-7 ......................................................... ....................... Standard Column (Auto Trans) .. 3B5-13 Tilt Column (Manual Trans) ............................................................................................. 3B5-19

Tilt Column (Auto Trans). ................................................................................................ 3B5-27

................ .................... TORQUE SPECIFICATIONS .. .. 3B5-35

SPECIAL TOOLS .......................................................................................................... 3B5-35

GENERAL DESCRIPTION

STEERING COLUMN

The function locking energy absorbing steering

column includes three important features in addition

to the steering function:

1. 'The column is energy absorbing, designed to

compress in a front-end collision to minimize the

possibility of an injury to the driver of the car.

2. The ignition switch and lock are mounted

conveniently on this column.

3. With the column mounted lock, the ignition and

steering operations can be locked to inhibit theft

of the car.

The turn signal lever provides for control of

headlight beams, windshield washer and wipers.

The column may be easily

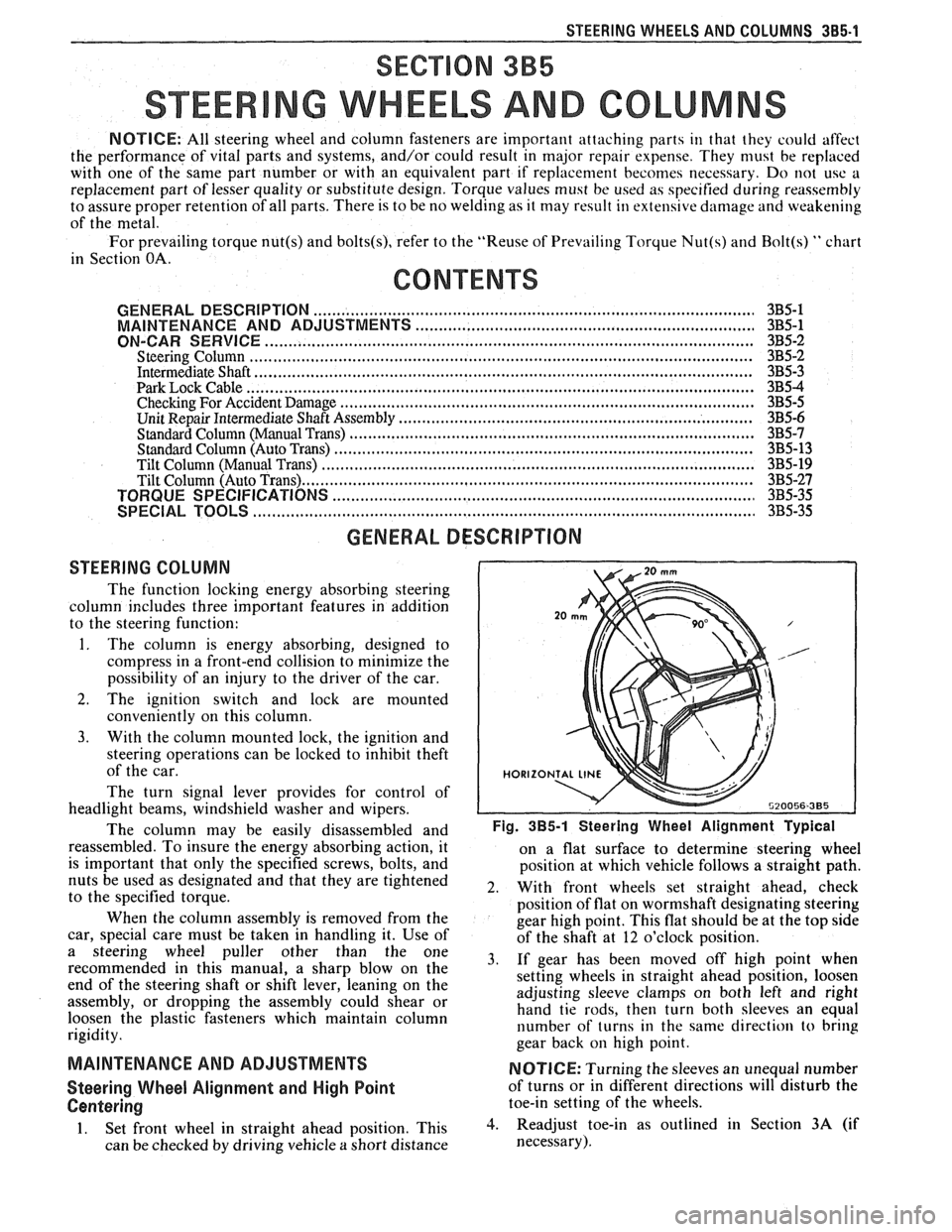

disassembled and Fig. 385-1 Steering Wheel Alignment ~ypical

reassembled. To insure the energy absorbing action, it

on a flat surface to determine steering wheel

is important that only the specified screws, bolts, and

position at which vehicle follows a straight path.

nuts be used as designated and that they are tightened

2. With front wheels set straight ahead, check to the specified torque.

position of flat on wormshaft designating steering

When the column assembly is removed from the

gear high point. This flat should be at the top side

car, special care must be taken in handling it. Use of

of the shaft at 12 o'clock position.

a steering puller other than the One 3, if gear has been moved off high when recommended in this manual, a sharp blow on the

setting wheels in straight ahead position, loosen

end of the steering shaft or shift lever, leaning on the

assembly, or dropping the assembly could shear or adjusting

sleeve clamps on both left and right

hand tie rods, then turn both sleeves an equal

loosen the plastic fasteners which maintain column

rigidity. number

of turns in the same direction

to bring

gear back

on high point.

MAINTENANCE AND ADJUSTMENTS NOTICE: Turning the sleeves an unequal number

Steering Wheel Alignment and High Point of turns or in different directions will disturb the

Centering toe-in setting of the wheels.

1. Set front wheel in straight ahead position, This 3. Readjust toe-in as outlined in Section 3A (if

can be checked by driving vehicle

a short distance necessary).

Page 153 of 1825

385-2 STEERING WHEELS AND COLUMNS

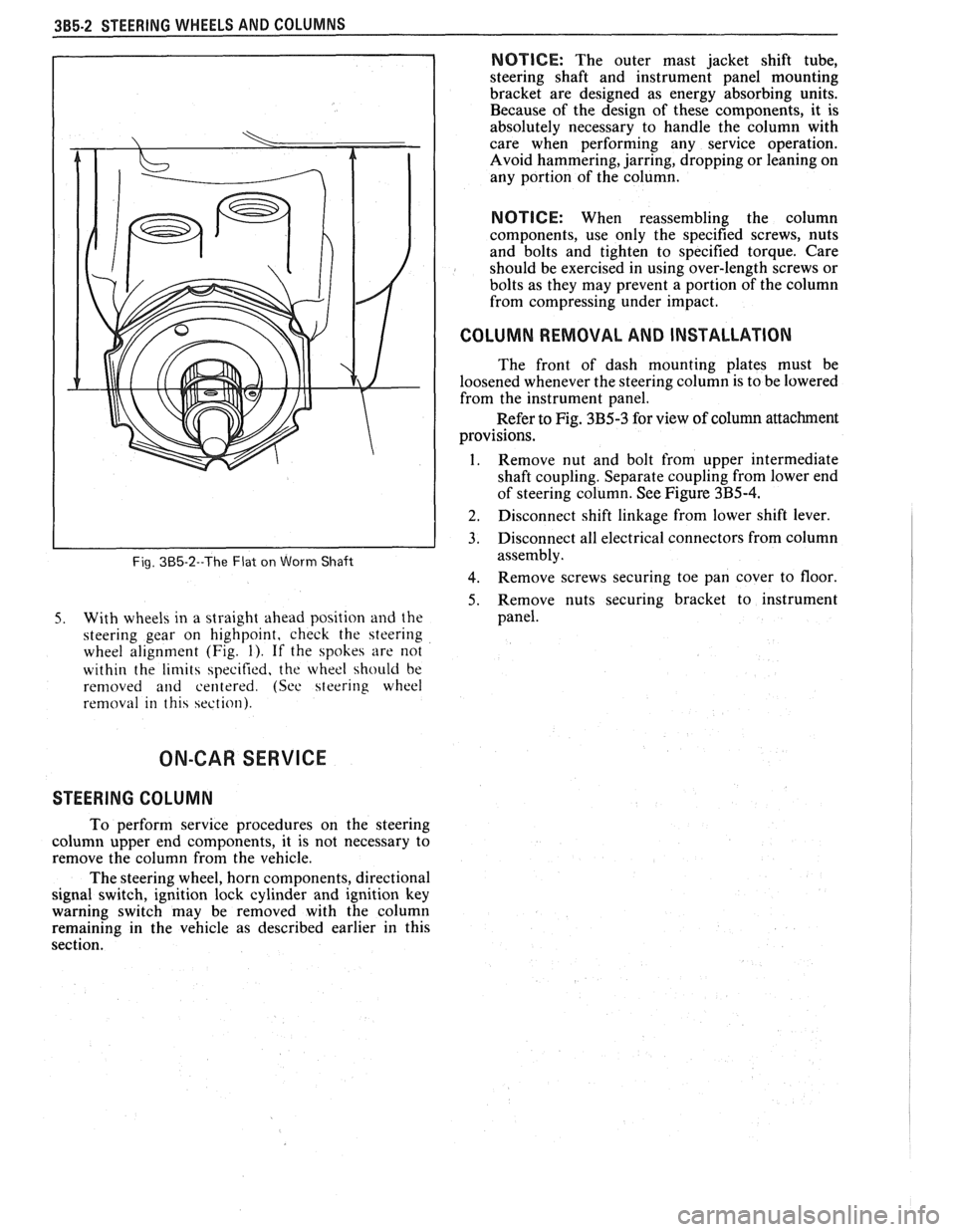

Fig. 385-2--The Flat on Worm Shaft

5. With wheels in a straight ahead position and the

steering gear on highpoint, check the steering

wheel alignment (Fig.

1). If the spokes are not

within the

limits specified, the wheel should be

removed

and centered. (See steering wheel

removal in this section).

NOTICE: The outer mast jacket shift tube,

steering shaft and instrument panel mounting

bracket are designed as energy absorbing units.

Because of the design of these components, it is

absolutely necessary to handle the column with

care when performing any service operation.

Avoid hammering, jarring, dropping or leaning on

any portion of the column.

NOTICE: When reassembling the column

components, use only the specified screws, nuts

and bolts and tighten to specified torque. Care

should be exercised in using over-length screws or

bolts as they may prevent a portion of the column

from compressing under impact.

I COLUMN REMOVAL AND INSTALLATION

The front of dash mounting plates must be

loosened whenever the steering column is to be lowered

from the instrument panel.

Refer to Fig. 3B5-3 for view of column attachment

provisions.

1. Remove nut and bolt from upper intermediate

shaft coupling. Separate coupling from lower end

of steering column. See Figure

3B5-4.

] 2. Disconnect shift linkage from lower shift lever.

3. Disconnect all electrical connectors from column

assembly.

4. Remove screws securing toe pan cover to floor

5. Remove nuts securing bracket to instrument

panel.

ON-CAR SERVICE

STEERING COLUMN

To perform service procedures on the steering

column upper end components, it is not necessary to

remove the column from the vehicle.

The steering wheel, horn components, directional

signal switch, ignition lock cylinder and ignition key

warning switch may be removed with the column

remaining in the vehicle as described earlier in this

section.

Page 157 of 1825

385.8 STEERING WHEELS AND COLUMNS

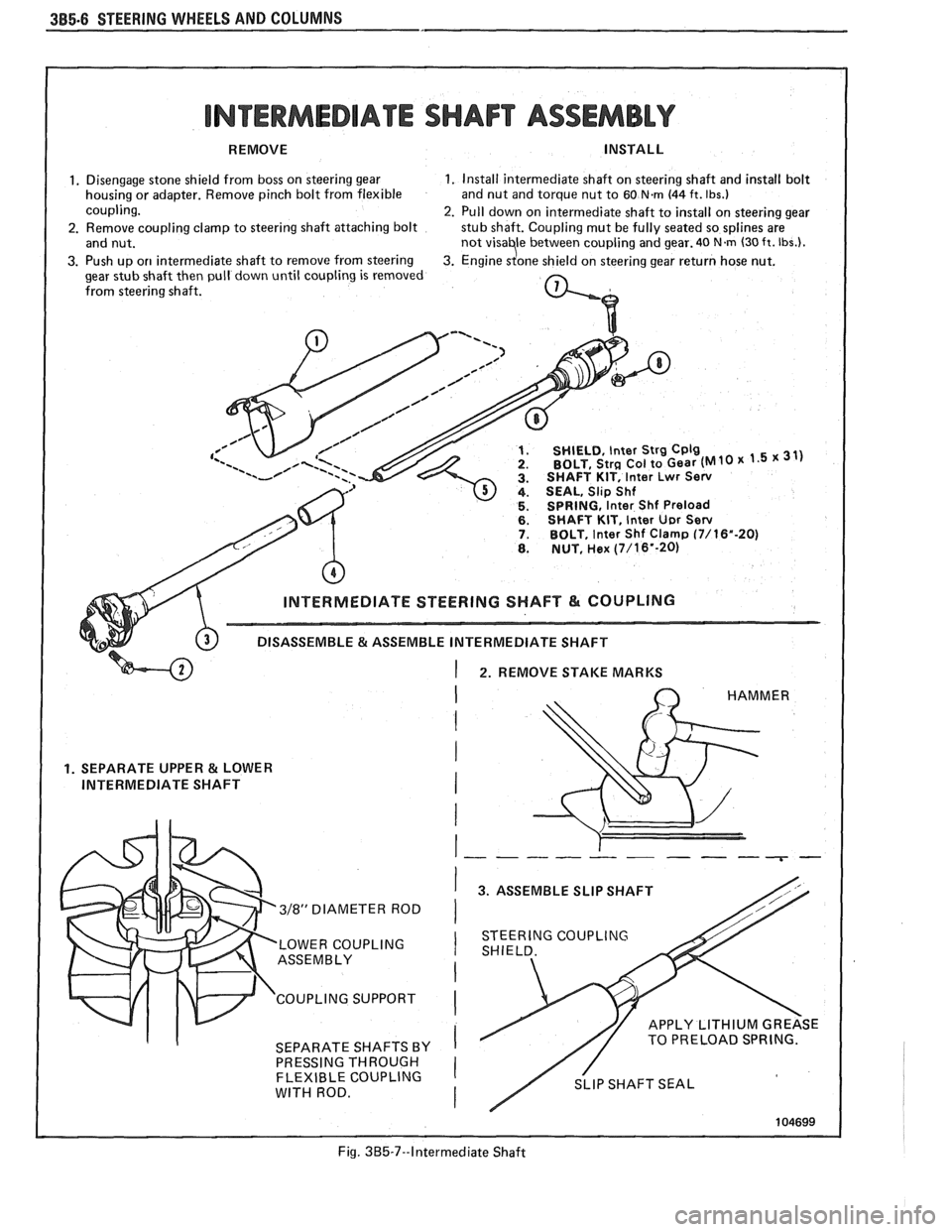

INTERMEDIATE SHAFT ASSEMBLY

REMOVE

1. Disengage stone shield from boss on steering gear

housing or adapter. Remove pinch bolt from flexible

coupling.

2. Remove coupling clamp to steering shaft attaching bolt

and nut.

3. Push up

on intermediate shaft to remove from steering

gear stub shaft then pull down until coupling is removed

from steering shaft. INSTALL

1. Install

intermediate shaft on steering shaft and install bolt

and nut and torque nut to 60 N.m (44 ft. Ibs.)

2. Pull down on intermediate shaft to install on steering gear

stub shaft. Coupling mut be fully seated so splines are

not visa

le between coupling and gear. 40 N.m (30ft. Ibs.).

3. Engine 4 one shield on steering gear return hose nut.

1. SHIELD, lnter Strg Cplg 2. BOLT, Str~ Col to Gear (MI0 31) 3. SHAFT KIT, lnter Lwr Sew 4. SEAL, Sl~p Shf 5. SPRING, lnter Shf Preload 6. SHAFT KIT, lnter UD~ Sew 7. BOLT, lnter Shf Clamp (7/16"-20) 8. NUT, Hex (7/16"-20)

1 2. REMOVE STAKE MARKS

1. SEPARATE UPPER & LOWER

INTERMEDIATE SHAFT

3/8" DIAMETER ROD

LOWER COUPLING

ASSEMBLY

COUPLING SUPPORT

SEPARATE SHAFTS BY

PRESSING THROUGH

FLEXIBLE COUPLING

WITH ROD. HAMMER

3. ASSEMBLE SLIP SHAFT /

STEERING COUPLING

SHIELD.

APPLY LITHIUM GREASE / // TO PRELOAD SPRING.

/ SLlP SHAFT SEAL

Fig. 385-7--Intermediate Shaft

Page 167 of 1825

385-16 STEERING WHEELS AND COLUMNS

5. Shaft assembly (42) to column 6. Bearing spring (7)

7. Turn signal cancelling cam (6)

8. Shaft lock (5) and cover (3) 9. Shaft lock retaining ring (4) using J 23653-A to depress

shaft lock (5) 10. Column to dash 1 1. Steering wheel 12. Jam nut (2) 13. Retainer (1) 14. Horn pad

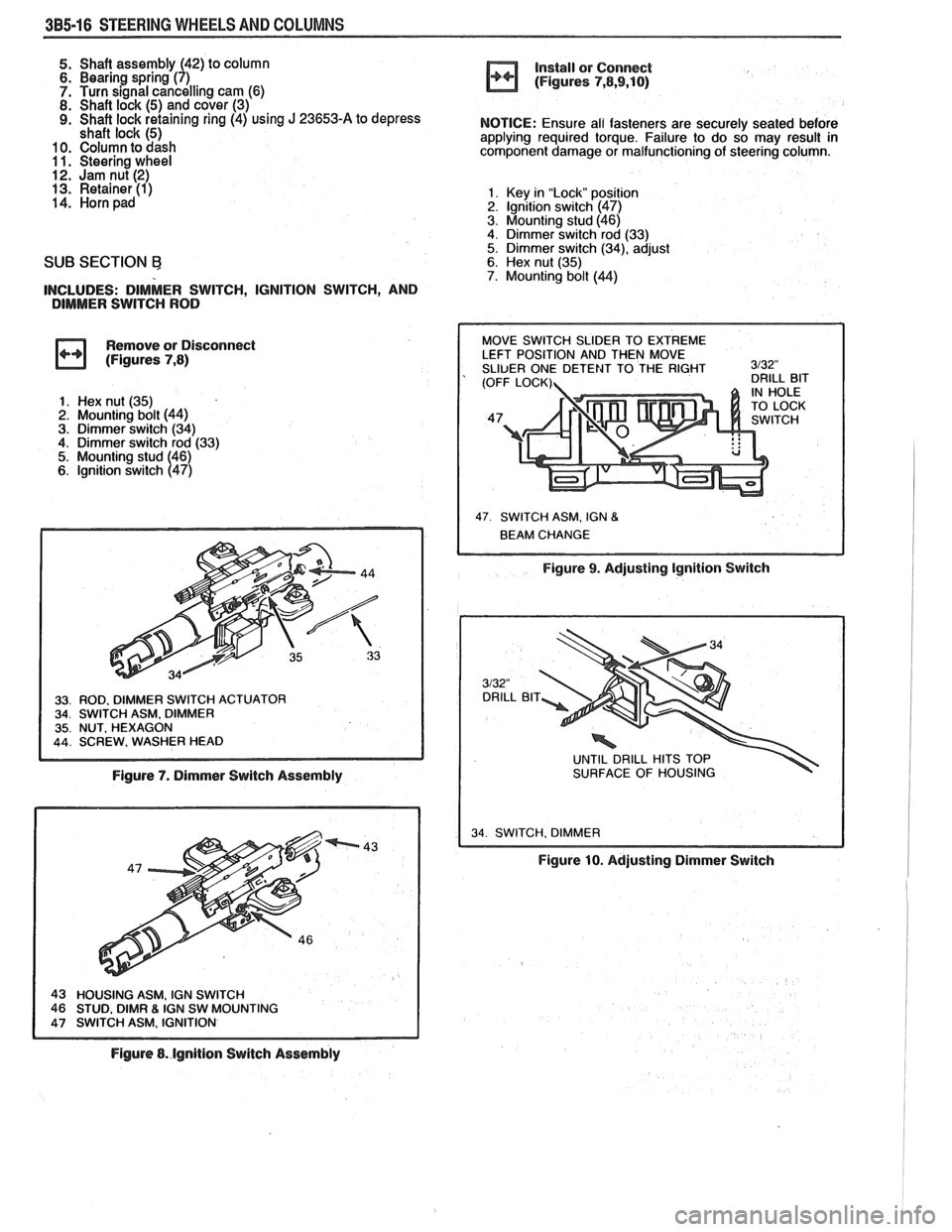

SUB SECTION Ej

INCLUDES: DIMMER SWITCH, IGNITION SWITCH, AND

DIMMER SWITCH ROD

Remove or Disconnect

(Figures

7,8)

1. Hex nut (35)

2. Mounting bolt (44)

3. Dimmer switch (34) 4. Dimmer switch rod (33)

5. Mounting stud (46)

6. lgnition switch (47)

Figure 7. Dimmer Switch Assembly

IGN SW MOUNTING

Figure 8. lgnition Switch Assembly install

or Connect

(Figures

7,8,9,10)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

1. Key in "Lock" posit~sn 2. lgnltion switch (47)

3. Mounting stud (46)

4. Dimmer switch rod (33)

5. Dimmer switch (34), adjust 6. Hex nut (35) 7. Mounting bolt (44)

47 SWITCH ASM. IGN 8

Figure 9. Adjusting Ignition Switch

UNTIL DRILL HITS TOP

SURFACE OF HOUSING

34 SWITCH. DIMMER I

Figure 10. Adjusting Dimmer Switch

Page 168 of 1825

STEERING WHEELS AND COLUMNS 385-17

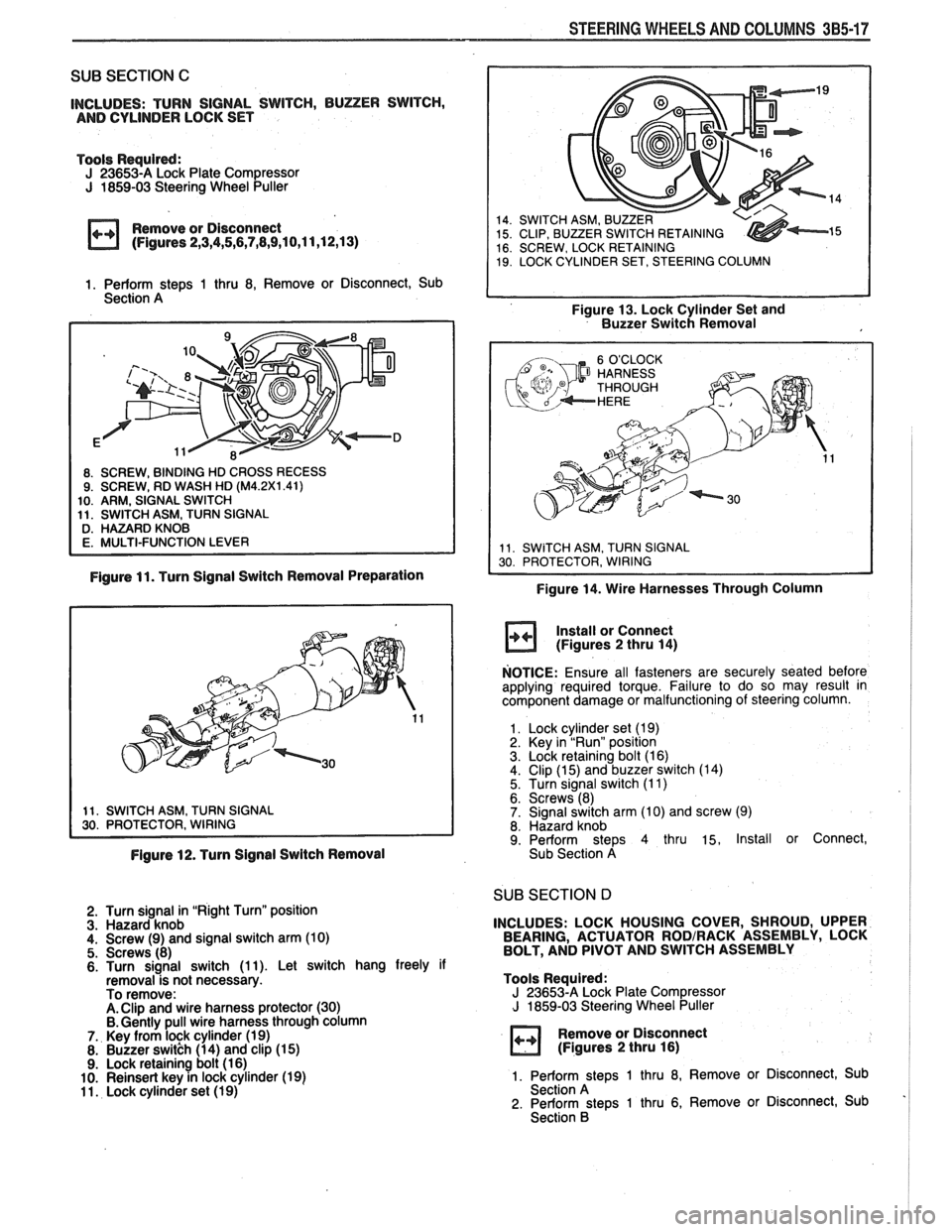

SUB SECTION C

INCLUDES: TURN SIGNAL SWITCH, BUZER SWITCH,

AND CYLINDER LOCK SET

Tools Required:

J 23653-A Lock Plate Compressor J 1859-03 Steering Wheel Puller

Remove or Disconnect

(Figures

2,3,4,5,6,7,8,9,10,11,12,13)

1. Perform ste~s 1 thru 8, Remove or Disconnect, Sub

Section A

, STEERING COLUMN

Figure 13. Lock Cylinder Set and

Buzzer Switch Removal

Figure 11. Turn Signal Switch Removal Preparation

Figure 14. Wire Harnesses Through Column

Install or Connect

(Figures

2 thru 14)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result In

component damage or malfunctioning of steering column.

1. Lock cylinder set (1 9)

2. Key in "Run" position 3. Lock retaining bolt (16) 4. Clip (15) and buzzer switch (14)

5. Turn signal switch (1 1) 6. Screws (8) 7. Signal switch arm (1 0) and screw (9) 8. Hazard knob 9. Perform steps 4 thru 15, Install or Connect,

Figure 12. Turn Signal Switch Removal Sub

Section A

SUB SECTION D I 2. Turn signal in "Right Turn" position 3. Hazard knob

4. Screw (9) and signal switch arm (10) 5. Screws (8)

6. Turn signal switch (1 1). Let switch hang freely if

removal-is not necessary.

To remove:

A. Clip and wire harness protector (30) B. Gently pull wire harness through column 7.. Key from lock cylinder (19)

8. Buzzer switkh (14) and clip (1 5) 9. Lock retaining bolt (1 6)

10. Reinsert key in lock cylinder (19) 1 1. Lock cylinder set (19)

INCLUDES: LOCK HOUSING COVER, SHROUD, UPPER

BEARING, ACTUATOR RODIRACK ASSEMBLY, LOCK

BOLT, AND PIVOT AND SWITCH ASSEMBLY

Tools Required:

J 23653-A Lock Plate Compressor J 1859-03 Steering Wheel Puller

Remove or Disconnect

(Figures 2 thru 16)

1. Perform stem 1 thru 8, Remove or Disconnect, Sub

Section A ' 2. Perform steps 1 thru 6, Remove or Disconnect, Sub

Section B

Page 169 of 1825

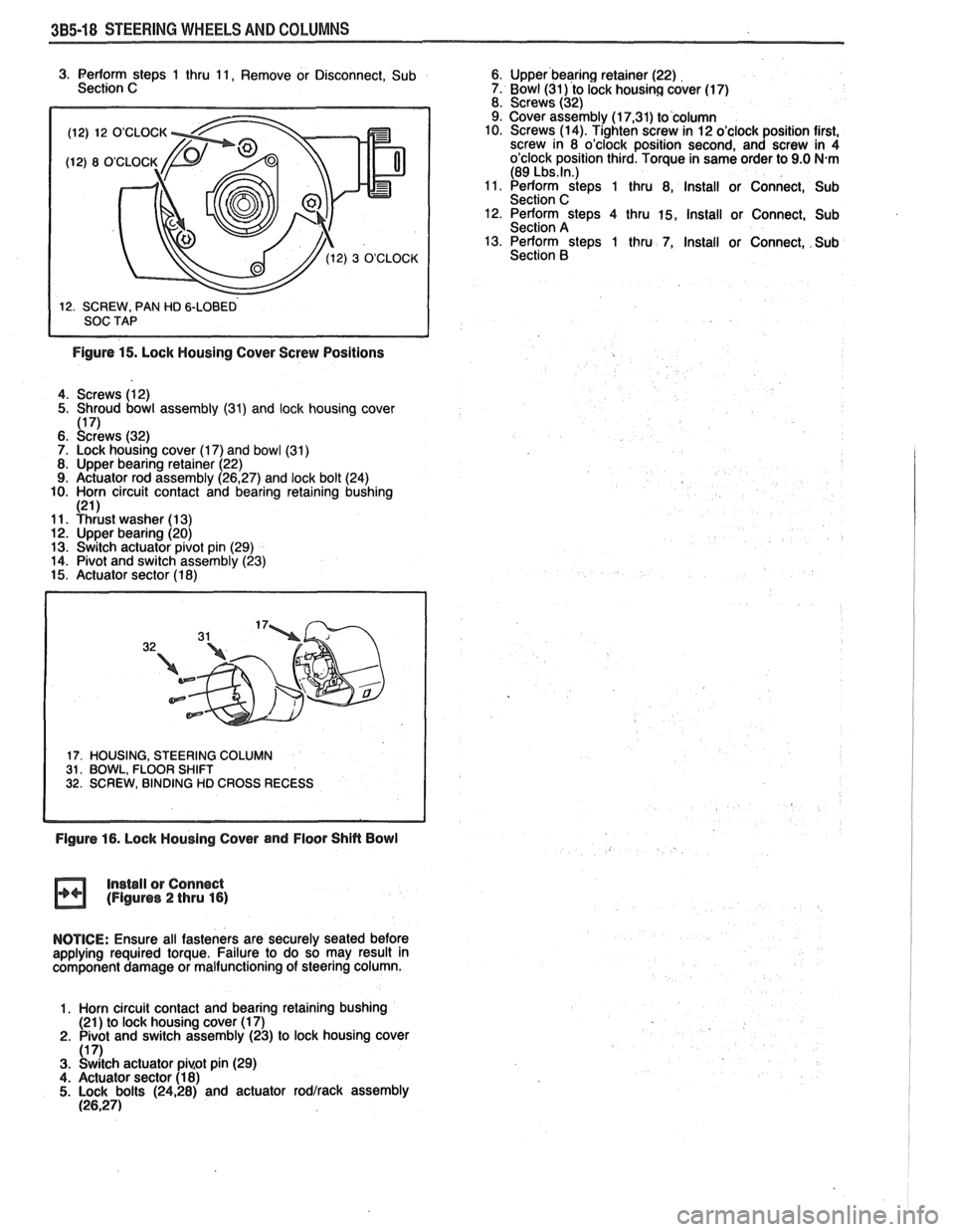

385-18 STEERING WHEELS AND COLUMNS

(12) 12 O'CLOCK

3. Perform steps 1 thru 11, Remove or Disconnect, Sub 6. Upper bearing retainer (22)

Section C 7. Bowl (31) to lock housing cover (17)

8. Screws (32)

9. Cover assembly (1

7,31) to column

10. Screws (14). Tighten screw in 12 o'clock position first,

screw in 8 o'clock position second, and screw in 4

o'clock position third. Torque in same order to 9.0

N.m (89 Lbs.ln.) 11. Perform steps 1 thru 8, Install or Connect, Sub

Section C 12. Perform steps 4 thru 15, Install or Connect, Sub

Section A

13. Perform steps 1 thru 7, Install or Connect, Sub

Section

B

Figure 15. Lock Housing Cover Screw Positions

4. Screws (12)

5. Shroud bowl assembly

(31) and lock housing cover 1171 6. ~c:dr'ews (32)

7. Lock housing cover (1 7) and bowl (31)

8. Upper bearing retainer (22)

9. Actuator rod assembly (26,27) and lock bolt (24)

10. Horn circuit contact and bearing retaining bushing

121 1 11. Yhiust washer (1 3) 12. Upper bearing (20)

13. Switch actuator pivot pin (29)

14. Pivot and switch assembly (23)

15. Actuator sector (1 8)

17. HOUSING, STEERING COLUMN 31. BOWL, FLOOR SHIFT 32. SCREW, BINDING HD CROSS RECESS

Figure 16. Lock Housing Cover and Floor Shin Bowl

Install

or Connect (Figures 2 thru 16)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

1. Horn circuit contact and bearing retaining bushing

(21 ) to lock housing cover (1 7)

2. Pivot and switch assembly (23) to lock housing cover

(1 7) 3. Switch actuator pi~ot pin (29)

4. Actuator sector (1 8) 5. Lock bolts (2428) and actuator rodlrack assembly (26,271