change wheel PONTIAC G5 2010 User Guide

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 2010, Model line: G5, Model: PONTIAC G5 2010Pages: 422, PDF Size: 2.22 MB

Page 248 of 422

Rocking Your Vehicle to Get It Out

Turn the steering wheel left and right to clear the area

around the front wheels. Shift back and forth between

R (Reverse) and a forward gear, or with a manual

transmission, between 1 (First) or 2 (Second) and

R (Reverse), spinning the wheels as little as possible.

To prevent transmission wear, wait until the wheels stop

spinning before shifting gears. Release the accelerator

pedal while shifting, and press lightly on the accelerator

pedal when the transmission is in gear. Slowly spinning

the wheels in the forward and reverse directions causes a

rocking motion that could free the vehicle. If that does not

get the vehicle out after a few tries, it might need to be

towed out. If the vehicle does need to be towed out, see

Towing Your Vehicle on page 5-30.

Loading the Vehicle

It is very important to know how much weight your

vehicle can carry. This weight is called the vehicle

capacity weight and includes the weight of all

occupants, cargo and all nonfactory-installed

options. Two labels on your vehicle show how much

weight it may properly carry, the Tire and Loading

Information label and the Certification label.

{WARNING:

Do not load the vehicle any heavier than the

Gross Vehicle Weight Rating (GVWR), or

either the maximum front or rear Gross Axle

Weight Rating (GAWR). If you do, parts on the

vehicle can break, and it can change the way

your vehicle handles. These could cause you

to lose control and crash. Also, overloading

can shorten the life of the vehicle.

5-24

Page 257 of 422

5. Clamp the steering wheel in a straight-aheadposition with a clamping device designed for towing.

6. Remove the key from the ignition.

7. Secure the vehicle to the dolly.

8. Release the parking brake only after the vehicle being towed is firmly attached to the towing vehicle.

Towing a Trailer (Automatic

Transmission)

{WARNING:

The driver can lose control when pulling a trailer if

the correct equipment is not used or the vehicle is

not driven properly. For example, if the trailer is

too heavy, the brakes may not work well or even

at all. The driver and passengers could be

seriously injured. The vehicle may also be

damaged; the resulting repairs would not be

covered by the vehicle warranty. Pull a trailer only

if all the steps in this section have been followed.

Ask your dealer/retailer for advice and information

about towing a trailer with the vehicle. The vehicle can tow a trailer if it is equipped with the

proper trailer towing equipment.

To identify the trailering capacity of the vehicle, read the

information in “Weight of the Trailer” that appears

later in this section.

Trailering is different than just driving the vehicle by

itself. Trailering means changes in handling,

acceleration, braking, durability and fuel economy.

Successful, safe trailering takes correct equipment, and

it has to be used properly.

The following information has many time-tested,

important trailering tips and safety rules. Many of these

are important for your safety and that of your

passengers. So please read this section carefully before

pulling a trailer.

Load-pulling components such as the engine,

transmission, rear axle, wheel assemblies and tires are

forced to work harder against the drag of the added

weight. The engine is required to operate at relatively

higher speeds and under greater loads, generating extra

heat. The trailer also adds considerably to wind

resistance, increasing the pulling requirements.

5-33

Page 296 of 422

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to torque specifications in

Capacities and Speci�cations on page 6-109.

If the vehicle has rear drum brakes, they do not have

wear indicators, but if a rear brake rubbing noise is heard,

have the rear brake linings inspected immediately. Rear

brake drums should be removed and inspected each time

the tires are removed for rotation or changing. When the

front brake pads are replaced, have the rear brakes

inspected, too.

Brake linings should always be replaced as complete

axle sets.

Brake Pedal Travel

See your dealer/retailer if the brake pedal does not

return to normal height, or if there is a rapid increase in

pedal travel. This could be a sign that brake service

might be required.

Brake Adjustment

Every moderate brake stop, the disc brakes adjust for

wear. If rarely making moderate or heavier brake stops,

the brakes might not adjust correctly. Very carefully

making a few moderate brake stops about every

1,000 miles (1 600 km) will adjust the brakes properly.

If the vehicle has rear drum brakes and the brake pedal

goes down farther than normal, the rear drum brakes

might need adjustment. Adjust them by backing up and

firmly applying the brakes a few times.

Replacing Brake System Parts

The braking system on a vehicle is complex. Its many

parts have to be of top quality and work well together if

the vehicle is to have really good braking. The vehicle

was designed and tested with top-quality brake parts.

When parts of the braking system are replaced — for

example, when the brake linings wear down and new

ones are installed — be sure to get new approved

replacement parts. If this is not done, the brakes might

not work properly. For example, if someone puts in brake

linings that are wrong for the vehicle, the balance

between the front and rear brakes can change — for the

worse. The braking performance expected can change in

many other ways if the wrong replacement brake parts

are installed.

6-32

Page 327 of 422

When rotating the vehicle’s tires, always use the

correct rotation pattern shown here.

Do not include the compact spare tire, if the

vehicle has one, in the tire rotation.

After the tires have been rotated, adjust the front

and rear inflation pressures as shown on the Tire

and Loading Information label. SeeIn�ation - Tire

Pressure on page 6-55 andLoading the Vehicle on

page 5-24.

If the vehicle has the Tire Pressure Monitor

System (TPMS), reset the TPMS sensors after

rotating the tires. See Tire Pressure Monitor

Operation on page 6-58 . Make certain that all wheel nuts are properly

tightened. See “Wheel Nut Torque” under

Capacities and Speci�cations on page 6-109

.

{WARNING:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the

vehicle. In an emergency, you can use a

cloth or a paper towel to do this; but be sure

to use a scraper or wire brush later, if

needed, to get all the rust or dirt off. See

Changing a Flat Tire on page 6-80.

6-63

Page 344 of 422

3. Remove the retainer that holds the tire sealant andcompressor kit.

4. Remove the kit from the foam container.

To store the tire sealant and compressor kit, reverse the

steps.

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on the hazard

warning flashers. See Hazard Warning Flashers

on page 4-3.

{WARNING:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you or

other people. You and they could be badly injured

or even killed. Find a level place to change your

tire. To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put an automatic transmission shift lever in P (Park), or shift a manual transmission to

1 (First) or R (Reverse).

3. Turn off the engine and do not restart while the vehicle is raised.

4. Do not allow passengers to remain in the vehicle.

To be even more certain the vehicle will not move,

you should put blocks at the front and rear of the

tire farthest away from the one being changed.

That would be the tire on the other side, at the

opposite end of the vehicle.

6-80

Page 345 of 422

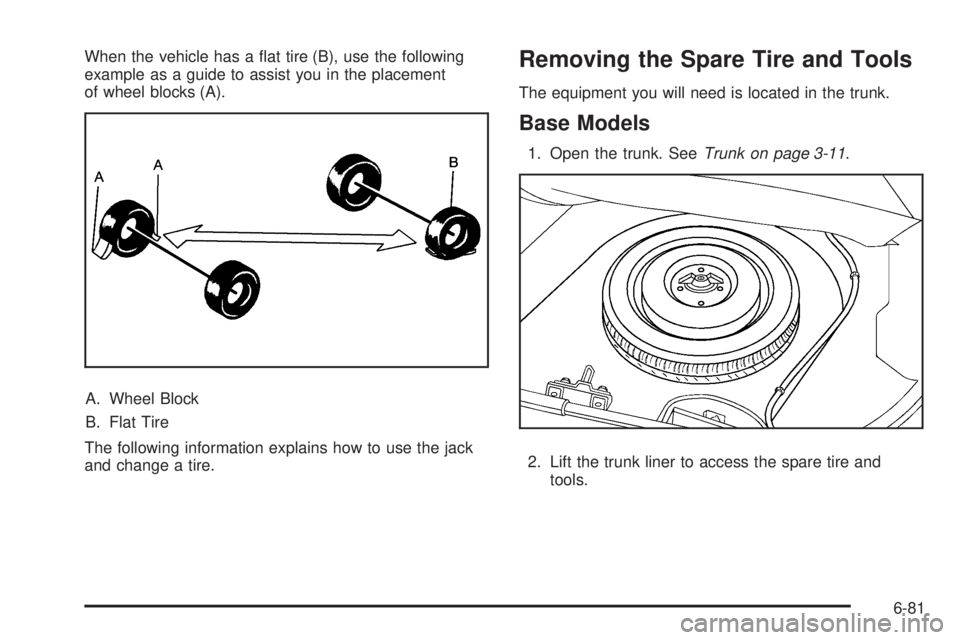

When the vehicle has a flat tire (B), use the following

example as a guide to assist you in the placement

of wheel blocks (A).A. Wheel Block

B. Flat Tire

The following information explains how to use the jack

and change a tire.Removing the Spare Tire and Tools

The equipment you will need is located in the trunk.

Base Models

1. Open the trunk. See Trunk on page 3-11.

2. Lift the trunk liner to access the spare tire and tools.

6-81

Page 421 of 422

Tires (cont.)Storing a Flat or Spare Tire and Tools ............6-90

Terminology and Definitions ...........................6-52

Uniform Tire Quality Grading .........................6-67

Wheel Alignment and Tire Balance .................6-68

Wheel Replacement ..................................... 6-68

When It Is Time for New Tires ......................6-64

Towing Recreational Vehicle ..................................... 5-30

Towing a Trailer .................................. 5-33, 5-39

Your Vehicle ............................................... 5-30

Traction Control System (TCS) .................................... 5-8

Traction System Enhanced ................................................... 4-27

Transmission Fluid, Automatic ........................................... 6-19

Transmission Operation, Automatic ....................3-24

Transmission Operation, Manual ........................3-27

Transportation Program, Courtesy ......................8-10

Trunk ............................................................ 3-11

Turn and Lane-Change Signals .......................... 4-4

Turn Signal/Multifunction Lever ........................... 4-4U

Uniform Tire Quality Grading............................6-67

Up-Shift Light ................................................. 4-25

V

Vehicle

Control ........................................................ 5-3

Loading ...................................................... 5-24

Parking Your ............................................... 3-32

Remote Start ................................................ 3-6

Running While Parked .................................. 3-34

Symbols ......................................................... iv

Vehicle Data Recording and Privacy ..................8-16

Vehicle Identification Number (VIN) ............................................ 6-101

Service Parts Identification Label ..................6-101

Vehicle Personalization DIC ........................................................... 4-43

Ventilation Adjustment ...................................... 4-17

Visors ........................................................... 3-15

13