brake PONTIAC G5 2010 Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 2010, Model line: G5, Model: PONTIAC G5 2010Pages: 422, PDF Size: 2.22 MB

Page 330 of 422

Vehicles that have a tire pressure monitoring

system could give an inaccurate low-pressure

warning if non-TPC Spec rated tires are installed

on your vehicle. Non-TPC Spec rated tires

may give a low-pressure warning that is higher or

lower than the proper warning level you would

get with TPC Spec rated tires. SeeTire Pressure

Monitor System on page 6-56 .

Your vehicle’s original equipment tires are listed

on the Tire and Loading Information Label.

See Loading the Vehicle on page 5-24 , for more

information about the Tire and Loading Information

Label and its location on your vehicle.

Different Size Tires and Wheels

If you add wheels or tires that are a different size than

your original equipment wheels and tires, this may

affect the way your vehicle performs, including its

braking, ride and handling characteristics, stability, and

resistance to rollover. Additionally, if your vehicle

has electronic systems such as, antilock brakes, traction

control, and electronic stability control, the performance

of these systems can be affected.

{WARNING:

If you add different sized wheels, your vehicle may

not provide an acceptable level of performance

and safety if tires not recommended for those

wheels are selected. You may increase the

chance that you will crash and suffer serious

injury. Only use GM specific wheel and tire

systems developed for your vehicle, and have

them properly installed by a GM certified

technician.

See Buying New Tires on page 6-64 andAccessories

and Modi�cations on page 6-3 for additional information.

6-66

Page 333 of 422

Each new wheel should have the same load-carrying

capacity, diameter, width, offset, and be mounted

the same way as the one it replaces.

If you need to replace any of your wheels, wheel bolts,

wheel nuts, or Tire Pressure Monitor System (TPMS)

sensors, replace them only with new GM original

equipment parts. This way, you will be sure to have the

right wheel, wheel bolts, wheel nuts, and TPMS

sensors for your vehicle.

{WARNING:

Using the wrong replacement wheels, wheel bolts,

or wheel nuts on your vehicle can be dangerous. It

could affect the braking and handling of your

vehicle, make your tires lose air and make you

lose control. You could have a collision in which

you or others could be injured. Always use the

correct wheel, wheel bolts, and wheel nuts for

replacement.Notice:

The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance, and tire or tire chain

clearance to the body and chassis.

See Changing a Flat Tire on page 6-80 for more

information.

Used Replacement Wheels

{WARNING:

Putting a used wheel on the vehicle is dangerous.

You cannot know how it has been used or how far

it has been driven. It could fail suddenly and

cause a crash. If you have to replace a wheel, use

a new GM original equipment wheel.

6-69

Page 334 of 422

Tire Chains

{WARNING:

If your vehicle has P205/55R16 or P205/50R17

size tires, do not use tire chains. They can

damage your vehicle because there is not enough

clearance.

Tire chains used on a vehicle without the proper

amount of clearance can cause damage to the

brakes, suspension, or other vehicle parts. The

area damaged by the tire chains could cause you

to lose control of your vehicle and you or others

may be injured in a crash.

Use another type of traction device only if its

manufacturer recommends it for use on your

vehicle and tire size combination and road

conditions. Follow that manufacturer’s instructions.

To help avoid damage to your vehicle, drive

slowly, readjust, or remove the device if it is

contacting your vehicle, and do not spin your

vehicle’s wheels.

If you do find traction devices that will fit, install

them on the front tires.Notice:

If your vehicle has a tire size other than

P205/55R16 or P205/50R17, use tire chains only

where legal and only when you must. Use only SAE

Class S-type chains that are the proper size for

your tires. Install them on the front tires and tighten

them as tightly as possible with the ends securely

fastened. Drive slowly and follow the chain

manufacturer’s instructions. If you can hear the

chains contacting your vehicle, stop and retighten

them. If the contact continues, slow down until

it stops. Driving too fast or spinning the wheels with

chains on will damage your vehicle.

If a Tire Goes Flat

It is unusual for a tire to blowout while you are driving,

especially if you maintain the tires properly. See

Tires on page 6-48 . If air goes out of a tire, It is much

more likely to leak out slowly. But if you should ever

have a blowout, here are a few tips about what to expect

and what to do:

If a front tire fails, the flat tire will create a drag that

pulls the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

6-70

Page 335 of 422

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you would

use in a skid. In any rear blowout, remove your foot from

the accelerator pedal. Get the vehicle under control

by steering the way you want the vehicle to go. It may

be very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place and stopping.1. Turn on the hazard warning flashers. See Hazard

Warning Flashers on page 4-3 .

2. Park the vehicle. Set the parking brake firmly and put the shift lever in P (Park).

3. Turn off the engine.

4. Inspect the flat tire.

{WARNING:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without the

appropriate safety equipment and training. If a jack

is provided with the vehicle, it is designed only for

changing a flat tire. If it is used for anything else,

you or others could be badly injured or killed if the

vehicle slips off the jack. If a jack is provided with

the vehicle, only use it for changing a flat tire.

This vehicle may come with a jack and spare tire or a

tire sealant and compressor kit. To use the jack and

spare tire, see Changing a Flat Tire on page 6-80 .To

use the tire sealant and compressor kit, see Tire Sealant

and Compressor Kit on page 6-72 .

6-71

Page 344 of 422

3. Remove the retainer that holds the tire sealant andcompressor kit.

4. Remove the kit from the foam container.

To store the tire sealant and compressor kit, reverse the

steps.

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on the hazard

warning flashers. See Hazard Warning Flashers

on page 4-3.

{WARNING:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you or

other people. You and they could be badly injured

or even killed. Find a level place to change your

tire. To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put an automatic transmission shift lever in P (Park), or shift a manual transmission to

1 (First) or R (Reverse).

3. Turn off the engine and do not restart while the vehicle is raised.

4. Do not allow passengers to remain in the vehicle.

To be even more certain the vehicle will not move,

you should put blocks at the front and rear of the

tire farthest away from the one being changed.

That would be the tire on the other side, at the

opposite end of the vehicle.

6-80

Page 354 of 422

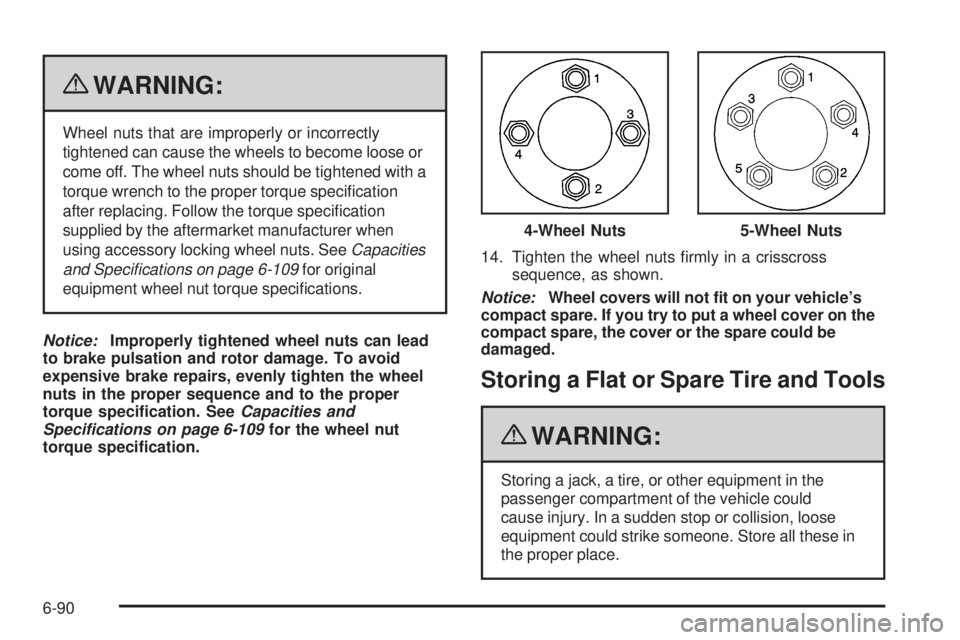

{WARNING:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become loose or

come off. The wheel nuts should be tightened with a

torque wrench to the proper torque specification

after replacing. Follow the torque specification

supplied by the aftermarket manufacturer when

using accessory locking wheel nuts. SeeCapacities

and Speci�cations on page 6-109 for original

equipment wheel nut torque specifications.

Notice: Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci�cation. See Capacities and

Specifications on page 6-109 for the wheel nut

torque speci�cation. 14. Tighten the wheel nuts firmly in a crisscross

sequence, as shown.

Notice: Wheel covers will not �t on your vehicle’s

compact spare. If you try to put a wheel cover on the

compact spare, the cover or the spare could be

damaged.

Storing a Flat or Spare Tire and Tools

{WARNING:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision, loose

equipment could strike someone. Store all these in

the proper place. 4-Wheel Nuts

5-Wheel Nuts

6-90

Page 370 of 422

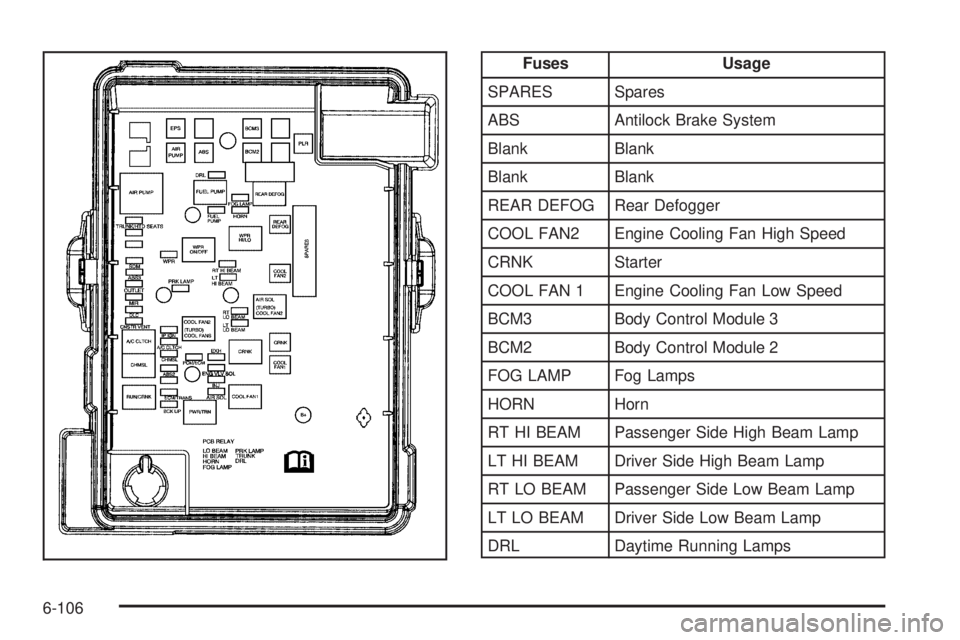

FusesUsage

SPARES Spares

ABS Antilock Brake System

Blank Blank

Blank Blank

REAR DEFOG Rear Defogger

COOL FAN2 Engine Cooling Fan High Speed

CRNK Starter

COOL FAN 1 Engine Cooling Fan Low Speed

BCM3 Body Control Module 3

BCM2 Body Control Module 2

FOG LAMP Fog Lamps

HORN Horn

RT HI BEAM Passenger Side High Beam Lamp

LT HI BEAM Driver Side High Beam Lamp

RT LO BEAM Passenger Side Low Beam Lamp

LT LO BEAM Driver Side Low Beam Lamp

DRL Daytime Running Lamps

6-106

Page 371 of 422

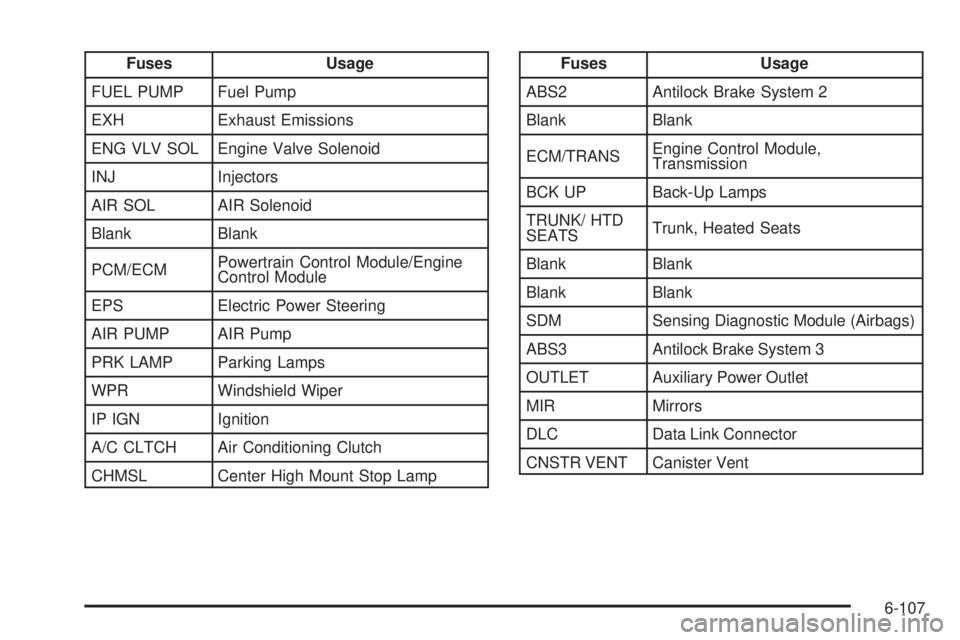

FusesUsage

FUEL PUMP Fuel Pump

EXH Exhaust Emissions

ENG VLV SOL Engine Valve Solenoid

INJ Injectors

AIR SOL AIR Solenoid

Blank Blank

PCM/ECM Powertrain Control Module/Engine

Control Module

EPS Electric Power Steering

AIR PUMP AIR Pump

PRK LAMP Parking Lamps

WPR Windshield Wiper

IP IGN Ignition

A/C CLTCH Air Conditioning Clutch

CHMSL Center High Mount Stop LampFuses Usage

ABS2 Antilock Brake System 2

Blank Blank

ECM/TRANS Engine Control Module,

Transmission

BCK UP Back-Up Lamps

TRUNK/ HTD

SEATS Trunk, Heated Seats

Blank Blank

Blank Blank

SDM Sensing Diagnostic Module (Airbags)

ABS3 Antilock Brake System 3

OUTLET Auxiliary Power Outlet

MIR Mirrors

DLC Data Link Connector

CNSTR VENT Canister Vent

6-107

Page 378 of 422

•Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system must

be repaired and the fluid level checked.

•Engine air cleaner filter inspection (vehicles driven

in dusty conditions only). SeeEngine Air Cleaner/

Filter on page 6-18.

•Brake system inspection (or every 12 months,

whichever occurs first).

Maintenance II

•Perform all services described in Maintenance I.

•Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts or

signs of wear.

•Engine cooling system inspection. Visual inspection

of hoses, pipes, fittings, and clamps and

replacement, if needed.

•Windshield wiper blade inspection for wear, cracking,

or contamination and windshield and wiper blade

cleaning, if contaminated. SeeWindshield and Wiper

Blades on page 6-98. Worn or damaged wiper blade

replacement. See Windshield Wiper Blade

Replacement on page 6-47 .

•Body hinges and latches, key lock cylinders, and

trunk lid hinges and latches lubrication. See

Recommended Fluids and Lubricants on page 7-10 .

More frequent lubrication may be required when

vehicle is exposed to a corrosive environment.

Applying silicone grease on weatherstrips with a

clean cloth makes them last longer, seal better, and

not stick or squeak.

•Restraint system component check. See Checking

the Restraint Systems on page 2-71 .

•Automatic transmission fluid level check and adding

fluid, if needed. SeeAutomatic Transmission Fluid

on page 6-19.

•Engine air cleaner filter inspection. See Engine Air

Cleaner/Filter on page 6-18 .

•Passenger compartment air filter replacement (or

every 12 months, whichever occurs first). More

frequent replacement may be required if vehicle is

driven regularly under dusty conditions.

7-4

Page 379 of 422

Additional Required Services

At Each Fuel Stop•

Engine oil level check. See Engine Oil on page 6-13.

•Engine coolant level check. See Engine Coolant on

page 6-24.

•Windshield washer fluid level check. See Windshield

Washer Fluid on page 6-28 .

Once a Month

•

Tire inflation check. See In�ation - Tire Pressure on

page 6-55.

•Tire wear inspection. See Tire Inspection and

Rotation on page 6-62 .

Once a Year

•

Starter switch check. See Owner Checks and

Services on page 7-8 .

•Parking brake and automatic transmission P (Park)

mechanism check. See Owner Checks and

Services on page 7-8 .

•Automatic transmission shiftlock control system

check. SeeOwner Checks and Services on

page 7-8.

•Ignition transmission lock check. See Owner

Checks and Services on page 7-8 .

•Engine cooling system and pressure cap pressure

check. Radiator and air conditioning condenser

outside cleaning. SeeCooling System on

page 6-20.

•Exhaust system and nearby heat shields inspection

for loose or damaged components.

•Throttle system inspection for interference, binding

or for damaged or missing parts. Replace parts as

needed. Replace any components that have

high effort or excessive wear. Do not lubricate

accelerator or cruise control cables.

•If the vehicle has a Tire Sealant and Compressor

Kit, check the sealant expiration date printed on

the instruction label of the kit. See Tire Sealant and

Compressor Kit on page 6-72 .

First Engine Oil Change After Every

40 000 km/25,000 Miles

•

Fuel system inspection for damage or leaks.

7-5