Wheel Replacement

Replace any wheel that is bent, cracked, or badly rusted

or corroded. If wheel nuts keep coming loose, the wheel,

wheel bolts, and wheel nuts should be replaced. If the

wheel leaks air, replace it (except some aluminum

wheels, which can sometimes be repaired). See your

dealer/retailer if any of these conditions exist.

Your dealer/retailer will know the kind of wheel

you need.

Each new wheel should have the same load-carrying

capacity, diameter, width, offset, and be mounted

the same way as the one it replaces.

If you need to replace any of your wheels, wheel bolts,

wheel nuts, or Tire Pressure Monitor System (TPMS)

sensors, replace them only with new GM original

equipment parts. This way, you will be sure to have

the right wheel, wheel bolts, wheel nuts, and TPMS

sensors for your vehicle.{CAUTION:

Using the wrong replacement wheels, wheel bolts,

or wheel nuts on your vehicle can be dangerous.

It could affect the braking and handling of your

vehicle, make your tires lose air and make you lose

control. You could have a collision in which you or

others could be injured. Always use the correct

wheel, wheel bolts, and wheel nuts for replacement.

Notice:The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance, and tire or tire chain

clearance to the body and chassis.

SeeChanging a Flat Tire on page 5-86for more

information.

5-83

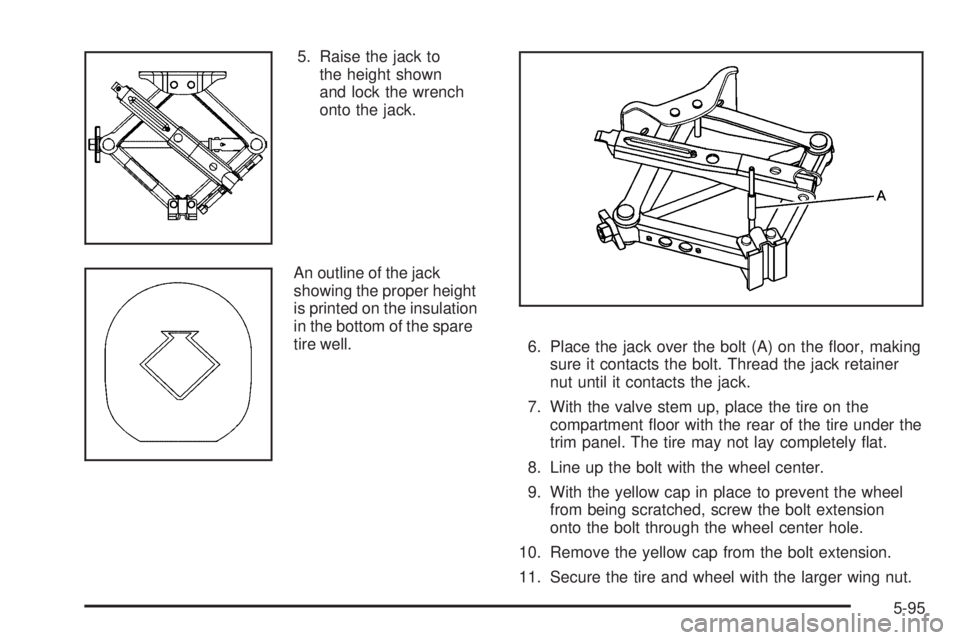

5. Raise the jack to

the height shown

and lock the wrench

onto the jack.

An outline of the jack

showing the proper height

is printed on the insulation

in the bottom of the spare

tire well.

6. Place the jack over the bolt (A) on the �oor, making

sure it contacts the bolt. Thread the jack retainer

nut until it contacts the jack.

7. With the valve stem up, place the tire on the

compartment �oor with the rear of the tire under the

trim panel. The tire may not lay completely �at.

8. Line up the bolt with the wheel center.

9. With the yellow cap in place to prevent the wheel

from being scratched, screw the bolt extension

onto the bolt through the wheel center hole.

10. Remove the yellow cap from the bolt extension.

11. Secure the tire and wheel with the larger wing nut.

5-95

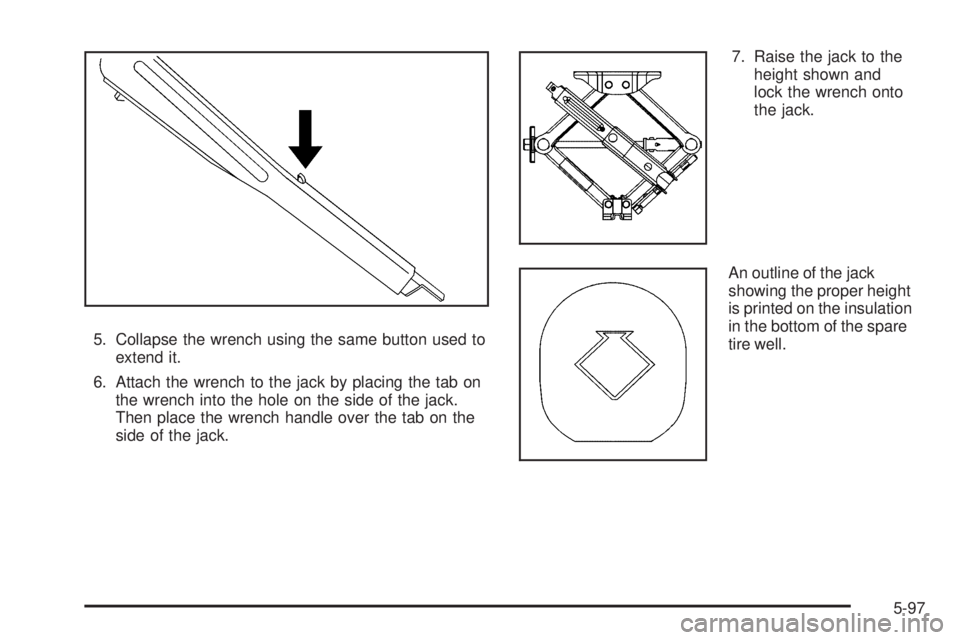

5. Collapse the wrench using the same button used to

extend it.

6. Attach the wrench to the jack by placing the tab on

the wrench into the hole on the side of the jack.

Then place the wrench handle over the tab on the

side of the jack.7. Raise the jack to the

height shown and

lock the wrench onto

the jack.

An outline of the jack

showing the proper height

is printed on the insulation

in the bottom of the spare

tire well.

5-97

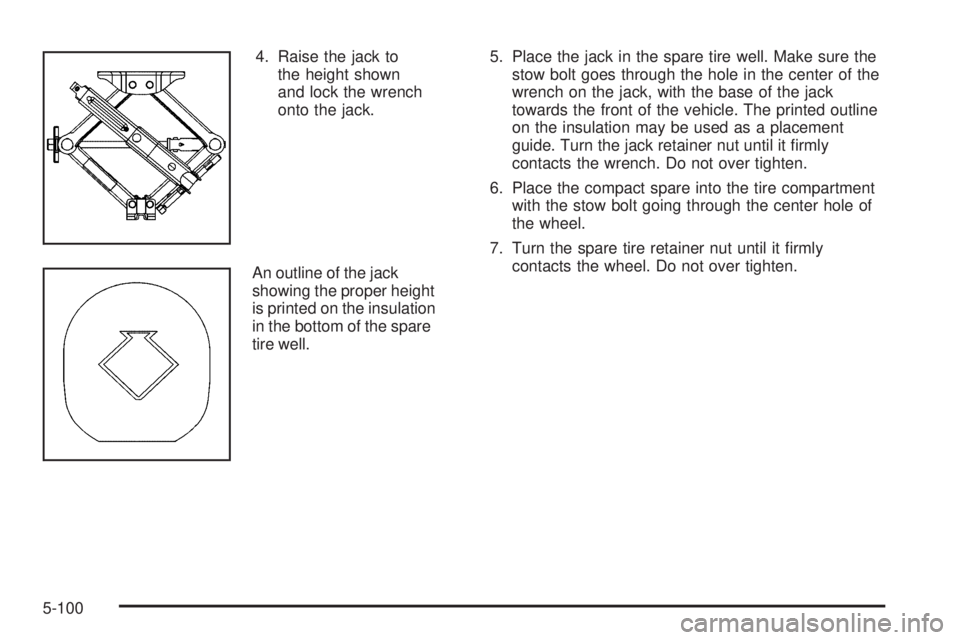

4. Raise the jack to

the height shown

and lock the wrench

onto the jack.

An outline of the jack

showing the proper height

is printed on the insulation

in the bottom of the spare

tire well.5. Place the jack in the spare tire well. Make sure the

stow bolt goes through the hole in the center of the

wrench on the jack, with the base of the jack

towards the front of the vehicle. The printed outline

on the insulation may be used as a placement

guide. Turn the jack retainer nut until it �rmly

contacts the wrench. Do not over tighten.

6. Place the compact spare into the tire compartment

with the stow bolt going through the center hole of

the wheel.

7. Turn the spare tire retainer nut until it �rmly

contacts the wheel. Do not over tighten.

5-100