torque PONTIAC GRAND AM 2005 Owners Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 2005, Model line: GRAND AM, Model: PONTIAC GRAND AM 2005Pages: 334, PDF Size: 2.27 MB

Page 89 of 334

If you have to leave your vehicle with the engine

running, be sure your vehicle is in PARK (P) and your

parking brake is firmly set before you leave it. After you

have moved the shift lever into PARK (P), hold the

regular brake pedal down. Then, see if you can move

the shift lever away from PARK (P) without first pushing

the button.

If you can, it means that the shift lever was not fully

locked into PARK (P).

Torque Lock

If you are parking on a hill and you do not shift your

automatic transaxle into PARK (P) properly, the weight of

the vehicle may put too much force on the parking pawl in

the transaxle. You may find it difficult to pull the shift lever

out of PARK (P). This is called “torque lock.” To prevent

torque lock, set the parking brake and then shift into

PARK (P) properly before you leave the driver’s seat. To

find out how, see “Shifting Into Park (P)” previously in the

section.

When you are ready to drive, move the shift lever out of

PARK (P) before you release the parking brake.

If torque lock does occur, you may need to have another

vehicle push yours a little uphill to take some of the

pressure from the parking pawl in the transaxle, so you

can pull the shift lever out of PARK (P).

Shifting Out of Park (P)

Your vehicle has an automatic transaxle shift lock

control system which locks the shift lever in PARK when

the ignition is in OFF. In addition, you have to fully

apply your regular brakes before you can shift from

PARK (P) when the ignition is in ON. SeeAutomatic

Transaxle Operation on page 2-20.

If you cannot shift out of PARK (P), ease pressure on

the shift lever and push the shift lever all the way

into PARK (P) as you maintain brake application. Then

move the shift lever into the gear you want.

If you hold the brake pedal down but still cannot shift

out of PARK (P), try this:

1. Turn the ignition key to ACCESSORY. There is no

shift interlock in this key position.

2. Apply and hold the brake until the end of Step 4.

3. Shift the transaxle to NEUTRAL (N).

4. Start the vehicle and then shift to the gear

you want.

5. Have the system fixed as soon as possible.

2-25

Page 243 of 334

{CAUTION:

The brake wear warning sound means that soon

your brakes will not work well. That could lead

to an accident. When you hear the brake wear

warning sound, have your vehicle serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong with

your brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to GM torque specifications.If you have rear drum brakes, they do not have wear

indicators, but if you ever hear a rear brake rubbing

noise, have the rear brake linings inspected immediately.

Also, the rear brake drums should be removed and

inspected each time the tires are removed for rotation or

changing. When you have the front brake pads

replaced, have the rear brakes inspected, too.

Brake linings should always be replaced as complete

axle sets.

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in

pedal travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you make a moderate brake stop, your disc

brakes adjust for wear. If you rarely make a moderate or

heavier stop, then your brakes might not adjust correctly.

If you drive in that way, then — very carefully — make a

few moderate brake stops about every 1,000 miles

(1 600 km), so your brakes will adjust properly.

5-35

Page 262 of 334

After the tires have been rotated, adjust the front and

rear inflation pressures as shown on the Tire and

Loading Information label.

Make certain that all wheel nuts are properly tightened.

See “Wheel Nut Torque” underCapacities and

Specifications on page 5-85.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if you need to, to

get all the rust or dirt off. SeeChanging a Flat

Tire on page 5-61.

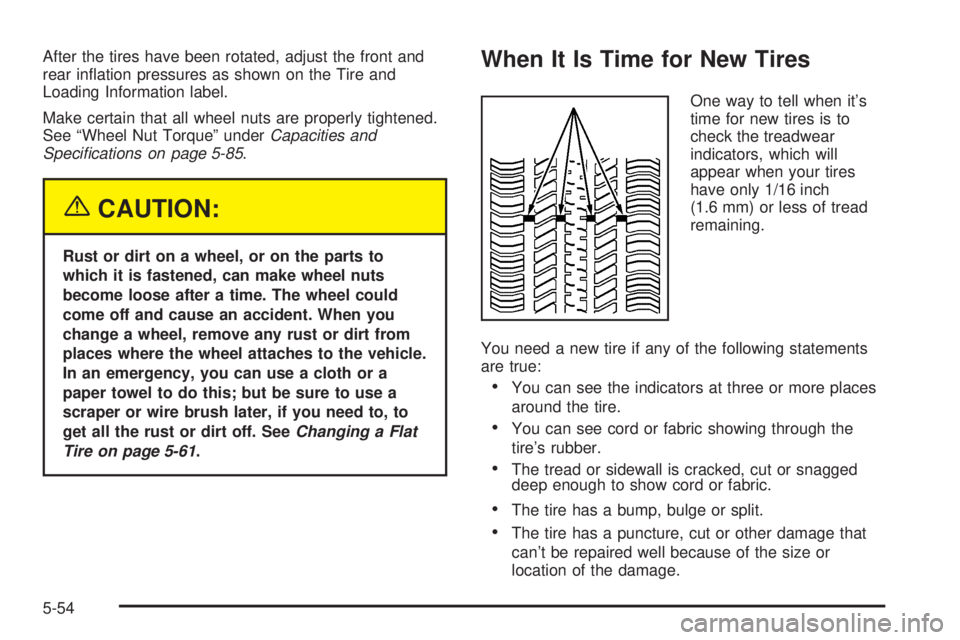

When It Is Time for New Tires

One way to tell when it’s

time for new tires is to

check the treadwear

indicators, which will

appear when your tires

have only 1/16 inch

(1.6 mm) or less of tread

remaining.

You need a new tire if any of the following statements

are true:

•You can see the indicators at three or more places

around the tire.

•You can see cord or fabric showing through the

tire’s rubber.

•The tread or sidewall is cracked, cut or snagged

deep enough to show cord or fabric.

•The tire has a bump, bulge or split.

•The tire has a puncture, cut or other damage that

can’t be repaired well because of the size or

location of the damage.

5-54

Page 276 of 334

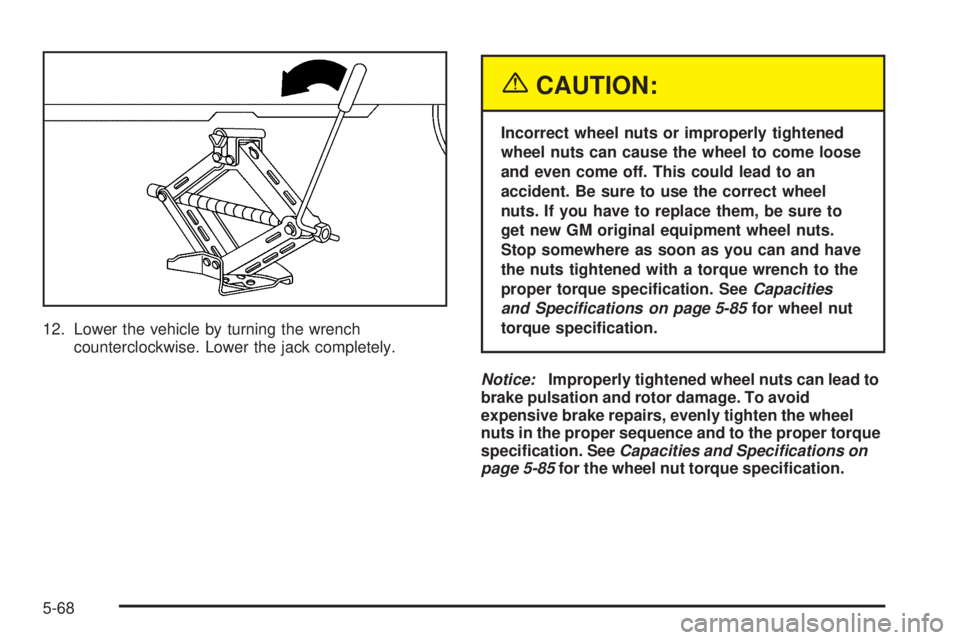

12. Lower the vehicle by turning the wrench

counterclockwise. Lower the jack completely.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci�cation. SeeCapacities

and Specifications on page 5-85for wheel nut

torque speci�cation.

Notice:Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper torque

speci�cation. SeeCapacities and Specifications on

page 5-85for the wheel nut torque speci�cation.

5-68

Page 293 of 334

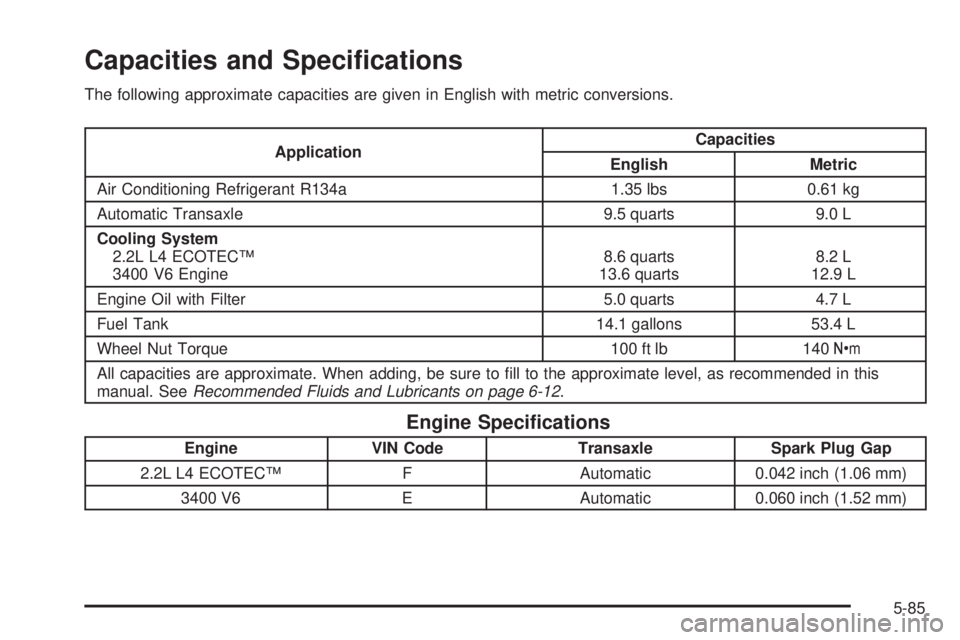

Capacities and Speci�cations

The following approximate capacities are given in English with metric conversions.

ApplicationCapacities

English Metric

Air Conditioning Refrigerant R134a 1.35 lbs 0.61 kg

Automatic Transaxle 9.5 quarts 9.0 L

Cooling System

2.2L L4 ECOTEC™

3400 V6 Engine8.6 quarts

13.6 quarts8.2 L

12.9 L

Engine Oil with Filter 5.0 quarts 4.7 L

Fuel Tank 14.1 gallons 53.4 L

Wheel Nut Torque 100 ft lb 140Y

All capacities are approximate. When adding, be sure to fill to the approximate level, as recommended in this

manual. SeeRecommended Fluids and Lubricants on page 6-12.

Engine Speci�cations

Engine VIN Code Transaxle Spark Plug Gap

2.2L L4 ECOTEC™ F Automatic 0.042 inch (1.06 mm)

3400 V6 E Automatic 0.060 inch (1.52 mm)

5-85