Service light PORSCHE 911 CARRERA 2006 5.G User Guide

[x] Cancel search | Manufacturer: PORSCHE, Model Year: 2006, Model line: 911 CARRERA, Model: PORSCHE 911 CARRERA 2006 5.GPages: 308, PDF Size: 3.69 MB

Page 254 of 308

254

Practical Tips, Emergency Service

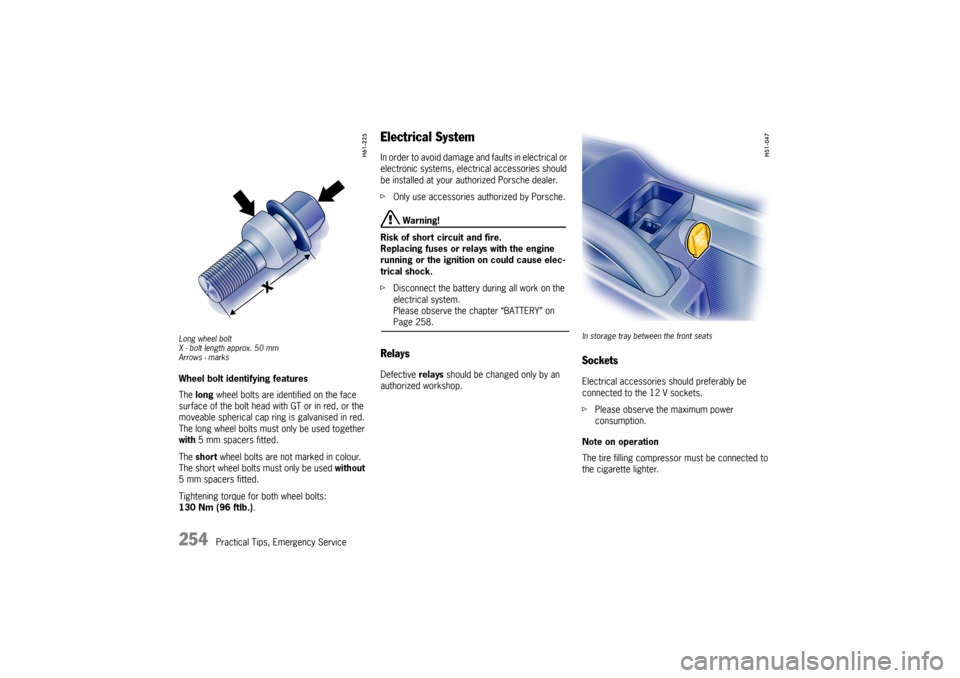

Long wheel bolt

X - bolt length approx. 50 mm

Arrows - marksWheel bolt identifying features

The long wheel bolts are identified on the face

surface of the bolt head with GT or in red, or the

moveable spherical cap ring is galvanised in red.

The long wheel bolts must only be used together

with 5 mm spacers fitted.

The short wheel bolts are not marked in colour.

The short wheel bolts must only be used without

5 mm spacers fitted.

Tightening torque for both wheel bolts:

130 Nm (96 ftlb.).

Electrical System In order to avoid damage and faults in electrical or

electronic systems, electrical accessories should

be installed at your authorized Porsche dealer.

fOnly use accessories authorized by Porsche.

Warning!

Risk of short circuit and fire.

Replacing fuses or relays with the engine

running or the ignition on could cause elec-

trical shock.

fDisconnect the battery during all work on the

electrical system.

Please observe the chapter “BATTERY” on Page 258.

Relays Defective relays should be changed only by an

authorized workshop.

In storage tray between the front seatsSocketsElectrical accessories should preferably be

connected to the 12 V sockets.

fPlease observe the maximum power

consumption.

Note on operation

The tire filling compressor must be connected to

the cigarette lighter.

Page 255 of 308

Practical Tips, Emergency Service

255

In the passenger’s footwellNote on operation

The sockets and thus the connected electrical

accessories function even if the ignition is

switched off or the ignition key is withdrawn.

If the engine is not running and the accessories

are switched on, the vehicle battery will be

discharged.

Do not operate additional accessories for more

than 5 minutes when engine is off.

Maximum power consumption for both

sockets together: 70 W.

fPlease observe the power specifications from

the accessory manufacturer.

Alarm system, central lockingThe status of the central locking and alarm system

is not changed by disconnecting the battery.

When the battery is disconnected, the alarm sys-

tem ceases to function. Overload protectionIf the central locking system is operated more

than ten times within a minute, further operation is

blocked for 30 seconds.

Load switch-off after 2 hours or 7 daysIf the ignition key is removed, loads which are

switched on or are in standby mode (such as the

luggage compartment light, interior light and

radio) are automatically switched off after approx.

2hours.

If the vehicle is not started or unlocked with the

remote control within 7days, the remote control

standby function is switched off (to save the

vehicle battery).

1. In this case, unlock the driver's door with the

key at the door lock.

Leave the door closed in order to prevent the

alarm system from being triggered.

2. Press button 1 on the remote control.

The remote control is now activated again.

Page 260 of 308

260

Practical Tips, Emergency Service

Warning!

Hydrogen gas generated by the battery

could cause an explosion, resulting in severe

personal injuries.

fCharge battery in a well ventilated area.

fNever charge a frozen battery. It may explode

because of gas trapped in the ice. Allow a fro-

zen battery to thaw out first.

fIf you get electrolyte, which is an acid, in your

eyes or on your skin, immediately rinse with

cold water for several minutes and call a doc-tor. Slow battery charging

1. Pay attention to all warnings and follow instruc-

tions that come with your battery charger.

2. When charging, ensure adequate ventilation.

3. Remove battery.

Please observe the chapter “REMOVING THE

BATTERY” on Page 262.

4. All vent caps should be open.

The fluid level should meet the indicator mark

in each cell.

5. Ensure that charger is switched off – danger of

short circuit!

6. Connect charger cables.

Charger cables must be connected

POSITIVE (+) to POSITIVE (+) and

NEGATIVE (–) to NEGATIVE (–).

7. Switch on charger.

Normally, a battery should be charged at no

more than 10 percent of its rated capacity.

Rated capacity of the battery in your vehicle is

listed on the battery housing.

8. After charging, turn off charger and disconnect

charger cables.

9. Tighten the vent caps and reinstall battery.

Please observe the chapter “INSTALLING THE

BATTERY” on Page 263.

Winter operation The capacity and ability of the battery to store

power decreases at low outside temperatures.

Additionally, more power is consumed while start-

ing, and the headlights, heater, rear window de-

fogger, etc., are used more frequently.

fLet your Porsche dealer test the battery’s

capacity before winter sets in.

The battery will discharge more quickly if your ve-

hicle is not driven on a daily basis over a distance

of several miles. The more often you drive your ve-

hicle, and the longer the distance driven on each

trip, the more opportunity the vehicle’s charging

system will have to recharge the batteries.

Page 261 of 308

Practical Tips, Emergency Service

261

Replacing battery The service life of the battery is subject to normal

wear; it depends greatly on care, climatic condi-

tions, and driving conditions (distances, loads).

fOnly use an original Porsche battery, with the

correct part number, as a replacement.

fPlease observe the disposal instructions for

batteries.

Putting vehicle into operationAfter the battery is connected or after an exhaus-

tively discharged battery is charged, the multi-

functional PSM light lights up on the instrument

panel and a message appears on the on-board

computer to indicate a fault.

This fault can be remedied with a few simple

steps:

1. Start the engine.

2. With the vehicle stationary, perform a few

steering movements to the left and right and

then drive a short distance in a straight line

until the multifunctinal PSM light goes out and

the message on the on-board computer

disappears.

3. If the warnings do not disappear, then:

Drive carefully to the nearest authorized

Porsche dealer.

Have the fault remedied.

4. After the warnings disappear:

Stop the vehicle in a suitable place.

fPerform adaptation of the power windows:

Please observe the chapter “STORING END

POSITION OF THE WINDOWS” on Page 29.Ignition key/ignition lock

fDo not insert the ignition key into the ignition

lock if the vehicle battery is discharged.

The ignition key can no longer be removed.

The key cannot be removed until the vehicle elec-

trical system is supplied with power again.

fPlease observe the chapter “EMERGENCY UN-

LOCKING OF THE LUGGAGE COMPARTMENT

LID” on Page 257.

fPlease observe the chapter “EMERGENCY

STARTING WITH JUMPER CABLES” on

Page 264.

f f f

Page 263 of 308

Practical Tips, Emergency Service

263

Installing the battery 1. Put battery in and push it all the way to the

stop.

2. Screw in fastening screw B.

Danger!

Risk of short circuit and explosion.

fImportant: connect the positive (+) cable first, and then the negative (–) ground wire.

3. Push on central vent hose C.

4. Fit plastic lid. Lock turn-locks A.

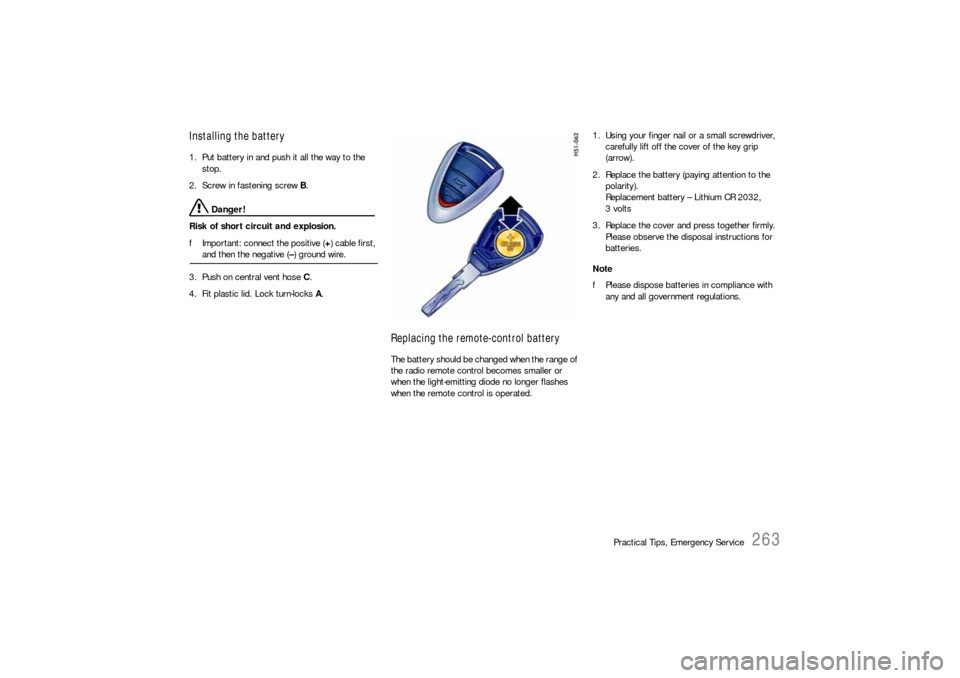

Replacing the remote-control battery The battery should be changed when the range of

the radio remote control becomes smaller or

when the light-emitting diode no longer flashes

when the remote control is operated.1. Using your finger nail or a small screwdriver,

carefully lift off the cover of the key grip

(arrow).

2. Replace the battery (paying attention to the

polarity).

Replacement battery – Lithium CR 2032,

3volts

3. Replace the cover and press together firmly.

Please observe the disposal instructions for

batteries.

Note

fPlease dispose batteries in compliance with

any and all government regulations.

Page 265 of 308

Practical Tips, Emergency Service

265

Connect jumper cables in the following

sequence:

Always observe the sequence below:

1. Connect the positive lead (red) to the

positive terminal of the discharged battery

first, then connect it to the positive terminal of

the donor battery.

2. First connect the negative cable (black) to

the negative terminal of the donor battery, then

connect it to a suitable grounding point on the

vehicle with the discharged battery.

This grounding point must lie as far as possible

from the battery.

For example, a solid metal part or the engine

block are suitable grounding points.

If no suitable grounding points are to be found

on either vehicle, the negative cable must

carefully be connected directly to the negative

terminal of the battery.

If a suitable grounding point is to be found only

on the donor vehicle, the negative cable must

first be connected to the terminal of the

discharged battery, then to the grounding point

of the donor vehicle.

3. Run the engine of the donor car at a higher

speed.4. Start the engine.

An attempted start using jumper cables should

not last more than 15 seconds. Then allow a

waiting period of at least one minute.

Note

Before disconnecting the jumper cables, electrical

loads such as the heated rear window and the

heating fan blower should be switched on (the ve-

hicle’s lights must not be switched on). This reduc-

es voltage peaks which may occur when discon-

necting the jumper cables.

With the engine running, remove both jumper ca-

bles in reverse order.

Page 266 of 308

266

Practical Tips, Emergency Service

Lights, Replacing Bulbs

Warning!

Risk of short circuit.

fAlways switch off the relevant consumer when

changing bulbs.

Risk of injury. The Bi Xenon headlights are

under high voltage when installed.

fBe careful during all work in the area of the Bi

Xenon headlights.

Risk of damage. Bulbs of a higher wattage

can damage the lamp housing.

fOnly the bulbs shown in the chart may be used.

fNew bulbs must be clean and free from oil,

grease and fingerprints. Therefore, never

touch bulbs with your bare hands.

Use a cloth or soft paper while replacing bulbs.

Caution!

Risk of damage to headlights due to exces-

sive temperatures and abrasion.

fAttach no coverings (e.g. films, “stone

guards”) in the area of the headlights.

fUse soapy water only to clean light lenses and

plastic headlight lenses.

In no case may chemical cleaners or other vol-

atile cleaning fluids be used.

fTo prevent scratches, do not rub with a dry or merely moist cloth, tissue or insect sponges.

Page 267 of 308

Practical Tips, Emergency Service

267

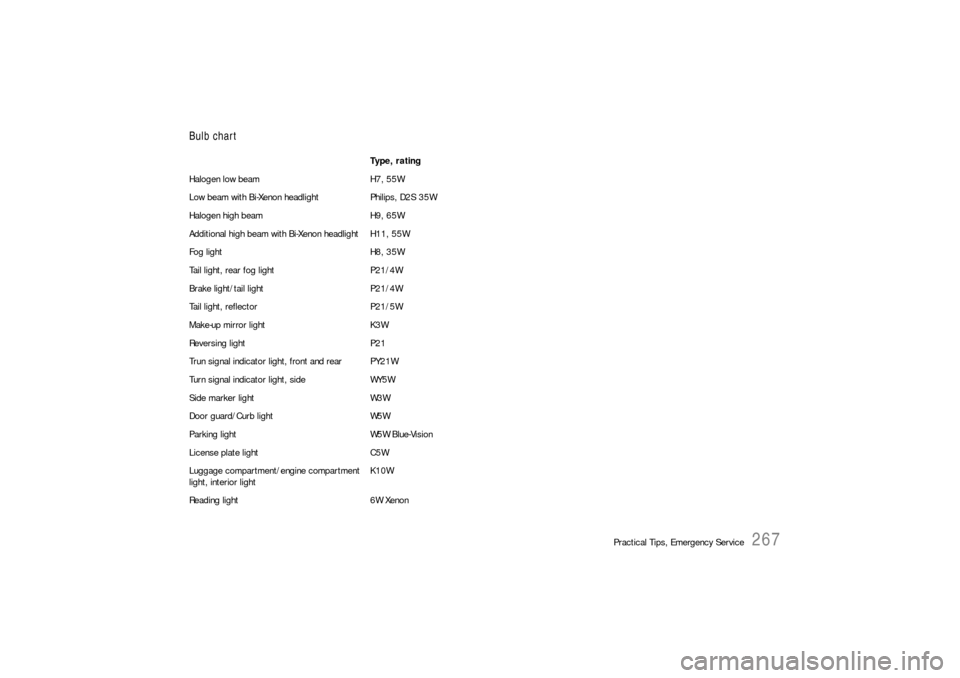

Bulb chart

Ty p e , r a t i n g

Halogen low beam H7, 55W

Low beam with Bi-Xenon headlight Philips, D2S 35W

Halogen high beam H9, 65W

Additional high beam with Bi-Xenon headlight H11, 55W

Fog light H8, 35W

Tail light, rear fog light P21/4W

Brake light/tail light P21/4W

Tail light, reflector P21/5W

Make-up mirror light K3W

Reversing light P21

Trun signal indicator light, front and rear PY21W

Turn signal indicator light, side WY5W

Side marker light W3W

Door guard/Curb light W5W

Parking light W5W Blue-Vision

License plate light C5W

Luggage compartment/engine compartment

light, interior lightK10W

Reading light 6W Xenon

Page 268 of 308

268

Practical Tips, Emergency Service

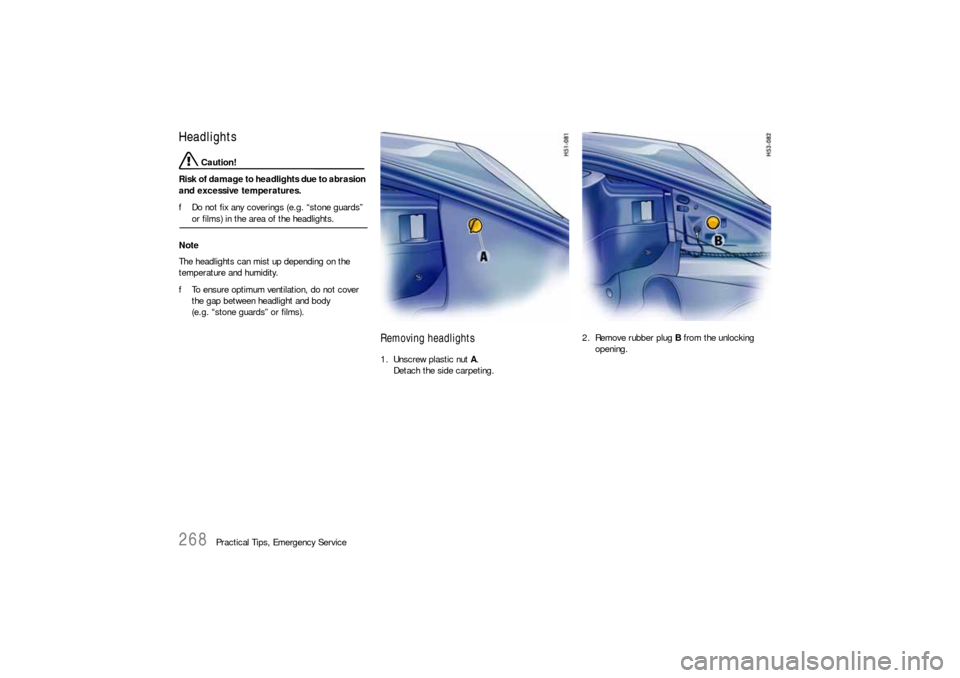

Headlights

Caution!

Risk of damage to headlights due to abrasion

and excessive temperatures.

fDo not fix any coverings (e.g. “stone guards” or films) in the area of the headlights.

Note

The headlights can mist up depending on the

temperature and humidity.

fTo ensure optimum ventilation, do not cover

the gap between headlight and body

(e.g. “stone guards” or films).

Removing headlights1. Unscrew plastic nut A.

Detach the side carpeting.2. Remove rubber plug B from the unlocking

opening.

Page 269 of 308

Practical Tips, Emergency Service

269

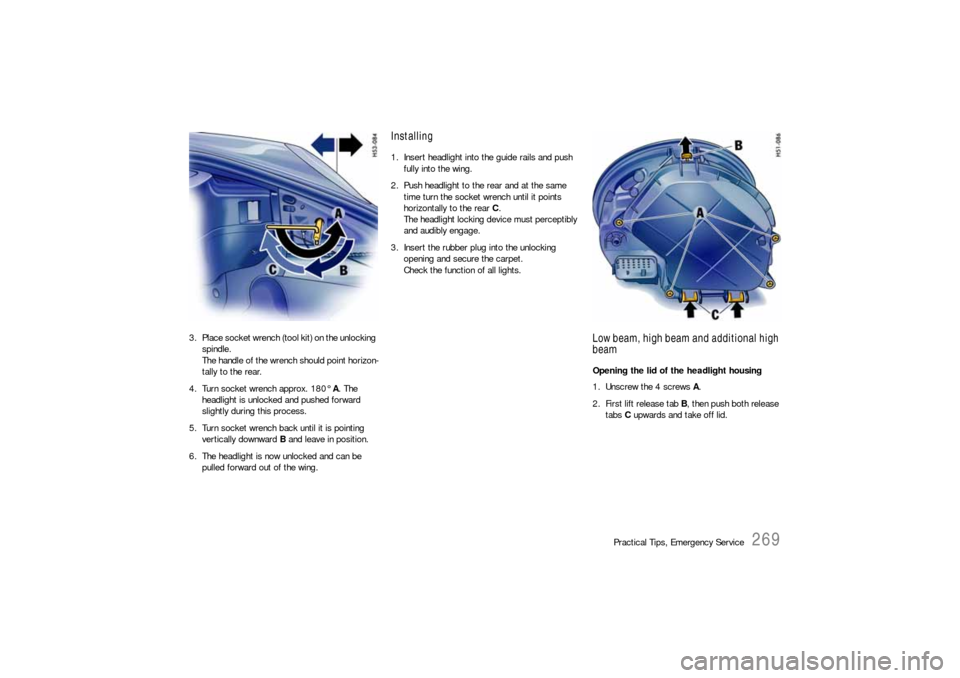

3. Place socket wrench (tool kit) on the unlocking

spindle.

The handle of the wrench should point horizon-

tally to the rear.

4. Turn socket wrench approx. 180° A. The

headlight is unlocked and pushed forward

slightly during this process.

5. Turn socket wrench back until it is pointing

vertically downward B and leave in position.

6. The headlight is now unlocked and can be

pulled forward out of the wing.

Installing1. Insert headlight into the guide rails and push

fully into the wing.

2. Push headlight to the rear and at the same

time turn the socket wrench until it points

horizontally to the rear C.

The headlight locking device must perceptibly

and audibly engage.

3. Insert the rubber plug into the unlocking

opening and secure the carpet.

Check the function of all lights.

Low beam, high beam and additional high

beamOpening the lid of the headlight housing

1. Unscrew the 4 screws A.

2. First lift release tab B, then push both release

tabs C upwards and take off lid.