ECU PORSCHE 911 GT3 2010 5.G Owner's Manual

[x] Cancel search | Manufacturer: PORSCHE, Model Year: 2010, Model line: 911 GT3, Model: PORSCHE 911 GT3 2010 5.GPages: 251, PDF Size: 14.33 MB

Page 203 of 251

202

Practical Tips, Emergency Service

Caution!

Using wheel cleaning agents:

Wheel cleaning agents can bleach the

anodised surface of the central bolt.

fOnly use wheel cleaning agents approved

by Porsche and use these sparingly and in accordance with instructions for use.

Emergency procedure for securing

central boltIf, in the event of a breakdown, no suitable torque

wrench is available for tightening the central bolt

to the high tightening torque, the emergency

procedure for securing the central bolt must be

performed.

fThe central bolt must always be fitted using

the original tool (stored in the luggage

compartment).

1.Tighten the central bolt with great force

using a long lever and loosen again

slightly (by approx. 1/4 turn).

Tighten the central bolt to precisely 74 ftlb.

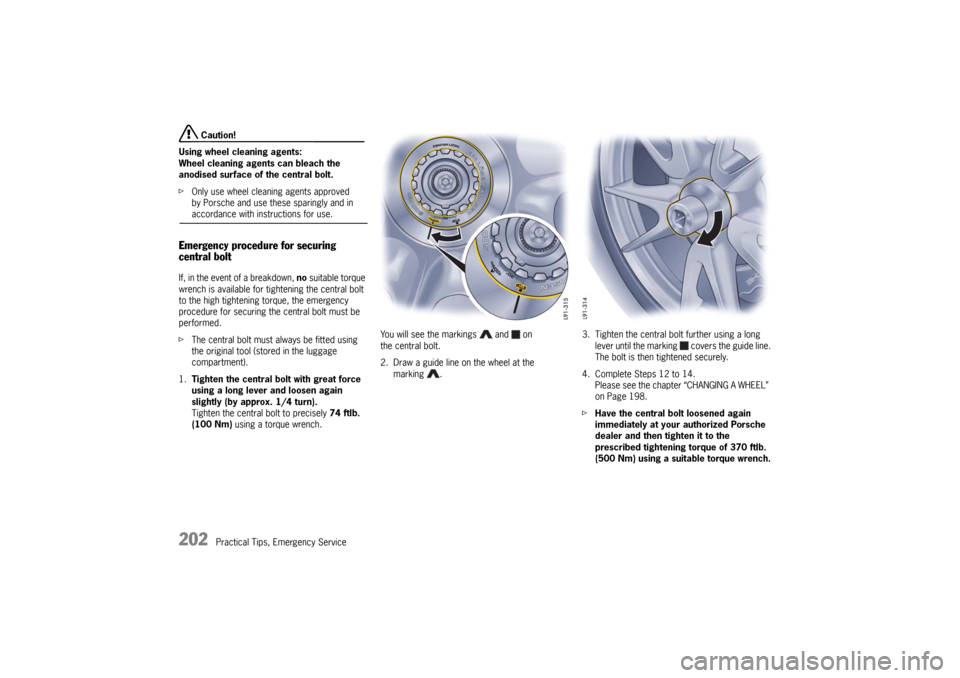

(100 Nm) using a torque wrench.You will see the markings and on

the central bolt.

2. Draw a guide line on the wheel at the

marking .3. Tighten the central bolt further using a long

lever until the marking covers the guide line.

The bolt is then tightened securely.

4. Complete Steps 12 to 14.

Please see the chapter “CHANGING A WHEEL”

on Page 198.

fHave the central bolt loosened again

immediately at your authorized Porsche

dealer and then tighten it to the

prescribed tightening torque of 370 ftlb.

(500 Nm) using a suitable torque wrench.10_GT3_21.book Seite 202 Donnerstag, 4. Juni 2009 12:48 12

Page 213 of 251

212

Practical Tips, Emergency Service

Battery care fEnsure that battery is securely mounted.

fKeep terminals and connections clean and

properly tightened.

Corrosion can be prevented by coating the

terminals and connections with petroleum jelly

or silicone spray.

fEnsure that vent caps are securely tightened to

prevent spillage.

Checking the electrolyte fluid level

Generally, the electrolyte level must be checked

more often in summer than in the winter, and more

often when driving long distances.

fWhen adding water, use only clean containers.

In no case may alcohol (e.g. window cleaner

residues) be permitted to enter the battery.

fUnscrew and open the filler vent caps of each

cell.

With the car on a level surface, the fluid level

should meet the indicator mark in each cell.

fIf necessary, top up with distilled water.

Do not use acid.

Only fill up to the mark, otherwise the electro-

lyte will overflow when the battery is being

charged and cause damage. Battery charging

Automotive batteries loose their efficiency when

not in use.

The charge available in your battery can be

measured with a battery hydrometer.

We recommend that the battery voltage be tested

by your authorized Porsche dealer who has the

appropriate equipment.

If the car is not driven for prolonged periods, the

battery must be charged at least every 6 weeks.

A discharged battery allows rapid formation of

sulfates, leading to premature deterioration of the

plates.

Warning!

Hydrogen gas generated by the battery

could cause an explosion, resulting in

serious personal injury or death.

fCharge battery in a well ventilated area.

fNever charge a frozen battery. It may explode

because of gas trapped in the ice. Allow a

frozen battery to thaw out first.

fIf you get electrolyte, which is an acid, in your

eyes or on your skin, immediately rinse with

cold water for several minutes and call a doctor. Slow battery charging

1. Pay attention to all warnings and follow instruc-

tions that come with your battery charger.

2. When charging, ensure adequate ventilation.

3. Remove battery.

Please see the chapter “REMOVING THE

BATTERY” on Page 214.

4. All vent caps should be open.

The fluid level should meet the indicator mark

in each cell.

5. Ensure that charger is switched off – danger of

short circuit!

6. Connect charger cables.

Charger cables must be connected

POSITIVE (+) to POSITIVE (+) and

NEGATIVE (–) to NEGATIVE (–).

7. Switch on charger.

Normally, a battery should be charged at no

more than 10 percent of its rated capacity.

Rated capacity of the battery in your vehicle is

listed on the battery housing.

8. After charging, turn off charger and disconnect

charger cables.

9. Tighten the vent caps and reinstall battery.

Please see the chapter “INSTALLING THE

BATTERY” on Page 215.

10_GT3_21.book Seite 212 Donnerstag, 4. Juni 2009 12:48 12

Page 222 of 251

Practical Tips, Emergency Service

221

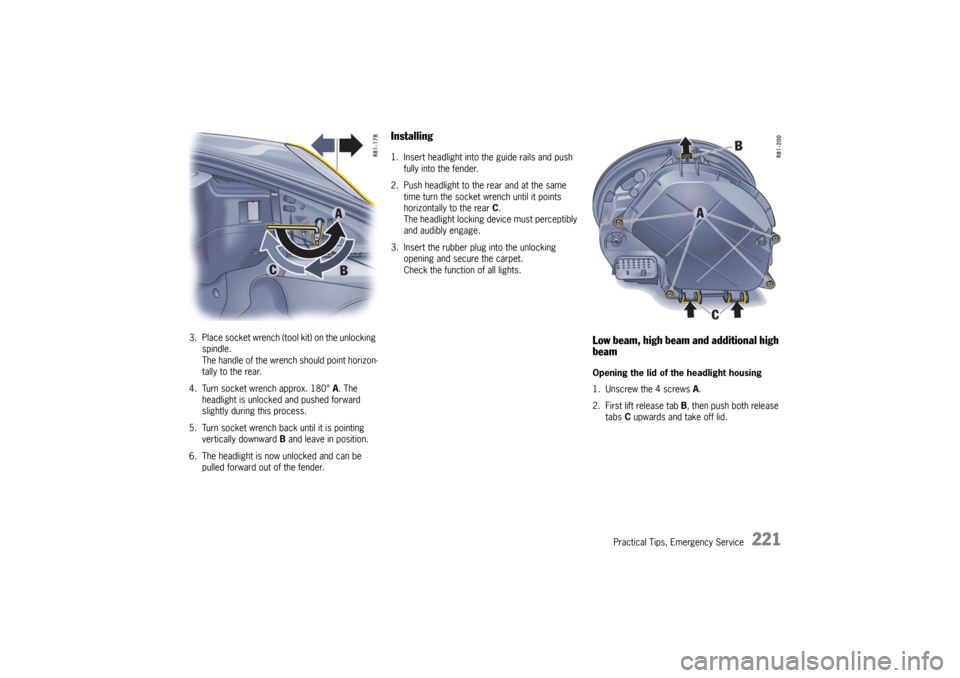

3. Place socket wrench (tool kit) on the unlocking

spindle.

The handle of the wrench should point horizon-

tally to the rear.

4. Turn socket wrench approx. 180° A. The

headlight is unlocked and pushed forward

slightly during this process.

5. Turn socket wrench back until it is pointing

vertically downward B and leave in position.

6. The headlight is now unlocked and can be

pulled forward out of the fender.

Installing1. Insert headlight into the guide rails and push

fully into the fender.

2. Push headlight to the rear and at the same

time turn the socket wrench until it points

horizontally to the rear C.

The headlight locking device must perceptibly

and audibly engage.

3. Insert the rubber plug into the unlocking

opening and secure the carpet.

Check the function of all lights.

Low beam, high beam and additional high

beamOpening the lid of the headlight housing

1. Unscrew the 4 screws A.

2. First lift release tab B, then push both release

tabs C upwards and take off lid.

10_GT3_21.book Seite 221 Donnerstag, 4. Juni 2009 12:48 12

Page 227 of 251

226

Practical Tips, Emergency Service

Changing bulb for side marker light1. Remove the cap in the wheel housing liner with

a screwdriver.

2. Insert the screwdriver into the opening in the

wheel housing liner parallel to the turn signal

housing (in direction of travel).

By pressing with the screwdriver, disengage

the securing spring of the turn signal housing.3. Swivel out the indicator light and undo bulb

holder (bayonet lock).

4. Remove the bulb from the holder and replace

it. Insert holder.

Check operation of the light.

5. Insert the turn signal’s retaining lugs A into the

side section at the front.

Push in turn signal until the securing spring B

is felt to engage.

6. Press the cap into the wheel housing liner.10_GT3_21.book Seite 226 Donnerstag, 4. Juni 2009 12:48 12

Page 231 of 251

230

Practical Tips, Emergency Service

Towing Certain state statutes and local ordinances

prohibit towing with a chain, rope or even a tow

bar.

In addition, damage to your vehicle may result

from improper procedures.

Consult your authorized Porsche dealer for

details. Vehicle towing Flat bed towing is the preferred type of towing to

be used on Porsche vehicles.

Under certain circumstances, wheel lifts may be

used when the vehicle will not roll.

The vehicle must be towed with all four

wheels off the ground, otherwise damage to

the vehicle may result.

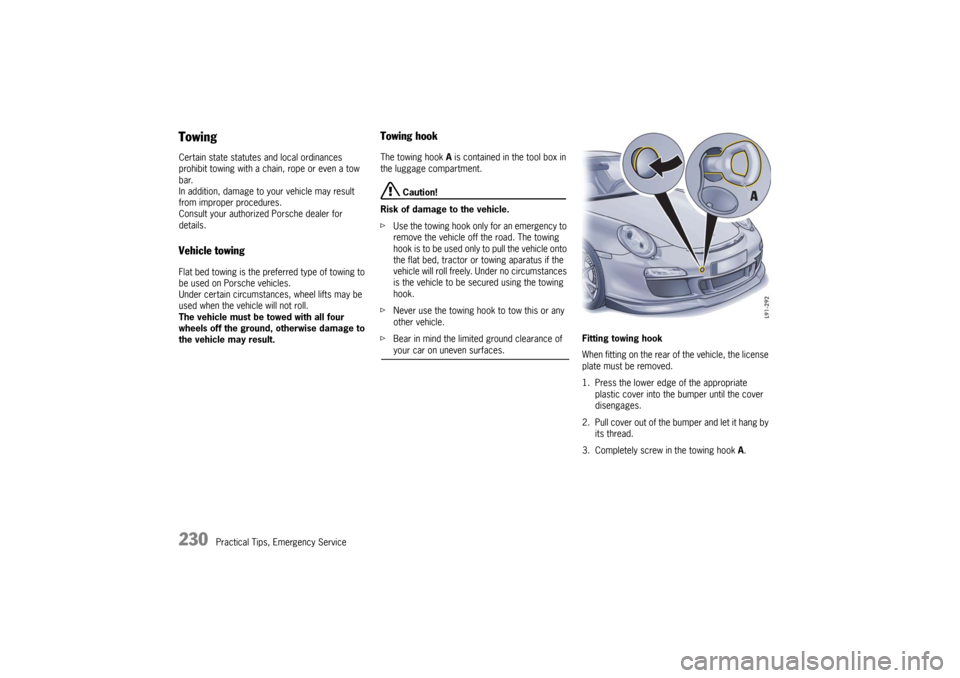

Towing hook The towing hook A is contained in the tool box in

the luggage compartment.

Caution!

Risk of damage to the vehicle.

fUse the towing hook only for an emergency to

remove the vehicle off the road. The towing

hook is to be used only to pull the vehicle onto

the flat bed, tractor or towing aparatus if the

vehicle will roll freely. Under no circumstances

is the vehicle to be secured using the towing

hook.

fNever use the towing hook to tow this or any

other vehicle.

fBear in mind the limited ground clearance of your car on uneven surfaces.Fitting towing hook

When fitting on the rear of the vehicle, the license

plate must be removed.

1. Press the lower edge of the appropriate

plastic cover into the bumper until the cover

disengages.

2. Pull cover out of the bumper and let it hang by

its thread.

3. Completely screw in the towing hook A.

10_GT3_21.book Seite 230 Donnerstag, 4. Juni 2009 12:48 12

Page 232 of 251

Practical Tips, Emergency Service

231

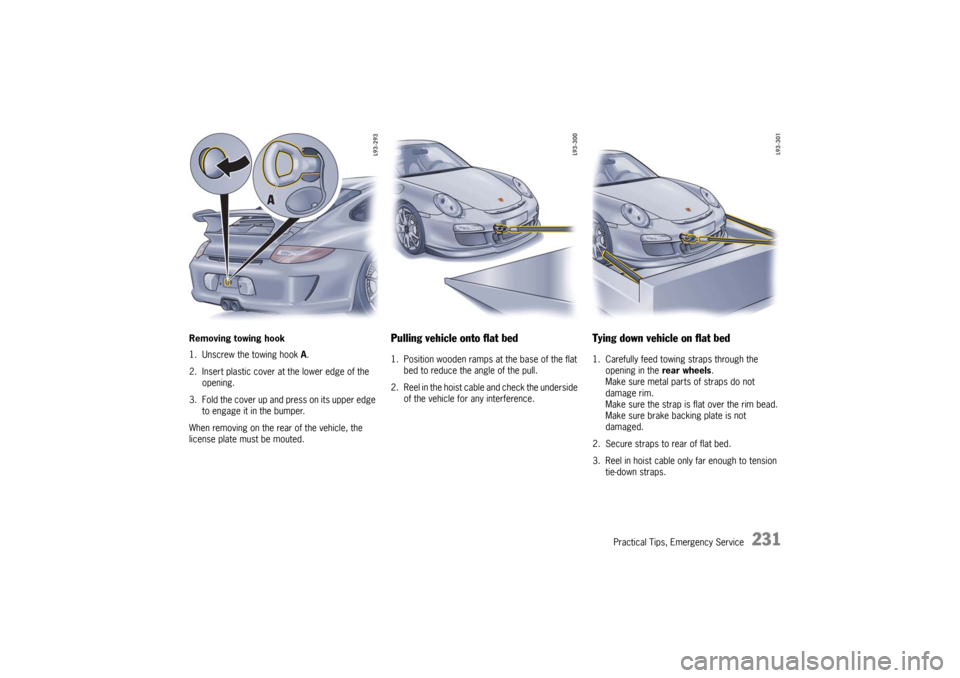

Removing towing hook

1. Unscrew the towing hook A.

2. Insert plastic cover at the lower edge of the

opening.

3. Fold the cover up and press on its upper edge

to engage it in the bumper.

When removing on the rear of the vehicle, the

license plate must be mouted.

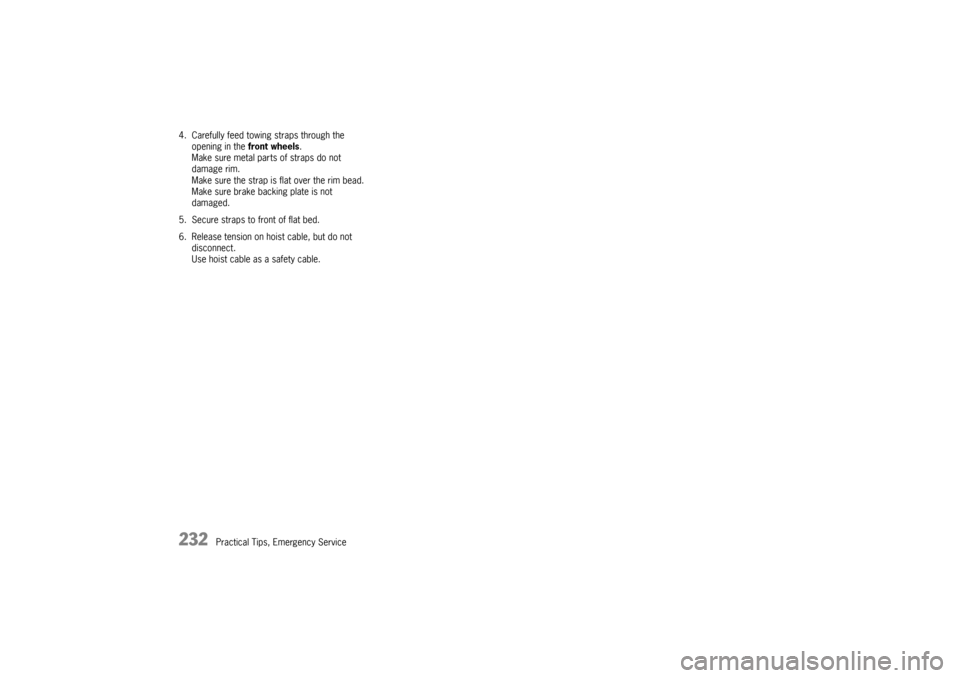

Pulling vehicle onto flat bed 1. Position wooden ramps at the base of the flat

bed to reduce the angle of the pull.

2. Reel in the hoist cable and check the underside

of the vehicle for any interference.

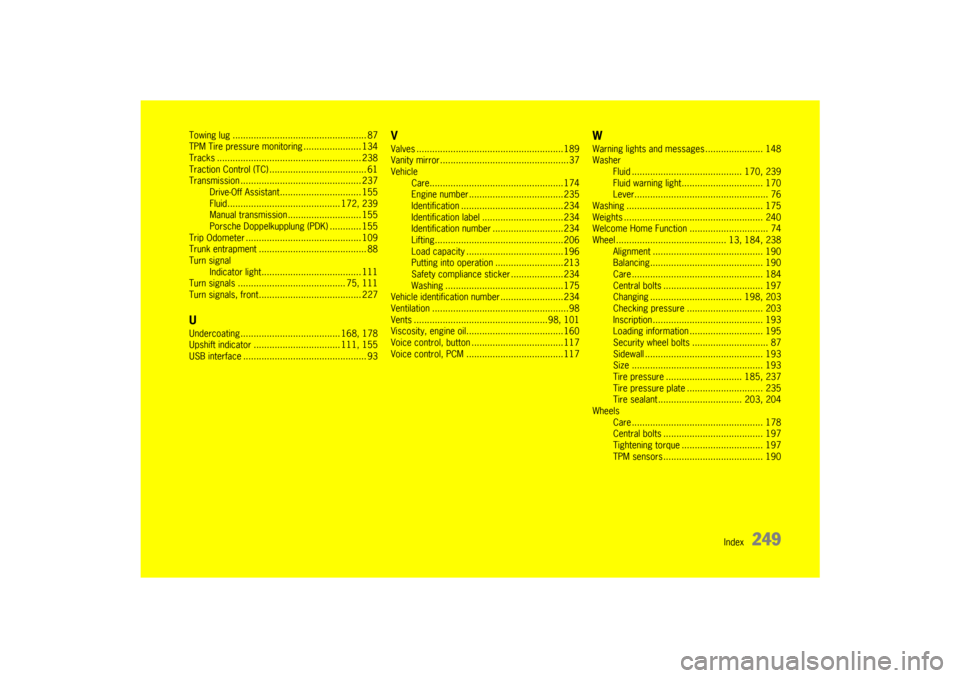

Tying down vehicle on flat bed 1. Carefully feed towing straps through the

opening in the rear wheels.

Make sure metal parts of straps do not

damage rim.

Make sure the strap is flat over the rim bead.

Make sure brake backing plate is not

damaged.

2. Secure straps to rear of flat bed.

3. Reel in hoist cable only far enough to tension

tie-down straps.

10_GT3_21.book Seite 231 Donnerstag, 4. Juni 2009 12:48 12

Page 233 of 251

232

Practical Tips, Emergency Service 4. Carefully feed towing straps through the

opening in the front wheels.

Make sure metal parts of straps do not

damage rim.

Make sure the strap is flat over the rim bead.

Make sure brake backing plate is not

damaged.

5. Secure straps to front of flat bed.

6. Release tension on hoist cable, but do not

disconnect.

Use hoist cable as a safety cable.

10_GT3_21.book Seite 232 Donnerstag, 4. Juni 2009 12:48 12

Page 250 of 251

Index

249

Towing lug ................................................... 87

TPM Tire pressure monitoring ...................... 134

Tracks ....................................................... 238

Traction Control (TC)..................................... 61

Transmission .............................................. 237

Drive-Off Assistant............................... 155

Fluid........................................... 172, 239

Manual transmission............................ 155

Porsche Doppelkupplung (PDK) ............ 155

Trip Odometer ............................................ 109

Trunk entrapment ......................................... 88

Turn signal

Indicator light...................................... 111

Turn signals ......................................... 75, 111

Turn signals, front....................................... 227UUndercoating...................................... 168, 178

Upshift indicator ................................. 111, 155

USB interface ............................................... 93

VValves ........................................................189

Vanity mirror.................................................37

Vehicle

Care...................................................174

Engine number....................................235

Identification .......................................234

Identification label ...............................234

Identification number ...........................234

Lifting.................................................206

Load capacity .....................................196

Putting into operation ..........................213

Safety compliance sticker ....................234

Washing .............................................175

Vehicle identification number ........................234

Ventilation ....................................................98

Vents ...................................................98, 101

Viscosity, engine oil.....................................160

Voice control, button ...................................117

Voice control, PCM .....................................117

WWarning lights and messages ...................... 148

Washer

Fluid .......................................... 170, 239

Fluid warning light............................... 170

Lever................................................... 76

Washing .................................................... 175

Weights ..................................................... 240

Welcome Home Function .............................. 74

Wheel .......................................... 13, 184, 238

Alignment .......................................... 190

Balancing........................................... 190

Care .................................................. 184

Central bolts ...................................... 197

Changing ................................... 198, 203

Checking pressure............................. 203

Inscription .......................................... 193

Loading information ............................ 195

Security wheel bolts ............................. 87

Sidewall ............................................. 193

Size .................................................. 193

Tire pressure ............................. 185, 237

Tire pressure plate ............................. 235

Tire sealant ................................ 203, 204

Wheels

Care .................................................. 178

Central bolts ...................................... 197

Tightening torque ............................... 197

TPM sensors...................................... 190

10_GT3_21.book Seite 249 Donnerstag, 4. Juni 2009 12:48 12