torque PORSCHE 911 TURBO 2004 4.G Information Manual

[x] Cancel search | Manufacturer: PORSCHE, Model Year: 2004, Model line: 911 TURBO, Model: PORSCHE 911 TURBO 2004 4.GPages: 61, PDF Size: 2.14 MB

Page 6 of 61

· 14 ·· 15 ·The new 911 Turbo |

The new 911 Turbo

The second 911 Turbo, launched

in 1977, developed 300 bhp from

a 3.3-litre intercooled engine.

Brake performance was similarly

enhanced, combining four-piston

aluminium fixed calipers with

cross-drilled discs.

In 1993, Porsche launched the

final 911Turbo to feature dedicated

rear-wheel drive. Based on the

Type 964 platform, it used a

3.6-litre engine to achieve a major

boost in output to 360 bhp.

Its Type 993 successor, launched

in 1995, set a range of new

benchmarks in supercar perform-

ance. All-wheel drive provided

greater active safety as well as

better driving dynamics. The

system also had a rear-axle bias

that retained the familiar Porsche

handling characteristics. Twin

exhaust turbochargers offered

better response and a more

harmonious build-up of power. The

last 911 Turbo to have an air-

cooled engine, it offered maximum

output of 408 bhp from a

3.6-litre displacement.

The first water-cooled 911 Turbo,

the Type 996, made its debut

in the year 2000. Also equipped

with all-wheel drive, it used

VarioCam Plus to achieve a major

improvement in all-round fuel

economy. The engine capacity

remained at 3.6 litres, while

output rose to 420 bhp fo r a

maximum speed of 305 km / h

(190 mph). The Type 996 model

was the first 911 Turbo with the

option of Tiptronic S transmission.

The subsequent launch of the

Turbo S version saw a further

rise in output to 450 bhp.

Now, the evolution of this

remarkable car has reached a

new pinnacle of achievement.

Over the following pages, we

will explore every aspect of the

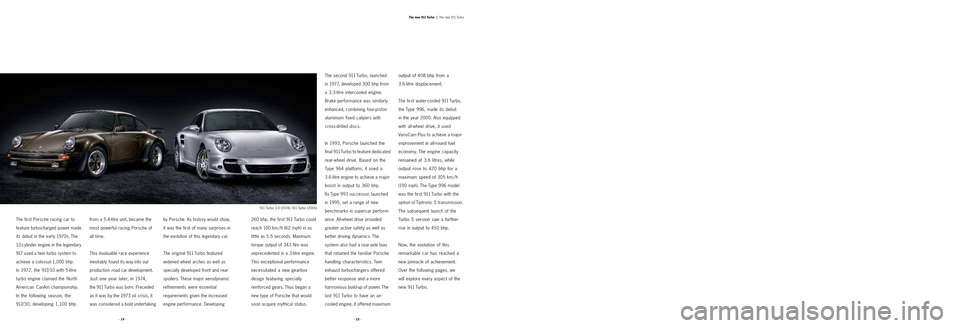

new 911 Turbo.The first Porsche racing car to

feature turbocharged power made

its debut in the early 1970s. The

12-cylinder engine in the legendary

917 used a twin turbo system to

achieve a colossal 1,000 bhp

.

In 1972, the 917/10 with 5-litre

turbo engine claimed the North

American CanAm

championship.

In the following season, the

917/30, developing 1,100 bhp

from a 5.4-litre unit, became the

most powerful racing Porsche of

all time.

This invaluable race experience

inevitably found its way into our

production

road car development.

Just one year later, in 1974,

the 911 Turbo was born. Preceded

as it was by the 1973 oil crisis, it

was considered a

bold undertakingby Porsche. As history would show,

it was the first of many surprises in

the evolution of this legendary car.

The original 911 Turbo featured

widened wheel arches as well as

specially developed front and rear

spoilers. These major aerodynamic

refinements were essential

requirements given the increased

engine performance. Developing260 bhp, the first 911 Turbo could

reach 100 km / h (62 mph) in as

little as 5.5 seconds. Maximum

torque output of 343 Nm was

unprecedented in a 3-litre engine.

This exceptional performance

necessitated a new gearbox

design featuring specially

reinforced gears. Thus began a

new type of Porsche that would

soon acquire mythical status.

911 Turbo 3.0 (1974), 911 Turbo (2006)

Page 7 of 61

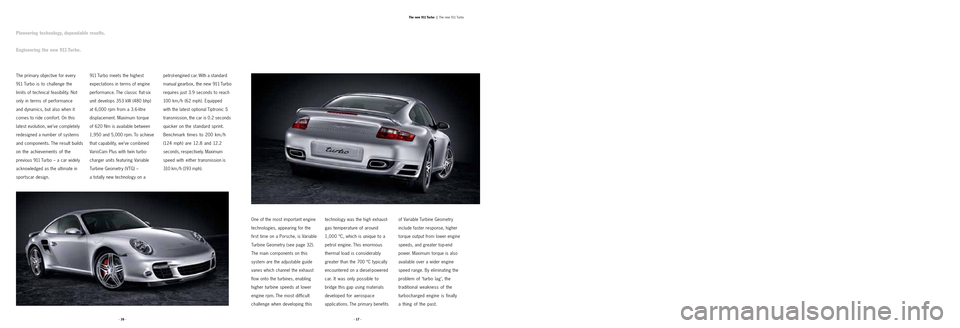

The primary objective for every

911 Turbo is to challenge the

limits of technical feasibility. Not

only in terms of performance

and dynamics, but also when it

comes to ride comfort. On this

latest evolution, we’ve completely

redesigned a number of systems

and components. The result builds

on the achievements of the

previous 911 Turbo – a car widely

acknowledged as the ultimate in

sportscar design.

As you would expect, the new 911 Turbo meets the highest

expectations in terms of engine

performance. The classic flat-six

unit develops 353 kW (480 bhp)

at 6,000 rpm from a 3.6-litre

displacement. Maximum torque

of 620 Nm is available between

1,950 and 5,000 rpm. To achieve

that capability, we’ve combined

VarioCam Plus with twin turbo-

charger units featuring Variable

Turbine Geometry (VTG) –

a totally new technology on apetrol-

engined car. With a standard

manual

gearbox, the new 911 Turbo

requires just 3.9 seconds to reach

100 km / h (62 mph). Equipped

with the latest optional Tiptronic S

transmission, the car is 0.2 seconds

quicker on the standard sprint.

Benchmark times to 200 km / h

(124 mph) are 12.8 and

12 . 2

seconds, respectively. Maximum

speed with either transmission is

310 km / h (193 mph).

One of the most important engine

technologies, appearing for the

first time on a Porsche, is Variable

Turbine Geometry (see page 32).

The main components on this

system are the adjustable guide

vanes which channel the exhaust

flow onto the turbines, enabling

higher turbine speeds at lower

engine rpm. The most difficult

challenge when developing this

technology was the high exhaust-

gas temperature of around

1,000 ºC, which is unique to a

petrol engine. This enormous

thermal load is considerably

greater than the 700 ºC typically

encountered on a diesel-powered

car. It was only possible to

bridge this gap using materials

developed for aerospace

applications. The primary benefitsof Variable Turbine Geometry

include faster response, higher

torque output from lower engine

speeds, and greater top-end

power. Maximum torque is also

available over a wider engine

speed range. By eliminating the

problem of ‘turbo lag’, the

traditional weakness of the

turbocharged engine is finally

a thing of the past.

· 16 ·· 17 ·The new 911 Turbo |

The new 911 Turbo

Pioneering technology, dependable results.

Engineering the new 911 Turbo.

Page 8 of 61

To apply these benefits efficiently

to the road, we required another

innovation in sportscar design: all-

wheel drive with Porsche Traction

Management (PTM). Using an

electronically controlled multi-plate

clutch, this intelligent technology

provides variable drive to each

axle. The front/rear split is con-

tin

uously adjusted based on current

road conditions and driver inputs.

Although biased towards the rear,

the front receives more power

whenever the situation requires.

Porsche Traction Management

is specifically designed to

optimise driving dynamics. The

additional traction provided by

both the all-wheel drive system

and PTM represents a major

improvement in active safety,

especially in the wet or on snow.

Another benchmark technology

on the new 911 Turbo is the

standard braking system. The

front and rear discs have a

generous diameter of 350 mm.On the optional Porsche Ceramic

Composite Brake (PCCB), the

front diameter is increased to

380 mm.

Other standard features on the

new 911 Turbo include a new

evolution of Porsche Stability

Management (PSM) as well as

Porsche Active Suspension

Management (PASM) featuring

electronic damper control.

A

limited-slip differential is available

for the rear axle as an option.

For even greater performance, the

car can be equipped with the

optional Sport Chrono Package

Turbo. Key features include

an ‘overboost’ function which

provides as much as 60 Nm

of additional torque under

acceleration. When the throttle

is fully open, the boost pressure

is increased temporarily by

approximately 0.2 bar. The

electronic throttle map is

also adjusted to give a more

dynamic response to pedal

inputs.

Other modifications when ‘Sport’

mode is selected include a major

rise in the trigger threshold used

by Porsche Stability Management

(PSM). The all-wheel drive system

featuring PTM provides a similar

increase in driver involvement

by sending a greater proportion

of drive torque directly to the

rear wheels. PASM provides a

stiffer suspension setup enabling

faster turn-in and better road

contact.

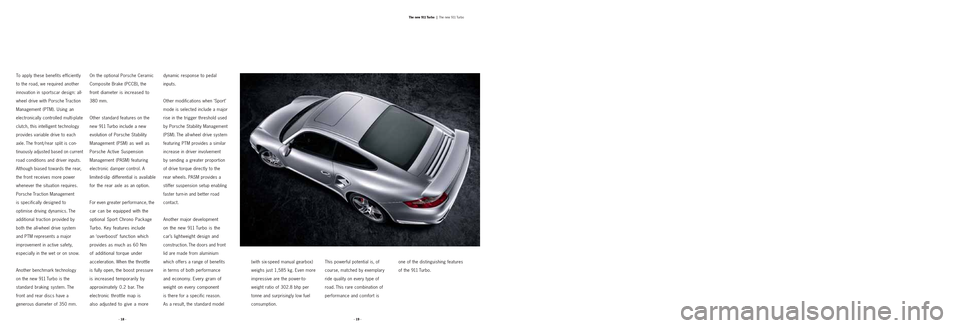

Another major development

on the new 911 Turbo is the

car’s lightweight design and

construction. The doors and front

lid are made from aluminium

which offers a range of benefits

in terms of both performance

and economy. Every gram of

weight on every component

is there for a specific reason.

As a result, the standard model (with six-speed manual gearbox)

weighs just 1,585 kg. Even more

impressive are the power-to-

weight ratio of 302.8 bhp per

tonne and surprisingly low fuel

consumption.This powerful potential is, of

course, matched by exemplary

ride quality on every type of

road. This rare combination of

performance and comfort is one of the distinguishing features

of the 911 Turbo.

· 18 ·· 19 ·The new 911 Turbo |

The new 911 Turbo

Page 11 of 61

Tiptronic S, the new 911 Turbo

requires just 3.7 seconds to

reach 100 km / h (62 mph), and

just 12.2 seconds for 200 km / h

(124 mph). Facilitating this

performance is the additionaltraction provided by the new

electronically controlled all-wheel

drive system (see page 48).

In appropriate track conditions,

the car’s maximum speed is

310 km / h (193 mph).

· 29 ·The new 911 Turbo |

Drive

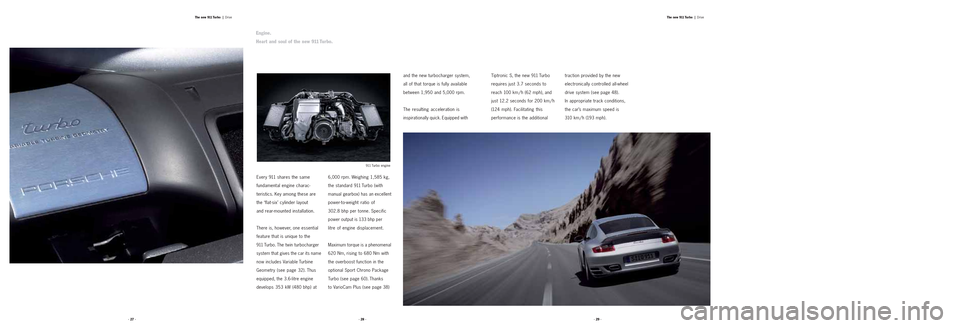

Every 911 shares the same

fundamental engine charac-

teristics. Key among these are

the ‘flat-six’ cylinder layout

and rear-mounted installation.

There is, however, one essential

feature that is unique to the

911 Turbo. The twin turbocharger

system that gives the car its name

now includes Variable Turbine

Geometry (see page 32). Thus

equipped, the 3.6-litre engine

develops 353 kW (480 bhp) at6,000 rpm. Weighing 1,585 kg,

the standard 911 Turbo (with

manual gearbox) has an excellent

power-to-weight ratio of

302.8 bhp per tonne. Specific

power output is 133 bhp per

litre of engine displacement.

Maximum torque is a phenomenal

620 Nm, rising to 680 Nm with

the overboost function in the

optional Sport Chrono Package

Turbo (see page 60). Thanks

to VarioCam Plus (see page 38)and the new turbocharger system,

all of that torque is fully available

between 1,950 and 5,000 rpm.

The resulting acceleration is

inspirationally quick. Equipped with

· 28 · · 27 ·The new 911 Turbo |

Drive

Engine.

Heart and soul of the new 911 Turbo.

911 Turbo engine

Page 12 of 61

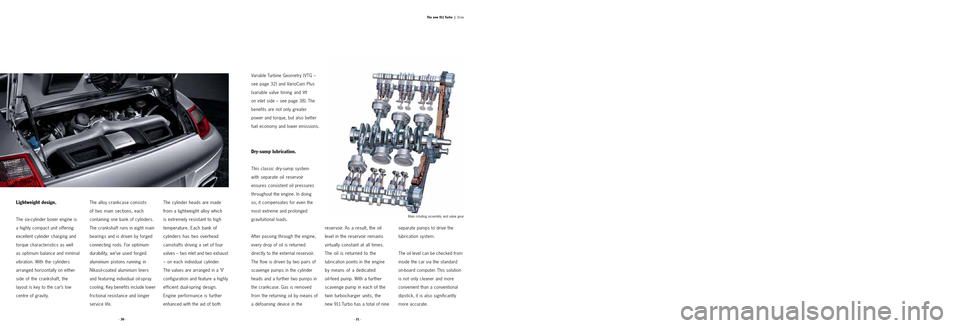

Lightweight design.

The six-cylinder boxer engine is

a highly compact unit offering

excellent cylinder charging and

torque characteristics as well

as optimum balance and minimal

vibration. With the cylinders

arranged horizontally on either

side of the crankshaft, the

layout is key to the car’s low

centre of gravity.

The alloy crankcase consists

of two main sections, each

containing one bank of cylinders.

The crankshaft runs in eight main

bearings and is driven by forged

connecting rods. For optimum

durability, we’ve used forged

aluminium pistons running in

Nikasil-coated aluminium liners

and featuring individual oil-spray

cooling. Key benefits include lower

frictional resistance and longer

service life.

The cylinder heads are made

from a lightweight alloy which

is extremely resistant to high

temperature. Each bank of

cylinders has two overhead

camshafts driving a set of four

valves – two inlet and two exhaust

– on each individual cylinder.

The valves are arranged in a ‘V’

configuration and feature a highly

efficient dual-spring design.

Engine performance is further

enhanced with the aid of bothVariable Turbine Geometry (VTG –

see page 32) and VarioCam Plus

(variable valve timing and lift

on inlet side – see page 38). The

benefits are not only greater

power and torque, but also better

fuel economy and lower emissions.

Dry-sump lubrication.

This classic dry-sump system

with separate oil reservoir

ensures consistent oil pressures

throughout the engine. In doing

so, it compensates for even the

most extreme and prolonged

gravitational loads.

After passing through the engine,

every drop of oil is returned

directly to the external reservoir.

The flow is driven by two pairs of

scavenge pumps in the cylinder

heads and a further two pumps in

the crankcase. Gas is removed

from the returning oil by means of

a defoaming device in the

reservoir. As a result, the oil

level in the reservoir remains

virtually constant at all times.

The oil is returned to the

lubrication points in the engine

by means of a dedicated

oil-feed pump. With a further

scavenge pump in each of the

twin turbocharger units, the

new 911 Turbo has a total of nineseparate pumps to drive the

lubrication system.

The oil level can be checked from

inside the car via the standard

on-board computer. This solution

is not only cleaner and more

convenient than a conventional

dipstick, it is also significantly

more accurate.

· 30 ·· 31 ·The new 911 Turbo |

Drive

Main rotating assembly and valve gear

Page 13 of 61

vanes are opened further. By

varying the vane angle, it is

possible to achieve the required

boost pressure over the entire

engine speed range. As a result,

there is no need for excess-

pressure valves as found on

conventional turbocharged

engines.

· 34 · · 32 ·· 33 ·The new 911 Turbo |

Drive

Variable Turbine Geometry (VTG).

Creating the optimum turbo for every scenario.

known as ‘turbo lag’, means there

is virtually no turbocharging effect

at lower engine speeds. To

overcome this problem, the twin

water-cooled turbochargers on

the new 911 Turbo feature Variable

Turbine Geometry (VTG). With

this technology, the gas-flow from

the engine is channelled onto Larger turbo units, which create

lower back-pressure at higher rpm,

take considerably longer to spin

up under power due to the large

cross-sectional area and relative

inertia of the heavier turbine.

Generally, this type of turbo will

only be effective in the medium

rpm range. This phenomenon,

Turbocharger guide vane adjuster Turbocharger with Variable Turbine Geometry (VTG)

up easily to its optimum speed.

The key disadvantage of using

a smaller turbo is that the back-

pressure generated at higher

engine speeds causes a significant

reduction in performance.

Resistance is caused by the smaller

cross-sectional area through which

the exhaust is required to flow.

The 911 Turbo has always been

synonymous with performance.

Now the car is more capable than

ever thanks to a new twin turbo

system featuring Variable Turbine

Geometry (VTG).

On a conventional turbocharger,

the exhaust flow drives a turbine

that is connected to a compressor

in the air intake tract. By ‘squeezing’

the incoming air, the amount

of oxygen in a given volume isincreased. Since compression also

causes an increase in temperature,

the air must be passed through

an ‘intercooler’ unit. With more

oxygen present in each cylinder

charge, more fuel can be burnt

yielding greater energy. Since

higher exhaust pressures generate

corresponding loads on the intake

side, the intake pressure must

be carefully controlled in order

to protect the engine. On the new

911 Turbo, the ‘boost pressure’ islimited using ‘wastegate’ valves

that bypass excess pressure

around the twin exhaust turbines.

Another important factor is the

size of the turbo unit. Since a

smaller turbine has a lower mass,

it generally responds more quickly

to increasing pressure, spinning

the turbines via electronically

adjustable guide vanes. By

changing the vane angle, the

system can replicate the

geometry in all types of turbo,

large or small.

With Variable Turbine Geometry

(VTG), it is possible to achieve

higher turbine speeds, and thus

higher boost pressure, at lower

engine rpm. Cylinder charging issignificantly improved, with a

corresponding increase in both

power and torque. Maximum

torque is reached at lower rpm

and is retained across a wider rev

range. A full 620 Nm is available

from as low as 1,950 rpm up to

5,000 rpm. Every throttle input is

met with exceptional response

and phenomenal acceleration.

When the boost pressure reaches

its maximum value, the guide

Page 14 of 61

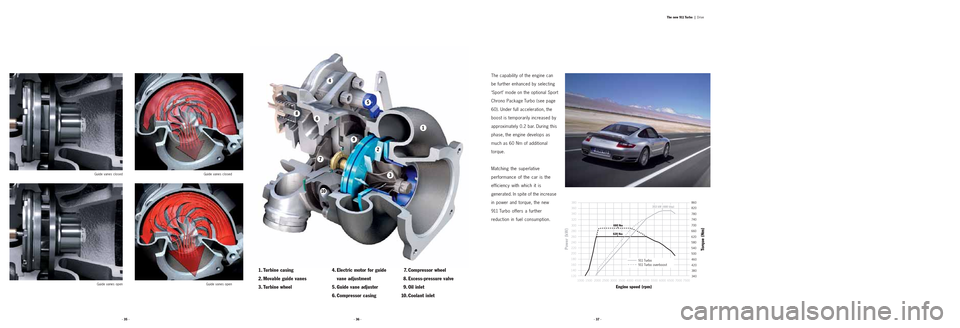

· 36 · · 35 ·· 37 ·The new 911 Turbo |

Drive

Guide vanes open Guide vanes closedGuide vanes open Guide vanes closed

The capability of the engine can

be further enhanced by selecting

‘Sport’ mode on the optional Sport

Chrono Package Turbo (see page

60). Under full acceleration, the

boost is temporarily increased by

approximately 0.2 bar. During this

phase, the engine develops as

much as 60 Nm of additional

torque.

Matching the superlative

performance of the car is the

efficiency with which it is

generated. In spite of the increase

in power and torque, the new

911 Turbo offers a further

reduction in fuel consumption.

1

2

3

4

5

6

7

8

9

10

1. Turbine casing

2. Movable guide vanes

3. Turbine wheel4. Electric motor for guide

vane adjustment

5. Guide vane adjuster

6. Compressor casing7. Compressor wheel

8. Excess-pressure valve

9. Oil inlet

10. Coolant inlet340 500 540

580

620 660 700

220 240

260

280

300

1500

7500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000

380 420

460

1000

Power (kW)

Engine speed (rpm)

620 Nm

120 140

160

180

200

Torque (Nm)

680 Nm

740 320

340 360380780 820860

353 kW (480 bhp)

911 Turbo

911 Turbo overboost

Page 15 of 61

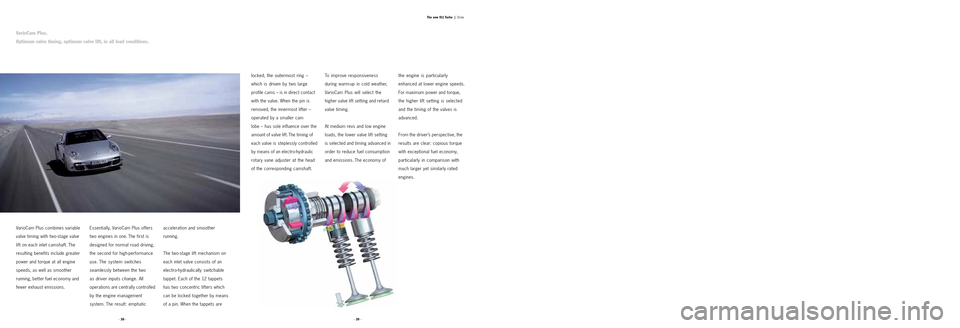

locked, the outermost ring –

which is driven by two large

profile cams – is in direct contact

with the valve. When the pin is

removed, the innermost lifter –

operated by a smaller cam

lobe – has sole influence over the

amount of valve lift. The timing of

each valve is steplessly controlled

by means of an electro-hydraulic

rotary vane adjuster at the head

of the corresponding camshaft.To improve responsiveness

during warm-up in cold weather,

VarioCam Plus will select the

higher valve lift setting and retard

valve timing.

At medium revs and low engine

loads, the lower valve lift setting

is selected and timing advanced in

order to reduce fuel consumption

and emissions. The economy of

the engine is particularly

enhanced at lower engine speeds.

For maximum power and torque,

the higher lift setting is selected

and the timing of the valves is

advanced.

From the driver’s perspective, the

results are clear: copious torque

with exceptional fuel economy,

particularly in comparison with

much larger yet similarly rated

engines.

· 39 ·The new 911 Turbo |

Drive

VarioCam Plus combines variable

valve timing with two-stage valve

lift on each inlet camshaft. The

resulting benefits include greater

power and torque at all engine

speeds, as well as smoother

running, better fuel economy and

fewer exhaust emissions.Essentially, VarioCam Plus offers

two engines in one. The first is

designed for normal road driving,

the second for high-performance

use. The system switches

seamlessly between the two

as driver inputs change. All

operations are centrally controlled

by the engine management

system. The result: emphaticacceleration and smoother

running.

The two-stage lift mechanism on

each inlet valve consists of an

electro-hydraulically switchable

tappet. Each of the 12 tappets

has two concentric lifters which

can be locked together by means

of a pin. When the tappets are

· 38 ·

VarioCam Plus.

Optimum valve timing, optimum valve lift, in all load conditions.

Page 18 of 61

are reduced thanks to lengthy

replacement intervals for both

the engine oil (18,000 miles) and

air filter unit (36,000 miles). The

spark plugs require changing after

36,000 miles or a maximum of

every four years. The generator,

power-steering pump and air-

conditioning compressor are all

driven by a single self-adjusting

belt with a service life of 54,000

miles. The hydraulic tappets

provide automatic adjustment of

all valve clearances, while the

drive chains on the camshafts

and auxiliary shafts will also last

the life of the car.

Basic servicing is required after

18,000 miles or a maximum of

two years on the road. The first

major service is due at 36,000

miles or every four years at the

latest. The results: lower running

costs and virtually uninterrupted

enjoyment from your Porsche.

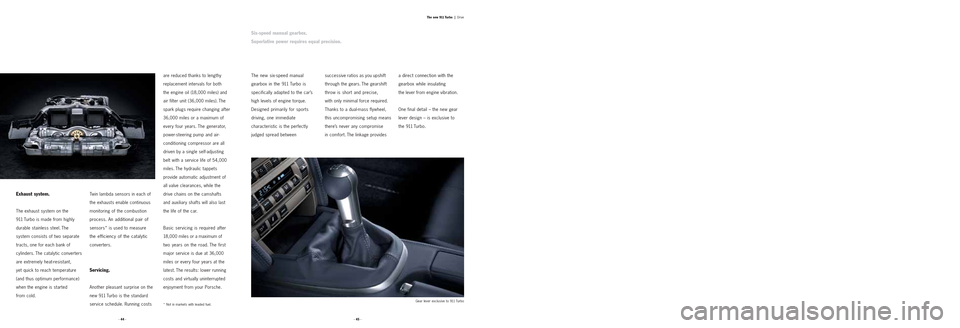

Exhaust system.

The exhaust system on the

911 Turbo is made from highly

durable stainless steel. The

system consists of two separate

tracts, one for each bank of

cylinders. The catalytic converters

are extremely heat-resistant,

yet quick to reach temperature

(and thus optimum performance)

when the engine is started

from cold.Twin lambda sensors in each of

the exhausts enable continuous

monitoring of the combustion

process. An additional pair of

sensors* is used to measure

the efficiency of the catalytic

converters.

Servicing.

Another pleasant surprise on the

new 911 Turbo is the standard

service schedule. Running costs

The new six-speed manual

gearbox in the 911 Turbo is

specifically adapted to the car’s

high levels of engine torque.

Designed primarily for sports

driving, one immediate

characteristic is the perfectly

judged spread betweensuccessive ratios as you upshift

through the gears. The gearshift

throw is short and precise,

with only minimal force required.

Thanks to a dual-mass flywheel,

this uncompromising setup means

there’s never any compromise

in comfort. The linkage provides

a direct connection with the

gearbox while insulating

the lever from engine vibration.

One final detail – the new gear

lever design – is exclusive to

the 911 Turbo.

· 44 ·· 45 ·The new 911 Turbo |

Drive

Six-speed manual gearbox.

Superlative power requires equal precision.

Gear lever exclusive to 911 Turbo* Not in markets with leaded fuel.

Page 20 of 61

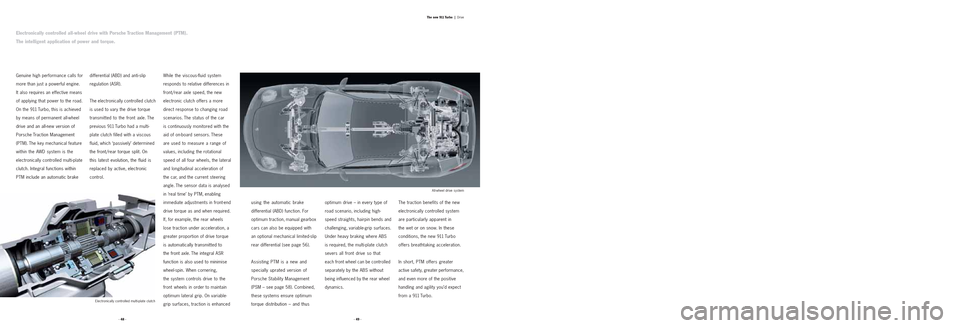

using the automatic brake

differential (ABD) function. For

optimum traction, manual gearbox

cars can also be equipped with

an optional mechanical limited-slip

rear differential (see page 56).

Assisting PTM is a new and

specially uprated version of

Porsche Stability Management

(PSM – see page 58). Combined,

these systems ensure optimum

torque distribution – and thus

optimum drive – in every type of

road scenario, including high-

speed straights, hairpin bends and

challenging, variable-grip surfaces.

Under heavy braking where ABS

is required, the multi-plate clutch

severs all front drive so that

each front wheel can be controlled

separately

by the ABS without

being influenced by the rear wheel

dynamics.

The traction benefits of the new

electronically controlled system

are particularly apparent in

the wet or on snow. In these

conditions, the new 911 Turbo

offers breathtaking acceleration.

In short, PTM offers greater

active safety, greater performance,

and even more of the positive

handling and agility you’d expect

from a 911 Turbo.

· 49 ·The new 911 Turbo |

Drive

differential (ABD) and anti-slip

regulation (ASR).

The electronically controlled clutch

is used to vary the drive torque

transmitted to the front axle. The

previous 911 Turbo had a multi-

plate clutch filled with a viscous

fluid, which ‘passively’ determined

the front/rear torque split. On

this latest evolution, the fluid is

replaced by active, electronic

control.While the viscous-fluid system

responds to relative differences in

front/rear axle speed, the new

electronic clutch offers a more

direct response to changing road

scenarios. The status of the car

is continuously monitored with the

aid of on-board sensors. These

are used to measure a range of

values, including the rotational

speed of all four wheels, the lateral

and longitudinal acceleration of

the car, and the current steering

angle. The sensor data is analysed

in ‘real time’ by PTM, enabling

immediate adjustments in front-end

drive torque as and when required.

If, for example, the rear wheels

lose traction under acceleration, a

greater proportion of drive torque

is automatically transmitted to

the front axle. The integral ASR

function is also used to minimise

wheel-spin. When

cornering,

the system controls drive to the

front wheels in order to maintain

optimum lateral grip. On variable-

grip surfaces, traction is enhanced

· 48 · Electronically controlled multi-plate clutchAll-wheel drive system

Genuine high performance calls for

more than just a powerful engine.

It also requires an effective means

of applying that power to the road.

On the 911 Turbo, this is achieved

by means of permanent all-wheel

drive and an all-new version of

Porsche Traction Management

(PTM). The key mechanical feature

within the AWD system is the

electronically controlled multi-plate

clutch. Integral functions within

PTM include an automatic brake

Electronically controlled all-wheel drive with Porsche Traction Management (PTM).

The intelligent application of power and torque.