ECU PORSCHE 944 1987 1.G User Guide

[x] Cancel search | Manufacturer: PORSCHE, Model Year: 1987, Model line: 944, Model: PORSCHE 944 1987 1.GPages: 66, PDF Size: 3.3 MB

Page 38 of 66

Power Assisted Steering

The hydraulic assistance system allows

effortless steering under all driving conditions.

Slight hissing or squeaking sounds during

sharp turns (turning steering wheel from lock

to lock) are normal and do not indicate a

defective steering mechanism.

If the engine is not running, po

wer assisted steering is no longer effective. You can

continue to steer the car but more effort

will be required to turn the steering wheel.

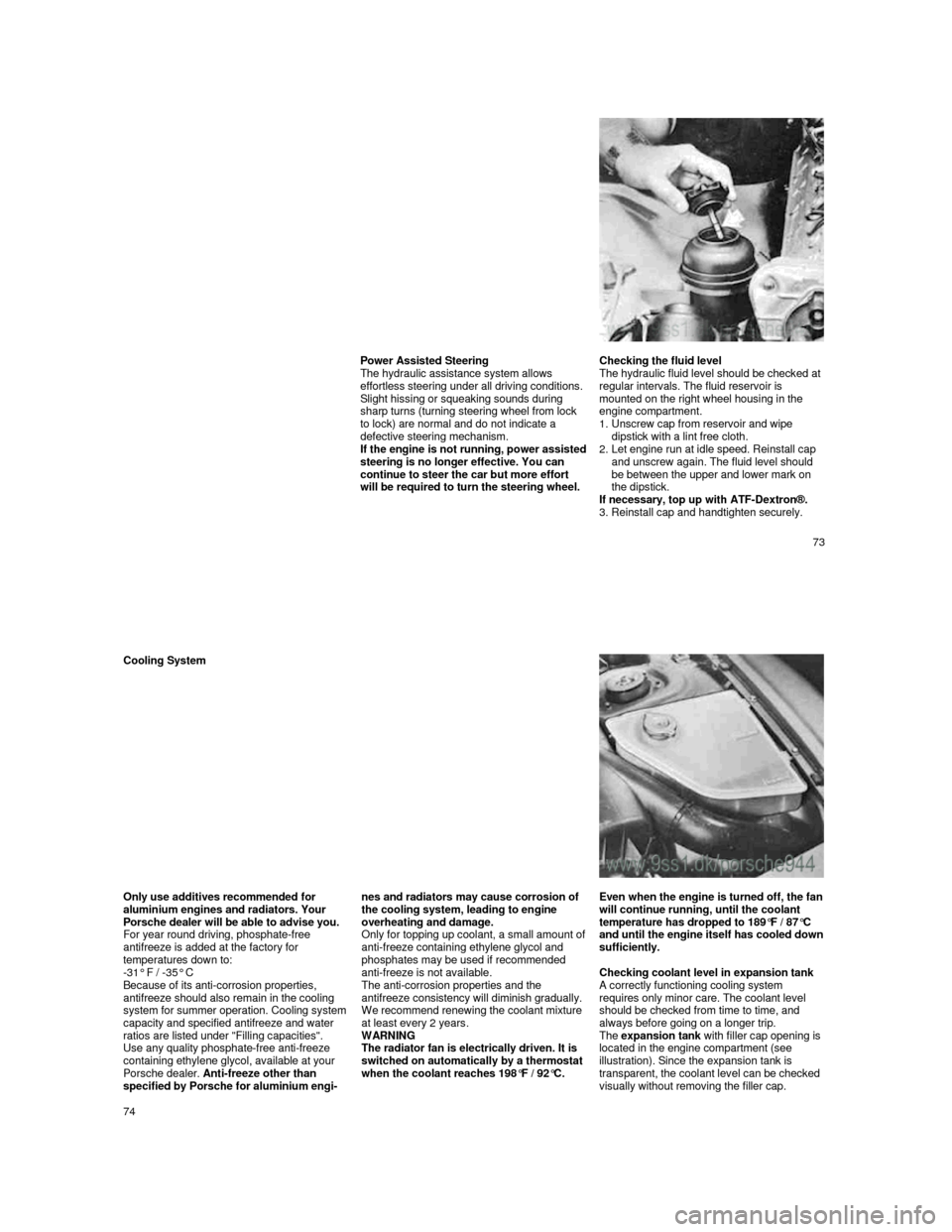

Checking the fluid level

The hydraulic fluid level should be checked at

regular intervals. The fluid reservoir is

mounted on the right wheel housing in the

engine compartment.

1.

Unscrew cap from reservoir and wipe

dipstick with a lint free cloth.

2.

Let engine run at idle speed. Reinstall cap

and unscrew again. The fluid level should

be between the upper and lower mark on

the dipstick.

If necessary, top up with ATF-Dextron®.

3. Reinstall cap and handtighten securely.

73

Cooling System

Only use additives recommended for

aluminium engines and radiators. Your

Porsche dealer will be able to advise you.

For year round driving, phosphate-free

antifreeze is added at the factory for

temperatures down to:

-31° F / -35° C

Because of its anti-corrosion properties,

antifreeze should also remain in the cooling

system for summer operation. Cooling system capacity and specified antifreeze and water

ratios are listed under "Filling capacities".

Use any quality phosphate-free anti-freeze

containing ethylene glycol, available at your

Porsche dealer. Anti-freeze other than

specified by Porsche for aluminium engi-

nes and radiators may cause corrosion of

the cooling system, leading to engine

overheating and damage.

Only

for topping up coolant, a small amount of anti-freeze containing ethylene glycol and

phosphates may be used if recommended

anti-freeze is not available.

The anti-corrosion properties and the

antifreeze consistency will diminish gradually.

We recommend renewing the coolant mixture

at least every 2 years.

WARNING

The radiator fan is electrically driven. It is

switched on automatically by a thermostat

when the coolant reaches 198°F / 92°C.

Even when the engine is turned off, the fan will continue running, until the coolant

temperature has dropped to 189°F / 87°C

and until the engine itself has cooled down sufficiently.

Checking coolant level in expansion tank

A correctly functioning cooling system requires only minor care. The coolant level

should be checked from time to time, and

always before going on a longer trip.

The

expansion tank with filler cap opening is

located in the engine compartment (see

illustration). Since the expansion tank is

transparent, the coolant level can be checked

visually without removing the filler cap.

74

Page 45 of 66

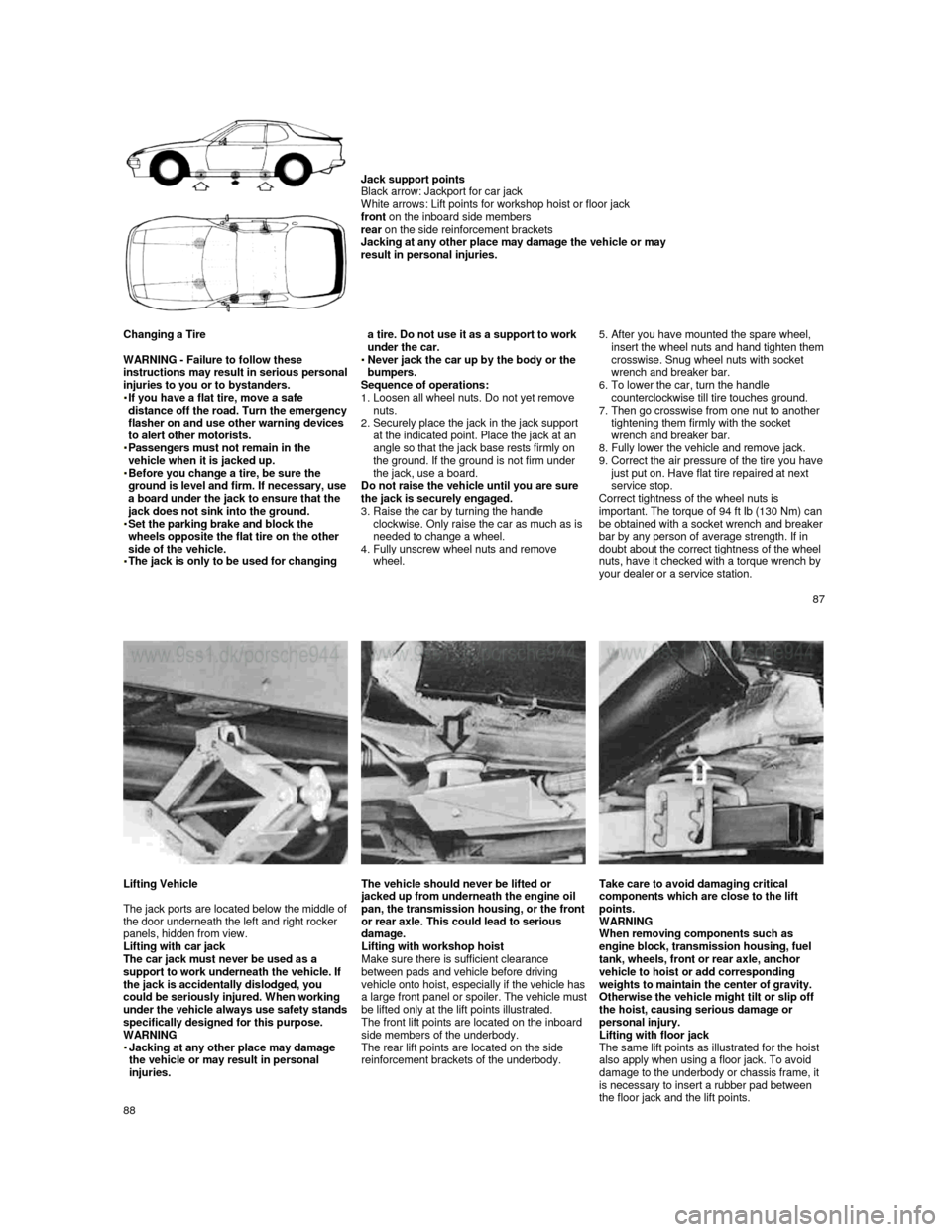

Jack support points

Black arrow: Jackport for car jack

White arrows: Lift points for workshop hoist or flo or jack

front on the inboard side members

rear on the side reinforcement brackets

Jacking at any other place may damage the vehicle o r may

result in personal injuries.

Changing a Tire

WARNING - Failure to follow these

instructions may result in serious personal injuries to you or to bystanders.

If you have a flat tire, move a safe distance off the road. Turn the emergency flasher on and use other warning devices

to alert other motorists.

Passengers must not remain in the vehicle when it is jacked up. Before you change a tire, be sure the ground is level and firm. If necessary, use a board under the jack to ensure that the jack does not sink into the ground. Set the parking brake and block the wheels opposite the flat tire on the other

side of the vehicle.

The jack is only to be used for changing

a tire. Do not use it as a support to work

under the car.

Never jack the car up by the body or the bumpers.

Sequence of operations:

1.

Loosen all wheel nuts. Do not yet remove

nuts.

2.

Securely place the jack in the jack support

at the indicated point. Place the jack at an

angle so that the jack base rests firmly on

the ground. If the ground is not firm under

the jack, use a board.

Do not raise the vehicle until you are sure

the jack is securely engaged.

3.

Raise the car by turning the handle

clockwise. Only raise the car as much as is

needed to change a wheel.

4.

Fully unscrew wheel nuts and remove wheel.

5. After you have mounted the spare wheel, insert the wheel nuts and hand tighten them crosswise. Snug wheel nuts with socket wrench and breaker bar.

6. To lower the car, turn the handle

counterclockwise till tire touches ground.

7.

Then go crosswise from one nut to another

tightening them firmly with the socket

wrench and breaker bar.

8. Fully lower the vehicle and remove jack.

9. Correct the air pressure of the tire you have just put on. Have flat tire repaired at next service stop.

Correct tightness of the wheel nuts is

important. The torque of 94 ft Ib (130 Nm) can

be obtained with a socket wrenc

h and breaker bar by any person of average strength. If in

doubt about the correct tightness of the wheel

nuts, have it checked with a torque wrench by

your dealer or a service station.

87

Lifting Vehicle

The jack ports are located below the middle of the door underneath the left and right rocker

panels, hidden from view.

Lifting with car jack

The car jack must never be used as a

support to work underneath the vehicle. If

the jack is accidentally dislodged, you

could be seriously injured. When working

under the vehicle always use safety stands specifically designed for this purpose.

WARNING

Jacking at any other place may damage the vehicle or may result in personal injuries.

The vehicle should never be lifted or jacked up from underneath the engine oil pan, the transmission housing, or the front or rear axle. This could lead to serious

damage.

Lifting with workshop hoist

Make sure there is sufficient clearance

between pads and vehicle before driving

vehicle onto hoist, especially if the vehicle

has a large front panel or spoiler. The vehicle must be lifted only at the lift points illustrated.

The front lift points are located on the inboard

side members of the underbody.

The rear lift points are located on the side

reinforcement brackets of the underbody.

Take care to avoid damaging critical

components which are close to the lift

points.

WARNING

When removing components such as

engine block, transmission housing, fuel

tank, wheels, front or rear axle, anchor

vehicle to hoist or add corresponding

weights to maintain the center of gravity.

Otherwise the vehicle might tilt or slip off

the hoist, causing serious damage or

personal injury.

Lifting with floor jack

The same lift points as illustrated for the hoist

also apply when using a floor jack. To avoid

damage to the underbody or chassis frame, it

is necessary to insert a rubber pad between

the floor jack and the lift points.

88

Page 46 of 66

If it fails to light up, the fuse is defective and

must be replaced. Replace black plastic

cover.

The central electrical system contains plug in

relays for various electrical switching

functions.

Defective relays should be tested and

replaced by an authorized Porsche dealer.

To prevent damage to the electrical system

we recommend having all work - including the

installation of electrical accessories -carried

out by your authorized Porsche dealer. . ,

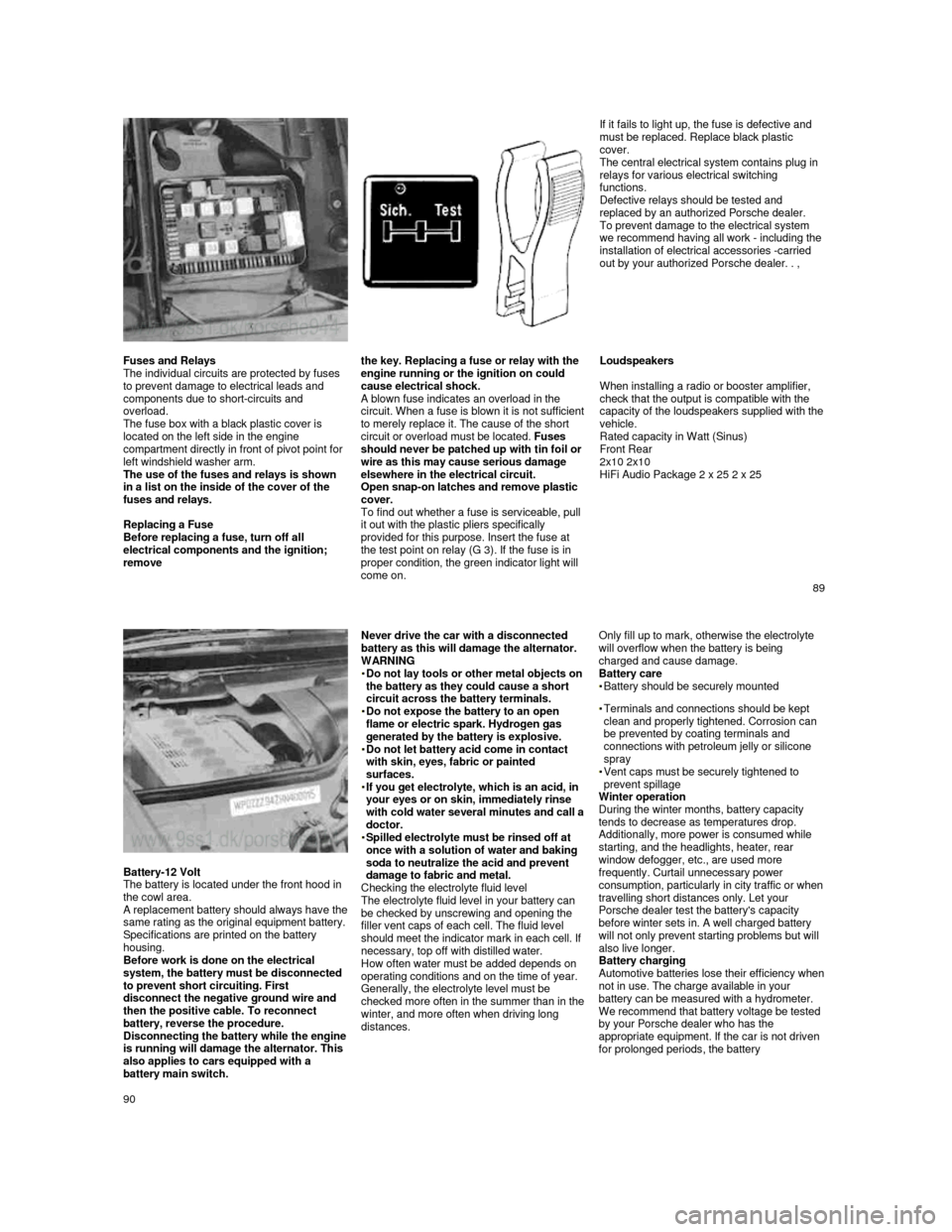

Fuses and Relays

The individual circuits are protected by fuses

to prevent damage to electrical leads and

components due to short-circuits and

overload.

The fuse box with a black plastic cover is

located on the left side in the engine

compartment directly in front of pivot point for

left windshield washer arm.

The use of the fuses and relays is shown

in a list on the inside of the cover of the

fuses and relays.

Replacing a Fuse

Before replacing a fuse, turn off all

electrical components and the ignition;

remove the key. Replacing a fuse or relay with the

engine running or the ignition on could

cause electrical shock.

A blown fuse indicates an overload in the circuit. When a fuse is blown it is not sufficient

to merely replace it. The cause of the short

circuit or overload must be located. Fuses

should never be patched up with tin foil or

wire as this may cause serious damage

elsewhere in the electrical circuit.

Open snap-on latches and remove plastic

cover.

To find out whether a fuse is serviceable, pull

it out with the plastic pliers specifically

provided for this purpose. Insert the fuse at

the test point on relay (G 3). If the fuse is in

proper condition, the green indicator light will

come on.

Loudspeakers

When installing a radio or booster amplifier,

check that the output is compatible with the

capacity of the loudspeakers supplied with the vehicle.

Rated capacity in Watt (Sinus)

Front Rear

2x10 2x10

HiFi Audio Package 2 x 25 2 x 25

89

Battery-12 Volt

The battery is located under the front hood in

the cowl area.

A replacement battery should always have the same rating as the original equipment battery.

Specifications are printed on the battery

housing.

Before work is done on the electrical

system, the battery must be disconnected

to prevent short circuiting. First

disconnect the negative ground wire and

then the positive cable. To reconnect

battery, reverse the procedure.

Disconnecting the battery while the engine is running will damage the alternator. This

also applies to cars equipped with a

battery main switch.

Never drive the car with a disconnected battery as this will damage the alternator. WARNING

Do not lay tools or other metal objects on the battery as they could cause a short

circuit across the battery terminals.

Do not expose the battery to an open flame or electric spark. Hydrogen gas

generated by the battery is explosive.

Do not let battery acid come in contact with skin, eyes, fabric or painted

surfaces.

If you get electrolyte, which is an acid, in your eyes or on skin, immediately rinse

with cold water several minutes and call a doctor. Spilled electrolyte must be rinsed off at once with a solution of water and baking

soda to neutralize the acid and prevent

damage to fabric and metal.

Checking the electrolyte fluid level

The electrolyte fluid level in your battery can

be checked by unscrewing and opening the

filler vent caps of each cell. The fluid level

should meet the indicator mark in each cell. If

necessary, top off with distilled water.

How often water must be added depends on

operating conditions and on the time of year.

Generally, the electrolyte level must be

checked more often in the summer than in the winter, and more often when driving long distances.

Only fill up to mark, otherwise the electrolyte will overflow when the battery is being charged and cause damage.

Battery care

Battery should be securely mounted

Terminals and connections should be kept

clean and properly tightened. Corrosion can

be prevented by coating terminals and

connections with petroleum jelly or silicone

spray

Vent caps must be securely tightened to

prevent spillage

Winter operation

During the winter months, battery capacity

tends to decrease as temperatures drop.

Additionally, more power is consumed while starting, and the headlights, heater, rear window defogger, etc., are used more

frequently. Curtail unnecessary power

consumption, particularly in city traffic or when travelling short distances only. Let your

Porsche dealer test the battery's capacity

before winter sets in. A well charged battery

will not only prevent starting problems but will

also live longer.

Battery charging

Automotive batteries lose their efficiency when not in use. The charge available in your

battery can be measured with a hydrometer.

We recommend that battery voltage be tested

by your Porsche dealer who has the

appropriate equipment. If the car is not driven

for prolonged periods, the battery

90

Page 49 of 66

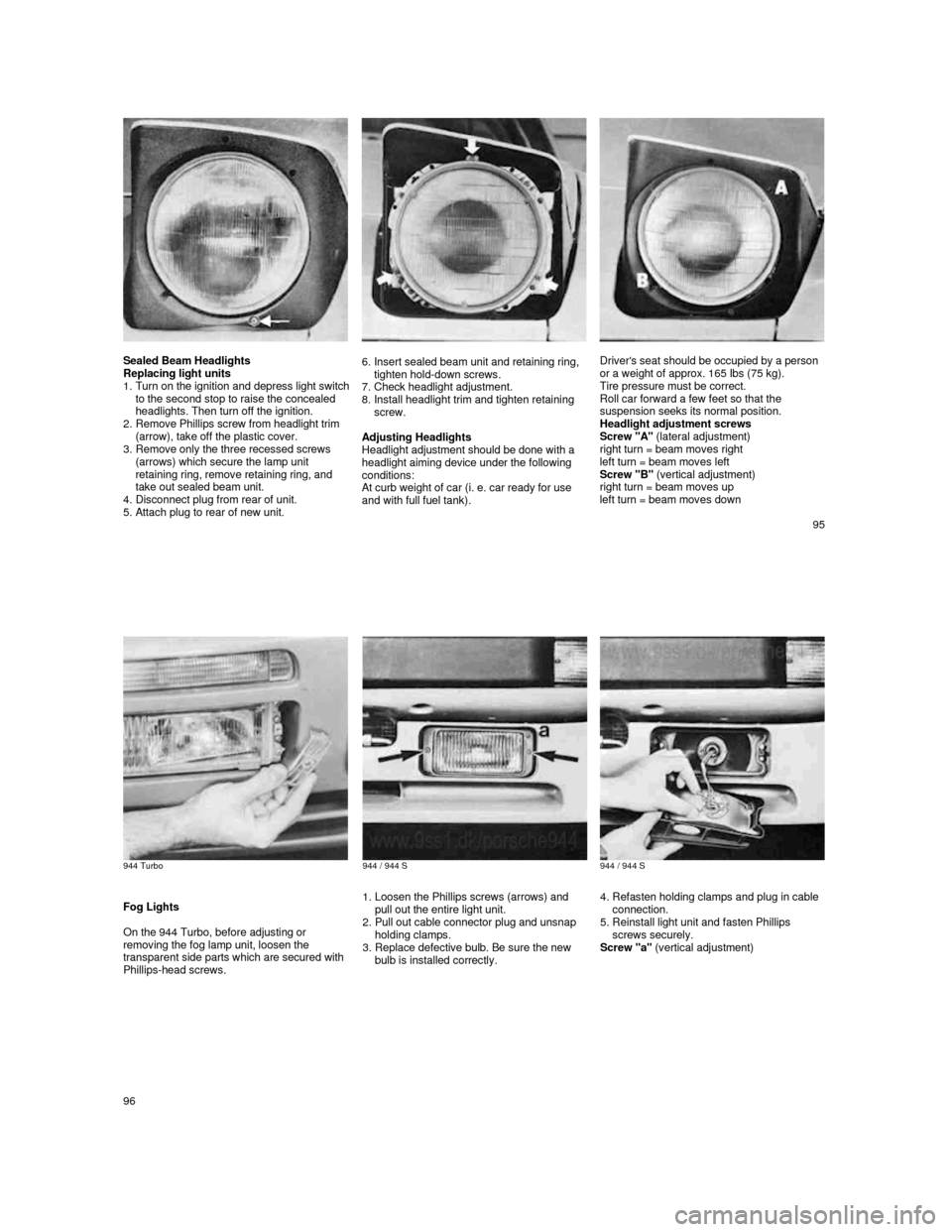

Sealed Beam Headlights

Replacing light units

1.

Turn on the ignition and depress light switch to the second stop to raise the concealed

headlights. Then turn off the ignition.

2.

Remove Phillips screw from headlight trim

(arrow), take off the plastic cover.

3.

Remove only the three recessed screws

(arrows) which secure the lamp unit

retaining ring, remove retaining ring, and

take out sealed beam unit.

4.

Disconnect plug from rear of unit.

5. Attach plug to rear of new unit.

6. Insert sealed beam unit and retaining ring,

tighten hold-down screws.

7.

Check headlight adjustment.

8. Install headlight trim and tighten retaining

screw.

Adjusting Headlights

Headlight adjustment should be done with a

headlight aiming device under the following

conditions:

At curb weight of car (i. e. car ready for use

and with full fuel tank).

Driver's seat should be occupied by a person

or a weight of approx. 165 Ibs (75 kg).

Tire pressure must be correct.

Roll car forward a few feet so that the

suspension seeks its normal position.

Headlight adjustment screws

Screw "A" (lateral adjustment)

right turn = beam moves right

left turn = beam moves left

Screw "B" (vertical adjustment)

right turn = beam moves up

left turn = beam moves down

95

944 Turbo

944 / 944 S

944 / 944 S

Fog Lights

On the 944 Turbo, before adjusting or

removing the fog lamp unit, loosen the

transparent side parts which are secured with

Phillips-head screws.

1. Loosen the Phillips screws (arrows) and

pull out the entire light unit.

2.

Pull out cable connector plug and unsnap

holding clamps.

3.

Replace defective bulb. Be sure the new

bulb is installed correctly.

4. Refasten holding clamps and plug in cable

connection.

5.

Reinstall light unit and fasten Phillips

screws securely.

Screw "a" (vertical adjustment)

96