transmission PORSCHE 944 1987 1.G User Guide

[x] Cancel search | Manufacturer: PORSCHE, Model Year: 1987, Model line: 944, Model: PORSCHE 944 1987 1.GPages: 66, PDF Size: 3.3 MB

Page 40 of 66

944 S

944 Turbo

9. When air bubbles at vent plug disappear, tighten the plug (required torque is 15-18

Nm or 11-13 ft lb).

10.

Check coolant level in tank and top up to

"max" mark, if necessary.

11.

Reinstall the expansion tank filler cap. After a test drive recheck the coolant level. See "filling capacities" for amount

required.

Manual Transmission oil

Both transmission and final drive are

combined in one housing. The lubricant used

is hypoid oil.

The manual transmission oil should be

checked and changed by your Porsche dealer

and at the intervals specified in your

Maintenance Schedule.

77

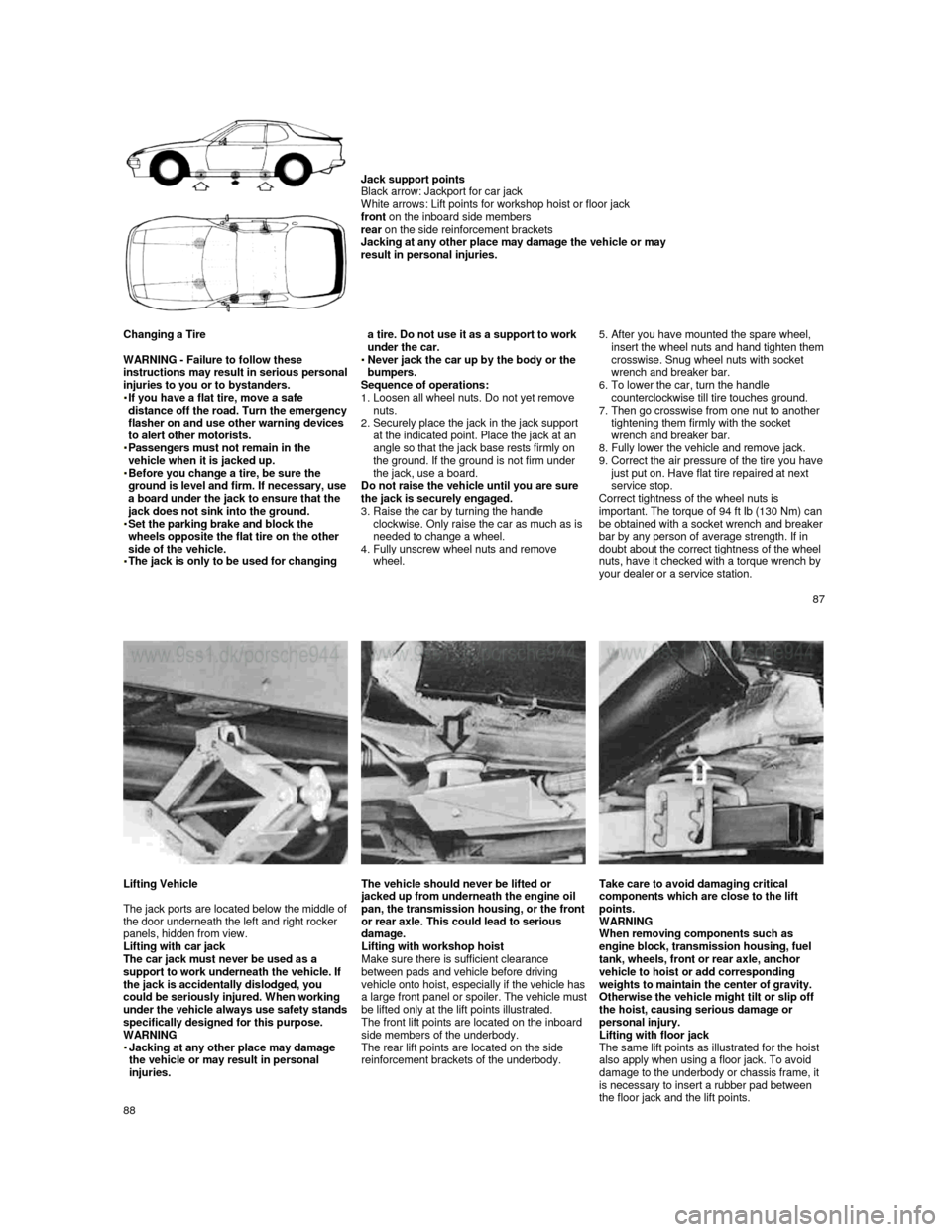

Automatic Transmission Fluid The torque converter and the transmission are lubricated with Automatic Transmission Fluid

(ATF). The final drive requires hypoid oil SAE

90 only.

Do not tow the car or run the engine

without ATF in the transmission.

Checking the ATF level

The ATF has to be checked at frequent

intervals, for instance, when the engine oil is

being checked or at least at the specified

intervals (see Maintenance schedule). A

correct ATF level is very important for the

proper functioning of the transmission. The

reading should be done when the ATF is warm, with the engine idling, the selector lever in Neutral and the parking brake applied.

The level of the ATF fluid can be checked

visually through the transparent reservoir. This reservoir is located at the rear end of the

transmission housing. You have enough ATF

if the fluid level is between the Min. and Max.

marks. It should never be above or below

these marks.

The difference between the two marks is 1

U.S. pint or 0.4 liter.

If level is too high or too low do not just add or

drain ATF. Have your dealer check and

correct the cause as soon as possible.

For correct ATF specifications, see "Filling

Capacities".

Changing the ATF

The ATF and the hypoidoil in the final drive

has to be changed at specified intervals (see

Maintenance schedule).

78

Page 45 of 66

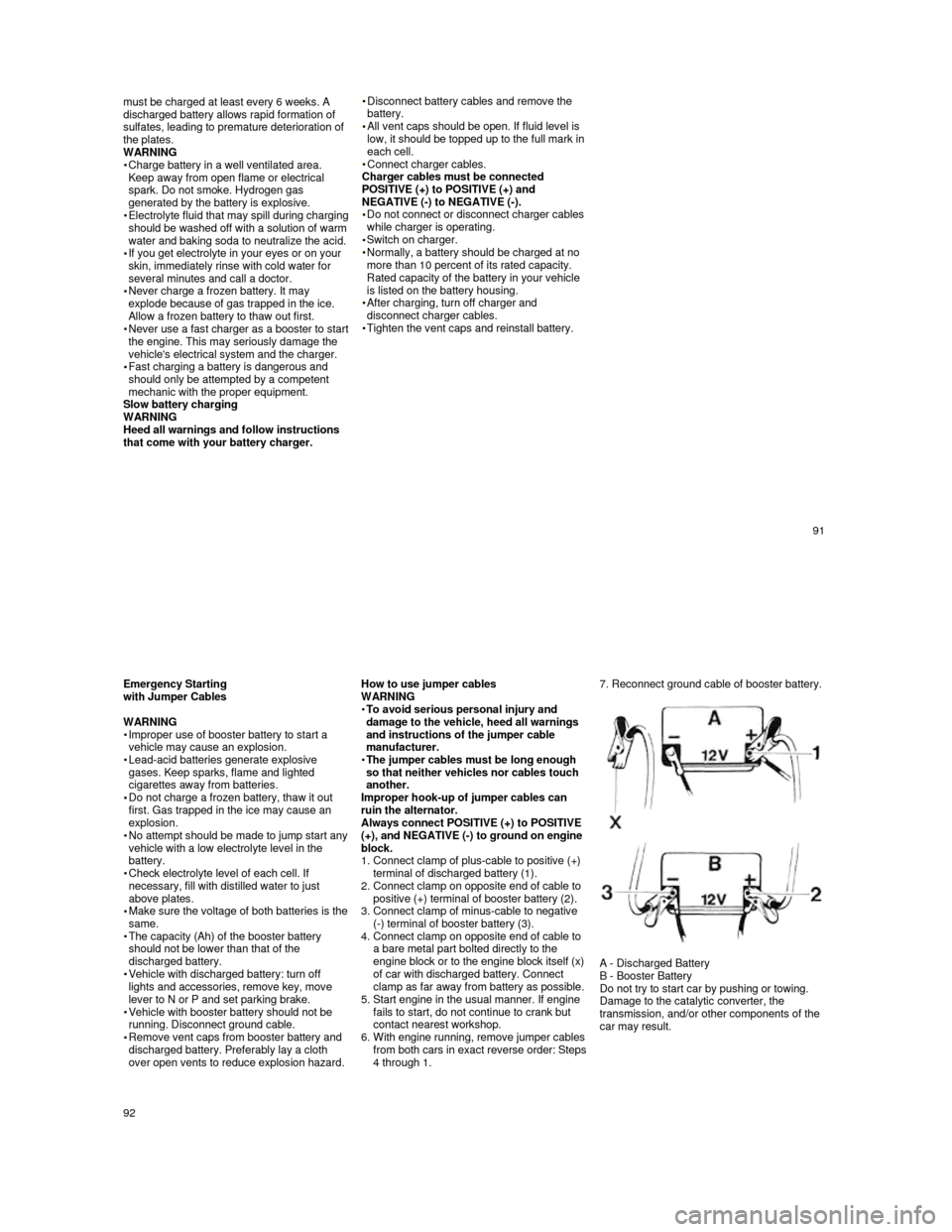

Jack support points

Black arrow: Jackport for car jack

White arrows: Lift points for workshop hoist or flo or jack

front on the inboard side members

rear on the side reinforcement brackets

Jacking at any other place may damage the vehicle o r may

result in personal injuries.

Changing a Tire

WARNING - Failure to follow these

instructions may result in serious personal injuries to you or to bystanders.

If you have a flat tire, move a safe distance off the road. Turn the emergency flasher on and use other warning devices

to alert other motorists.

Passengers must not remain in the vehicle when it is jacked up. Before you change a tire, be sure the ground is level and firm. If necessary, use a board under the jack to ensure that the jack does not sink into the ground. Set the parking brake and block the wheels opposite the flat tire on the other

side of the vehicle.

The jack is only to be used for changing

a tire. Do not use it as a support to work

under the car.

Never jack the car up by the body or the bumpers.

Sequence of operations:

1.

Loosen all wheel nuts. Do not yet remove

nuts.

2.

Securely place the jack in the jack support

at the indicated point. Place the jack at an

angle so that the jack base rests firmly on

the ground. If the ground is not firm under

the jack, use a board.

Do not raise the vehicle until you are sure

the jack is securely engaged.

3.

Raise the car by turning the handle

clockwise. Only raise the car as much as is

needed to change a wheel.

4.

Fully unscrew wheel nuts and remove wheel.

5. After you have mounted the spare wheel, insert the wheel nuts and hand tighten them crosswise. Snug wheel nuts with socket wrench and breaker bar.

6. To lower the car, turn the handle

counterclockwise till tire touches ground.

7.

Then go crosswise from one nut to another

tightening them firmly with the socket

wrench and breaker bar.

8. Fully lower the vehicle and remove jack.

9. Correct the air pressure of the tire you have just put on. Have flat tire repaired at next service stop.

Correct tightness of the wheel nuts is

important. The torque of 94 ft Ib (130 Nm) can

be obtained with a socket wrenc

h and breaker bar by any person of average strength. If in

doubt about the correct tightness of the wheel

nuts, have it checked with a torque wrench by

your dealer or a service station.

87

Lifting Vehicle

The jack ports are located below the middle of the door underneath the left and right rocker

panels, hidden from view.

Lifting with car jack

The car jack must never be used as a

support to work underneath the vehicle. If

the jack is accidentally dislodged, you

could be seriously injured. When working

under the vehicle always use safety stands specifically designed for this purpose.

WARNING

Jacking at any other place may damage the vehicle or may result in personal injuries.

The vehicle should never be lifted or jacked up from underneath the engine oil pan, the transmission housing, or the front or rear axle. This could lead to serious

damage.

Lifting with workshop hoist

Make sure there is sufficient clearance

between pads and vehicle before driving

vehicle onto hoist, especially if the vehicle

has a large front panel or spoiler. The vehicle must be lifted only at the lift points illustrated.

The front lift points are located on the inboard

side members of the underbody.

The rear lift points are located on the side

reinforcement brackets of the underbody.

Take care to avoid damaging critical

components which are close to the lift

points.

WARNING

When removing components such as

engine block, transmission housing, fuel

tank, wheels, front or rear axle, anchor

vehicle to hoist or add corresponding

weights to maintain the center of gravity.

Otherwise the vehicle might tilt or slip off

the hoist, causing serious damage or

personal injury.

Lifting with floor jack

The same lift points as illustrated for the hoist

also apply when using a floor jack. To avoid

damage to the underbody or chassis frame, it

is necessary to insert a rubber pad between

the floor jack and the lift points.

88

Page 47 of 66

must be charged at least every 6 weeks. A

discharged battery allows rapid formation of

sulfates, leading to premature deterioration of

the plates.

WARNING

Charge battery in a well ventilated area.

Keep away from open flame or electrical

spark. Do not smoke. Hydrogen gas

generated by the battery is explosive.

Electrolyte fluid that may spill during charging should be washed off with a solution of warm water and baking soda to neutralize the acid. If you get electrolyte in your eyes or on your

skin, immediately rinse with cold water for

several minutes and call a doctor.

Never charge a frozen battery. It may

explode because of gas trapped in the ice.

Allow a frozen battery to thaw out first. Never use a fast charger as a booster to start the engine. This may seriously damage the

vehicle's electrical system and the charger.

Fast charging a battery is dangerous and

should only be attempted by a competent

mechanic with the proper equipment.

Slow battery charging

WARNING

Heed all warnings and follow instructions

that come with your battery charger.

Disconnect battery cables and remove the

battery.

All vent caps should be open. If fluid level is low, it should be topped up to the full mark in

each cell.

Connect charger cables.

Charger cables must be connected

POSITIVE (+) to POSITIVE (+) and

NEGATIVE (-) to NEGATIVE (-).

Do not connect or disconnect charger cables while charger is operating. Switch on charger. Normally, a battery should be charged at no

more than 10 percent of its rated capacity.

Rated capacity of the battery in your vehicle

is listed on the battery housing.

After charging, turn off charger and disconnect charger cables. Tighten the vent caps and reinstall battery.

91

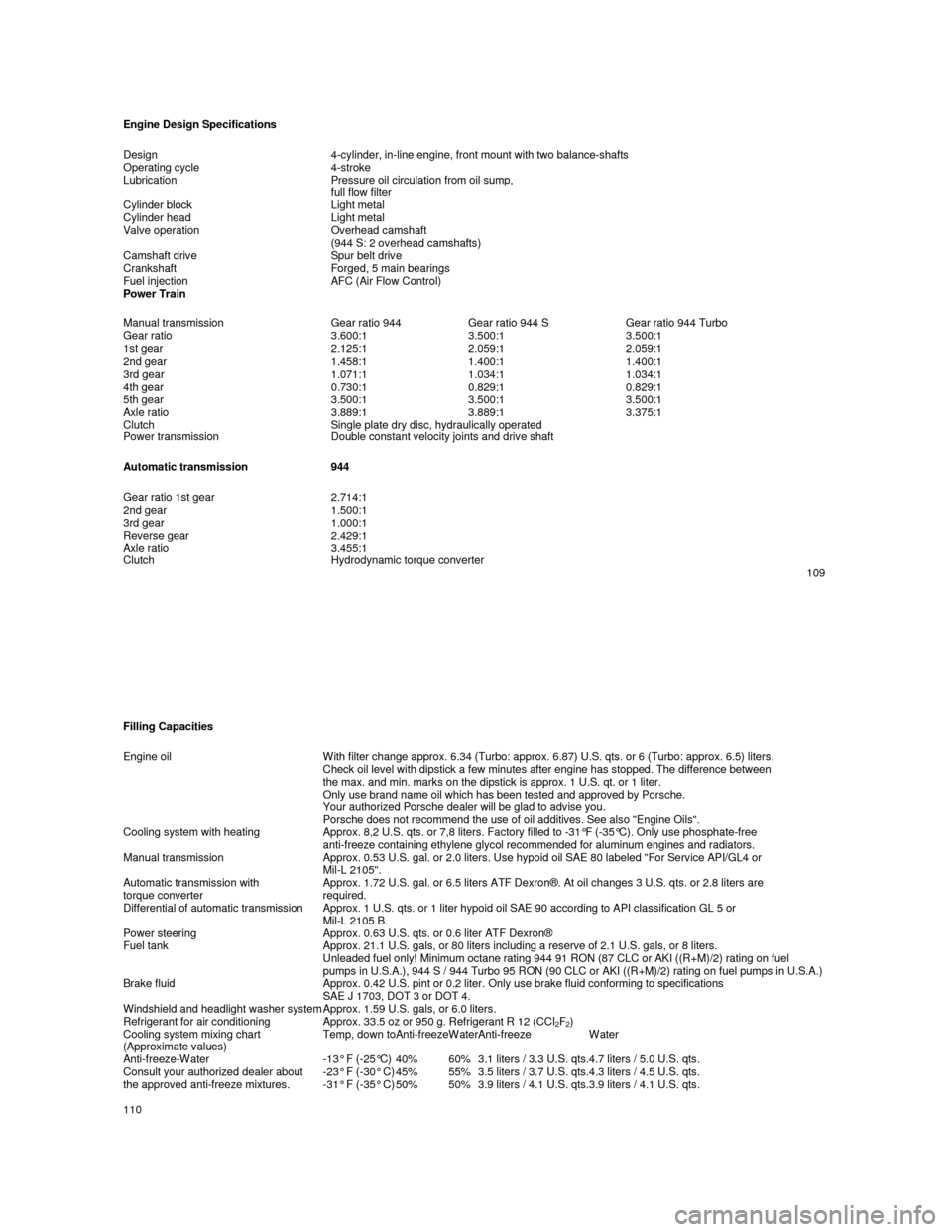

Emergency Starting with Jumper Cables

WARNING

Improper use of booster battery to start a

vehicle may cause an explosion.

Lead-acid batteries generate explosive

gases. Keep sparks, flame and lighted

cigarettes away from batteries.

Do not charge a frozen battery, thaw it out

first. Gas trapped in the ice may cause an

explosion.

No attempt should be made to jump start any vehicle with a low electrolyte level in the

battery.

Check electrolyte level of each cell. If

necessary, fill with distilled water to just

above plates.

Make sure the voltage of both batteries is the same. The capacity (Ah) of the booster battery

should not be lower than that of the

discharged battery.

Vehicle with discharged battery: turn off

lights and accessories, remove key, move

lever to N or P and set parking brake.

Vehicle with booster battery should not be

running. Disconnect ground cable.

Remove vent caps from booster battery and

discharged battery. Preferably lay a cloth

over open vents to reduce explosion hazard.

How to use jumper cables WARNING

To avoid serious personal injury and damage to the vehicle, heed all warnings

and instructions of the jumper cable

manufacturer. The jumper cables must be long enough so that neither vehicles nor cables touch

another.

Improper hook-up of jumper cables can

ruin the alternator.

Always connect POSITIVE (+) to POSITIVE

(+), and NEGATIVE (-) to ground on engine

block.

1. Connect clamp of plus-cable to positive (+) terminal of discharged battery (1).

2.

Connect clamp on opposite end of cable to

positive (+) terminal of booster battery (2).

3.

Connect clamp of minus-cable to negative

(-) terminal of booster battery (3).

4.

Connect clamp on opposite end of cable to

a bare metal part bolted directly to the

engine block or to the engine block itself (x)

of car with discharged battery. Connect

clamp as far away from battery as possible.

5. Start engine in the usual manner. If engine

fails to start, do not continue to crank but

contact nearest workshop.

6.

With engine running, remove jumper cables from both cars in exact reverse order: Steps 4 through 1.

7. Reconnect ground cable of booster battery.

A - Discharged Battery

B - Booster Battery

Do not try to start car by pushing or towing.

Damage to the catalytic converter, the

transmission, and/or other components of the

car may result.

92

Page 56 of 66

Engine Design Specifications

Design

Operating cycle

Lubrication

Cylinder block

Cylinder head

Valve operation

Camshaft drive

Crankshaft

Fuel injection 4-cylinder, in-line engine, front mount with two ba

lance-shafts

4-stroke

Pressure oil circulation from oil sump,

full flow filter

Light metal

Light metal

Overhead camshaft

(944 S: 2 overhead camshafts)

Spur belt drive

Forged, 5 main bearings

AFC (Air Flow Control) Power Train

Manual transmission

Gear ratio

1st gear

2nd gear

3rd gear

4th gear

5th gear

Axle ratio Gear ratio 944

3.600:1

2.125:1

1.458:1

1.071:1

0.730:1

3.500:1

3.889:1 Gear ratio 944 S

3.500:1

2.059:1

1.400:1

1.034:1

0.829:1

3.500:1

3.889:1 Gear ratio 944 Turbo

3.500:1

2.059:1

1.400:1

1.034:1

0.829:1

3.500:1

3.375:1

Clutch

Power transmission Single plate dry disc, hydraulically operated

Double constant velocity joints and drive shaft

Automatic transmission 944

Gear ratio 1st gear

2nd gear

3rd gear

Reverse gear

Axle ratio

Clutch 2.714:1

1.500:1

1.000:1

2.429:1

3.455:1

Hydrodynamic torque converter

109

Filling Capacities

Engine oil With filter change approx. 6.34 (Turbo: approx. 6.87) U.S. qts. or 6 (Turbo: approx. 6.5) liters.

Check oil level with dipstick a few minutes after e ngine has stopped. The difference between

the max. and min. marks on the dipstick is approx. 1 U.S. qt. or 1 liter.

Only use brand name oil which has been tested and a pproved by Porsche.

Your authorized Porsche dealer will be glad to advi se you.

Porsche does not recommend the use of oil additives . See also "Engine Oils".

Cooling system with heating

Approx. 8,2 U.S. qts. or 7,8 liters. Factory filled to -31°F (-35°C). Only use phosphate-free

anti-freeze containing ethylene glycol recommended for aluminum engines and radiators.

Manual transmission

Approx. 0.53 U.S. gal. or 2.0 liters. Use hypoid oi l SAE 80 labeled "For Service API/GL4 or

Mil-L 2105".

Automatic transmission with

torque converter Approx. 1.72 U.S. gal. or 6.5 liters ATF Dexron®. At oil c hanges 3 U.S. qts. or 2.8 liters are

required.

Differential of automatic transmission

Approx. 1 U.S. qts. or 1 liter hypoid oil SAE 90 ac cording to API classification GL 5 or

Mil-L 2105 B.

Power steering

Approx. 0.63 U.S. qts. or 0.6 liter ATF Dexron®

Fuel tank Approx. 21.1 U.S. gals, or 80 liters including a re serve of 2.1 U.S. gals, or 8 liters.

Unleaded fuel only! Minimum octane rating 944 91 RO N (87 CLC or AKI ((R+M)/2) rating on fuel

pumps in U.S.A.), 944 S / 944 Turbo 95 RON (90 CLC or AKI ((R+M)/2) rating on fuel pumps in U.S.A.)

Brake fluid Approx. 0.42 U.S. pint or 0.2 liter. Only use brake fluid conforming to specifications

SAE J 1703, DOT 3 or DOT 4.

Windshield and headlight washer system

Approx. 1.59 U.S. gals, or 6.0 liters.

Refrigerant for air conditioning Approx. 33.5 oz or 950 g. Refrigerant R 12 (CCI2F2)

Cooling system mixing chart

(Approximate values)

Anti-freeze-Water

Consult your authorized dealer about

the approved anti-freeze mixtures. Temp, down to

-13° F (-25°C) -23° F (-30° C) -31° F (-35° C)

Anti-freeze

40%

45%

50% Water

60% 55% 50%

Anti-freeze

3.1 liters / 3.3 U.S. qts.3.5 liters / 3.7 U.S. qts.3.9 liters / 4.1 U.S. qts.

Water

4.7 liters / 5.0 U.S. qts.

4.3 liters / 4.5 U.S. qts. 3.9 liters / 4.1 U.S. qts.

110

Page 59 of 66

Wheel Alignment

Wheel camber*

Toe-in*

Toe angle difference*

Caster*

* at DIN curb weight Front

Rear

Front

Rear

-20' ± 15',

maximum difference left to right 20'

-1° ± 20', maximum difference left to right 30'

+ 10' ±5'

0° ± 10', maximum difference left to right 20' at 20° to left and right -1° ± 20'

2,5° + 30' - 15'

Brake System

Hydraulic dual circuit brake system with

front/rear brake circuits

internally ventilated disc brakes front and rearBrake power assist

Parking brake acting on rear wheels

Chassis, Suspension

Unitized construction

Front suspension

Rear suspension

Shock absorbers

Stabilizers

Independent coil/shock absorber struts, positive ki

ng-pin offset

Independent - diagonal arm, one torsion bar each

Double acting hydraulic shock absorbers, front and rear

Diameter - front: 20 mm (optional 21,5), Turbo: 22. 5 mm or 24 x 3.7 mm

rear: 14 mm or 20 mm (optional), Turbo: 18 mm

115

Performance*

Maximum speed

Acceleration 0-60 mph Time at end 1/4 mile*

Time at end 1/4 mile*

Manual transmission944

131 mph (210 km/h) 8.3 seconds

16.2 seconds

30.1 seconds

944 S

142 mph (228 km/h)

7.7 seconds

15.4 seconds

27.8 seconds

944 Turbo

152 mph (245 km/h)

6.1 seconds

14.4 seconds

26.0 seconds

Automatic transmission944

131 mph (210 km/h)

9.8 seconds

17.2 seconds

17.2 seconds

* At curb weight and half-load capacity, excluding optional equipment and accessories.

Climbing Performance

1st gear

2nd gear

3rd gear

4th gear

5th gear

Manual transmission944

approx. 61%

approx. 33%

approx. 21%

approx. 14%

approx. 8%

944 S

approx. 62% approx. 36%

approx. 22%

approx. 14%

approx. 9%

944 Turbo

approx. 62%

approx. 49%

approx. 30%

approx. 20%

approx. 14%

Automatic transmission944

approx. 36%

approx. 18%

approx. 10%

116

Page 62 of 66

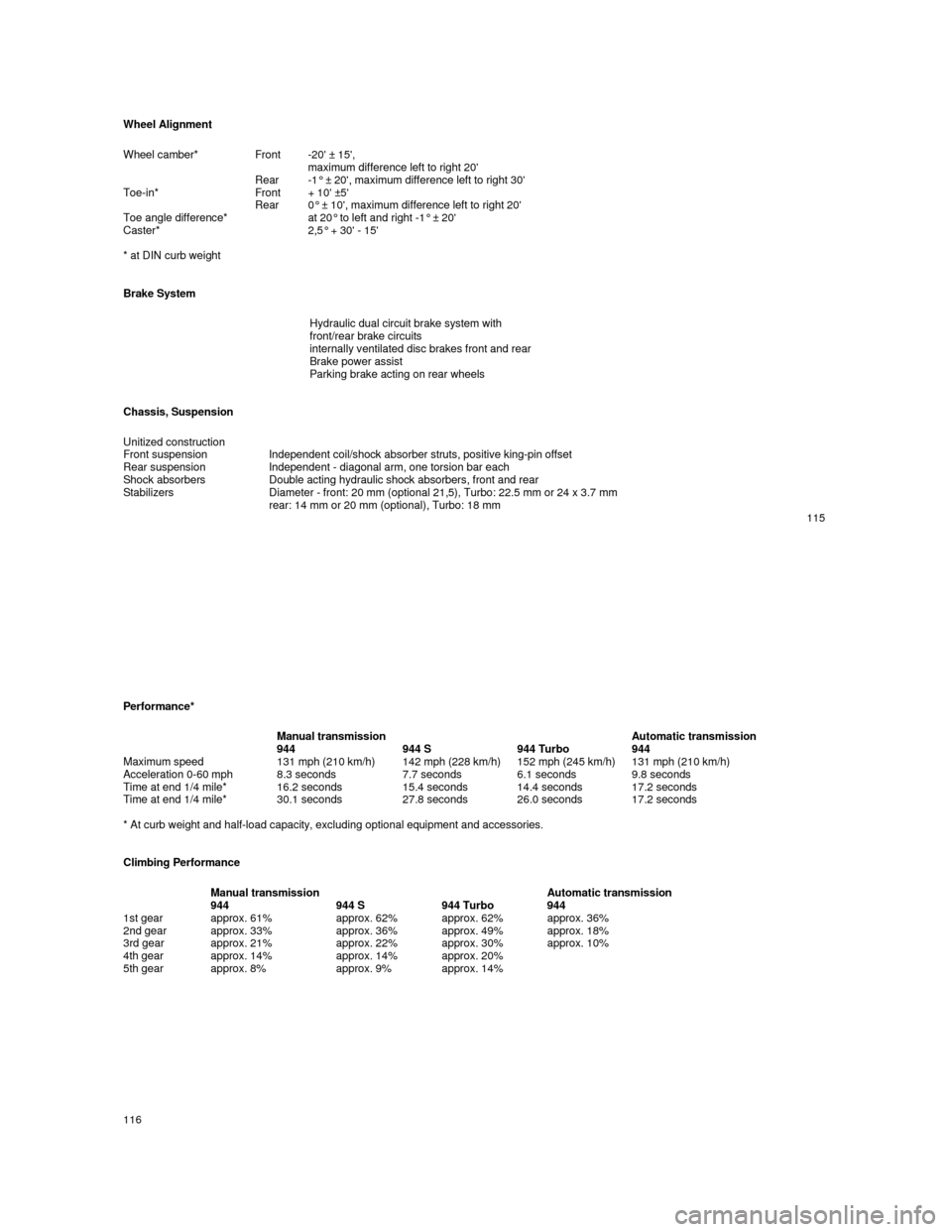

Full-power Curves 944Turbo Acceleration Curve Manual gearbox

944Turbo

121

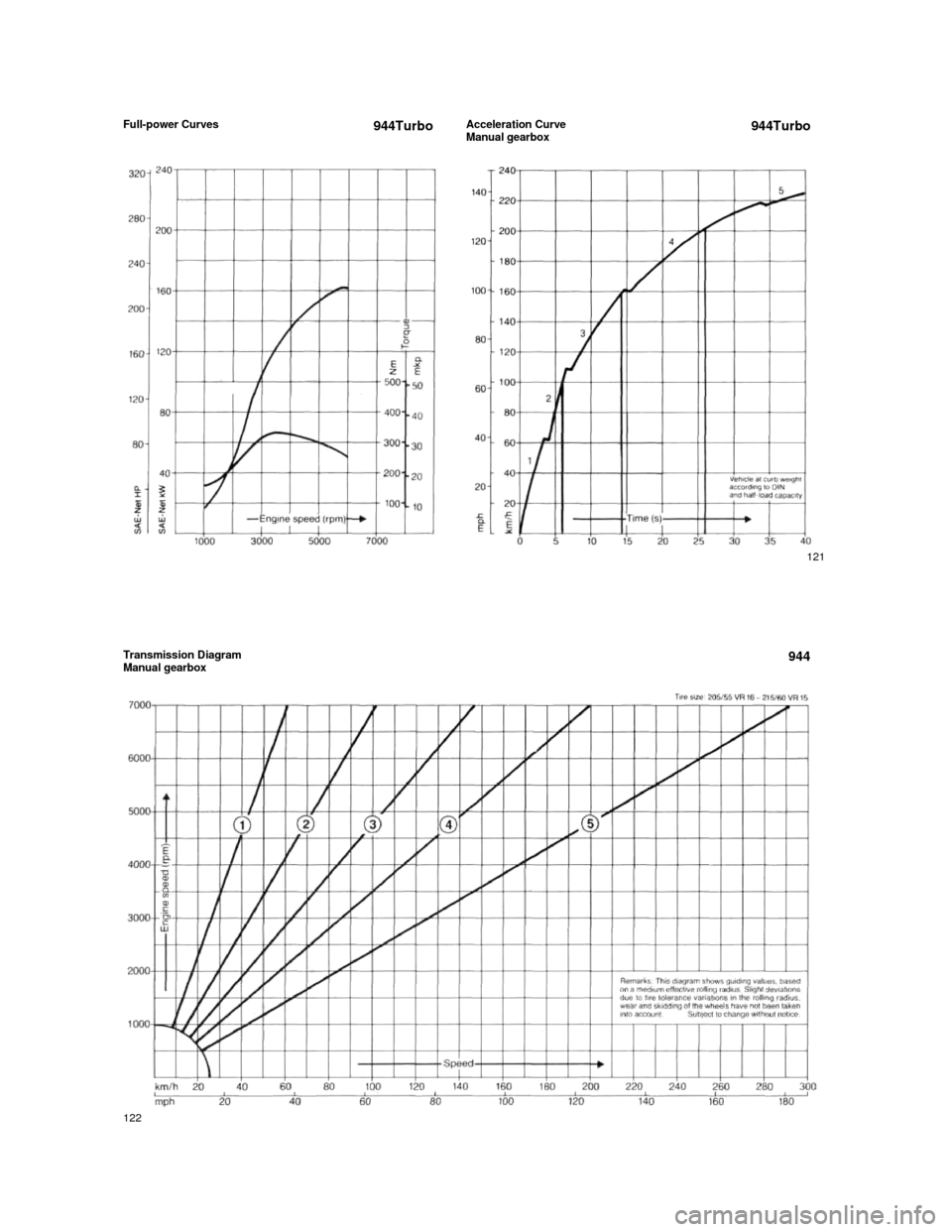

Transmission Diagram Manual gearbox

944

122

Page 63 of 66

Transmission Diagram Automatic 944

123

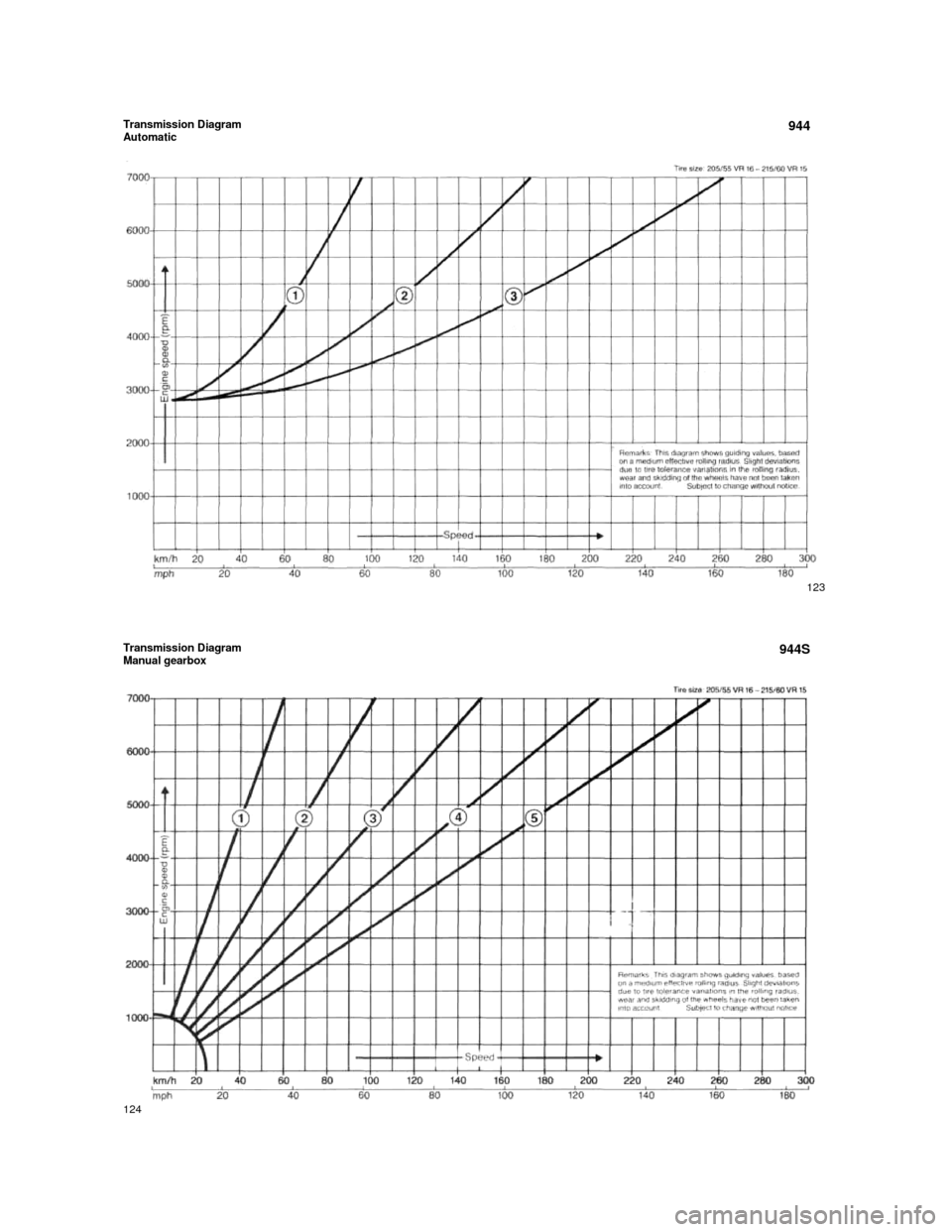

Transmission Diagram Manual gearbox

944S

124

Page 64 of 66

Transmission Diagram Manual gearbox 944Turbo

125

Gas Station Information Fuses and relays

The fuses are located within the

central electric box at the rear left

of the e

ngine compartment in front of the pivot point for the left windshield wiperarm (under black plastic cover). The use of the

fuses and relays is shown in a

list on the inside of the cover of

the fuses and relays.

Fuel recommendation

944: 91 RON (87 CLC or AKI

((R+M)/2) rating on fuel pumps in

U.S.A.) minimum.

944 S / 944 Turbo: 95 RON (90

CLC or AKI ((R+M)/2) rating on

fuel pumps in U.S.A.)

UNLEADED FUEL ONLY.

Fuel tank capacity: 21.1. U.S.

gals, or 80 liters.

Federal law prohibits use of

leaded fuel in this vehicle. Starting Manual transmission: Only start in Neutral, clutch pedal depressed. Automatic transmission:

Start in Park.

Starting cold or hot engine

Just turn ignition key. No need to

depress accelerator pedal.

Emergency starting

Car must not be started by

pushing or towing.

Seat adjustment

Pull lever in front of seat.

Backrest

Lift lever on side of seatback.

Fuel cap

Located in the right rear panel. To close, turn cap clockwise to stop. 126

Page 65 of 66

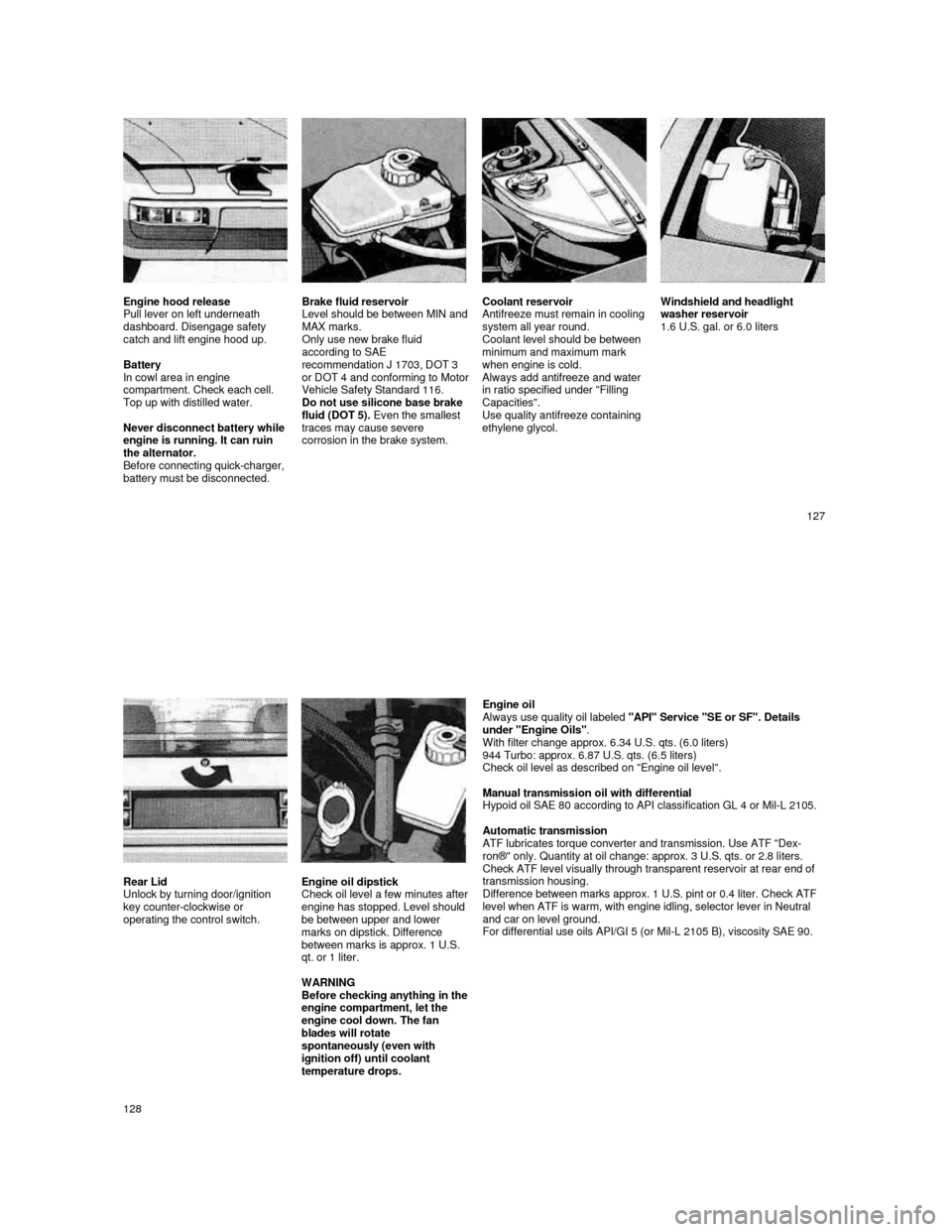

Engine hood release

Pull lever on left underneath

dashboard. Disengage safety

catch and lift engine hood up.

Battery

In cowl area in engine

compartment. Check each cell.

Top up with distilled water.

Never disconnect battery while

engine is running. It can ruin

the alternator.

Before connecting quick-charger,

battery must be disconnected. Brake fluid reservoir

Level should be between MIN and MAX marks.

Only use new brake fluid

according to SAE

recommendation J 1703, DOT 3

or DOT 4 and conforming to Motor Vehicle Safety Standard 116.

Do not use silicone base brake

fluid (DOT 5). Even the smallest

traces may cause severe

corrosion in the brake system.

Coolant reservoir

Antifreeze must remain in cooling

system all year round.

Coolant level should be between

minimum and maximum mark

when engine is cold. Always add antifreeze and water in ratio specified under "Filling

Capacities".

Use quality antifreeze containing

ethylene glycol.

Windshield and headlight

washer reservoir

1.6 U.S. gal. or 6.0 liters

127

Rear Lid

Unlock by turning door/ignition

key counter-clockwise or

operating the control switch.

Engine oil dipstick

Check oil level a few minutes after engine has stopped. Level should

be between upper and lower

marks on dipstick. Difference

between marks is approx. 1 U.S.

qt. or 1 liter.

WARNING

Before checking anything in

the engine compartment, let the

engine cool down. The fan

blades will rotate

spontaneously (even with

ignition off) until coolant

temperature drops.

Engine oil Always use quality oil labeled "API" Service "SE or SF". Details

under "Engine Oils" .

With filter change approx. 6.34 U.S. qts. (6.0 lite rs)

944 Turbo: approx. 6.87 U.S. qts. (6.5 liters)

Check oil level as described on "Engine oil level".

Manual transmission oil with differential

Hypoid oil SAE 80 according to API classification G L 4 or Mil-L 2105.

Automatic transmission

ATF lubricates torque converter and transmission. U se ATF "Dex-

ron®" only. Quantity at oil change: approx. 3 U.S. qts. or 2.8 liters.

Check ATF level visually through transparent reserv oir at rear end of

transmission housing.

Difference between marks approx. 1 U.S. pint or 0.4 liter. Check ATF

level when ATF is warm, with engine idling, selecto r lever in Neutral

and car on level ground.

For differential use oils API/GI 5 (or Mil-L 2105 B ), viscosity SAE 90.

128