wheel torque Ram 1500 2011 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2011, Model line: 1500, Model: Ram 1500 2011Pages: 636, PDF Size: 4.88 MB

Page 404 of 636

mode by pressing the “ESC Off” switch. Once the situa-

tion requiring ESC to be switched to the “Partial Off”

mode is overcome, turn ESC back on by momentarily

pressing the “ESC Off” switch. This may be done while

the vehicle is in motion.

WARNING!

In the “Partial Off” mode, the engine torque reduc-

tion and stability features are desensitized. There-

fore, the enhanced vehicle stability offered by ESC is

unavailable.

All Four-Wheel Drive Vehicles In 4WD AUTO And

4WD LOCK Modes Can Also Choose The

Following ESC Operating Mode. This Is The Only

ESC Operating Mode in 4WD LOW:

Full Off

This mode is intended for off-road use when ESC stabil-

ity features could inhibit vehicle maneuverability due to

trail conditions. This mode is entered by pressing and

holding the “ESC Off” switch for five seconds when the

vehicle is stopped and the engine is running. After five

seconds, the “ESP Off Indicator Light” will illuminate

and the “ESC Off” message will appear in the odometer.

Press and release the trip odometer button located on the

instrument cluster to clear this message.

NOTE:The “ESC OFF” message will display and the

audible chime will sound when the shift lever is placed

402 STARTING AND OPERATING

Page 506 of 636

CAUTION!

Before raising the wheel off the ground, make sure

that the jack will not damage surrounding truck parts

and adjust the jack position as required.

NOTE: If the bottle jack will not lower by turning the

dial (thumbwheel) by hand, it may be necessary to use

the jack drive tube in order to lower the jack.

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause a collision. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire. 5. Remove the wheel nuts and pull the wheel off. On

single rear-wheel (SRW) trucks, install the spare wheel

and wheel nuts with the cone shaped end of the wheel

nuts toward the wheel. On 3500 dual rear-wheel models

(DRW) the wheel nuts are a two-piece assembly with a

flat face. Lightly tighten the wheel nuts. To avoid the risk

of forcing the vehicle off the jack, do not fully tighten the

wheel nuts until the vehicle has been lowered.

6. Using the wheel wrench, finish tightening the wheel

nuts using a crisscross pattern. The correct wheel nut

tightness is 130 ft lbs (177 N·m) torque (1500 Series), 135 ft

lbs (183 N·m) torque for 2500/3500 single-rear wheel

(SRW) models, and 145 ft lbs (197 N·m) for 3500 dual

rear-wheel models. If in doubt about the correct tight-

ness, have them checked with a torque wrench by your

authorized dealer or at a service station.

504 WHAT TO DO IN EMERGENCIES

Page 508 of 636

CAUTION!

•Use a back-and-forth motion to remove the hub

cap. Do not use a twisting motion when removing

the hub cap, damage to the hub cap finish may

occur.

•The rear hub caps on the dual rear wheel has two

pry-off notches. Make sure that the hook of the

jack handle driver is located squarely in the cap

notch before attempting to pull off.

You must use the flat end of the lug wrench to pry off the

wheel skins. Insert the flat tip completely and using a

back-and-forth motion, loosen the wheel skin. Repeat this

procedure around the tire until the skin pops off.

Replace the wheel skins first using a rubber mallet. When

replacing the hub caps, tilt the cap retainer over the lug nut bolt circle and strike the high side down with a

rubber mallet. Be sure that the hub caps and wheel skins

are firmly seated around the wheel.

Wheel Nuts

All wheel nuts should be tightened occasionally to elimi-

nate the possibility of wheel studs being sheared or the

bolt holes in the wheels becoming elongated. This is

especially important during the first few hundred miles/

kilometers of operation to allow the wheel nuts to

become properly set. All wheel nuts should first be firmly

seated against the wheel. The wheel nuts should then be

tightened to recommended torque. Tighten the wheel

nuts to final torque in increments. Progress around the

bolt circle, tightening the wheel nut opposite to the wheel

nut just previously tightened until final torque is

achieved. Recommended torques are shown in the fol-

lowing chart.

506 WHAT TO DO IN EMERGENCIES

Page 509 of 636

Disc

WheelsType Nut Stud Size Torque

Ft. Lbs.Torque

Newton

Meters

Cone 9/16-18 120-150 160-200

Flanged 9/16-18 130-160 190-220

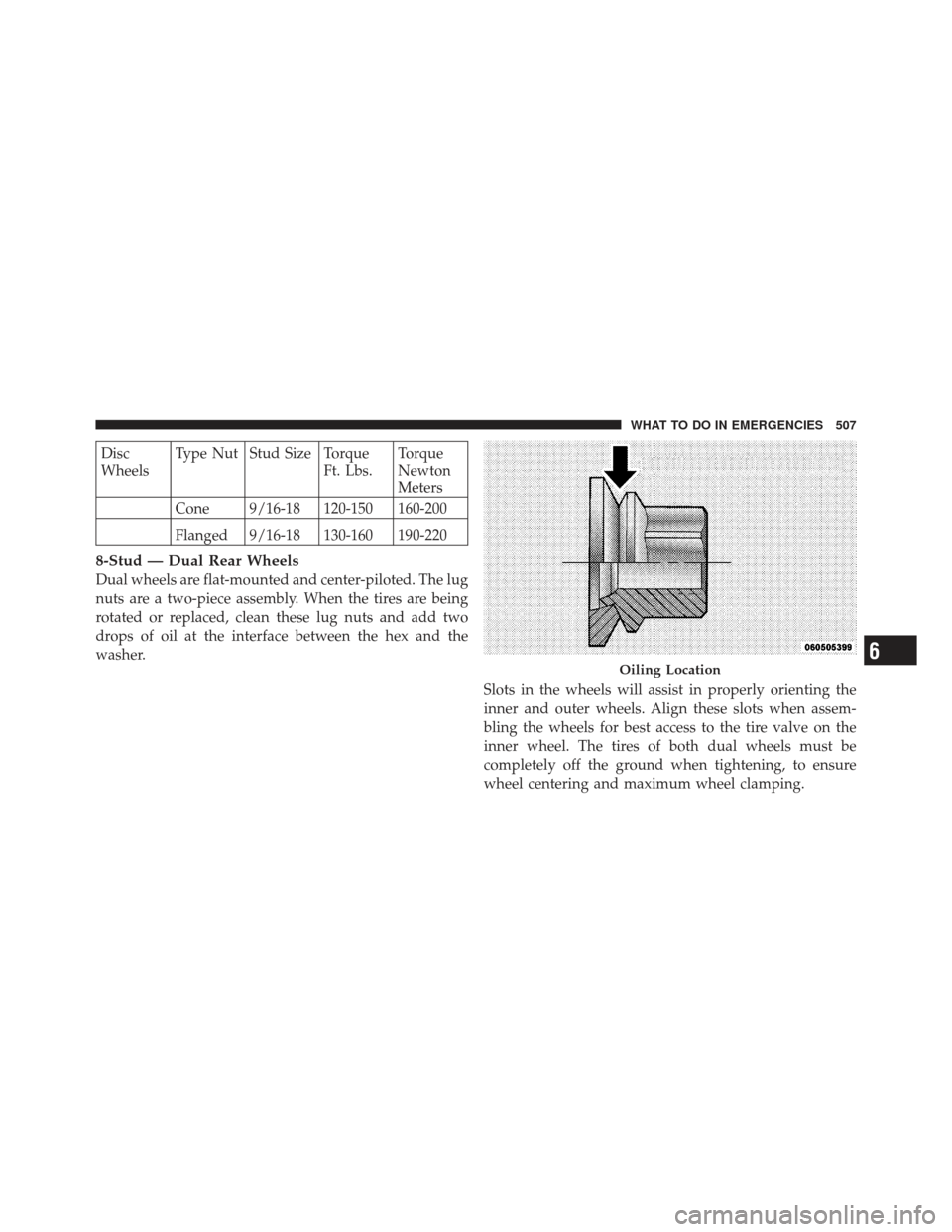

8-Stud — Dual Rear Wheels

Dual wheels are flat-mounted and center-piloted. The lug

nuts are a two-piece assembly. When the tires are being

rotated or replaced, clean these lug nuts and add two

drops of oil at the interface between the hex and the

washer.

Slots in the wheels will assist in properly orienting the

inner and outer wheels. Align these slots when assem-

bling the wheels for best access to the tire valve on the

inner wheel. The tires of both dual wheels must be

completely off the ground when tightening, to ensure

wheel centering and maximum wheel clamping.

Oiling Location6

WHAT TO DO IN EMERGENCIES 507

Page 510 of 636

Dual wheel models require a special heavy-duty lug nut

tightening adapter (included with the vehicle) to cor-

rectly tighten the lug nuts. Also, when it is necessary to

remove and install dual rear wheels, use a proper vehicle

lifting device.

NOTE:When installing a spare tire as part of a dual rear

wheel end combination, the tire diameter of the two

individual tires must be compared. If there is a significant

difference, the larger tire should be installed in a front

location. The correct direction of rotation for dual tire

installations must also be observed. These dual rear wheels should be tightened as follows:

1. Tighten the wheel nuts in the numbered sequence to a

snug fit.

2. Retighten the wheel nuts in the same sequence to the

torques listed in the table. Go through the sequence a

Tightening Pattern

508 WHAT TO DO IN EMERGENCIES

Page 511 of 636

second time to verify that specific torque has been

achieved. Retighten to specifications at 100 miles

(160 km) and after 500 miles (800 km).

It is recommended that wheel stud nuts be kept torqued

to specifications at all times. Torque wheel stud nuts to

specifications at each lubrication interval.

To Stow The Flat Or Spare

NOTE:Vehicles equipped with aluminum wheels can-

not be stored under the vehicle because the wheel

retainer will not fit through the wheel pilot hole. Secure

the flat tire in the bed of the truck. Have the flat tire

repaired or replaced immediately.

WARNING!

A loose tire thrown forward in a collision or hard

stop could injure the occupants in the vehicle. Have

the deflated (flat) tire repaired or replaced immedi-

ately.

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Attach the wheel wrench to the extension tube. Rotate the

winch mechanism until the wheel is drawn into place

against the underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip, or click three or

four times. It cannot be overtightened. Push against the

tire several times to be sure it is firmly in place.

6

WHAT TO DO IN EMERGENCIES 509

Page 634 of 636

Vehicle Loading...................... 412,453

Vehicle Modifications/Alterations .............. 7

Vehicle Storage ....................... 301,569

Video Entertainment System™

(Rear Seat Video System) .................. 286

Voice Recognition System (VR) .............. 101

Voltmeter ............................. 219

Warning Lights (Instrument Cluster

Description) ......................... 206,210

Warnings and Cautions ..................... 6

Warranty Information ..................... 608

Washers, Windshield .................. 130,540

Washing Vehicle ......................... 558

Water Driving Through ..................... 366

Wheel and Wheel Trim .................... 560

Wheel and Wheel Trim Care ................ 560

Wheel Cover ........................... 505 Wheel Nut Torque

....................... 506

Winch ................................ 370

Accessories ......................... 374

Operation .......................... 375

Rigging Techniques ................... 388

Usage ............................. 370

Wind Buffeting ....................... 37,161

Window Fogging ........................ 301

Windows .............................. 34

Power ............................. 34

Rear Sliding ........................ 181

Windshield Defroster ...................... 84

Windshield Washers ................ 129,130,540

Fluid .......................... 129,540

Windshield Wiper Blades .................. 540

Windshield Wipers ....................... 129

Wiper Blade Replacement .................. 540

Wipers, Intermittent ...................... 130

632 INDEX