cable Ram 1500 2011 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2011, Model line: 1500, Model: Ram 1500 2011Pages: 636, PDF Size: 4.88 MB

Page 512 of 636

HOISTING

A conventional floor jack may be used at the jacking

locations. Refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts of the underbody.

CAUTION!

Never use a floor jack directly under the differential

housing of a loaded truck or damage to your vehicle

may result.

JUMP-STARTING PROCEDURES

If your vehicle has a discharged battery it can be jump-

started using a set of jumper cables and a battery in

another vehicle or by using a portable battery booster

pack. Jump-starting can be dangerous if done improperly

so please follow the procedures in this section carefully.NOTE:

When using a portable battery booster pack

follow the manufacturer ’s operating instructions and

precautions.

CAUTION!

Do not use a portable battery booster pack or any

other booster source with a system voltage greater

than 12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

WARNING!

Do not attempt jump-starting if the battery is frozen.

It could rupture or explode and cause personal injury.

Preparations For Jump-Start

The battery in your vehicle is located in the front of the

engine compartment, behind the left headlight assembly.

510 WHAT TO DO IN EMERGENCIES

Page 514 of 636

3. If using another vehicle to jump-start the battery, park

the vehicle within the jumper cables reach, set the

parking brake and make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other as this

could establish a ground connection and personal

injury could result.

Jump-Starting Procedure

WARNING!

Failure to follow this procedure could result in per-

sonal injury or property damage due to battery ex-

plosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster vehicle

or the discharged vehicle.

1. Connect the positive (+)end of the jumper cable to the

positive (+)post of the discharged vehicle.

2. Connect the opposite end of the positive (+)jumper

cable to the positive (+)post of the booster battery.

3. Connect the negative end (-)of the jumper cable to the

negative (-)post of the booster battery.

4. Connect the opposite end of the negative (-)jumper

cable to a good engine ground (exposed metal part of the

discharged vehicle’s engine) away from the battery and

the fuel injection system.

512 WHAT TO DO IN EMERGENCIES

Page 515 of 636

WARNING!

Do not connect the cable to the negative post (-) of the

discharged battery. The resulting electrical spark

could cause the battery to explode and could result in

personal injury.

5. Start the engine in the vehicle that has the booster

battery, let the engine idle a few minutes, and then start

the engine in the vehicle with the discharged battery.

Once the engine is started, remove the jumper cables in

the reverse sequence:

6. Disconnect the negative (-)jumper cable from the

engine ground of the vehicle with the discharged battery.

7. Disconnect the negative end (-)of the jumper cable

from the negative (-)post of the booster battery. 8. Disconnect the opposite end of the positive

(+)jumper

cable from the positive (+)post of the booster battery.

9. Disconnect the positive (+)end of the jumper cable

from the positive (+)post of the discharged vehicle.

If frequent jump-starting is required to start your vehicle

you should have the battery and charging system in-

spected at your authorized dealer.

CAUTION!

Accessories that can be plugged into the vehicle

power outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular phones, etc.).

Eventually, if plugged in long enough, the vehicle’s

battery will discharge sufficiently to degrade battery

life and/or prevent the engine from starting.6

WHAT TO DO IN EMERGENCIES 513

Page 539 of 636

WARNING! (Continued)

•Battery gas is flammable and explosive. Keep

flame or sparks away from the battery. Do not use

a booster battery or any other booster source with

an output greater than 12 Volts. Do not allow cable

clamps to touch each other.

•Battery posts, terminals, and related accessories

contain lead and lead compounds. Wash hands

after handling.

CAUTION!

•It is essential when replacing the cables on the

battery that the positive cable is attached to the

positive post and the negative cable is attached to

the negative post. Battery posts are marked posi-

tive (+) and negative (-) and are identified on the

battery case. Cable clamps should be tight on the

terminal posts and free of corrosion.

•If a “fast charger” is used while the battery is in

the vehicle, disconnect both vehicle battery cables

before connecting the charger to the battery. Do

not use a “fast charger” to provide starting voltage.

7

MAINTAINING YOUR VEHICLE 537

Page 546 of 636

Cooling System

WARNING!

You or others can be badly burned by hot coolant or

steam from your radiator. If you see or hear steam

coming from under the hood, do not open the hood

until the radiator has had time to cool. Never try to

open a cooling system pressure cap when the radiator

is hot.

Engine Coolant Checks

Check the engine coolant (antifreeze) protection every

12 months (before the onset of freezing weather, where

applicable). If the engine coolant (antifreeze) is dirty or

rusty in appearance, the system should be drained,

flushed and refilled with fresh coolant. Check the front of

the A/C condenser for any accumulation of bugs, leaves,

etc. If dirty, clean by gently spraying water from a garden

hose vertically down the face of the condenser.Check the coolant recovery bottle tubing for brittle rub-

ber, cracking, tears, cuts and tightness of the connection

at the bottle and radiator. Inspect the entire system for

leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

engine coolant (antifreeze) from the radiator drain cock.

If the cap is sealing properly, the engine coolant (anti-

freeze) will begin to drain from the coolant recovery

bottle. DO NOT REMOVE THE COOLANT PRESSURE

CAP WHEN THE COOLING SYSTEM IS HOT.

Cooling System – Drain, Flush, And Refill

If the engine coolant (antifreeze) is dirty or contains a

considerable amount of sediment, clean and flush with a

reliable cooling system cleaner. Follow with a thorough

rinsing to remove all deposits and chemicals. Properly

dispose of old engine coolant (antifreeze) solution.

544 MAINTAINING YOUR VEHICLE

Page 571 of 636

CAUTION! (Continued)

•When replacing a blown fuse, it is important to

use only a fuse having the correct amperage rating.

The use of a fuse with a rating other than indicated

may result in a dangerous electrical system over-

load. If a properly rated fuse continues to blow, it

indicates a problem in the circuit that must be

corrected.

VEHICLE STORAGE

If you are storing your vehicle for more than 21 days, we

recommend that you take the following steps to mini-

mize the drain on your vehicle’s battery:

•Disconnect the Ignition-Off Draw (IOD) fuse located in

the Integrated Power Module, located in the engine

compartment. The IOD cavity includes a snap-in re-

tainer that allows the fuse to be disconnected without

removing it from the fuse block.

•As an alternative to the above steps you may discon-

nect the negative cables from both batteries.

•Any time you store your vehicle or keep it out of

service (i.e., vacation) for two weeks or more, run the

air conditioning system at idle for about five minutes

in the fresh air and high blower setting. This will

ensure adequate system lubrication to minimize the

possibility of compressor damage when the system is

started again.

NOTE:

•When reinstalling the IOD fuse push firmly until fully

seated; the gauges in the instrument cluster will do a

full sweep when the ignition switch is turned to the

RUN position. This is a normal condition.

•When the vehicle is shipped from the factory, the IOD

fuse is in the up or extracted position. If the radio,

interior lamps, keyless entry or other features do not

work with the key OFF, check the position of the fuse

7

MAINTAINING YOUR VEHICLE 569

Page 573 of 636

BULB REPLACEMENT

Dual Or Quad Headlamp/Front Park And Turn

Signal — If Equipped

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Remove the four plastic push-in fasteners that secure

the upper radiator seal to the grille support and both

fender ledges.

4. Remove the two plastic push-in rivets that secure the

upper radiator seal to the radiator.

5. Remove the upper radiator seal from the vehicle.

6. Remove the two headlamp assembly attachment

screws.7. Reach into the front wheel house ahead of the front

wheel, remove the fastener, and lift the cover over the

access hole in the front of the wheel house splash shield.

Access to the rear of the lamp can be gained through this

access hole.

7

MAINTAINING YOUR VEHICLE 571

Page 595 of 636

64,000 Miles (104,000 km) or 48 Months Maintenance Service Schedule

❏Change the engine oil and engine oil filter.

❏ Rotate the tires, rotate at the first sign of irregular wear, even if it occurs before 64,000 miles (104 000 km).

❏ Replace the engine air cleaner filter.

❏ Replace the ignition cables (3.7L Engine).

❏ Replace the spark plugs (3.7L and 5.7L Engines).

❏ Lube the front drive shaft fitting (2500/3500 (4x4) models only).

❏ Inspect the brake linings; replace if necessary.

❏ Adjust parking brake on vehicles equipped with four-wheel disc brakes.

❏ Change the automatic transmission fluid and filter(s) if using your vehicle for any of the following: police, taxi, fleet, or frequent trailer towing.

❏ Change the transfer case fluid if using your vehicle for any of the following: police, taxi, fleet, or frequent trailer towing.

❏ Inspect the front suspension, tie rod ends and boot seals for cracks or leaks and all parts for damage, wear, improper looseness or end play;

replace if necessary.

Odometer Reading Date

Repair Order #Dealer Code

Signature, Authorized Service Center

8

M

A I

N T

E

N A

N CE

S

C

H E

D

U L

E

SMAINTENANCE SCHEDULES 593

Page 598 of 636

96,000 Miles (156,000 km) or 72 Months Maintenance Service Schedule

❏Change the engine oil and engine oil filter.

❏ Rotate the tires, rotate at the first sign of irregular wear, even if it occurs before 96,000 miles (156 000 km).

❏ Replace the engine air cleaner filter.

❏ Replace the ignition cables (4.7L Engine).

❏ Replace the top row and side row of spark plugs (4.7L Engine).**

❏ Replace the spark plugs (3.7L and 5.7L Engines).

❏ Inspect and replace PCV valve if necessary.†

❏ Lube the front drive shaft fitting (2500/3500 (4x4) models only).

❏ Adjust parking brake on vehicles equipped with four-wheel disc brakes.

❏ Inspect the transfer case fluid.

❏ Inspect the brake linings, replace if necessary.

❏ Inspect the CV joints.

❏ Inspect exhaust system.

❏ Inspect the front suspension, tie rod ends and boot seals for cracks or leaks and all parts for damage, wear, improper looseness or end play;

replace if necessary.

❏ Inspect the front and rear axle fluid, change if using your vehicle for police, taxi, fleet, off-road or frequent trailer towing.

Odometer Reading Date

Repair Order #Dealer Code

Signature, Authorized Service Center

8

M

A I

N T

E

N A

N CE

S

C

H E

D

U L

E

S596 MAINTENANCE SCHEDULES

Page 601 of 636

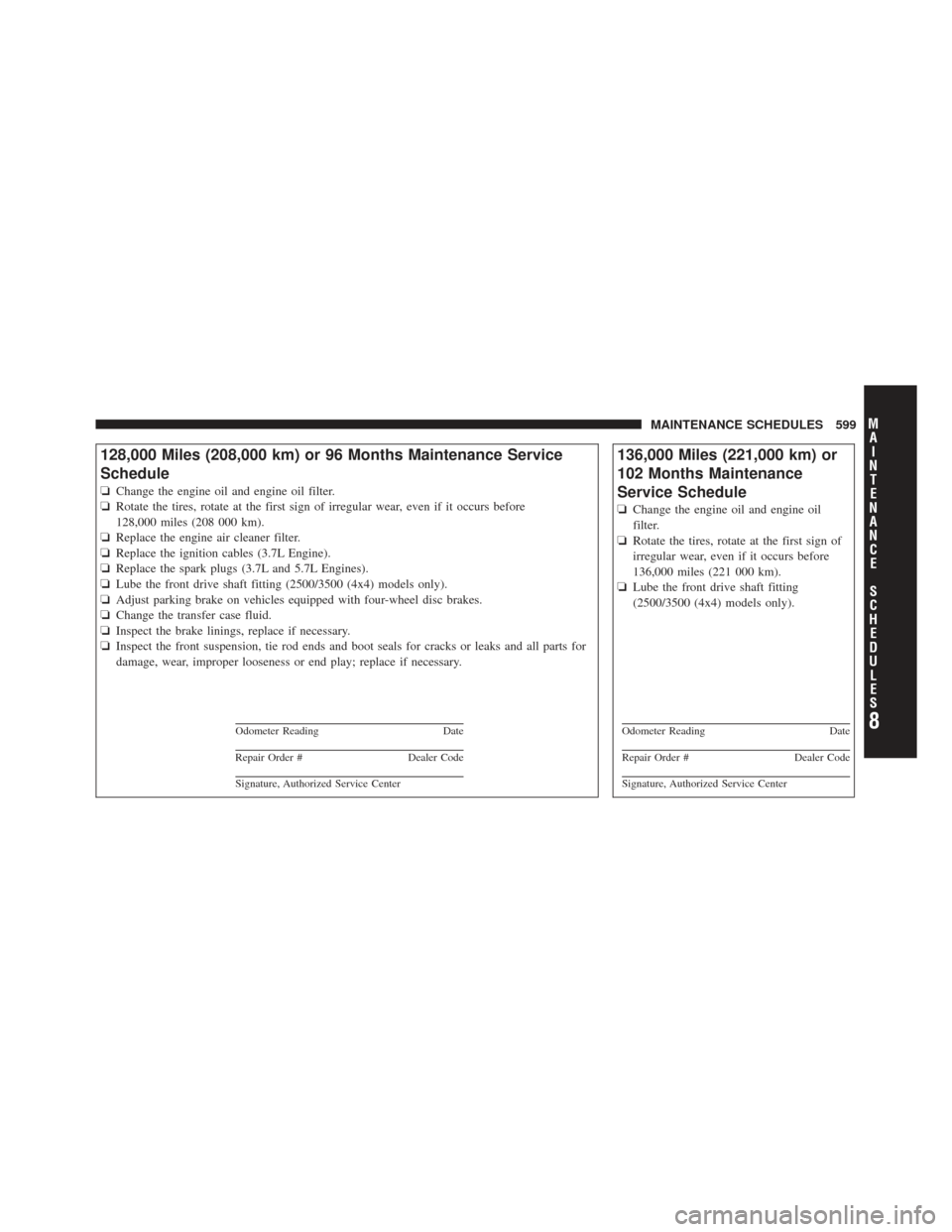

128,000 Miles (208,000 km) or 96 Months Maintenance Service

Schedule

❏Change the engine oil and engine oil filter.

❏ Rotate the tires, rotate at the first sign of irregular wear, even if it occurs before

128,000 miles (208 000 km).

❏ Replace the engine air cleaner filter.

❏ Replace the ignition cables (3.7L Engine).

❏ Replace the spark plugs (3.7L and 5.7L Engines).

❏ Lube the front drive shaft fitting (2500/3500 (4x4) models only).

❏ Adjust parking brake on vehicles equipped with four-wheel disc brakes.

❏ Change the transfer case fluid.

❏ Inspect the brake linings, replace if necessary.

❏ Inspect the front suspension, tie rod ends and boot seals for cracks or leaks and all parts for

damage, wear, improper looseness or end play; replace if necessary.

Odometer Reading Date

Repair Order #Dealer Code

Signature, Authorized Service Center

136,000 Miles (221,000 km) or

102 Months Maintenance

Service Schedule

❏Change the engine oil and engine oil

filter.

❏ Rotate the tires, rotate at the first sign of

irregular wear, even if it occurs before

136,000 miles (221 000 km).

❏ Lube the front drive shaft fitting

(2500/3500 (4x4) models only).

Odometer Reading Date

Repair Order #Dealer Code

Signature, Authorized Service Center

8

M

A I

N T

E

N A

N CE

S

C

H E

D

U L

E

SMAINTENANCE SCHEDULES 599