fuel Ram 1500 2015 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: 1500, Model: Ram 1500 2015Pages: 347, PDF Size: 2.02 MB

Page 239 of 347

WARNING!

Do not coast in NEUTRAL and never turn off the

ignition to coast down a hill. These are unsafe

practices that limit your response to changing traffic

or road conditions. You might lose control of the

vehicle and have a collision.

CAUTION!

Towing the vehicle, coasting, or driving for any other

reason with the transmission in NEUTRAL can cause

severe transmission damage. Refer to “Recreational

Towing” in “Starting And Operating” and “Towing A

Disabled Vehicle” in “What To Do In Emergencies”

for further information.DRIVE (D)

This range should be used for most city and highway

driving. It provides the smoothest upshifts and down-

shifts, and the best fuel economy. The transmission

automatically upshifts through underdrive first, second,

and third gears, direct fourth gear and overdrive fifth and

sixth gears. The DRIVE position provides optimum driv-

ing characteristics under all normal operating conditions.

When frequent transmission shifting occurs (such as

when operating the vehicle under heavy loading condi-

tions, in hilly terrain, traveling into strong head winds, or

while towing heavy trailers), use the Electronic Range

Select (ERS) shift control (refer to “Electronic Range

Select (ERS) Operation” in this section for further infor-

mation) to select a lower gear range. Under these condi-

tions, using a lower gear range will improve performance

and extend transmission life by reducing excessive shift-

ing and heat buildup.

4

STARTING AND OPERATING 237

Page 245 of 347

WARNING!

Do not use the “TOW/HAUL” feature when driving

in icy or slippery conditions. The increased engine

braking could cause the rear wheels to slide, and the

vehicle to swing around with the possible loss of

vehicle control, which could cause an accident possi-

bly resulting in personal injury or death.

Torque Converter Clutch

A feature designed to improve fuel economy has been

included in the automatic transmission on your vehicle.

A clutch within the torque converter engages automati-

cally at calibrated speeds. This may result in a slightly

different feeling or response during normal operation in

the upper gears. When the vehicle speed drops or during

some accelerations, the clutch automatically disengages.NOTE:

•

The torque converter clutch will not engage (and 68RFE-

equipped trucks will not shift to sixth gear), until the

transmission fluid and engine coolant are warm [usually

after 1 to 3 miles (2 to 5 km) of driving]. Because the

engine speed is higher when the torque converter clutch

is not engaged, it may seem as if the transmission is not

shifting properly when cold. This is normal. Using the

Electronic Range Select (ERS) shift control, when the

transmission is sufficiently warm, will demonstrate that

the transmission is able to shift into and out of Overdrive.

•If the vehicle has not been driven for several days, the

first few seconds of operation after shifting the transmis-

sion into gear may seem sluggish. This is due to the fluid

partially draining from the torque converter into the

transmission. This condition is normal and will not

cause damage to the transmission. The torque converter

will refill within five seconds after starting the engine.

4

STARTING AND OPERATING 243

Page 247 of 347

Truck models with manual transmission are equipped

with a clutch interlocking ignition system. The clutch

pedal must be fully pressed to start the vehicle.

Fully press the clutch pedal before shifting gears. As you

release the clutch pedal, lightly press the accelerator

pedal.

This transmission has a “creeper” first gear which should

be used to start from a standing position when carrying a

payload or towing a trailer. Damage to the clutch can result

from starting in second or third gear with a loaded vehicle.

An unloaded vehicle may be launched in second gear. Use

each gear in numerical order – do not skip a gear.

NOTE:When loaded, pulling a trailer or on a grade, the

truck should always start in first gear and not skip gears.

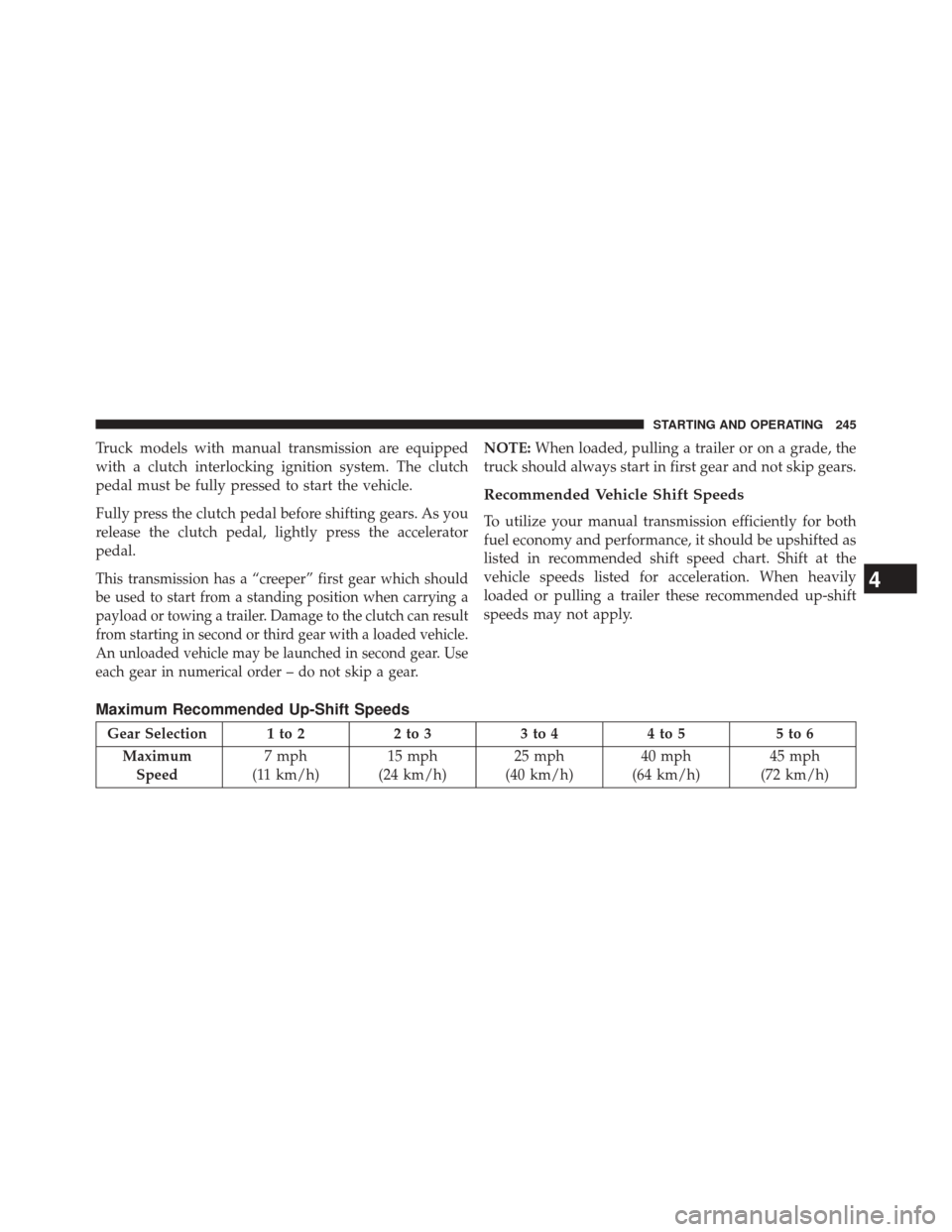

Recommended Vehicle Shift Speeds

To utilize your manual transmission efficiently for both

fuel economy and performance, it should be upshifted as

listed in recommended shift speed chart. Shift at the

vehicle speeds listed for acceleration. When heavily

loaded or pulling a trailer these recommended up-shift

speeds may not apply.

Maximum Recommended Up-Shift Speeds

Gear Selection 1 to 2 2 to 33 to 44 to 5 5 to 6

Maximum Speed 7 mph

(11 km/h) 15 mph

(24 km/h) 25 mph

(40 km/h) 40 mph

(64 km/h) 45 mph

(72 km/h)

4

STARTING AND OPERATING 245

Page 254 of 347

WARNING!

In case of engine runaway due to flammable fumes

from fuel spills or turbocharger oil leaks being

sucked into the engine, do the following to help

avoid personal injury and/or vehicle damage:

1. Turn the ignition switch to the OFF position.

2. Using a CO2 or dry chemical type fire extinguisher,

direct the spray from the fire extinguisher into the

grille on the passenger side so that the spray enters

the engine air intake.

The inlet for the engine air intake is located behind

the passenger side headlamp and receives air

through the grille.

FUEL REQUIREMENTS

Use good quality diesel fuel from a reputable supplier in

your vehicle. Federal law requires that you must fuel this

vehicle with Ultra Low Sulfur Highway Diesel fuel (15

ppm Sulfur maximum) and prohibits the use of Low

Sulfur Highway Diesel fuel (500 ppm Sulfur maximum)

to avoid damage to the emissions control system.

For most year-round service, No. 2 diesel fuel meeting

ASTM (formerly known as the American Society for

Testing and Materials) specification D-975 Grade S15 will

provide good performance. If the vehicle is exposed to

extreme cold (below 20°F or -7°C), or is required to

operate at colder-than-normal conditions for prolonged

periods, use climatized No. 2 diesel fuel or dilute the No.

2 diesel fuel with 50% No. 1 diesel fuel. This will provide

better protection from fuel gelling or wax-plugging of the

fuel filters.

252 STARTING AND OPERATING

Page 255 of 347

WARNING!

Do not use alcohol or gasoline as a fuel blending

agent. They can be unstable under certain conditions

and hazardous or explosive when mixed with diesel

fuel.

Diesel fuel is seldom completely free of water. To prevent

fuel system trouble, drain the accumulated water from

the fuel/water separator using the fuel/water separator

drain provided on both fuel filters. If you buy good

quality fuel and follow the cold weather advice above,

fuel conditioners should not be required in your vehicle.

If available in your area, a high cetane “premium” diesel

fuel may offer improved cold-starting and warm-up

performance.

CAUTION!

If the “Water in Fuel Indicator Light” remains on, DO

NOT START engine before you drain the water from

the fuel filter(s) to avoid engine damage. Refer to

“Maintenance Procedures/Draining Fuel/Water Sepa-

rator Filter” in “Maintaining Your Vehicle” for fur-

ther information.

Fuel Specifications

The Cummins® diesel engine has been developed to take

advantage of the high energy content and generally

lower cost No. 2 Ultra Low Sulfur diesel fuel or No. 2

Ultra Low Sulfur climatized diesel fuels. Experience has

shown that it also operates on No. 1 Ultra Low Sulfur

diesel fuels or other fuels within specification.

4

STARTING AND OPERATING 253

Page 256 of 347

NOTE:

•If you accidentally fill the fuel tank with gasoline on

your diesel vehicle, Do not start the vehicle. If you

restart your vehicle you risk damaging the engine and

fuel system. Please call your local dealer for service.

• A maximum blend of 5% biodiesel meeting ASTM

specification D-975 may be used with your Cummins®

diesel engine. (Chassis Cab models not configured

with B20 capability.)

• A maximum blend of 20% biodiesel meeting ASTM

specification D-7467 may be used with your Cum-

mins® diesel engine. (Pickup models and Chassis Cab

models configured with B20 Capability.)

• In addition, commercially available fuel additives are

not necessary for the proper operation of your Cum-

mins® diesel engine. However, if seasonably adjusted

fuel is not available and you are operating below 20°F (-6°C), Mopar® Premium Diesel Fuel Treatment (or

equivalent) may be beneficial to avoid fuel gelling.

• No. 1 Ultra Low Sulfur diesel fuel should only be used

where extended arctic conditions (-10°F or -23°C) exist.

Bio-Diesel Fuel Requirements

Chassis Cab Models

A maximum blend of 5% biodiesel meeting ASTM speci-

fication D975 may be used with your Cummins diesel

engine. If operation with Biodiesel blends greater than

5% but not greater than 20% (B6-B20) is desired, the truck

must first be reconfigured by an authorized Ram dealer

and the provisions in the following section must be

adhered to.

254 STARTING AND OPERATING

Page 257 of 347

Pickup Models And Chassis Cab Models Ordered

With B20 Option

Your vehicle has been validated and approved for the use

of Biodiesel in blends up to 20% (B20) provided that you

comply with the requirements outlined below. It is im-

portant that you understand and comply with these

requirements. Failure to comply with Oil Change require-

ments for vehicles operating on biodiesel blends up to

B20 will result in premature engine wear. Such wear is

not covered by the New Vehicle Limited Warranty.

Biodiesel is a fuel produced from renewable resources

typically derived from animal fat, rapeseed oil (Rapeseed

Methyl Ester (RME) base), or soybean oil (Soy Methyl

Ester (SME or SOME) base). Biodiesel fuel has inherent

limitations which require that you understand and ad-

here to the following requirements if you use blends of

Biodiesel greater then 5% but not greater than 20%

(B6-B20). There are no unique restrictions for the use ofB5. Use of blends greater than 20% is not approved. Use

of blends greater than 20% can result in engine damage.

Such damage is not covered by the New Vehicle Limited

Warranty.

Fuel Quality — Must Comply With ASTM

Standards

The quality of Biodiesel fuel may vary widely. Only fuel

produced by a BQ9000 supplier to the following specifi-

cations may be blended to meet Biodiesel blend (B6–B20)

fuel meeting ASTM specification D-7467:

•

Pretrodiesel fuel meeting ASTM specification D-975

and Biodiesel fuel (B100) meeting ASTM specification

D-6751.

Fuel Oxidation Stability — Must Use Fuel Within

Six Months Of Manufacture

Biodiesel fuel has poor oxidation stability which can

result in long term storage problems. Fuel produced to

4

STARTING AND OPERATING 255

Page 258 of 347

approved ASTM standards, if stored properly, provides

for protection against fuel oxidation for up to six months.

Fuel Water Separation — Must Use MOPAR®/

Cummins® Approved Fuel Filter Elements

You must use MOPAR®/Cummins® approved fuel filter

elements in both your engine mounted filter and frame

mounted filter.

Biodiesel fuel has a natural affinity to water and water

accelerates microbial growth. Your MOPAR®/

Cummins® filtration system is designed to provide ad-

equate fuel water separation capabilities.

Bio-Diesel Fuel Properties — Low Ambient

Temperatures

Biodiesel fuel may gel or solidify at low ambient tem-

peratures, which may pose problems for both storage and

operation. Precautions can be necessary at low ambienttemperatures, such as storing the fuel in a heated build-

ing or a heated storage tank, or using cold temperature

additives.

Fuel In Oil Dilution — Must Adhere To Required

Oil Change Interval

Fuel dilution of lubricating oil has been observed with

the use of Biodiesel fuel. Fuel in oil must not exceed 5%.

To ensure this limit is met your oil change interval must

be maintained to the following schedule:

•

Ram PickUp 2500/3500 Only — 15,000 Miles*

• Ram 3500/4500/5500 Chassis Cab — 12,500 Miles*

(*unless otherwise notified with a oil service message)

256 STARTING AND OPERATING

Page 259 of 347

CAUTION!

•Under no circumstances should oil change inter-

vals exceed 15,000 miles (24 000 km) pickup or

12,500 miles (20 000 km) chassis cab if operation

occurs with greater than 5% biodiesel blends. Oil

change intervals should not exceed 6 months in

either case. Failure to comply with these Oil

Change requirements for vehicles operating on

biodiesel blends up to B20 may result in premature

engine wear. Such wear is not covered by the New

Vehicle Limited Warranty.

• B20 Biodiesel capable: The engine may suffer se-

vere damage if operated with concentrations of

Biodiesel higher than 20%.

ADDING FUEL — 2500/3500 DIESEL MODELS

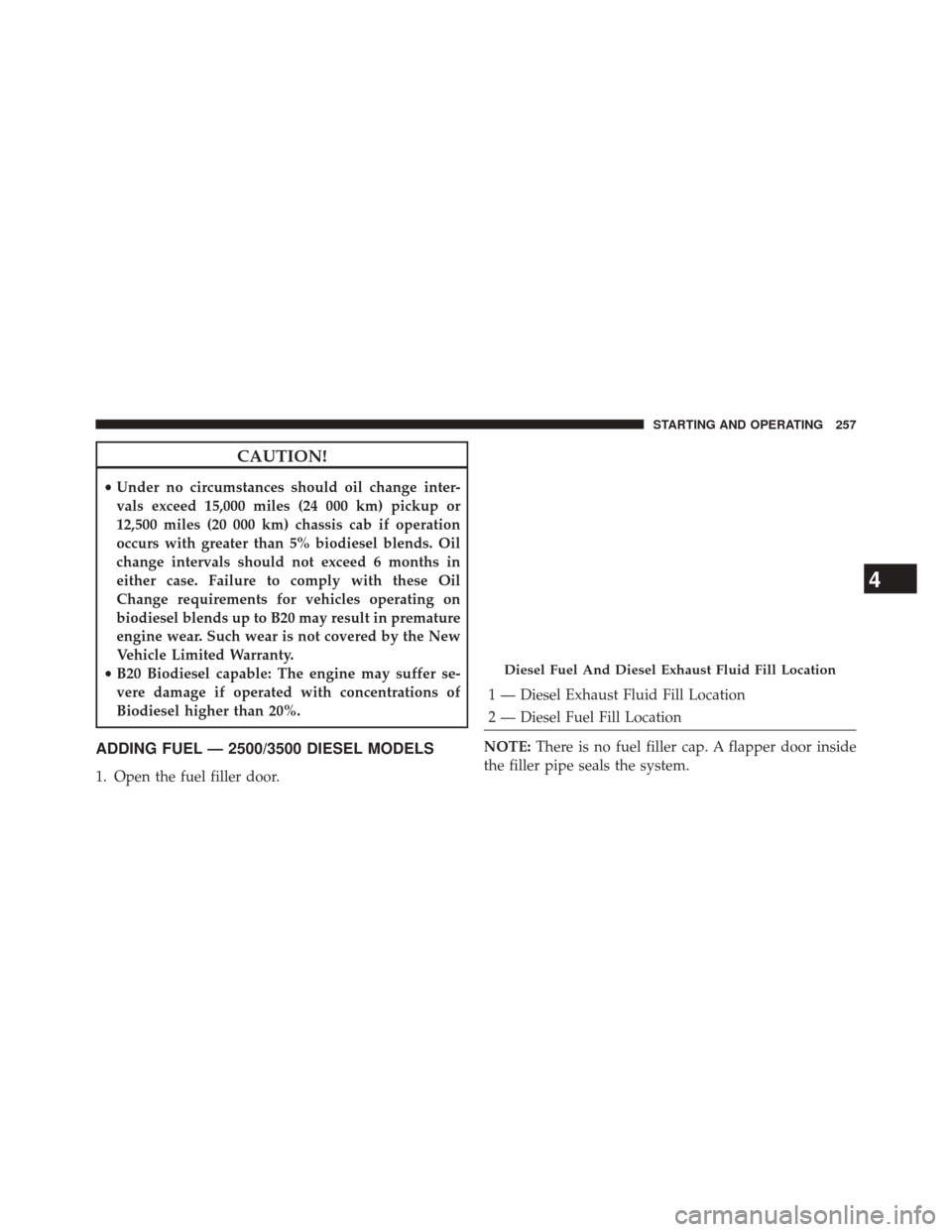

1. Open the fuel filler door.

1 — Diesel Exhaust Fluid Fill Location

2 — Diesel Fuel Fill Location

NOTE: There is no fuel filler cap. A flapper door inside

the filler pipe seals the system.

Diesel Fuel And Diesel Exhaust Fluid Fill Location

4

STARTING AND OPERATING 257

Page 260 of 347

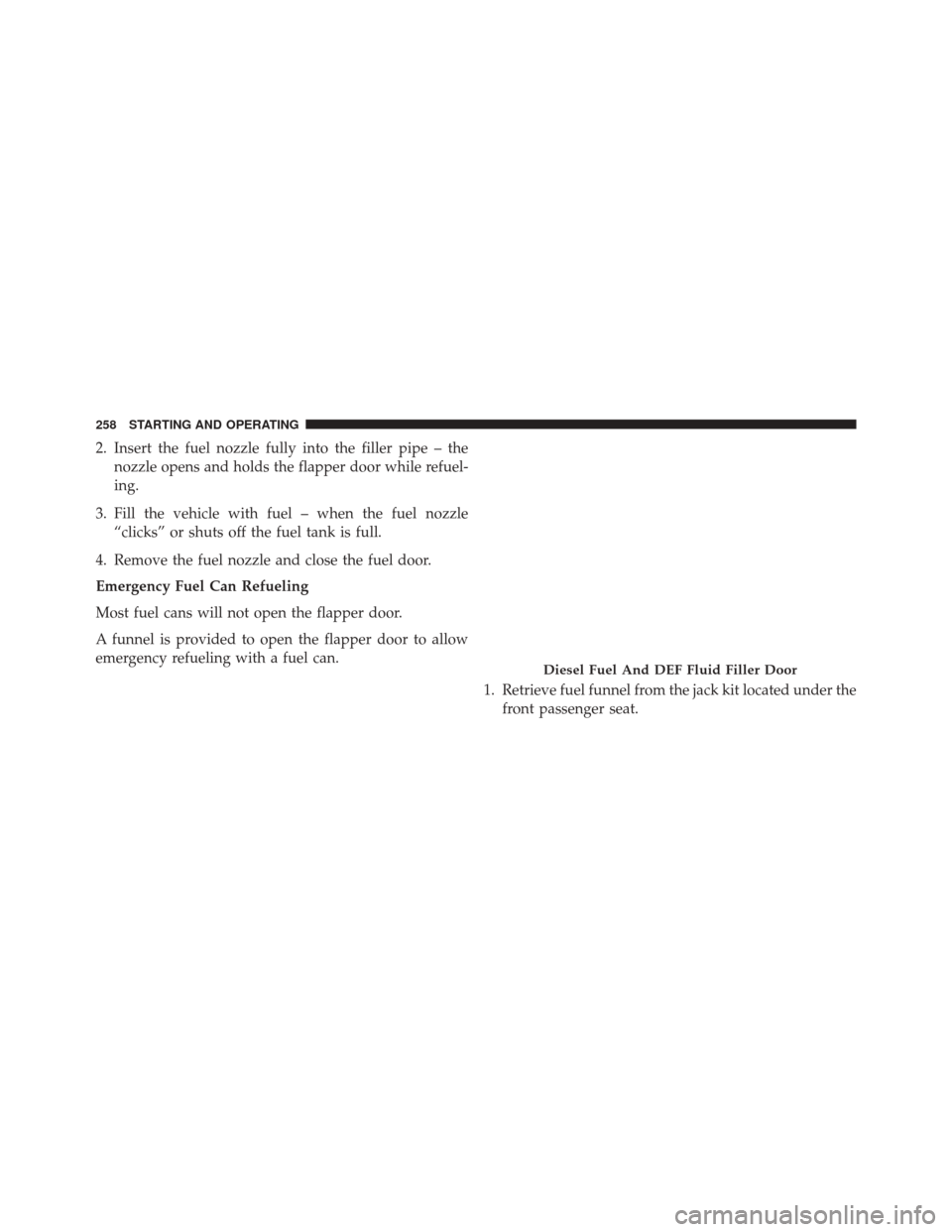

2. Insert the fuel nozzle fully into the filler pipe – thenozzle opens and holds the flapper door while refuel-

ing.

3. Fill the vehicle with fuel – when the fuel nozzle “clicks” or shuts off the fuel tank is full.

4. Remove the fuel nozzle and close the fuel door.

Emergency Fuel Can Refueling

Most fuel cans will not open the flapper door.

A funnel is provided to open the flapper door to allow

emergency refueling with a fuel can.

1. Retrieve fuel funnel from the jack kit located under thefront passenger seat.

Diesel Fuel And DEF Fluid Filler Door

258 STARTING AND OPERATING