fuel cap Ram 1500 2015 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: 1500, Model: Ram 1500 2015Pages: 347, PDF Size: 2.02 MB

Page 263 of 347

WARNING!

A fire may result if fuel is pumped into a portable

container that is on a truck bed. You could be burned.

Always place fuel containers on the ground while

filling.

Fuel Filler Cap

If the fuel filler cap is lost or damaged, be sure the

replacement cap is for use with this vehicle.

CAUTION!

Damage to the fuel system or emission control sys-

tem could result from using an improper fuel tank

filler tube cap. A poorly fitting cap could let impuri-

ties into the fuel system.

WARNING!

•Never have any smoking materials lit in or near the

vehicle when the fuel filler cap is removed or the

tank filled.

• Never add fuel to the vehicle when the engine is

running.

Avoid Using Contaminated Fuel

Fuel that is contaminated by water or dirt can cause

severe damage to the engine fuel system. Proper main-

tenance of the engine fuel filter and fuel tank is essential.

Refer to “Maintenance Procedures” in “Maintaining Your

Vehicle” for further information.

Bulk Fuel Storage — Diesel Fuel

If you store quantities of fuel, good maintenance of the

stored fuel is also essential. Fuel contaminated with

water will promote the growth of “microbes.” These

4

STARTING AND OPERATING 261

Page 265 of 347

Adding Diesel Exhaust Fluid

The DEF gauge (located on the instrument cluster) will

display the level of DEF remaining in the tank. Refer to

“Instrument Cluster” and “Instrument Cluster Descrip-

tions” in “Understanding Your Instrument Panel” for

further information.

NOTE:Driving conditions (altitude, vehicle speed, load,

etc.) will effect the amount of DEF that is used in your

vehicle.

DEF Fill Procedure

NOTE: Refer to “Fluids, Lubricants, and Genuine Parts”

in “Maintaining Your Vehicle” for the correct fluid type.

1. Remove cap from DEF tank (located on drivers side of the vehicle or in fuel door).DEF Filler Cap Chassis Cab Models

4

STARTING AND OPERATING 263

Page 266 of 347

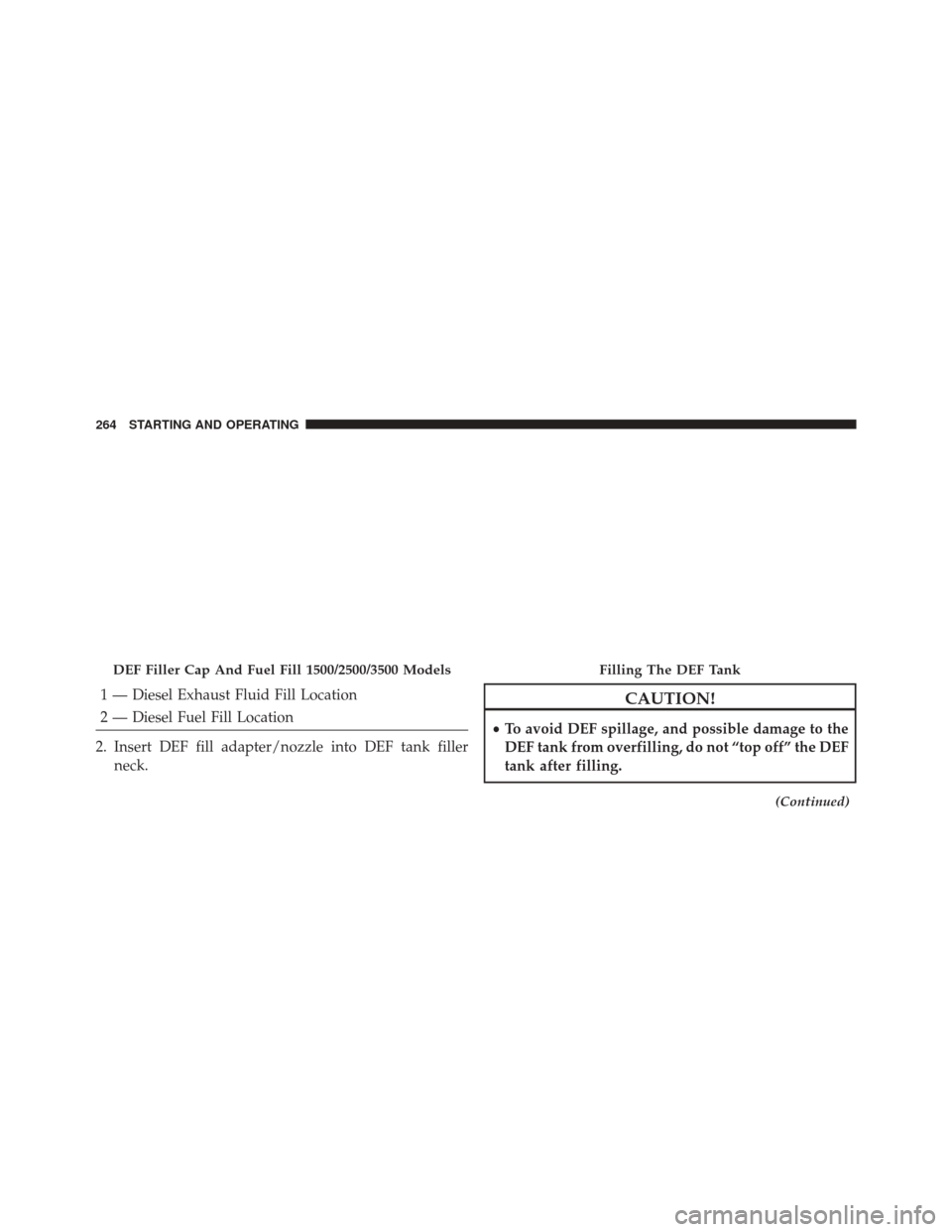

1 — Diesel Exhaust Fluid Fill Location

2 — Diesel Fuel Fill Location

2. Insert DEF fill adapter/nozzle into DEF tank filler neck.CAUTION!

•To avoid DEF spillage, and possible damage to the

DEF tank from overfilling, do not “top off” the DEF

tank after filling.

(Continued)

DEF Filler Cap And Fuel Fill 1500/2500/3500 ModelsFilling The DEF Tank

264 STARTING AND OPERATING

Page 267 of 347

CAUTION!(Continued)

•DO NOT OVERFILL. DEF will freeze below 12ºF

(-11ºC). The DEF system is designed to work in

temperatures below the DEF freezing point, how-

ever, if the tank is overfilled and freezes, the

system could be damaged.

• When DEF is spilled, clean the area immediately

with water and use an absorbent material to soak

up the spills on the ground.

• Do not attempt to start your engine if DEF is

accidentally added to the diesel fuel tank as it can

result in severe damage to your engine, including

but not limited to failure of the fuel pump and

injectors.

3. Stop filling the DEF tank immediately when any of the following happen: DEF stops flowing from the fill

bottle into the DEF tank, DEF splashes out the filler

neck, or a DEF pump nozzle automatically shuts off. 4. Reinstall cap onto DEF tank.

Filling The Def Tank In Cold Climates

Since DEF will begin to freeze at 12°F (-11°C), your vehicle

is equipped with an automatic DEF heating system. This

allows the DEF injection system to operate properly at

temperatures below 12°F (-11°C). If your vehicle is not in

operation for an extended period of time with tempera-

tures below 12°F (-11°C), the DEF in the tank may freeze. If

the tank is overfilled and freezes, it could be damaged.

Therefore, do not overfill the DEF tank.

Extra care should be taken when filling with portable

containers to avoid overfilling. Note the level of the DEF

gauge in your instrument cluster. On pickup applications,

you may safely add a maximum of 2 gallons of DEF from

portable containers when your DEF gauge is reading ½ full.

On Chassis Cab applications a maximum of 2 gallons may

be added when the DEF gauge is reading ¾ full.

4

STARTING AND OPERATING 265

Page 297 of 347

CAUTION!

Due to lack of lubricants in alcohol or gasoline, the

use of these fuels can cause damage to the fuel

system.

NOTE:

• A maximum blend of 5% biodiesel, meeting ASTM

specification D-975 may be used with your Cummins®

diesel engine. (Chassis Cab models not configured

with B20 capability.)

• A maximum blend of 20% biodiesel, meeting ASTM

specification D-7467 may be used with your Cum-

mins® diesel engine. (Pickup models and Chassis Cab

models configured with B20 capability.) •

Use of biodiesel mixture in excess of 20% can nega-

tively impact the fuel filter’s ability to separate water

from the fuel, resulting in high pressure fuel system

corrosion or damage.

• Ethanol blends are not recommended or approved for

use with your Cummins® diesel engine.

• In addition, commercially available fuel additives are

not necessary for the proper operation of your Cum-

mins® diesel engine.

Intervention Regeneration Strategy — Message

Process Flow

The Cummins® diesel engine meets all EPA Heavy Duty

Diesel Engine Emissions Standards, resulting in one of

the lowest emitting diesel engines ever produced.

6

MAINTAINING YOUR VEHICLE 295

Page 317 of 347

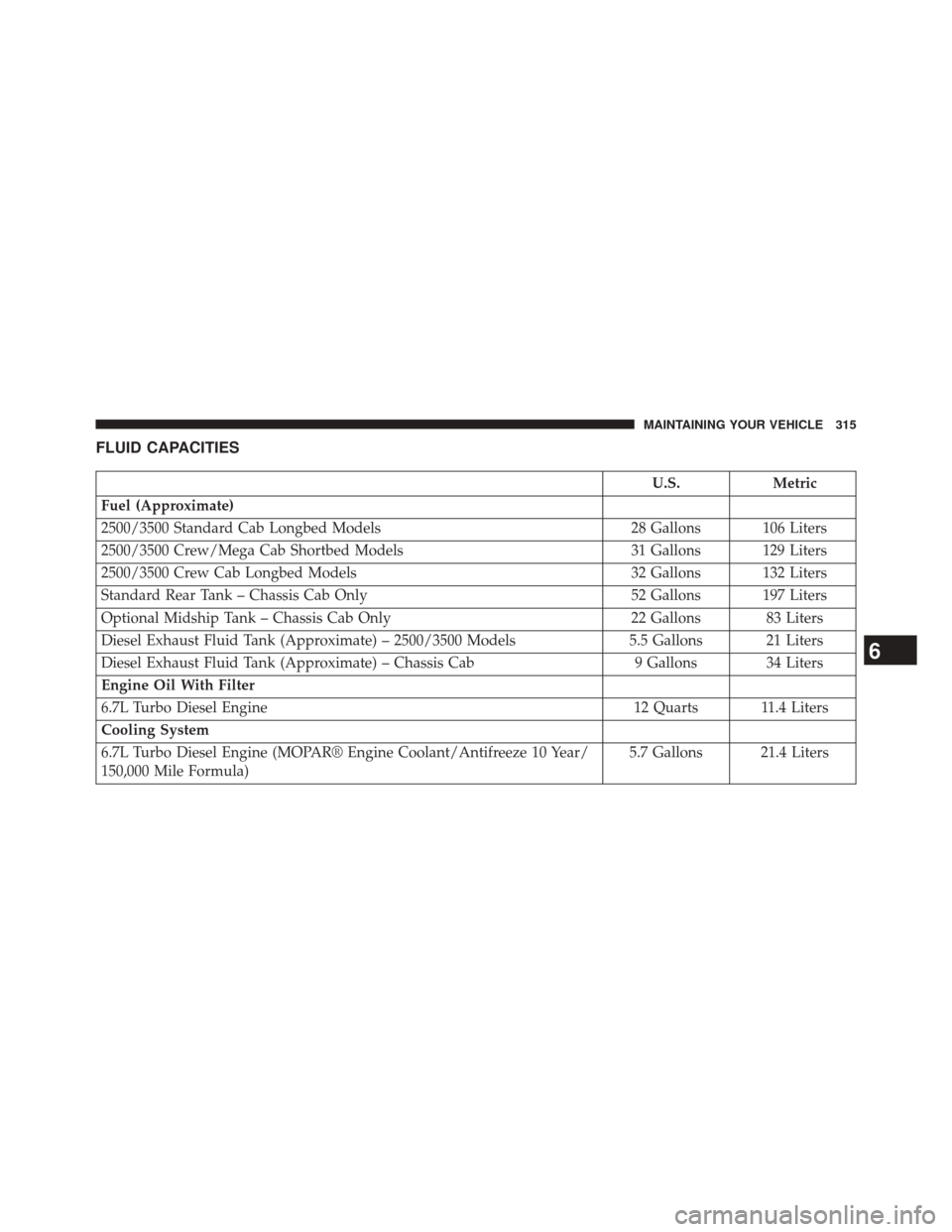

FLUID CAPACITIES

U.S.Metric

Fuel (Approximate)

2500/3500 Standard Cab Longbed Models 28 Gallons 106 Liters

2500/3500 Crew/Mega Cab Shortbed Models 31 Gallons 129 Liters

2500/3500 Crew Cab Longbed Models 32 Gallons 132 Liters

Standard Rear Tank – Chassis Cab Only 52 Gallons 197 Liters

Optional Midship Tank – Chassis Cab Only 22 Gallons 83 Liters

Diesel Exhaust Fluid Tank (Approximate) – 2500/3500 Models 5.5 Gallons 21 Liters

Diesel Exhaust Fluid Tank (Approximate) – Chassis Cab 9 Gallons 34 Liters

Engine Oil With Filter

6.7L Turbo Diesel Engine 12 Quarts 11.4 Liters

Cooling System

6.7L Turbo Diesel Engine (MOPAR® Engine Coolant/Antifreeze 10 Year/

150,000 Mile Formula) 5.7 Gallons 21.4 Liters

6

MAINTAINING YOUR VEHICLE 315

Page 319 of 347

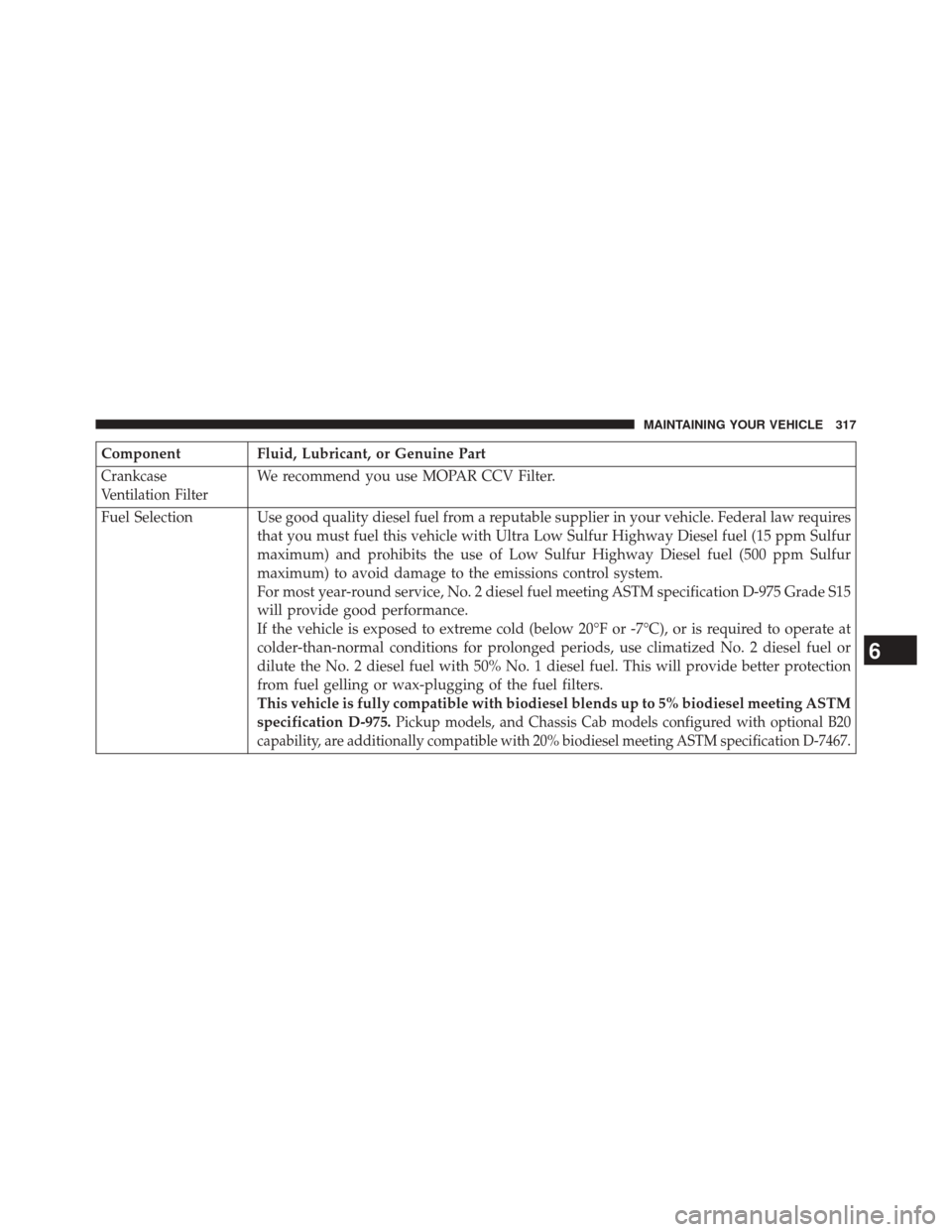

ComponentFluid, Lubricant, or Genuine Part

Crankcase

Ventilation FilterWe recommend you use MOPAR CCV Filter.

Fuel Selection Use good quality diesel fuel from a reputable supplier in your vehicle. Federal law requires that you must fuel this vehicle with Ultra Low Sulfur Highway Diesel fuel (15 ppm Sulfur

maximum) and prohibits the use of Low Sulfur Highway Diesel fuel (500 ppm Sulfur

maximum) to avoid damage to the emissions control system.

For most year-round service, No. 2 diesel fuel meeting ASTM specification D-975 Grade S15

will provide good performance.

If the vehicle is exposed to extreme cold (below 20°F or -7°C), or is required to operate at

colder-than-normal conditions for prolonged periods, use climatized No. 2 diesel fuel or

dilute the No. 2 diesel fuel with 50% No. 1 diesel fuel. This will provide better protection

from fuel gelling or wax-plugging of the fuel filters.

This vehicle is fully compatible with biodiesel blends up to 5% biodiesel meeting ASTM

specification D-975.

Pickup models, and Chassis Cab models configured with optional B20

capability, are additionally compatible with 20% biodiesel meeting ASTM specification D-7467.

6

MAINTAINING YOUR VEHICLE 317

Page 336 of 347

Adding Engine Coolant (Antifreeze)............116

Adding Fuel ..............................91

Air bag Light .............................17

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . .104

Alarm Light ..............................17

Anti-Lock Warning Light .....................17

Antifreeze (Engine Coolant) ..................115

Capacities ........................... .122

Disposal ..............................118

Automatic Transmission Fluid Type ........................... .126

Axle Fluid ............................. .126

Battery .................................113

Brake Fluid ............................ .126

Brake System ........................... .120

Fluid Check .......................... .120

Master Cylinder ....................... .120

Warning Light .......................17,33 Capacities, Antifreeze (Engine Coolant)

..........122

Capacities, Fluid ......................... .122

Caps, Filler Oil (Engine) .......................... .103

Radiator (Coolant Pressure) ................118

Charge Air Cooler ........................ .120

Check Engine Light (Malfunction Indicator Light) . . .17

Coolant Pressure Cap (Radiator Cap) ...........118

Cooling System ...........................114

Adding Coolant (Antifreeze) ...............116

Coolant Capacity ...................... .122

Coolant Level ..........................114

Disposal of Used Coolant ..................118

Drain, Flush, and Refill ...................115

Points to Remember .....................119

Pressure Cap ..........................118

Radiator Cap ..........................118

Selection of Coolant (Antifreeze) .........115,123

334 INDEX - RAM 1500

Page 337 of 347

Diesel Fuel...............................85

Diesel Fuel Requirements ....................85

Bulk Storage of .........................94

Diesel Fuel System, Re-Priming ...............111

Disposal Antifreeze (Engine Coolant) ................118

Draining Fuel/Water Separator Filter ...........107

Electronic Vehicle Information Center (EVIC) ......41

Engine ................................ .100

Air Cleaner .......................... .104

Block Heater ........................78,84

Break-In Recommendations .................13

Compartment ......................... .100

Coolant (Antifreeze) .....................123

Identification ......................... .100

Idling ................................82

Oil............................. .102 , 123

Oil Filler Cap ......................... .103Filters

Air Cleaner .......................... .104

Engine Fuel .......................... .107

Engine Oil ....................... .104 , 123

Engine Oil Disposal .....................104

Flashers Turn Signal .........................17,32

Fluid Capacities ......................... .122

Fluid Level Checks Brake ............................... .120

Fluid, Brake ............................ .126

Fluids, Lubricants and Genuine Parts ...........123

Fog Lights ...............................17

Fuel ...................................85

Adding ...............................91

Diesel ............................85,123

Filter ............................... .107

Requirements ...........................85

Specifications ...........................86

INDEX - RAM 1500 335

Page 338 of 347

Tank Capacity......................... .122

Fueling .................................91

Gauges Speedometer ........................17,35

Tachometer .........................17,30

Voltmeter ..............................80

Information Center, Vehicle ...................41

Instrument Cluster .........................16

Intervention Regeneration Strategy ..............49

Keyless Enter-N-Go ........................77

Lights Airbag .............................17,35

Alarm .............................17,36

Anti-Lock ..........................17,30

Brake Warning .......................17,33 Check Engine (Malfunction Indicator)

......17,30

Fog ...............................17,38

High Beam .........................17,34

High Beam Indicator ..................17,34

Instrument Cluster ....................17,30

Seat Belt Reminder ....................17,35

Security Alarm ...................... .17, 36

Tire Pressure Monitoring (TPMS) .............36

Warning (Instrument Cluster Description) . . . .17 , 30

Maintenance Procedures ....................101

Maintenance Schedule ..................... .128

New Vehicle Break-In Period ..................13

Oil, Engine ............................. .102

Capacity ............................ .122

Change Interval ....................... .103

Dipstick ............................. .102

336 INDEX - RAM 1500