lock Ram 1500 2015 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: 1500, Model: Ram 1500 2015Pages: 871, PDF Size: 24.83 MB

Page 718 of 871

5. Turn the ignition OFF.

Block both the front and rear of the wheel diagonally

opposite the jacking position. For example, if the right

front wheel is being changed, block the left rear wheel.

NOTE:Passengers should not remain

in the vehicle when the vehicle is

being jacked.

Jack Instructions (2500, 3500 Series)

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

(Continued)

WARNING!(Continued)

•Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

•Turn on the Hazard Warning flasher.

•Block the wheel diagonally opposite the wheel to

be raised.

•Set the parking brake firmly and set an automatic

transmission in PARK; a manual transmission in

REVERSE.

•Never start or run the engine with the vehicle on a

jack.

•Do not let anyone sit in the vehicle when it is on a

jack.

•Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

(Continued)

716 WHAT TO DO IN EMERGENCIES

Page 720 of 871

1. Remove the spare wheel, jack, and tools from storage.

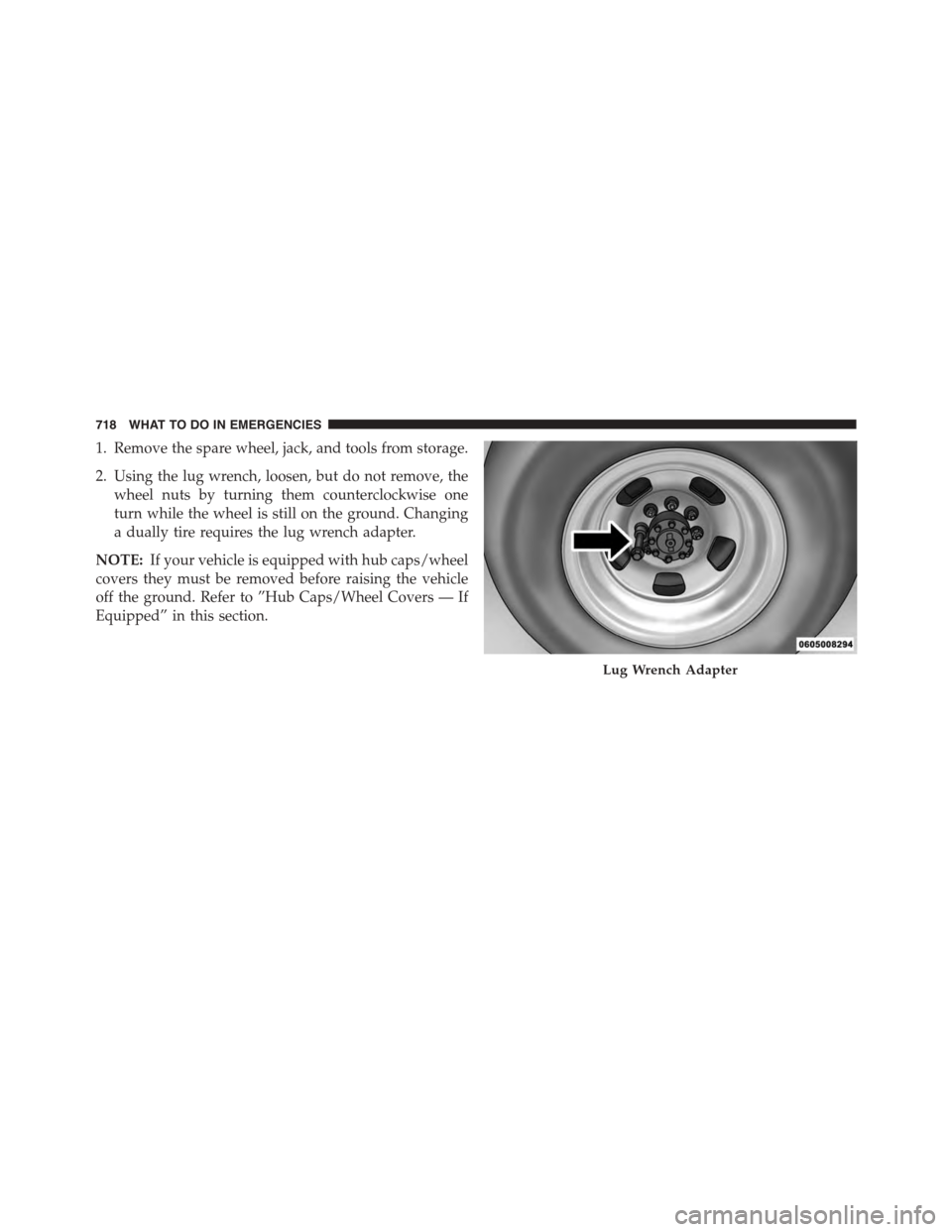

2. Using the lug wrench, loosen, but do not remove, the

wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground. Changing

a dually tire requires the lug wrench adapter.

NOTE:If your vehicle is equipped with hub caps/wheel

covers they must be removed before raising the vehicle

off the ground. Refer to ”Hub Caps/Wheel Covers — If

Equipped” in this section.

Lug Wrench Adapter

718 WHAT TO DO IN EMERGENCIES

Page 722 of 871

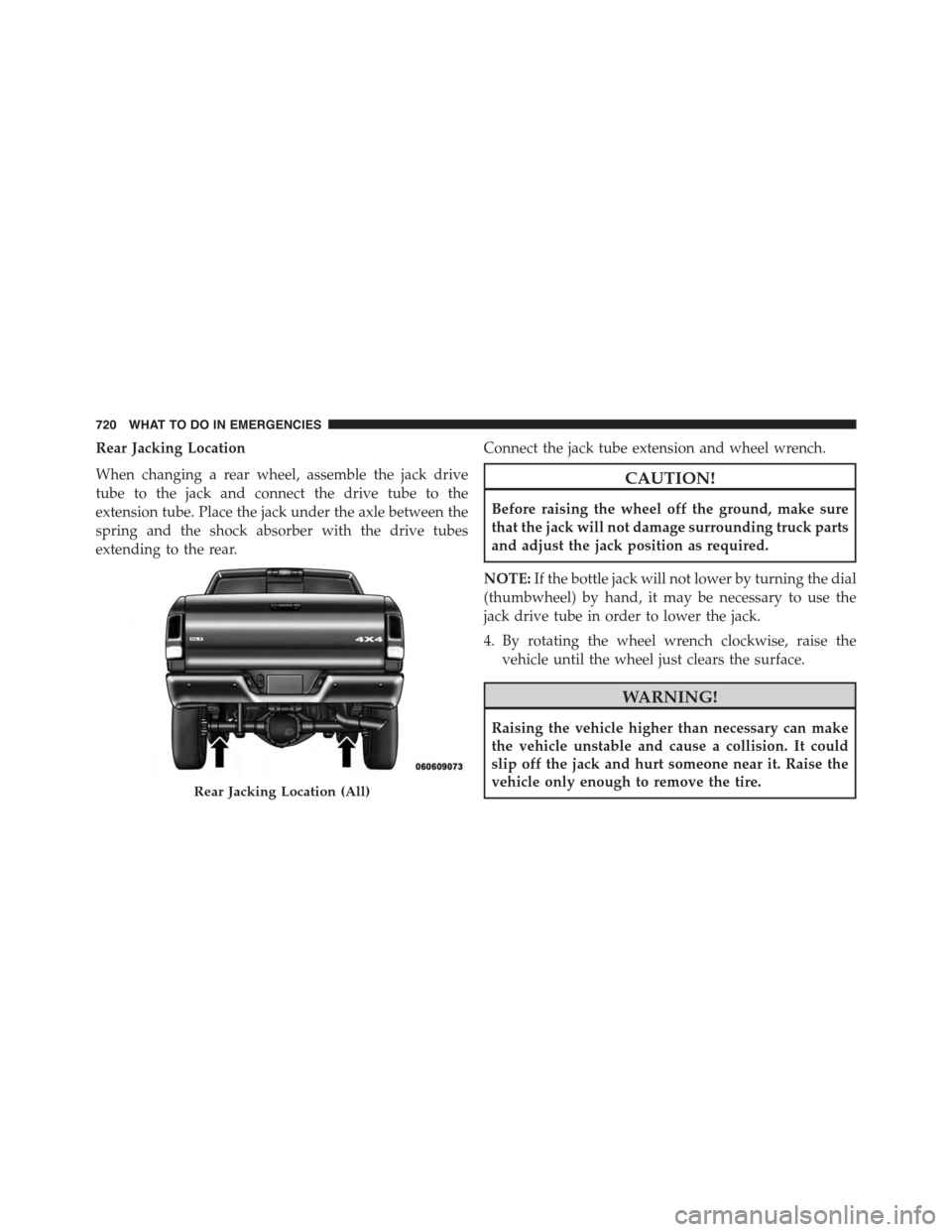

Rear Jacking Location

When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle between the

spring and the shock absorber with the drive tubes

extending to the rear.

Connect the jack tube extension and wheel wrench.

CAUTION!

Before raising the wheel off the ground, make sure

that the jack will not damage surrounding truck parts

and adjust the jack position as required.

NOTE:If the bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to use the

jack drive tube in order to lower the jack.

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause a collision. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.Rear Jacking Location (All)

720 WHAT TO DO IN EMERGENCIES

Page 724 of 871

6. Finish tightening the lug nuts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. For the correct lug

nut torque refer to “Torque Specifications” in this

section. If in doubt about the correct tightness, have

them checked with a torque wrench by you authorized

dealer or service station.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack parts and the extra tire and wheel

in the places provided.

7. Install the wheel center cap and remove the wheel

blocks. Do not install chrome or aluminum wheel

center caps on the spare wheel. This may result in cap

damage.

8. Lower the jack to its fully closed position. Stow the

replaced tire, jack, and tools as previously described.

NOTE:If the bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to use the

jack drive tube in order to lower the jack.

Dual Rear Wheel Placement

722 WHAT TO DO IN EMERGENCIES

Page 727 of 871

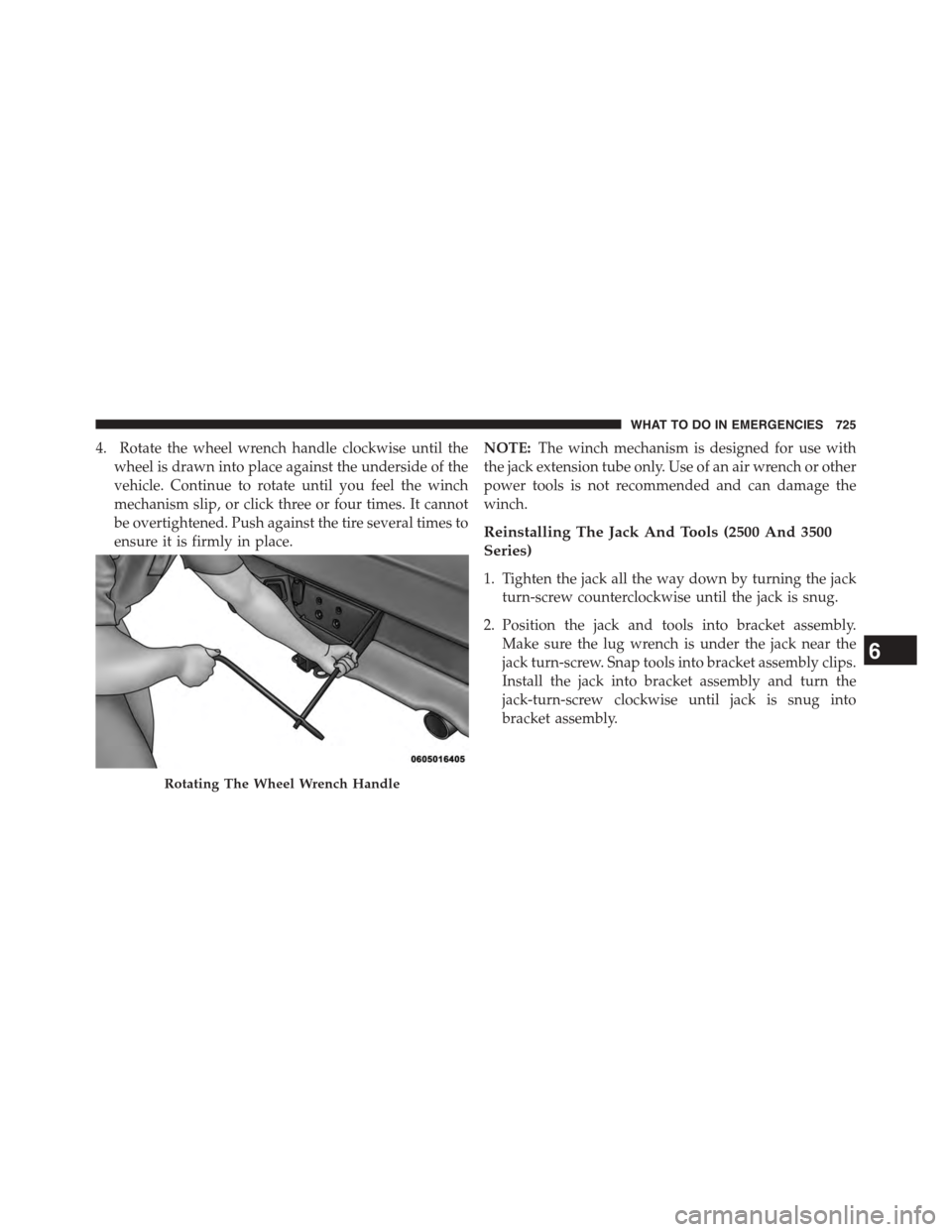

4. Rotate the wheel wrench handle clockwise until the

wheel is drawn into place against the underside of the

vehicle. Continue to rotate until you feel the winch

mechanism slip, or click three or four times. It cannot

be overtightened. Push against the tire several times to

ensure it is firmly in place.

NOTE:The winch mechanism is designed for use with

the jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

Reinstalling The Jack And Tools (2500 And 3500

Series)

1. Tighten the jack all the way down by turning the jack

turn-screw counterclockwise until the jack is snug.

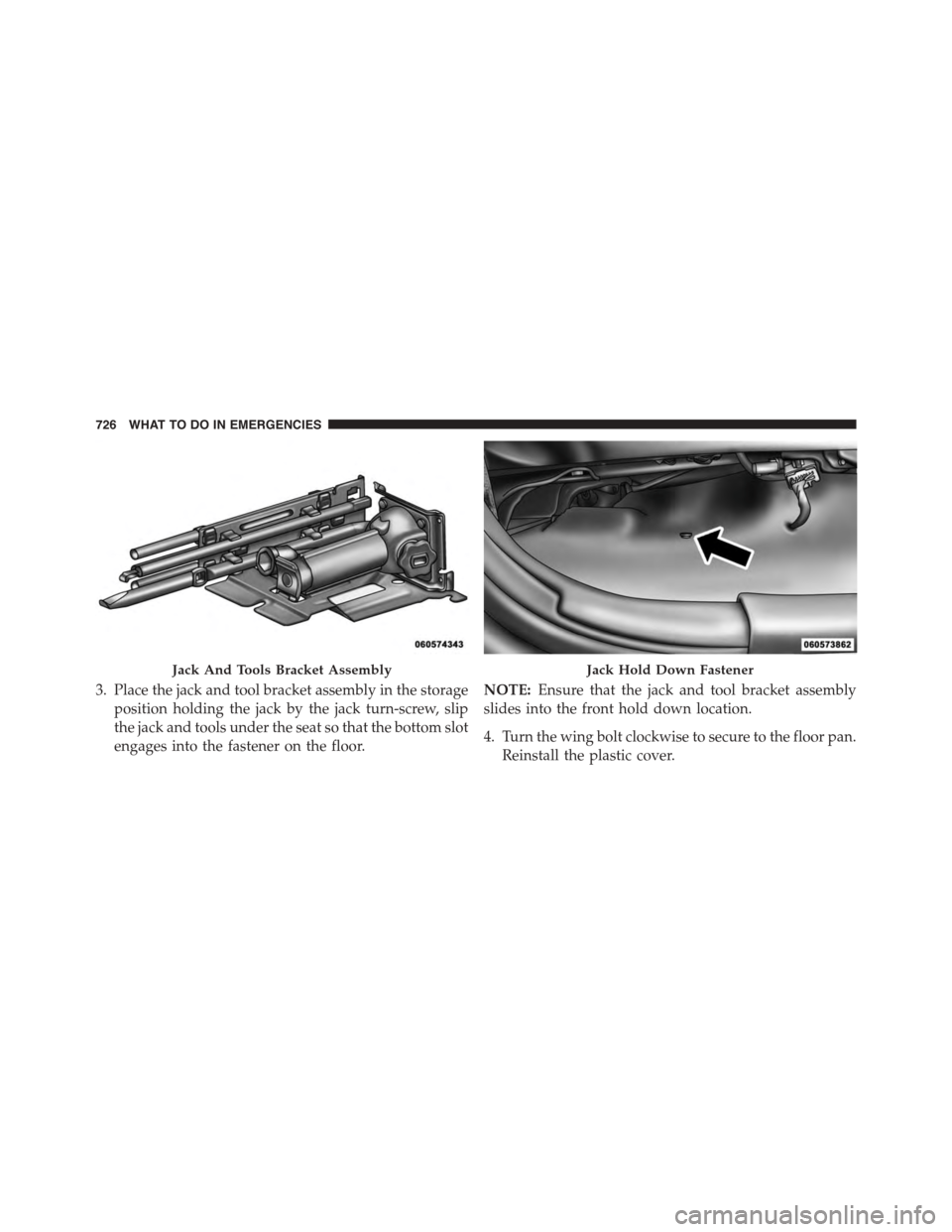

2. Position the jack and tools into bracket assembly.

Make sure the lug wrench is under the jack near the

jack turn-screw. Snap tools into bracket assembly clips.

Install the jack into bracket assembly and turn the

jack-turn-screw clockwise until jack is snug into

bracket assembly.

Rotating The Wheel Wrench Handle

6

WHAT TO DO IN EMERGENCIES 725

Page 728 of 871

3. Place the jack and tool bracket assembly in the storage

position holding the jack by the jack turn-screw, slip

the jack and tools under the seat so that the bottom slot

engages into the fastener on the floor.

NOTE:Ensure that the jack and tool bracket assembly

slides into the front hold down location.

4. Turn the wing bolt clockwise to secure to the floor pan.

Reinstall the plastic cover.

Jack And Tools Bracket AssemblyJack Hold Down Fastener

726 WHAT TO DO IN EMERGENCIES

Page 733 of 871

WARNING!

•Take care to avoid the radiator cooling fan when-

ever the hood is raised. It can start anytime the

ignition switch is ON. You can be injured by

moving fan blades.

•Remove any metal jewelry such as rings, watch

bands and bracelets that could make an inadvertent

electrical contact. You could be seriously injured.

•Batteries contain sulfuric acid that can burn your

skin or eyes and generate hydrogen gas which is

flammable and explosive. Keep open flames or

sparks away from the battery.

1. Set the parking brake, shift the automatic transmission

into PARK and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electri-

cal accessories.

3. If using another vehicle to jump-start the battery, park

the vehicle within the jumper cables reach, set the

parking brake and make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other as this

could establish a ground connection and personal

injury could result.

Jump-Starting Procedure

WARNING!

Failure to follow this jump-starting procedure could

result in personal injury or property damage due to

battery explosion.

6

WHAT TO DO IN EMERGENCIES 731

Page 741 of 871

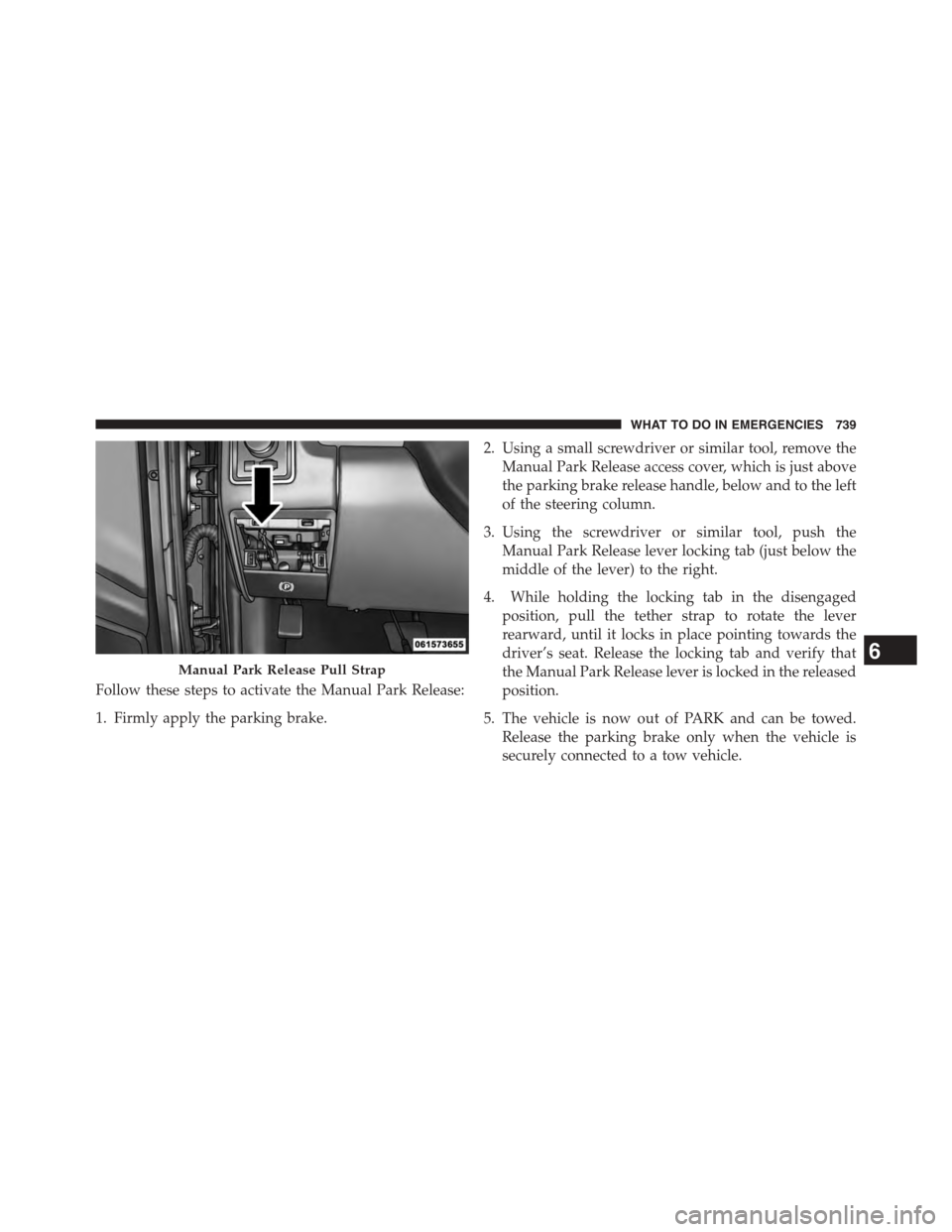

Follow these steps to activate the Manual Park Release:

1. Firmly apply the parking brake.

2. Using a small screwdriver or similar tool, remove the

Manual Park Release access cover, which is just above

the parking brake release handle, below and to the left

of the steering column.

3. Using the screwdriver or similar tool, push the

Manual Park Release lever locking tab (just below the

middle of the lever) to the right.

4. While holding the locking tab in the disengaged

position, pull the tether strap to rotate the lever

rearward, until it locks in place pointing towards the

driver’s seat. Release the locking tab and verify that

the Manual Park Release lever is locked in the released

position.

5. The vehicle is now out of PARK and can be towed.

Release the parking brake only when the vehicle is

securely connected to a tow vehicle.

Manual Park Release Pull Strap6

WHAT TO DO IN EMERGENCIES 739

Page 742 of 871

To Reset The Manual Park Release:

1. Push the locking tab to the right, to unlock the lever.

2. Rotate the Manual Park Release lever forward to its

original position, until the locking tab snaps into place

to secure the lever.

3. Pull gently on the tether strap to confirm that the lever

is locked in its stowed position.

4. Re-install the access cover.

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial wrecker service. If the trans-

mission and drivetrain are operable, disabled vehicles

may also be towed as described under “Recreational

Towing” in the “Starting and Operating” section.

NOTE:Vehicles equipped with air suspension must be

placed in Transport mode, before tying them down (from

the body) on a trailer or flatbed truck. Refer to#Air

Suspension#in#Starting and Operating#for more infor-

mation. If the vehicle cannot be placed in Transport mode

(for example, engine will not run), tie-downs must be

fastened to the axles (not to the body). Failure to follow

these instructions may cause fault codes to be set and/or

cause loss of proper tie-down tension.

740 WHAT TO DO IN EMERGENCIES

Page 764 of 871

Engine Air Cleaner Filter Installation

NOTE:Inspect and clean the housing if dirt or debris is

present before replacing the air filter element.

1. Install the air cleaner filter element into the housing

assembly with the air cleaner filter inspection surface

facing downward.

2. Install the air cleaner cover onto the housing assembly

locating tabs.

3. Latch the spring clips and lock the air cleaner cover to

the housing assembly.

Accessory Drive Belt Inspection

WARNING!

•Do not attempt to inspect an accessory drive belt

with vehicle running.

(Continued)

WARNING!(Continued)

•When working near the radiator cooling fan, dis-

connect the fan motor lead. The fan is temperature

controlled and can start at any time regardless of

ignition switch position. You could be injured by

the moving fan blades.

•You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent me-

chanic.

When inspecting accessory drive belts, small cracks that

run across ribbed surface of belt from rib to rib, are

considered normal. These are not a reason to replace belt.

However, cracks running along a rib (not across) are not

762 MAINTAINING YOUR VEHICLE