power steering Ram 1500 2015 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: 1500, Model: Ram 1500 2015Pages: 871, PDF Size: 24.83 MB

Page 652 of 871

Frontal Area

The frontal area is the maximum height multiplied by the

maximum width of the front of a trailer.

Trailer Sway Control

The trailer sway control can be a mechanical telescoping

link that can be installed between the hitch receiver and

the trailer tongue that typically provides adjustable fric-

tion associated with the telescoping motion to dampen

any unwanted trailer swaying motions while traveling.

If equipped, the electronic Trailer Sway Control (TSC)

recognizes a swaying trailer and automatically applies

individual wheel brakes and/or reduces engine power to

attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue weight,

just as if it were luggage located at a hitch ball or some other

connecting point of the vehicle. These kinds of hitches are

the most popular on the market today and they are com-

monly used to tow small and medium sized trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying lever-

age through spring (load) bars. They are typically used

for heavier loads to distribute trailer tongue weight to the

tow vehicle’s front axle and the trailer axle(s). When used

in accordance with the manufacturer’s directions, it pro-

vides for a more level ride, offering more consistent

steering and brake control, thereby enhancing towing

safety. The addition of a friction/hydraulic sway control

also dampens sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer stability.

Trailer sway control and a weight distributing (load

equalizing) hitch are recommended for heavier Tongue

Weights (TW) and may be required depending on vehicle

and trailer configuration/loading to comply with GAWR

requirements.

650 STARTING AND OPERATING

Page 665 of 871

sliding the manual brake control lever will display the

GAIN setting for 10 seconds and the “Trailer Brake Status

Indicator Light” will not be displayed.

If a fault is detected in the trailer wiring or the Integrated

Trailer Brake Module (ITBM), the “Trailer Brake Status

Indicator Light” will flash.

GAIN Adjustment Buttons (+/-)

Pressing these buttons will adjust the brake control

power output to the trailer brakes in 0.5 increments. The

GAIN setting can be increased to a maximum of 10 or

decreased to a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer brake control

for the specific towing condition and should be changed

as towing conditions change. Changes to towing condi-

tions include trailer load, vehicle load, road conditions

and weather.

Adjusting GAIN

NOTE:This should only be performed in a traffic free

environment at speeds of approximately 20–25 mph

(30–40 km/h).

1. Make sure the trailer brakes are in good working

condition, functioning normally and properly ad-

justed. See your trailer dealer if necessary.

2.Hook up the trailer and make the electrical connections

according to the trailer manufacturer’s instructions.

3. When a trailer with electric/EOH brakes is plugged

in, the trailer connected message should appear in the

EVIC/DID (if the connection is not recognized by the

ITBM, braking functions will not be available), the

GAIN setting will illuminate and the correct type of

trailer must be selected from the EVIC/DID options.

4. Press the UP or DOWN button on the steering wheel

until “TRAILER TOW” appears on the screen.

5

STARTING AND OPERATING 663

Page 751 of 871

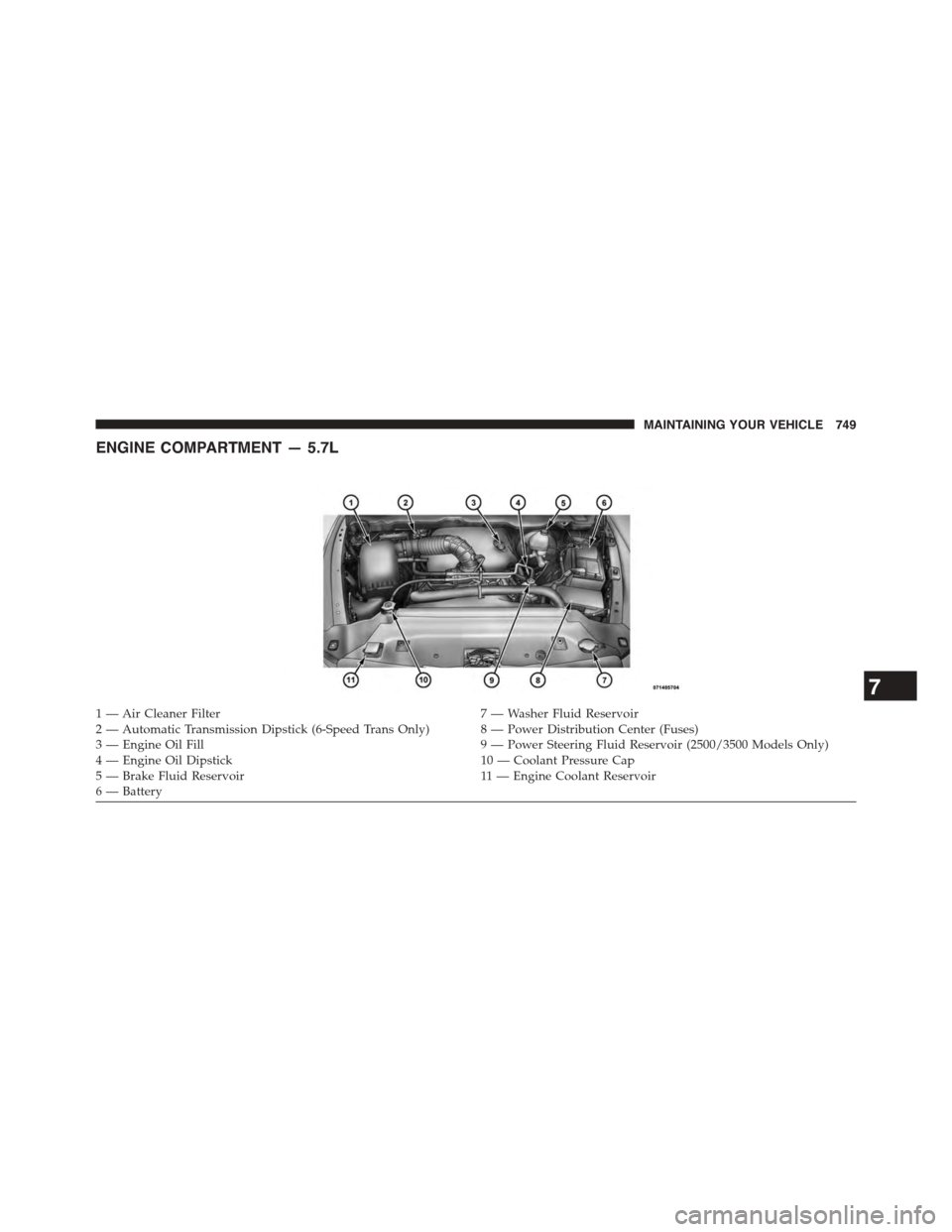

ENGINE COMPARTMENT — 5.7L

1 — Air Cleaner Filter7 — Washer Fluid Reservoir2 — Automatic Transmission Dipstick (6-Speed Trans Only) 8 — Power Distribution Center (Fuses)3 — Engine Oil Fill9 — Power Steering Fluid Reservoir (2500/3500 Models Only)4 — Engine Oil Dipstick10 — Coolant Pressure Cap5 — Brake Fluid Reservoir11 — Engine Coolant Reservoir6 — Battery

7

MAINTAINING YOUR VEHICLE 749

Page 752 of 871

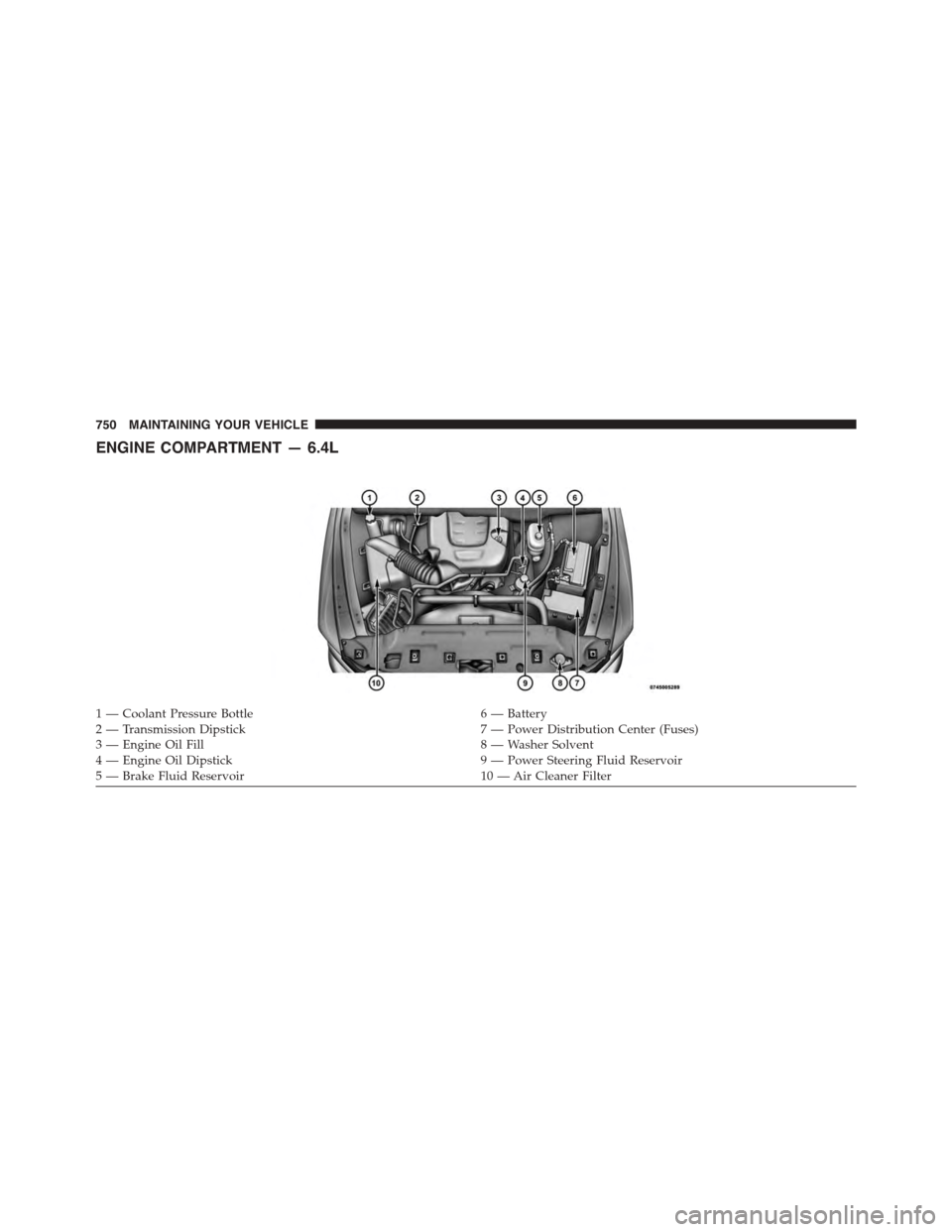

ENGINE COMPARTMENT — 6.4L

1 — Coolant Pressure Bottle6 — Battery2 — Transmission Dipstick7 — Power Distribution Center (Fuses)3—EngineOilFill8—WasherSolvent4 — Engine Oil Dipstick9 — Power Steering Fluid Reservoir5 — Brake Fluid Reservoir10 — Air Cleaner Filter

750 MAINTAINING YOUR VEHICLE

Page 757 of 871

CAUTION!(Continued)

•Your vehicle has been built with improved fluids

that protect the performance and durability of your

vehicle and also allow extended maintenance inter-

vals. Do not use chemical flushes in these compo-

nents as the chemicals can damage your engine,

transmission, power steering or air conditioning.

Such damage is not covered by the New Vehicle

Limited Warranty. If a flush is needed because of

component malfunction, use only the specified

fluid for the flushing procedure.

Engine Oil

Checking Oil Level

To assure proper lubrication of your vehicle’s engine, the

engine oil must be maintained at the correct level. Check

the oil level at regular intervals, such as every fuel stop.

The best time to check the engine oil level is about five

minutes after a fully warmed up engine is shut off.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings. Always

maintain the oil level within the SAFE zone on the

dipstick. Adding one quart of oil when the reading is at

the bottom of the SAFE zone will result in a reading at the

top of the safe zone on these engines.

CAUTION!

Overfilling or underfilling the crankcase will cause

oil aeration or loss of oil pressure. This could damage

your engine.7

MAINTAINING YOUR VEHICLE 755

Page 800 of 871

WARNING!(Continued)

•Before replacing a fuse, make sure that the ignition

is off and that all the other services are switched off

and/or disengaged.

•If the replaced fuse blows again, contact an autho-

rized dealer.

•If a general protection fuse for safety systems (air

bag system, braking system), power unit systems

(engine system, gearbox system) or steering system

blows, contact an authorized dealer.

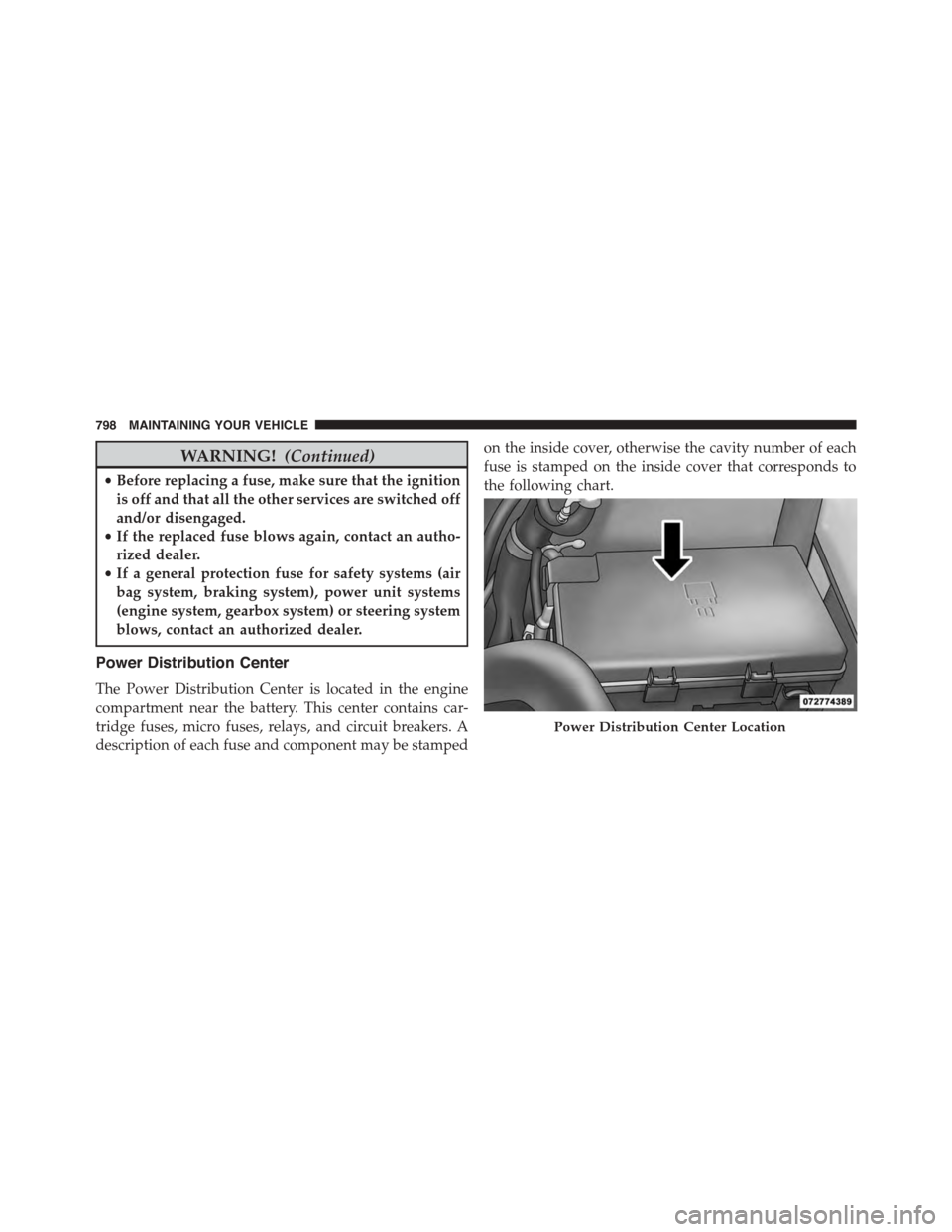

Power Distribution Center

The Power Distribution Center is located in the engine

compartment near the battery. This center contains car-

tridge fuses, micro fuses, relays, and circuit breakers. A

description of each fuse and component may be stamped

on the inside cover, otherwise the cavity number of each

fuse is stamped on the inside cover that corresponds to

the following chart.

Power Distribution Center Location

798 MAINTAINING YOUR VEHICLE

Page 807 of 871

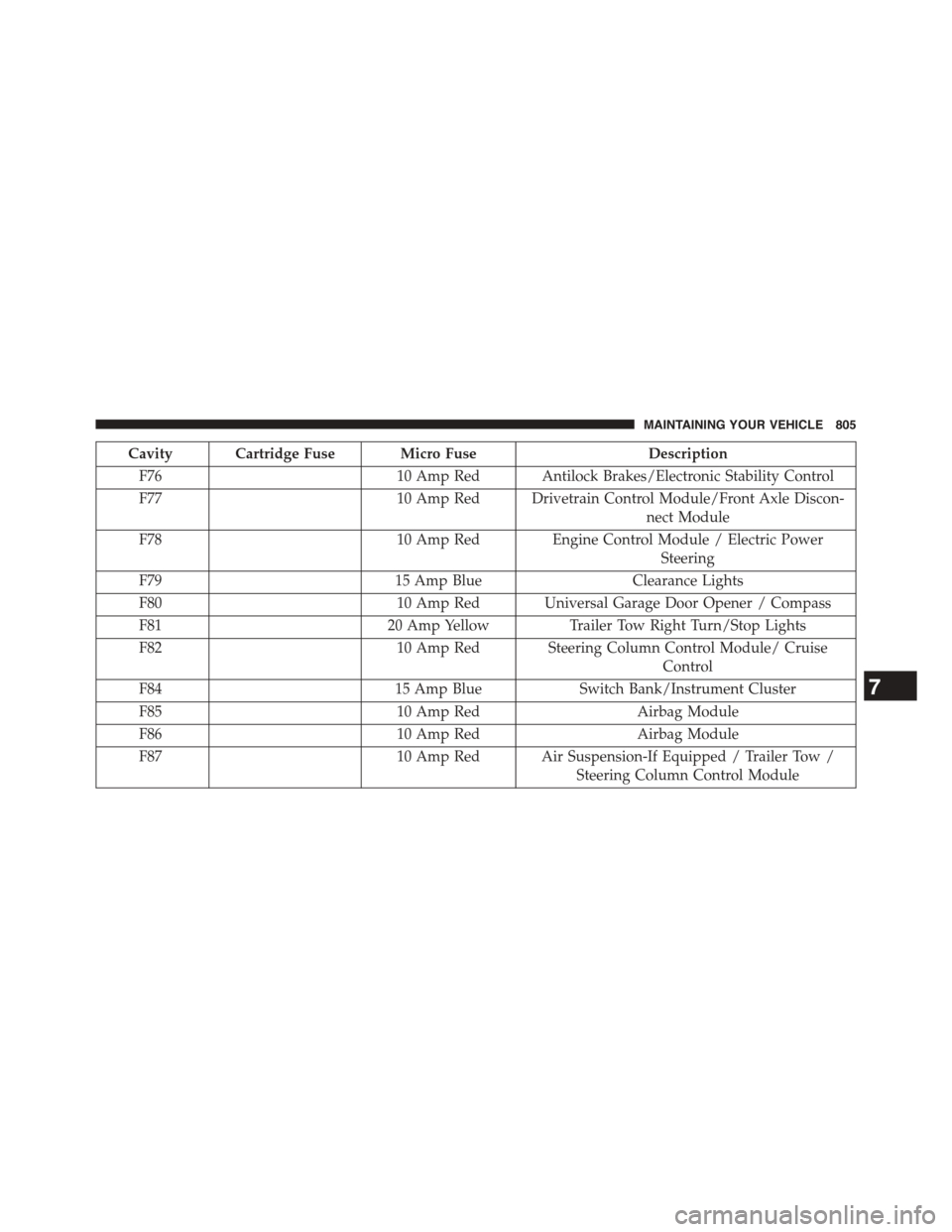

Cavity Cartridge Fuse Micro FuseDescription

F7610 Amp Red Antilock Brakes/Electronic Stability Control

F7710 Amp Red Drivetrain Control Module/Front Axle Discon-

nect Module

F7810 Amp Red Engine Control Module / Electric Power

Steering

F7915 Amp BlueClearance Lights

F8010 Amp Red Universal Garage Door Opener / Compass

F8120 Amp YellowTrailer Tow Right Turn/Stop Lights

F8210 Amp Red Steering Column Control Module/ Cruise

Control

F8415 Amp BlueSwitch Bank/Instrument Cluster

F8510 Amp RedAirbag Module

F8610 Amp RedAirbag Module

F8710 Amp Red Air Suspension-If Equipped / Trailer Tow /

Steering Column Control Module

7

MAINTAINING YOUR VEHICLE 805

Page 808 of 871

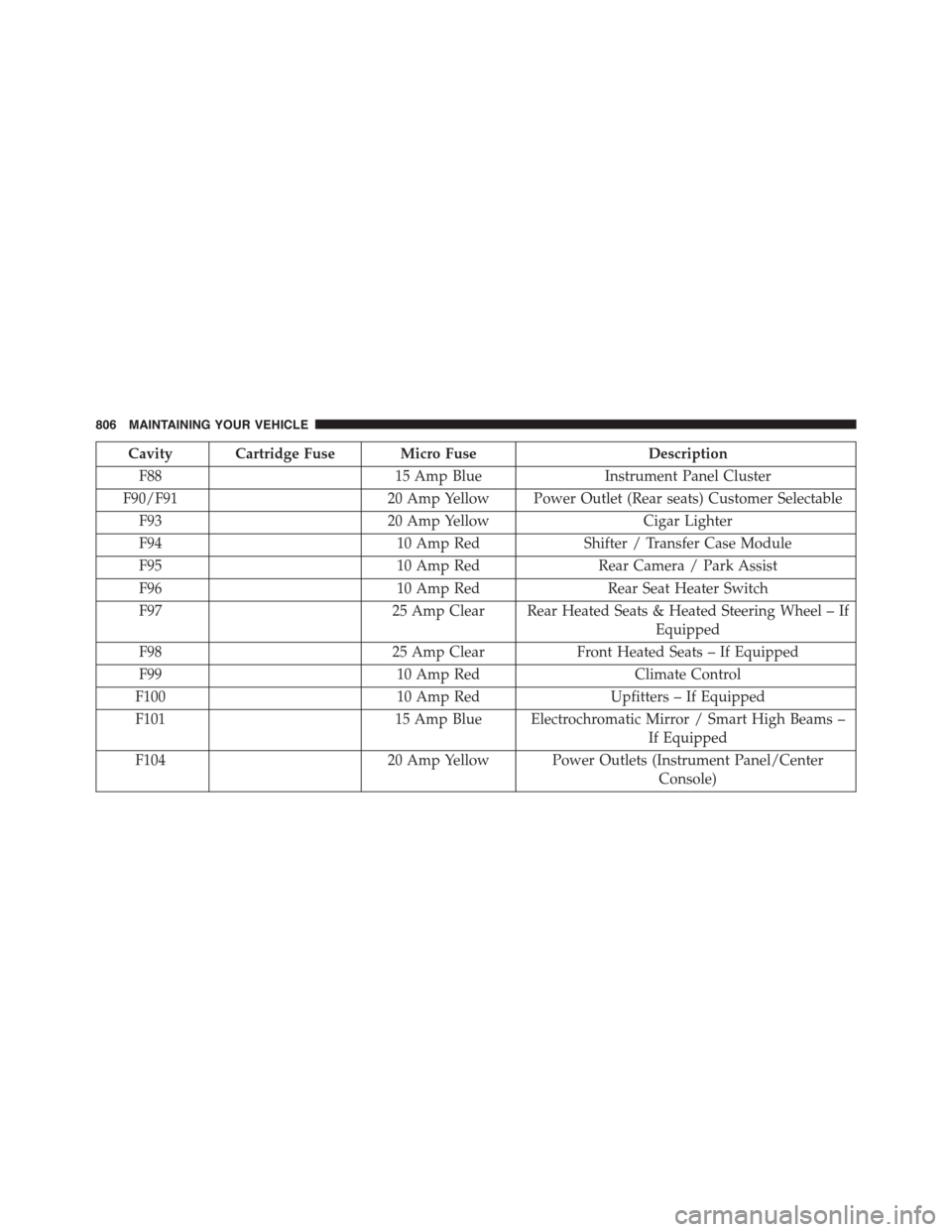

Cavity Cartridge Fuse Micro FuseDescription

F8815 Amp BlueInstrument Panel Cluster

F90/F9120 Amp Yellow Power Outlet (Rear seats) Customer Selectable

F9320 Amp YellowCigar Lighter

F9410 Amp RedShifter / Transfer Case Module

F9510 Amp RedRear Camera / Park Assist

F9610 Amp RedRear Seat Heater Switch

F9725 Amp Clear Rear Heated Seats & Heated Steering Wheel – If

Equipped

F9825 Amp ClearFront Heated Seats – If Equipped

F9910 Amp RedClimate Control

F10010 Amp RedUpfitters – If Equipped

F10115 Amp Blue Electrochromatic Mirror / Smart High Beams –

If Equipped

F10420 Amp Yellow Power Outlets (Instrument Panel/Center

Console)

806 MAINTAINING YOUR VEHICLE

Page 827 of 871

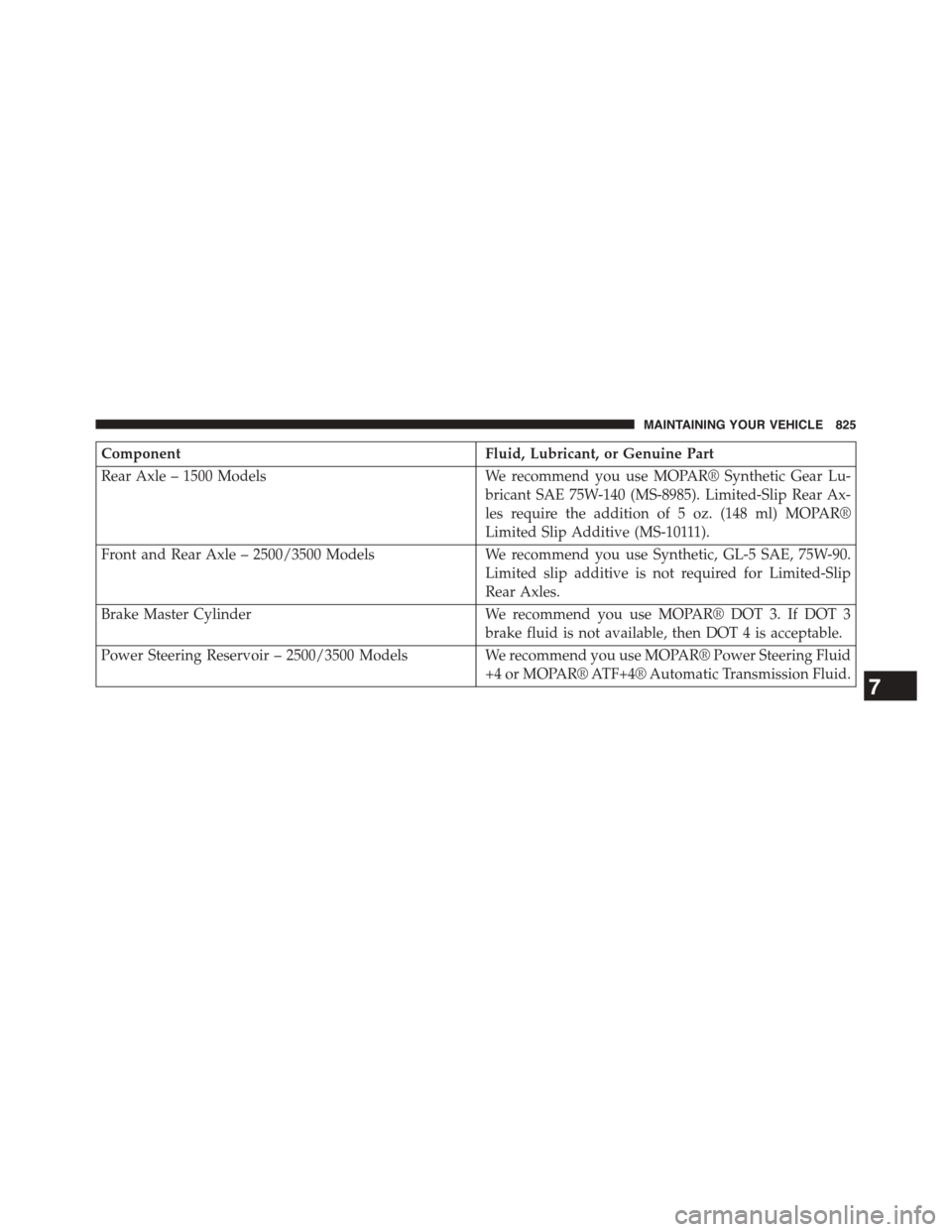

ComponentFluid, Lubricant, or Genuine Part

Rear Axle – 1500 ModelsWe recommend you use MOPAR® Synthetic Gear Lu-

bricant SAE 75W-140 (MS-8985). Limited-Slip Rear Ax-

les require the addition of 5 oz. (148 ml) MOPAR®

Limited Slip Additive (MS-10111).

Front and Rear Axle – 2500/3500 ModelsWe recommend you use Synthetic, GL-5 SAE, 75W-90.

Limited slip additive is not required for Limited-Slip

Rear Axles.

Brake Master CylinderWe recommend you use MOPAR® DOT 3. If DOT 3

brake fluid is not available, then DOT 4 is acceptable.

Power Steering Reservoir – 2500/3500 ModelsWe recommend you use MOPAR® Power Steering Fluid

+4 or MOPAR® ATF+4® Automatic Transmission Fluid.

7

MAINTAINING YOUR VEHICLE 825

Page 831 of 871

NOTE: 1500 Models Only

•Under no circumstances should oil change intervals

exceed 10,000 miles (16,000 km) or twelve months on

1500 trucks, whichever comes first.

2500 – 3500 Models

•Under no circumstances should oil change intervals

exceed 8,000 miles (13,000 km) or twelve months on

2500 – 3500 trucks, whichever comes first.

Severe Duty All Models

•Change Engine Oil at 4000 miles (6,500 km) if the vehicle

is operated in a dusty and off road environment. This

type of vehicle use is considered Severe Duty

Once A Month Or Before A Long Trip:

•Check engine oil level

•Check windshield washer fluid level

•Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before the oil indicator system turns on.

•Check the fluid levels of the coolant reservoir, brake

master cylinder, power steering (2500/3500 Models

Only) and automatic transmission (six-speed only)

and fill as needed

•Check function of all interior and exterior lights

8

MAINTENANCE

SCHEDULES

MAINTENANCE SCHEDULES 829