axle Ram 1500 2015 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: 1500, Model: Ram 1500 2015Pages: 871, PDF Size: 24.83 MB

Page 661 of 871

WARNING!(Continued)

•When hauling cargo or towing a trailer, do not

overload your vehicle or trailer. Overloading can

cause a loss of control, poor performance or dam-

age to brakes, axle, engine, transmission, steering,

suspension, chassis structure or tires.

•Safety chains must always be used between your

vehicle and trailer. Always connect the chains to

the hook retainers of the vehicle hitch. Cross the

chains under the trailer tongue and allow enough

slack for turning corners.

•Vehicles with trailers should not be parked on a

grade. When parking, apply the parking brake on

the tow vehicle. Put the tow vehicle transmission in

PARK. For four-wheel drive vehicles, make sure

the transfer case is not in NEUTRAL. Always,

block or%chock%the trailer wheels.

(Continued)

WARNING!(Continued)

•GCWR must not be exceeded.

•Total weight must be distributed between the tow

vehicle and the trailer such that the following four

ratings are not exceeded:

1. GVWR

2. GTW

3. GAWR

4. Tongue weight rating for the trailer hitch uti-

lized.

5

STARTING AND OPERATING 659

Page 673 of 871

•Check the runners and cutting edge for excessive wear.

The cutting edge should be¼to½in (6 cm to 1.2 cm)

above ground in snow plowing position.

•Check that snowplow lighting is connected and func-

tioning properly.

Snowplow Prep Package Model Availability

For Information about snowplow applications visit

www.ramtrucks.com or refer to the current Body Build-

ers Guide.

1. The maximum number of occupants in the truck

should not exceed two.

2. The total GVWR or the Front GAWR or the Rear

GAWR should never be exceeded.

3. Cargo capacity will be reduced by the addition of

options or passengers, etc.

The loaded vehicle weight, including the snowplow

system, all aftermarket accessories, driver, passengers,

options, and cargo, must not exceed either the Gross

Vehicle Weight (GVWR) or Gross Axle Weight (GAWR)

ratings. These weights are specified on the Safety Com-

pliance Certification Label on the driver’s side door

opening.

NOTE:Detach the snowplow when transporting pas-

sengers.

Vehicle front end wheel alignment was set to specifica-

tions at the factory without consideration for the weight

of the plow. Front end toe-in should be checked and reset

if necessary at the beginning and end of the snowplow

season. This will help prevent uneven tire wear.

The blade should be lowered whenever the vehicle is

parked.

5

STARTING AND OPERATING 671

Page 676 of 871

NOTE:Vehicles equipped with air suspension must be

placed in Transport mode before tying them down (from

the body) on a trailer or flatbed truck. Refer to “Air

Suspension – If Equipped” for more information. If the

vehicle cannot be placed in Transport mode (for example,

engine will not run), tie-downs must be fastened to the

axles (not to the body). Failure to follow these instruc-

tions may cause fault codes to be set and/or cause loss of

proper tie-down tension.

Recreational Towing — Two-Wheel Drive Models

DO NOT flat tow this vehicle. Damage to the drivetrain

will result.

Recreational towing (for two-wheel drive models) is

allowedONLYif the rear wheels areOFFthe ground.

This may be accomplished using a tow dolly or vehicle

trailer. If using a tow dolly, follow this procedure:

1. Properly secure the dolly to the tow vehicle, following

the dolly manufacturer’s instructions.

NOTE:If vehicle is equipped with air suspension, ensure

the vehicle is set to Normal Ride Height.

2. Drive the rear wheels onto the tow dolly.

3. Firmly apply the parking brake. Place automatic trans-

mission in PARK, manual transmission in gear (not in

NEUTRAL).

4. Properly secure the rear wheels to the dolly, following

the dolly manufacturer’s instructions.

5. Turn the ignition switch to the OFF position and

remove the Key Fob.

6. Install a suitable clamping device, designed for tow-

ing, to secure the front wheels in the straight position.

674 STARTING AND OPERATING

Page 702 of 871

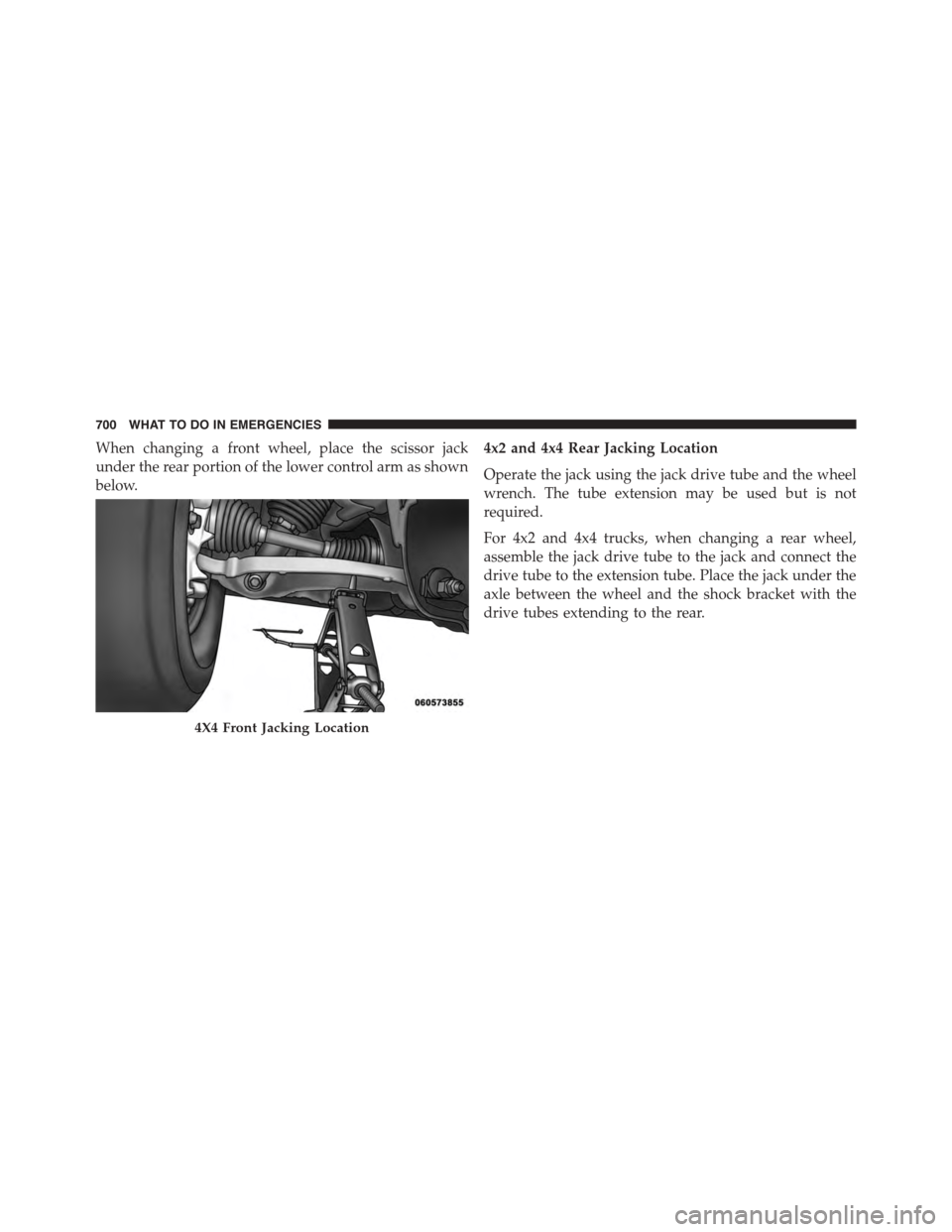

When changing a front wheel, place the scissor jack

under the rear portion of the lower control arm as shown

below.

4x2 and 4x4 Rear Jacking Location

Operate the jack using the jack drive tube and the wheel

wrench. The tube extension may be used but is not

required.

For 4x2 and 4x4 trucks, when changing a rear wheel,

assemble the jack drive tube to the jack and connect the

drive tube to the extension tube. Place the jack under the

axle between the wheel and the shock bracket with the

drive tubes extending to the rear.

4X4 Front Jacking Location

700 WHAT TO DO IN EMERGENCIES

Page 721 of 871

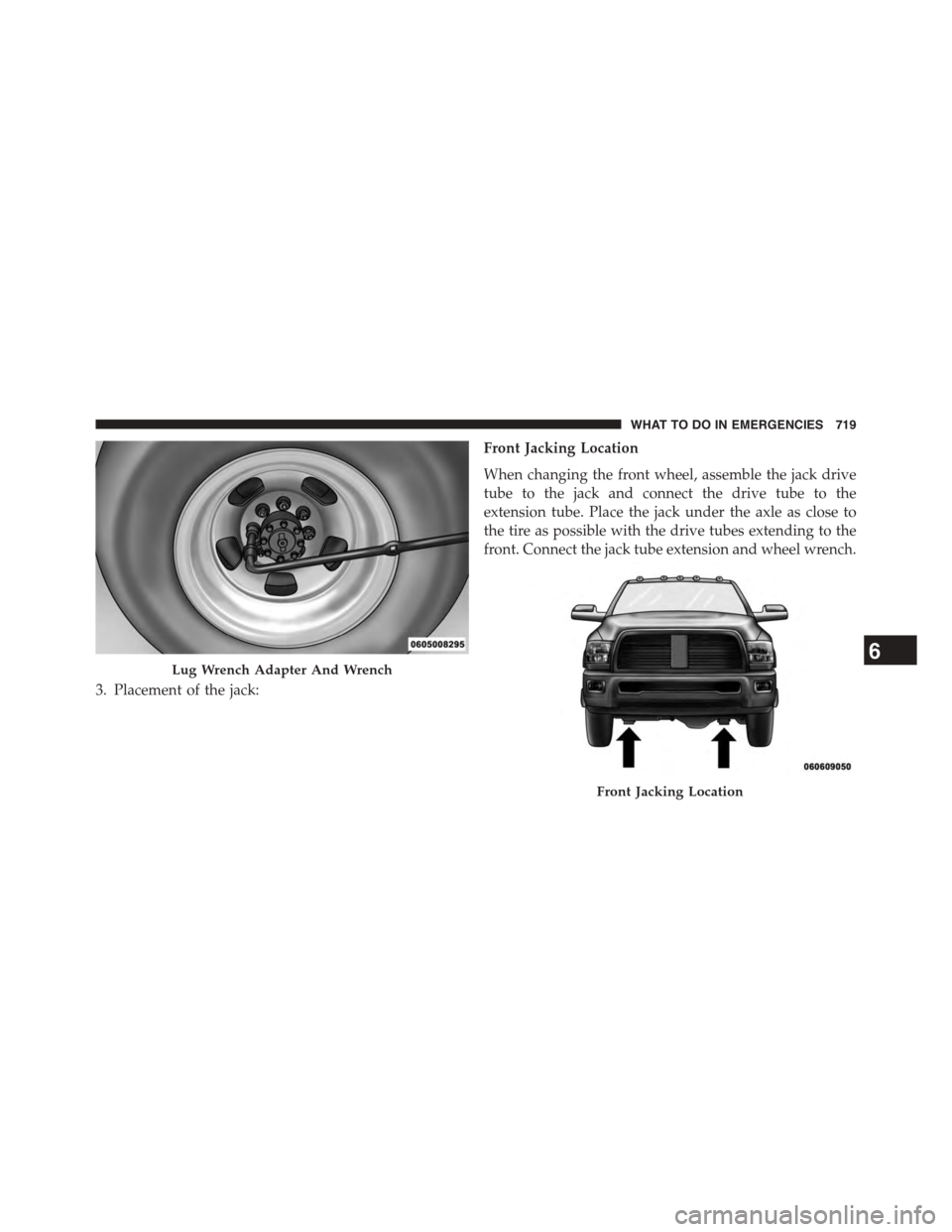

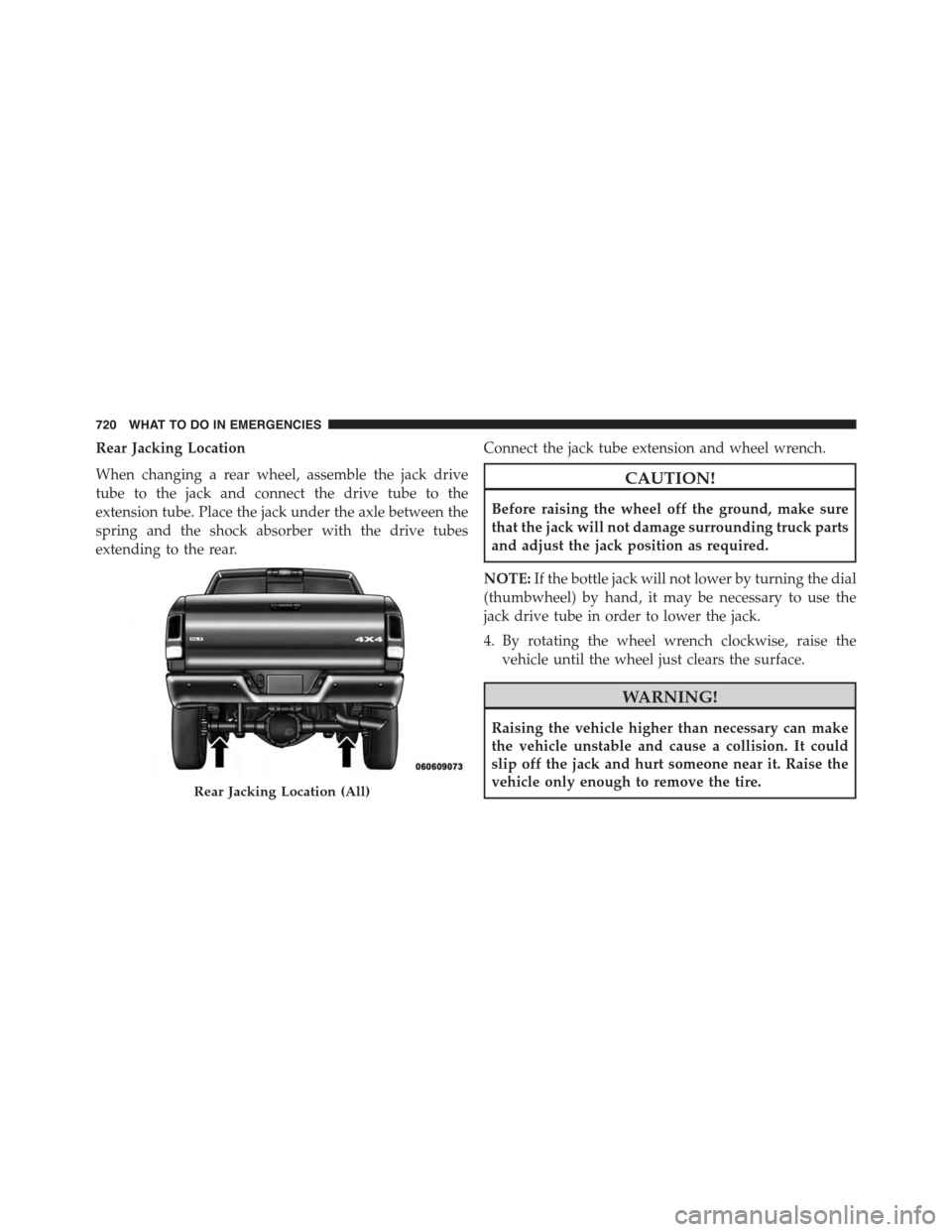

3. Placement of the jack:

Front Jacking Location

When changing the front wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle as close to

the tire as possible with the drive tubes extending to the

front. Connect the jack tube extension and wheel wrench.

Lug Wrench Adapter And Wrench

Front Jacking Location

6

WHAT TO DO IN EMERGENCIES 719

Page 722 of 871

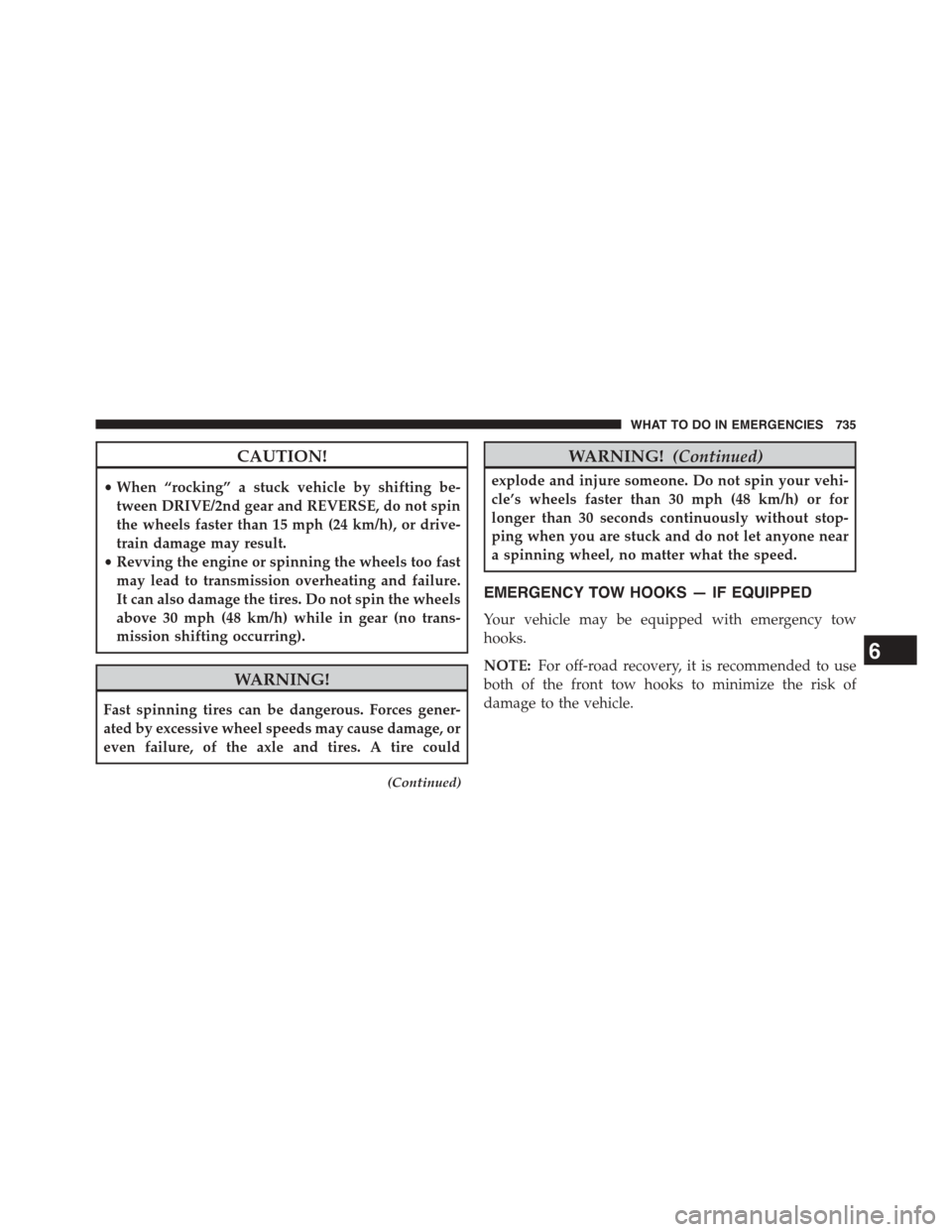

Rear Jacking Location

When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle between the

spring and the shock absorber with the drive tubes

extending to the rear.

Connect the jack tube extension and wheel wrench.

CAUTION!

Before raising the wheel off the ground, make sure

that the jack will not damage surrounding truck parts

and adjust the jack position as required.

NOTE:If the bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to use the

jack drive tube in order to lower the jack.

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause a collision. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.Rear Jacking Location (All)

720 WHAT TO DO IN EMERGENCIES

Page 737 of 871

CAUTION!

•When “rocking” a stuck vehicle by shifting be-

tween DRIVE/2nd gear and REVERSE, do not spin

the wheels faster than 15 mph (24 km/h), or drive-

train damage may result.

•Revving the engine or spinning the wheels too fast

may lead to transmission overheating and failure.

It can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no trans-

mission shifting occurring).

WARNING!

Fast spinning tires can be dangerous. Forces gener-

ated by excessive wheel speeds may cause damage, or

even failure, of the axle and tires. A tire could

(Continued)

WARNING!(Continued)

explode and injure someone. Do not spin your vehi-

cle’s wheels faster than 30 mph (48 km/h) or for

longer than 30 seconds continuously without stop-

ping when you are stuck and do not let anyone near

a spinning wheel, no matter what the speed.

EMERGENCY TOW HOOKS — IF EQUIPPED

Your vehicle may be equipped with emergency tow

hooks.

NOTE:For off-road recovery, it is recommended to use

both of the front tow hooks to minimize the risk of

damage to the vehicle.

6

WHAT TO DO IN EMERGENCIES 735

Page 742 of 871

To Reset The Manual Park Release:

1. Push the locking tab to the right, to unlock the lever.

2. Rotate the Manual Park Release lever forward to its

original position, until the locking tab snaps into place

to secure the lever.

3. Pull gently on the tether strap to confirm that the lever

is locked in its stowed position.

4. Re-install the access cover.

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial wrecker service. If the trans-

mission and drivetrain are operable, disabled vehicles

may also be towed as described under “Recreational

Towing” in the “Starting and Operating” section.

NOTE:Vehicles equipped with air suspension must be

placed in Transport mode, before tying them down (from

the body) on a trailer or flatbed truck. Refer to#Air

Suspension#in#Starting and Operating#for more infor-

mation. If the vehicle cannot be placed in Transport mode

(for example, engine will not run), tie-downs must be

fastened to the axles (not to the body). Failure to follow

these instructions may cause fault codes to be set and/or

cause loss of proper tie-down tension.

740 WHAT TO DO IN EMERGENCIES

Page 748 of 871

▫Adding Washer Fluid..................771

▫Exhaust System......................772

▫Cooling System......................774

▫Brake System........................782

▫Rear Axle And 4x4 Front Driving Axle Fluid

Level..............................784

▫Transfer Case........................785

▫Automatic Transmission................786

▫Appearance Care And Protection From

Corrosion...........................790

!FUSES..............................797

▫Power Distribution Center...............798

!VEHICLE STORAGE....................807

!REPLACEMENT BULBS.................808

!BULB REPLACEMENT..................809

▫Base Quad / Premium Bi-Halogen: Low Beam

Headlamp, High Beam Headlamp, Front Park

And Turn — If Equipped...............810

▫Fog Lamps — If Equipped..............812

▫Rear Tail/Stop, Turn Signal And Backup Lamps

..................................812

▫Center High-Mounted Stoplamp (CHMSL) With

Cargo Lamp.........................814

▫Cab Top Clearance Lamps — If Equipped . . . .816

▫Rear Lamp Bar ID Marker (Dual Rear Wheels) —

If Equipped..........................817

▫Side Marker Lamps (Dual Rear Wheels) —

If Equipped.........................818

746 MAINTAINING YOUR VEHICLE

Page 786 of 871

WARNING!(Continued)

•Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

Rear Axle And 4x4 Front Driving Axle Fluid Level

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the axle assembly should be

inspected. If gear oil leakage is suspected inspect the

fluid level. Refer to “Fluids, Lubricants, and Genuine

Parts” in “Maintaining Your Vehicle” for further informa-

tion. This inspection should be made with the vehicle in

a level position.

For 1500 Model axles, the fluid level should be even with

the bottom of the fill hole (within 1/4 in (6.4 mm) of edge

of hole) for the FDU215 HD front axle and C235FE rear

axle.

For all 2500/3500 Model axles, the fluid level should be

1/4 in ± 1/4 in (6.4 mm ± 6.4 mm) below the fill hole on

the 9.25 in front and 3/4 in ± 1/4 in (19 mm ± 6.4 mm) on

10.5 in rear axles. The 11.5 in rear axle level should be

1/4 in ± 1/4 in (6.4 mm ± 6.4 mm) below the fill hole.

Drain And Refill

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Lubricant Selection

Refer to “Fluids, Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for further information.

784 MAINTAINING YOUR VEHICLE