maintenance schedule Ram 1500 2016 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2016, Model line: 1500, Model: Ram 1500 2016Pages: 338, PDF Size: 1.63 MB

Page 125 of 338

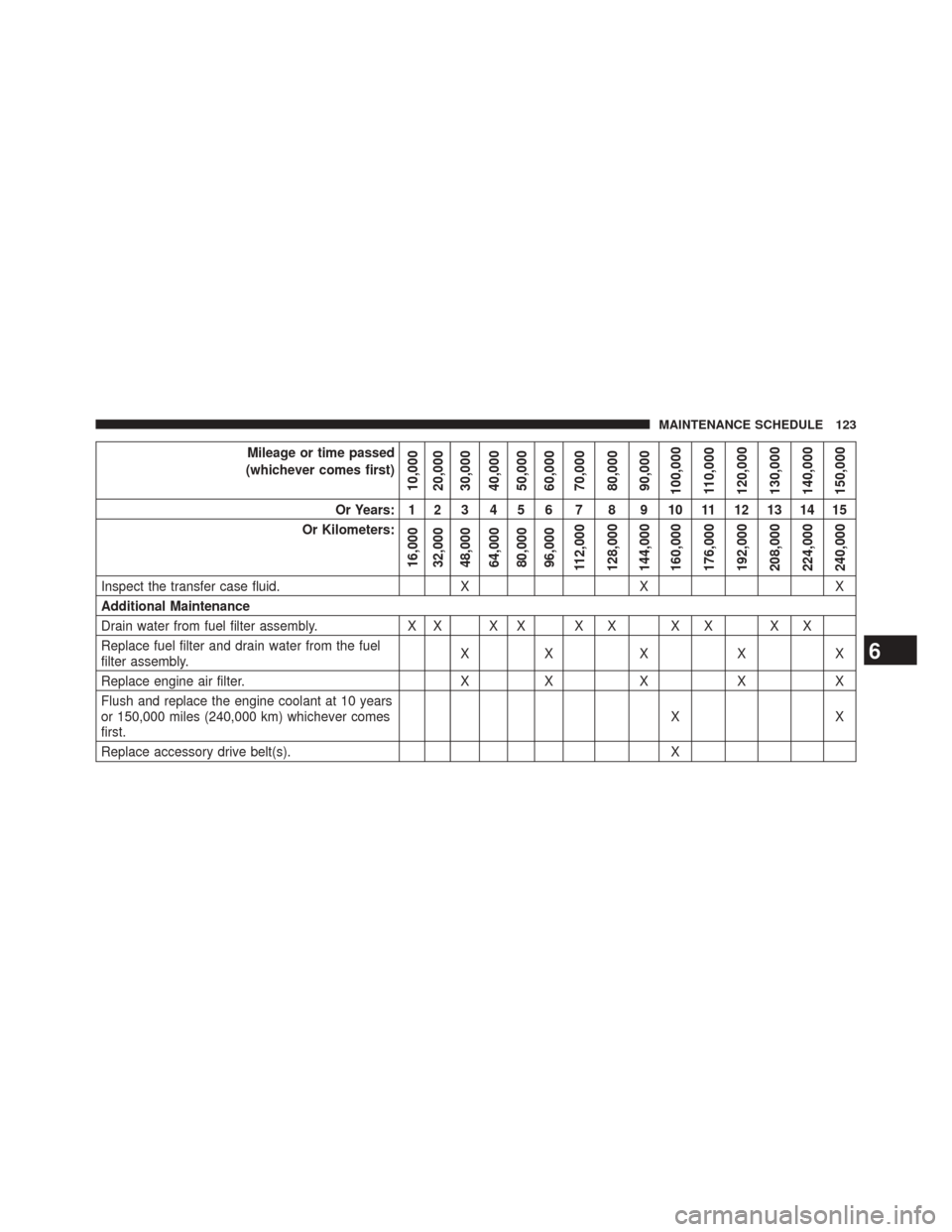

Mileage or time passed

(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Inspect the transfer case fluid. XX X

Additional Maintenance

Drain water from fuel filter assembly. X X X X X X X X X X

Replace fuel filter and drain water from the fuel

filter assembly. XX X X X

Replace engine air filter. XX X X X

Flush and replace the engine coolant at 10 years

or 150,000 miles (240,000 km) whichever comes

first. XX

Replace accessory drive belt(s). X

6

MAINTENANCE SCHEDULE 123

Page 126 of 338

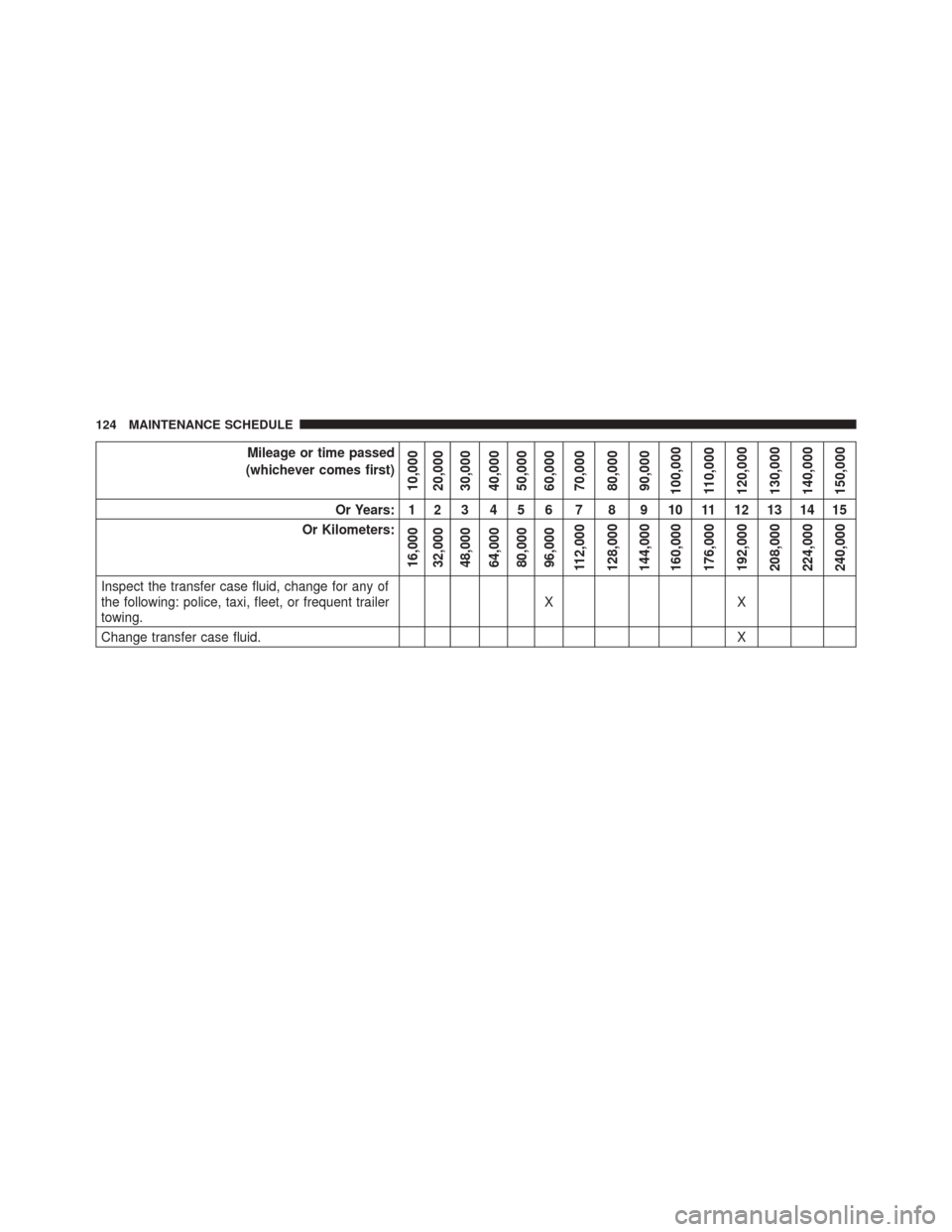

Mileage or time passed

(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Inspect the transfer case fluid, change for any of

the following: police, taxi, fleet, or frequent trailer

towing. XX

Change transfer case fluid. X

124 MAINTENANCE SCHEDULE

Page 127 of 338

WARNING!

•You can be badly injured working on or around a

motor vehicle. Do only service work for which you

have the knowledge and the right equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent me-

chanic.

• Failure to properly inspect and maintain your ve-

hicle could result in a component malfunction and

effect vehicle handling and performance. This

could cause an accident.

Additional Maintenance — B6 To B20 Biodiesel

NOTE:

• Under no circumstances should oil change intervals

exceed 8,000 miles (12 875 km) or six months, which-

ever comes first when using Biodiesel blends greater

than 5% (B5).

• The owner is required to monitor mileage for B6-B20

biodiesel, the automatic oil change indicator system

does not reflect the use of biofuels.

6

MAINTENANCE SCHEDULE 125

Page 128 of 338

Additional Maintenance Chart — B6 to B20 Biodiesel

Mileage or time passed

(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional B6 to B20 Maintenance

Replace fuel filter and drain water from the fuel

filter assembly. XXX X X X X

126 MAINTENANCE SCHEDULE

Page 129 of 338

WARNING!

•You can be badly injured working on or around a

motor vehicle. Do only service work for which you

have the knowledge and the right equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent me-

chanic.

• Failure to properly inspect and maintain your ve-

hicle could result in a component malfunction and

effect vehicle handling and performance. This

could cause an accident.

6

MAINTENANCE SCHEDULE 127

Page 133 of 338

TABLE OF CONTENTSSECTIONPAGE

1

INTRODUCTION ............................................................133

2

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE ...........................137

3

UNDERSTANDING THE FEATURES OF YOUR VEHICLE ............................143

4

UNDERSTANDING YOUR INSTRUMENT PANEL ..................................149

5

STARTING AND OPERATING .................................................193

6

WHAT TO DO IN EMERGENCIES ..............................................261

7

MAINTAINING YOUR VEHICLE ...............................................267

8

MAINTENANCE SCHEDULE ..................................................313

1

2

3

4

5

6

7

8

Page 273 of 338

MAINTENANCE PROCEDURES

The pages that follow contain therequiredmaintenance

services determined by the engineers who designed your

vehicle.

Besides those maintenance items specified in the fixed

maintenance schedule, there are other components which

may require servicing or replacement in the future.

CAUTION!

• Failure to properly maintain your vehicle or per-

form repairs and service when necessary could

result in more costly repairs, damage to other

components or negatively impact vehicle perfor-

mance. Immediately have potential malfunctions

examined by an authorized dealership or qualified

repair center.

(Continued)

CAUTION! (Continued)

•Your vehicle has been built with improved fluids

that protect the performance and durability of your

vehicle and also allow extended maintenance inter-

vals. Do not use chemical flushes in these compo-

nents as the chemicals can damage your engine,

transmission, power steering or air conditioning.

Such damage is not covered by the New Vehicle

Limited Warranty. If a flush is needed because of

component malfunction, use only the specified

fluid for the flushing procedure.

Engine Oil

Checking Oil Level

To assure proper lubrication of your vehicle’s engine, the

engine oil must be maintained at the correct level. Check

the oil level at regular intervals. The best time to check

the oil level is before starting the engine after it has been

7

MAINTAINING YOUR VEHICLE 271

Page 275 of 338

only when the level on the dipstick is below the “ADD”

mark. The total capacity from the ADD mark to the Full

mark is 2 qts (1.9L).

CAUTION!

Overfilling or underfilling the crankcase will cause

oil aeration or loss of oil pressure. This could damage

your engine.

Never operate the engine with oil level below the “ADD”

mark or above the upper “SAFE” mark.

Change Engine Oil

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Engine Oil Selection

For best performance and maximum protection under all

types of operating conditions, the manufacturer only recommends engine oils that are API CJ-4 certified and

meet the requirements of FCA LLC. Use MOPAR or an

equivalent oil meeting FCA Material Standard MS-10902.

Products meeting Cummins CES 20081 may also be used.

The identification of these engine oils are typically lo-

cated on the back of the oil container.

American Petroleum Institute (API) Engine Oil

Identification Symbol

This symbol means that the oil has

been certified by the American Petro-

leum Institute (API). The manufac-

turer only recommends API Certified

engine oils.

Oils with a high ash content may produce damaging

deposits on cylinder head valves and/or aftertreatment

7

MAINTAINING YOUR VEHICLE 273

Page 293 of 338

flushed and refilled with fresh coolant. Check the front of

the A/C condenser (if equipped) or radiator for any

accumulation of bugs, leaves, etc. If dirty, clean by gently

spraying water from a garden hose vertically down the

face of the A/C condenser (if equipped) or the back of the

radiator core.

Check the engine cooling system hoses for brittle rubber,

cracking, tears, cuts and tightness of the connection at the

coolant recovery bottle and radiator. Inspect the entire

system for leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

engine coolant (antifreeze) from the radiator drain cock.

The radiator drain cock is located in the lower radiator

tank. If the cap is sealing properly, the engine coolant(antifreeze) will begin to drain from the coolant expan-

sion bottle. DO NOT REMOVE THE COOLANT PRES-

SURE CAP WHEN THE COOLING SYSTEM IS HOT.

Cooling System — Drain Flush And Refill

If the engine coolant (antifreeze) is dirty or contains a

considerable amount of sediment, clean and flush with a

reliable cooling system cleaner. Follow with a thorough

rinsing to remove all deposits and chemicals. Properly

dispose of old engine coolant (antifreeze).

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Selection Of Coolant

Refer to “Fluids, Lubricants, And Genuine Parts” in

“Maintaining Your Vehicle” for further information.

7

MAINTAINING YOUR VEHICLE 291

Page 300 of 338

WARNING!(Continued)

•Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in an accident.

Clutch Hydraulic System

The clutch hydraulic system is a sealed maintenance-free

system. In the event of leakage or other malfunction, the

system must be replaced.

Transfer Case — If Equipped

Drain And Refill

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Selection of Lubricant

Refer to “Fluids, Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for fluid specifications.

Fluid Level Check

This fluid level can be checked by removing the filler

plug. The fluid level should be to the bottom edge of the

filler plug hole with the vehicle in a level position.

Manual Transmission — If Equipped

Selection of Lubricant

Refer to “Fluids, Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for fluid specifications.

Fluid Level Check

The fluid level can be checked by removing the filler

plug. If the level of the lubricant is more than 1/2 in

(12 mm) below the bottom of the filler hole while the

298 MAINTAINING YOUR VEHICLE