ECO Ram 1500 2016 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2016, Model line: 1500, Model: Ram 1500 2016Pages: 916, PDF Size: 7.55 MB

Page 693 of 916

Weight-Distributing Hitch

A weight-distributing system works by applying lever-

age through spring (load) bars. They are typically used

for heavier loads to distribute trailer tongue weight to the

tow vehicle’s front axle and the trailer axle(s). When used

in accordance with the manufacturer’s directions, it pro-

vides for a more level ride, offering more consistent

steering and brake control, thereby enhancing towing

safety. The addition of a friction/hydraulic sway control

also dampens sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer stability.

Trailer sway control and a weight distributing (load

equalizing) hitch are recommended for heavier Tongue

Weights (TW) and may be required depending on vehicle

and trailer configuration/loading to comply with GAWR

requirements.

WARNING!

•An improperly adjusted weight distributing hitch

system may reduce handling, stability and braking

performance and could result in a collision.

•Weight distributing systems may not be compat-

ible with surge brake couplers. Consult with your

hitch and trailer manufacturer or a reputable Rec-

reational Vehicle dealer for additional information.

5

STARTING AND OPERATING 691

Page 695 of 916

Recommended Distribution Hitch Adjustment

Towing With 1500 Air Suspension

1. Set air suspension to normal ride height. No action is

required if already in normal ride height.

NOTE:The vehicle must remain in the engine running

position while attaching a trailer for proper leveling of

the air suspension system.

2. Position the truck to be ready to connect to the trailer

(do not connect the trailer).

3. Under radio suspension settings, turn on jack mode.

Jack mode will be canceled and procedure must be

restarted if the vehicle is driven at speeds above 5mph

(8kph).

4. Measure the height of the top of the front wheel

opening on the fender to ground, this is height H1.

Improper Adjustment Of Weight-Distributing Hitch

(Incorrect)

5

STARTING AND OPERATING 693

Page 697 of 916

NOTE:For all towing conditions, we recommend towing

with tow haul mode engaged.

All Other 1500(Non-Air Suspension)/2500/3500 Trucks

1. Position the truck to be ready to connect to the trailer

(do not connect the trailer).

NOTE:For Ram 2500/3500 trucks equipped with rear air

suspension, normal ride height or alternate ride height

can be used. The vehicle must remain in the engine

running position while attaching a trailer for proper

leveling of the air suspension system. It may not be

possible to enter alternate ride height while lightly

loaded.

2. Measure the height of the top of the front wheel

opening on the fender to ground, this is height H1.

3. Attach the trailer to the vehicle without the weight

distribution bars connected.4. Measure the height of the top of the front wheel

opening on the fender to ground, this is height H2.

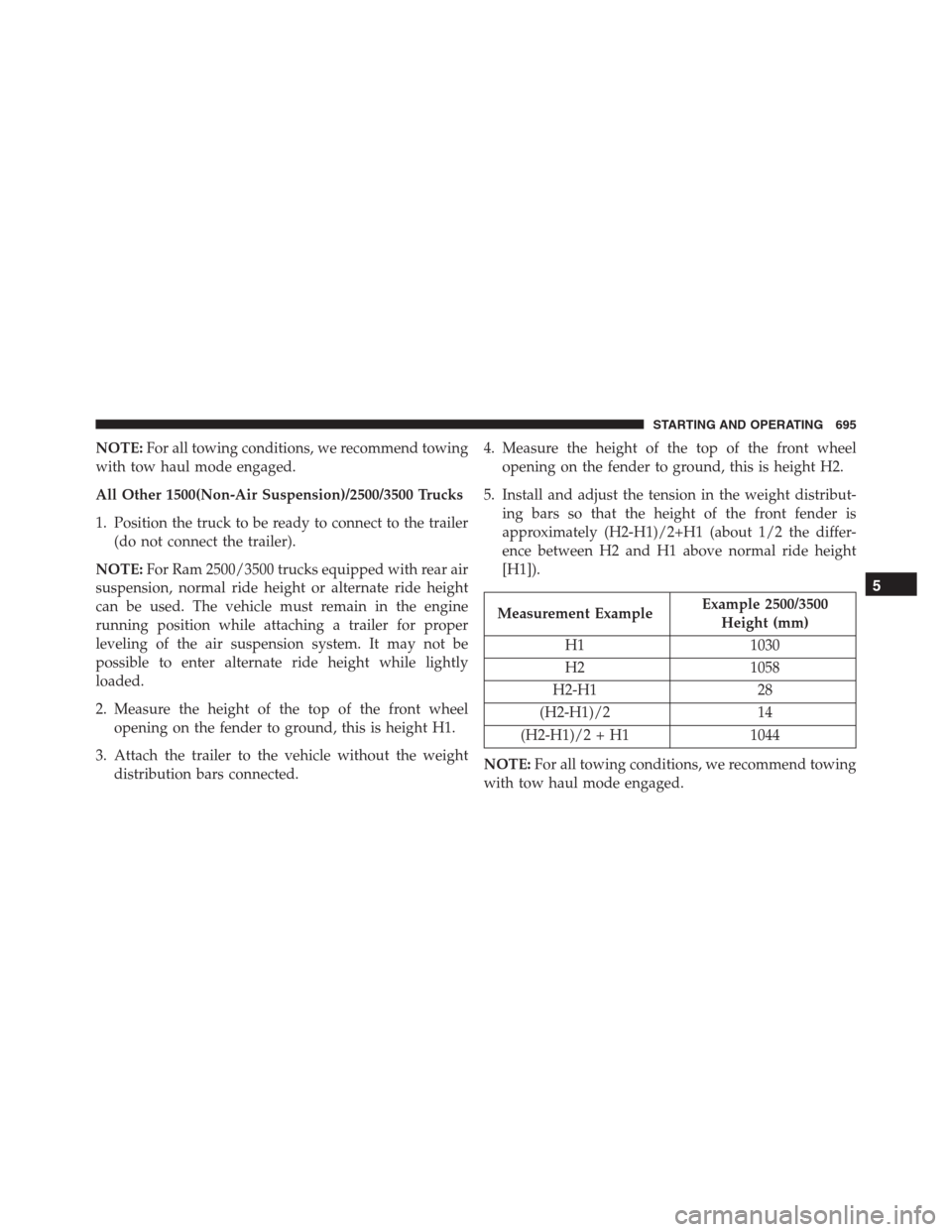

5. Install and adjust the tension in the weight distribut-

ing bars so that the height of the front fender is

approximately (H2-H1)/2+H1 (about 1/2 the differ-

ence between H2 and H1 above normal ride height

[H1]).

Measurement ExampleExample 2500/3500

Height (mm)

H1 1030

H2 1058

H2-H1 28

(H2-H1)/2 14

(H2-H1)/2 + H1 1044

NOTE:For all towing conditions, we recommend towing

with tow haul mode engaged.

5

STARTING AND OPERATING 695

Page 700 of 916

Consider the following items when computing the

weight on the rear axle of the vehicle:

•The tongue weight of the trailer

•The weight of any other type of cargo or equipment

put in or on your vehicle

•The weight of the driver and all passengersNOTE:Remember that everything put into or on the

trailer adds to the load on your vehicle. Also, additional

factory-installed options or dealer-installed options must

be considered as part of the total load on your vehicle.

Refer to “Tire Safety Information/Tire and Loading In-

formation Placard” in “Starting And Operating” for

further information.

Towing Requirements

To promote proper break-in of your new vehicle drive-

train components the following guidelines are recom-

mended:

CAUTION!

•Do not tow a trailer at all during the first 500 miles

(805 km) the new vehicle is driven. The engine, axle

or other parts could be damaged.

(Continued)

698 STARTING AND OPERATING

Page 704 of 916

•Trailer brakes are recommended for trailers over

1,000 lbs (454 kg) and required for trailers in excess of

1,653 lbs (750 kg).

Integrated Trailer Brake Module — If Equipped

Your vehicle may have an Integrated Trailer Brake Mod-

ule (ITBM) for Electric and Electric Over Hydraulic

(EOH) trailer brakes.

NOTE:This module has been designed and verified with

electric trailer brakes and new electric over hydraulic

systems. Some previous EOH systems may not be com-

patible with ITBM.

Integrated Trailer Brake Module (ITBM)

1 — GAIN Adjustment Button

2 — GAIN Adjustment Button

3 — Manual Brake Control Lever 702 STARTING AND OPERATING

Page 705 of 916

The user interface consists of the following:

Manual Brake Control Lever

Slide the manual brake control lever to the left to activate

power to the trailer’s electric brakes independent of the

tow vehicle’s brakes. If the manual brake control lever is

activated while the brake is also applied, the greater of

the two inputs determines the power sent to the trailer

brakes.

The trailer and the vehicle’s brake lamps will come on

when either vehicle braking or manual trailer brakes are

applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical connection status.

If no electrical connection is detected after the ignition is

turned on, pushing the GAIN adjustment button orsliding the manual brake control lever will display the

GAIN setting for 10 seconds and the “Trailer Brake Status

Indicator Light” will not be displayed.

If a fault is detected in the trailer wiring or the Integrated

Trailer Brake Module (ITBM), the “Trailer Brake Status

Indicator Light” will flash.

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake control

power output to the trailer brakes in 0.5 increments. The

GAIN setting can be increased to a maximum of 10 or

decreased to a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer brake control

for the specific towing condition and should be changed

as towing conditions change. Changes to towing condi-

tions include trailer load, vehicle load, road conditions

and weather.

5

STARTING AND OPERATING 703

Page 706 of 916

Adjusting GAIN

NOTE:This should only be performed in a traffic free

environment at speeds of approximately 20–25 mph

(30–40 km/h).

1. Make sure the trailer brakes are in good working

condition, functioning normally and properly ad-

justed. See your trailer dealer if necessary.

2. Hook up the trailer and make the electrical connec-

tions according to the trailer manufacturer’s instruc-

tions.

3. When a trailer with electric/EOH brakes is plugged

in, the trailer connected message should appear in the

EVIC/DID (if the connection is not recognized by the

ITBM, braking functions will not be available), the

GAIN setting will illuminate and the correct type of

trailer must be selected from the EVIC/DID options.4. Push the UP or DOWN button on the steering wheel

until “TRAILER TOW” appears on the screen.

5. Push the RIGHT arrow on the steering wheel to enter

“TRAILER TOW”.

6. Push the UP or DOWN buttons until Trailer Brake

Type appears on the screen.

7. Push the RIGHT arrow and then push the UP or

DOWN buttons until the proper Trailer Brake Type

appears on the screen.

8. In a traffic-free environment, tow the trailer on a dry,

level surface at a speed of 20–25 mph (30–40 km/h)

and squeeze the manual brake control lever com-

pletely.

9. If the trailer wheels lockup (indicated by squealing

tires), reduce the GAIN setting; if the trailer wheels

turn freely, increase the GAIN setting.

704 STARTING AND OPERATING

Page 713 of 916

WARNING!(Continued)

Do not expect that the airbag will perform as de-

scribed earlier in this manual.

2500/3500 Models Only

Snowplow Prep Packages are available as a factory

installed option. These packages include components

necessary to equip your vehicle with a snowplow.

NOTE:Before installation of a snowplow it is highly

recommended that the owner/installer obtain and follow

the recommendations contained within the current Body

Builders Guide. See your authorized dealer, installer or

snowplow manufacturer for this information. There are

unique electrical systems that must be connected to

properly assure operator safety and prevent overloading

vehicle systems.

WARNING!

Attaching a snowplow to this vehicle could adversely

affect performance of the airbag system in a collision.

Do not expect that the airbag will perform as de-

scribed earlier in this manual.

CAUTION!

The “Lamp Out” indicator could illuminate if exte-

rior lamps are not properly installed.

Before Plowing

•Check the hydraulic system for leaks and proper fluid

level.

•Check the mounting bolts and nuts for proper tight-

ness.

5

STARTING AND OPERATING 711

Page 715 of 916

Maintain and operate your vehicle and snowplow equip-

ment following the recommendations provided by the

specific snowplow manufacturer.

Over The Road Operation With Snowplow

Attached

The blade restricts air flow to the radiator and causes the

engine to operate at higher than normal temperatures.

Therefore, when transporting the plow, angle the blade

completely and position it as low as road or surface

conditions permit. Do not exceed 40 mph (64 km/h). The

operator should always maintain a safe stopping distance

and allow adequate passing clearance.

Operating Tips

Under ideal snow plowing conditions, 20 mph (32 km/h)

should be maximum operating speed. The operator

should be familiar with the area and surface to be

cleaned. Reduce speed and use extreme caution when

plowing unfamiliar areas or under poor visibility.

General Maintenance

Snowplows should be maintained in accordance with the

plow manufacturer’s instructions.

Keep all snowplow electrical connections and battery

terminals clean and free of corrosion.

When plowing snow, to avoid transmission and drivetrain

damage, the following precautions should be observed.

•Operate with transfer case in 4L when plowing small or

congested areas where speeds are not likely to exceed

15 mph (24 km/h). At higher speeds operate in 4H.

•Vehicles with automatic transmissions should use 4L

range when plowing deep or heavy snow for extended

periods of time to avoid transmission overheating.

•Do not shift the transmission unless the engine has

returned to idle and wheels have stopped. Make a

practice of stepping on the brake pedal while shifting

the transmission.

5

STARTING AND OPERATING 713

Page 721 of 916

shift to NEUTRAL (N) is complete. After the shift is

completed and the NEUTRAL (N) light stays on,

release the NEUTRAL (N) button.

6. Release the parking brake.

7. Shift the transmission into REVERSE.

8. Release the brake pedal (and clutch pedal on manual

transmissions) for five seconds and ensure that there is

no vehicle movement.

9. Repeat steps 7 and 8 with automatic transmission in

DRIVE or manual transmission in first gear.

10. Shift the transmission to NEUTRAL. Firmly apply

the parking brake. Turn OFF the engine. For vehicles

with Keyless Enter-N-Go, push and hold the EN-

GINE START/STOP button until the engine shuts off.11. Shift the transmission into PARK or place manual

transmission in gear (NOT in Neutral). On 8-speed

transmissions the shifter will automatically select

PARK when the engine is turned off.

12. Turn the ignition switch to the OFF position, then

cycle the Key or the Keyless Enter-N-Go button to the

RUN position and back to the OFF position. Remove

the Key Fob from the ignition switch.

13. Attach the vehicle to the tow vehicle using a suitable

tow bar.

14. Release the parking brake.

NOTE:With electronic shift transfer case:

•Steps 2 through 4 are requirements that must be met

before pushing the NEUTRAL (N) button, and must

continue to be met until the shift has been completed.

If any of these requirements are not met before push-

ing the NEUTRAL (N) button or are no longer met

5

STARTING AND OPERATING 719