change wheel Ram 1500 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 1500, Model: Ram 1500 2018Pages: 372, PDF Size: 7.1 MB

Page 164 of 372

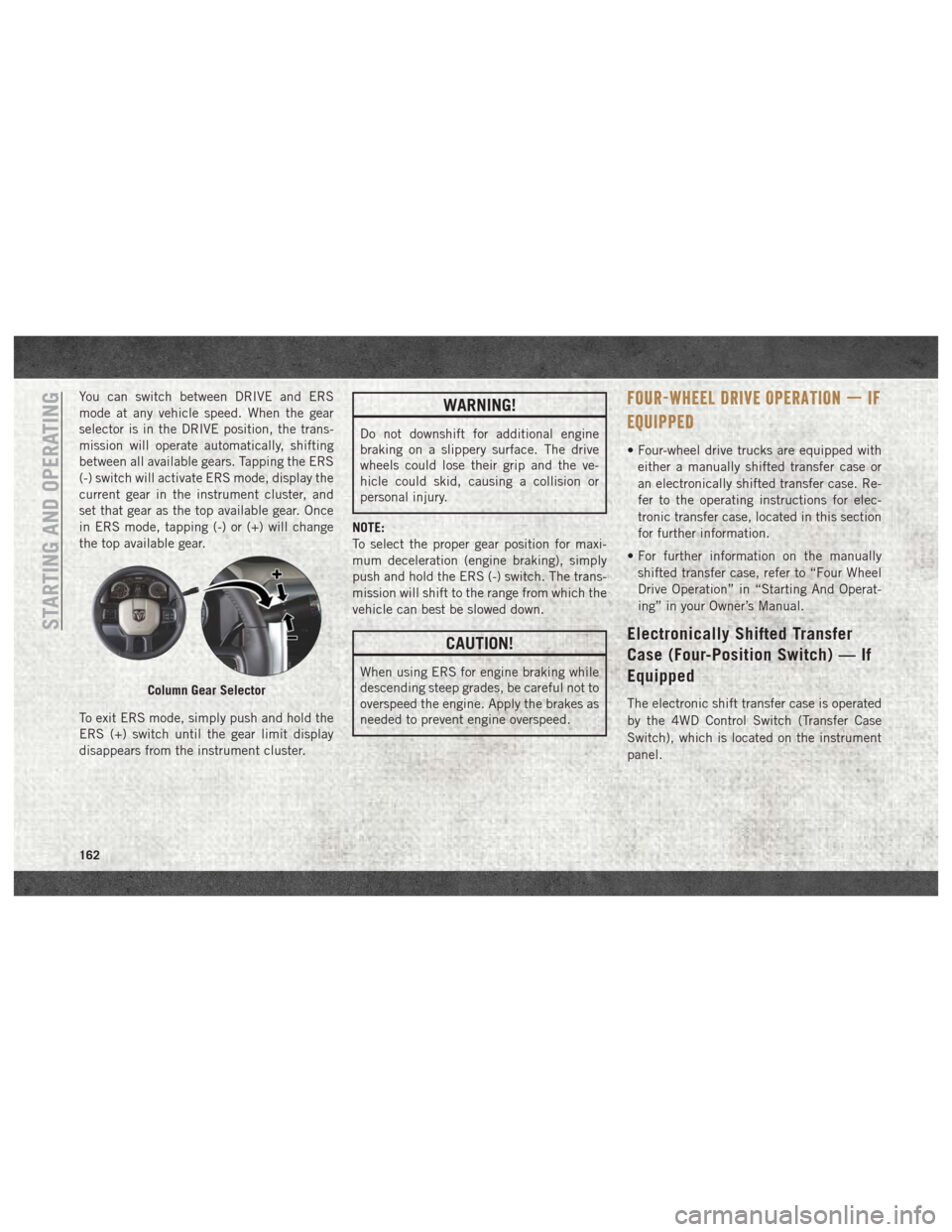

You can switch between DRIVE and ERS

mode at any vehicle speed. When the gear

selector is in the DRIVE position, the trans-

mission will operate automatically, shifting

between all available gears. Tapping the ERS

(-) switch will activate ERS mode, display the

current gear in the instrument cluster, and

set that gear as the top available gear. Once

in ERS mode, tapping (-) or (+) will change

the top available gear.

To exit ERS mode, simply push and hold the

ERS (+) switch until the gear limit display

disappears from the instrument cluster.WARNING!

Do not downshift for additional engine

braking on a slippery surface. The drive

wheels could lose their grip and the ve-

hicle could skid, causing a collision or

personal injury.

NOTE:

To select the proper gear position for maxi-

mum deceleration (engine braking), simply

push and hold the ERS (-) switch. The trans-

mission will shift to the range from which the

vehicle can best be slowed down.

CAUTION!

When using ERS for engine braking while

descending steep grades, be careful not to

overspeed the engine. Apply the brakes as

needed to prevent engine overspeed.

FOUR-WHEEL DRIVE OPERATION — IF

EQUIPPED

• Four-wheel drive trucks are equipped with either a manually shifted transfer case or

an electronically shifted transfer case. Re-

fer to the operating instructions for elec-

tronic transfer case, located in this section

for further information.

• For further information on the manually shifted transfer case, refer to “Four Wheel

Drive Operation” in “Starting And Operat-

ing” in your Owner’s Manual.

Electronically Shifted Transfer

Case (Four-Position Switch) — If

Equipped

The electronic shift transfer case is operated

by the 4WD Control Switch (Transfer Case

Switch), which is located on the instrument

panel.Column Gear Selector

STARTING AND OPERATING

162

Page 173 of 372

if the vehicle speed exceeds 66 mph

(106 km/h). The vehicle will return to NRH

from Aero Mode if the vehicle speed re-

mains between 30 mph (48 km/h) and

35 mph (56 km/h) for greater than 20 sec-

onds or if the vehicle speed falls below

30 mph (48 km/h).

NOTE:

Automatic Aero Mode may be disabled

through vehicle settings in the instrument

cluster when equipped with Uconnect 3.0, or

your Uconnect Radio when equipped with

Uconnect 5.0, 8.4A, or 8.4AN.

• Entry/Exit Mode (Lowers the vehicle approxi-

mately 2 in (51 mm)) - This position lowers

the vehicle for easier passenger entry and

exit as well as lowering the rear of the

vehicle for easier loading and unloading of

cargo. To enter Entry/Exit Mode, push the

“Down” button once from the NHR while

the vehicle speed is below 33 mph (53 km/

h). Once the vehicle speed goes below

15 mph (24 km/h) the vehicle height will

begin to lower. If the vehicle speed remains

between 15 mph (24 km/h) and 25 mph

(40 km/h) for greater than 60 seconds, or the vehicle speed exceeds 25 mph

(40 km/h) the Entry/Exit change will be

cancelled. To return to Normal Height

Mode, push the “Up” button once while in

Entry/Exit or drive the vehicle over 15 mph

(24 km/h). Entry/Exit mode may not be

available due to vehicle payload, an instru-

ment cluster message will be displayed

when this occurs. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” in the Owner’s Manual

for further information.

Air Suspension Modes

The Air Suspension system has multiple

modes to protect the system in unique situa-

tions:

AERO Mode

To improve aerodynamics, the air suspension

system has a feature which will put the ve-

hicle into AERO height automatically. Refer

to “Instrument Cluster Display” in “Getting

To Know Your Instrument Panel” in the Own-

er’s Manual for further information.

NOTE:

This mode is intended to be enabled with

engine running.

Tire/Jack Mode

To assist with changing a tire, the air suspen-

sion system has a feature which allows the

automatic leveling to be disabled. Refer to

“Instrument Cluster Display” in “Getting To

Know Your Instrument Panel” in the Owner’s

Manual for further information.

NOTE:

This mode is intended to be enabled with

engine running.

Transport Mode

For towing your vehicle with four wheels off

the ground, the air suspension system has a

feature which will put the vehicle into Entry/

Exit height and disable the automatic load

leveling system. Refer to “Instrument Cluster

Display” in “Getting To Know Your Instru-

ment Panel” in the Owner’s Manual for fur-

ther information.

171

Page 174 of 372

NOTE:

This mode is intended to be enabled with

engine running.

Wheel Alignment Mode

Before performing a wheel alignment, this

mode must be enabled. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” in the Owner’s Manual for

further information.

NOTE:

This mode is intended to be enabled with

engine running.

Protection Strategy

In order to “protect” the air suspension sys-

tem, the vehicle will disable load leveling as

required (suspension overloaded, battery

charge low, etc.). Load leveling will automati-

cally resume as soon as system operation

requirements are met. See your authorized

dealer if system does not resume.

NOTE:

If towing with air suspension refer to “Trailer

Towing” in “Starting And Operating” for fur-

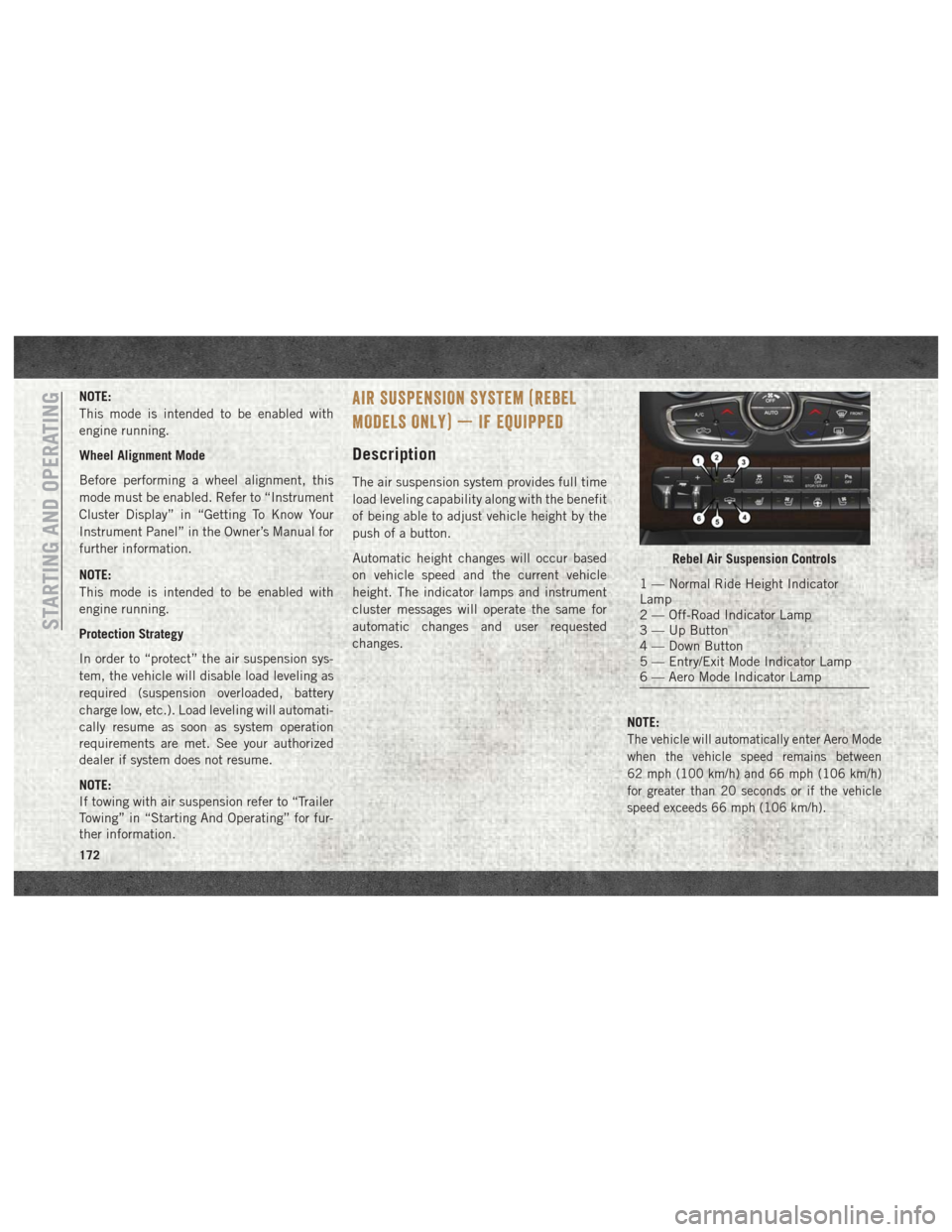

ther information.AIR SUSPENSION SYSTEM (REBEL

MODELS ONLY) — IF EQUIPPED

Description

The air suspension system provides full time

load leveling capability along with the benefit

of being able to adjust vehicle height by the

push of a button.

Automatic height changes will occur based

on vehicle speed and the current vehicle

height. The indicator lamps and instrument

cluster messages will operate the same for

automatic changes and user requested

changes.NOTE:

The vehicle will automatically enter Aero Mode

when the vehicle speed remains between

62 mph (100 km/h) and 66 mph (106 km/h)

for greater than 20 seconds or if the vehicle

speed exceeds 66 mph (106 km/h).

Rebel Air Suspension Controls

1 — Normal Ride Height Indicator

Lamp

2 — Off-Road Indicator Lamp

3 — Up Button

4 — Down Button

5 — Entry/Exit Mode Indicator Lamp

6 — Aero Mode Indicator Lamp

STARTING AND OPERATING

172

Page 176 of 372

to “Instrument Cluster Display” in “Getting

To Know Your Instrument Panel” in the Own-

er’s Manual for further information.

NOTE:

This mode is intended to be enabled with

engine running.

Tire/Jack Mode

To assist with changing a tire, the air suspen-

sion system has a feature which allows the

automatic leveling to be disabled. Refer to

“Instrument Cluster Display” in “Getting To

Know Your Instrument Panel” in the Owner’s

Manual for further information.

NOTE:

This mode is intended to be enabled with

engine running.

Transport Mode

For towing your vehicle with four wheels off

the ground, the air suspension system has a

feature which will put the vehicle into Entry/

Exit height and disable the automatic loadleveling system. Refer to “Instrument Cluster

Display” in “Getting To Know Your Instru-

ment Panel” in the Owner’s Manual for fur-

ther information.

NOTE:

This mode is intended to be enabled with

engine running.

Wheel Alignment Mode

Before performing a wheel alignment, this

mode must be enabled. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” in the Owner’s Manual for

further information.

NOTE:

This mode is intended to be enabled with

engine running.

Protection Strategy

In order to “protect” the air suspension sys-

tem, the vehicle will disable load leveling as

required (suspension overloaded, battery

charge low, etc.). Load leveling will automati-

cally resume as soon as system operation

requirements are met. See your authorized

dealer if system does not resume. NOTE:

If towing with air suspension refer to “Trailer

Towing” in “Starting And Operating” for fur-

ther information.

AIR SUSPENSION SYSTEM

(2500/3500 MODELS) — IF

EQUIPPED

Description

This air suspension system is a rear leveling

ride height system. The main purpose of this

system is to maintain the truck’s rear ride

height level. There are two selectable heights

that can be chosen based on your operating

conditions.

The system requires that the ignition be in

ON/RUN position or the engine running with

zero vehicle speed for all user requested

changes and load leveling.

STARTING AND OPERATING

174

Page 182 of 372

NOTE:

If the vehicle speed remains below 8 mph

(13 km/h), the Rear View Camera image will

be displayed continuously until deactivated

via the touchscreen button "X".

If equipped with a Cargo Camera, a touch-

screen button

to indicate the current

active Camera image being displayed is made

available whenever the Rear View Camera

image is displayed.

If equipped with a Cargo Camera, a touch-

screen button

to switch the display to

Cargo Camera image is made available when-

ever the Rear View Camera image is dis-

played.

A touchscreen button "X" to disable display of

the camera image is made available when the

vehicle is not in REVERSE gear.

When enabled, active guide lines are overlaid

on the image to illustrate the width of the

vehicle and its projected backup path based

on the steering wheel position. The active

guide lines will show separate zones that will

help indicate the distance to the rear of the

vehicle. NOTE:

For further information about how to access

and change the programmable features of the

ParkView Rear Backup Camera, refer to

“Uconnect Settings ” in “Multimedia” in the

Owner’s Manual for further information.

WARNING!

Drivers must be careful when backing up

even when using the ParkView Rear Back

Up Camera. Always check carefully behind

your vehicle, and be sure to check for

pedestrians, animals, other vehicles, ob-

structions, or blind spots before backing

up. You are responsible for the safety of

your surroundings and must continue to

pay attention while backing up. Failure to

do so can result in serious injury or death.

CAUTION!

• To avoid vehicle damage, ParkView

should only be used as a parking aid.

The ParkView camera is unable to view

every obstacle or object in your drive

path.

CAUTION!

• To avoid vehicle damage, the vehiclemust be driven slowly when using

ParkView to be able to stop in time when

an obstacle is seen. It is recommended

that the driver look frequently over his/

her shoulder when using ParkView.

NOTE:

If snow, ice, mud, or any foreign substance

builds up on the camera lens, clean the lens,

rinse with water, and dry with a soft cloth. Do

not cover the lens.

Turning Rear View Camera Image On:

1. Press the "Controls" button located on the bottom of the Uconnect display.

2. Press the "Backup Camera" button

to turn the Rear View Camera system on.

NOTE:

Once initiated by the "Backup Camera" but-

ton, the Rear View Camera image may be

deactivated by pressing the "X" button on the

touchscreen. On deactivation, the previous

selected screen will appear.

STARTING AND OPERATING

180

Page 196 of 372

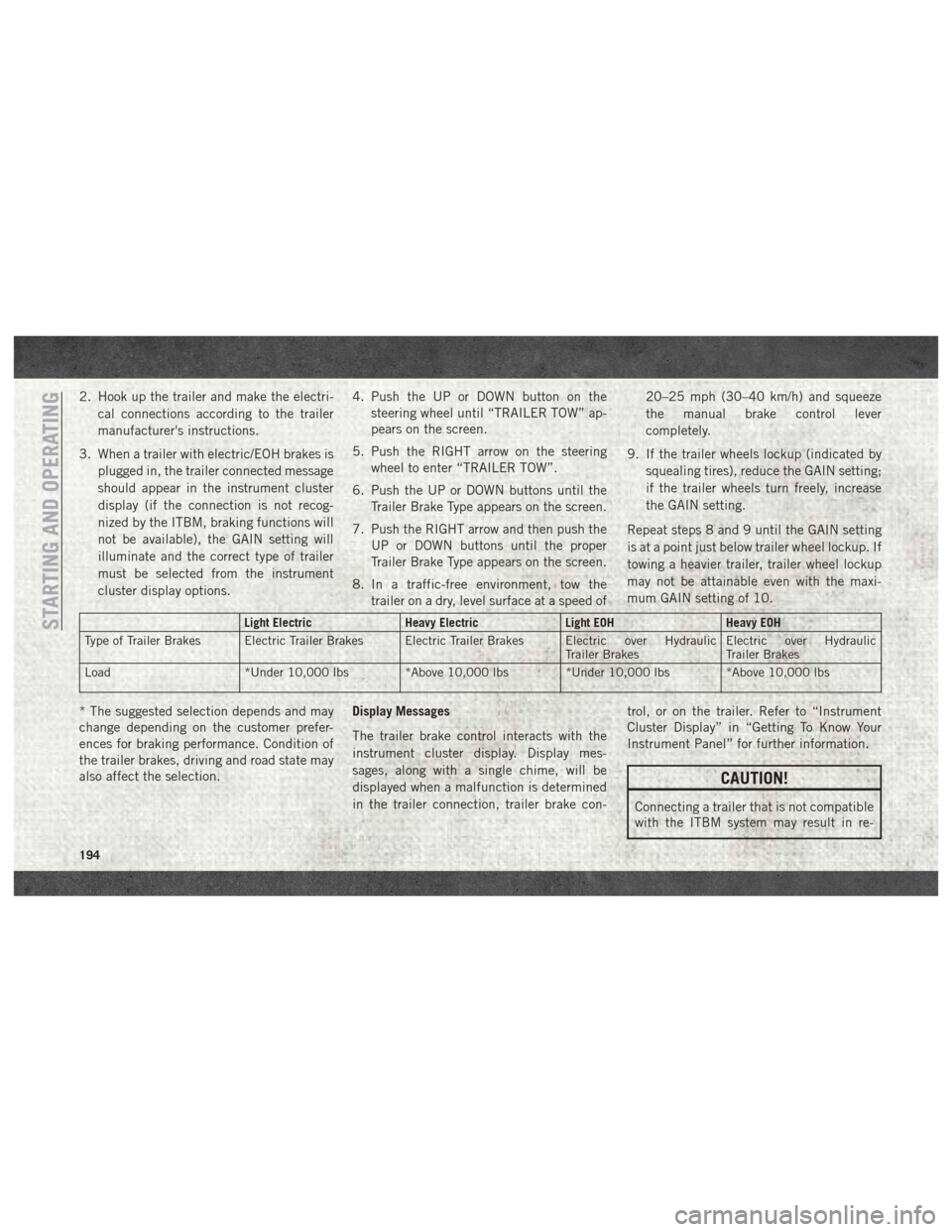

2. Hook up the trailer and make the electri-cal connections according to the trailer

manufacturer's instructions.

3. When a trailer with electric/EOH brakes is plugged in, the trailer connected message

should appear in the instrument cluster

display (if the connection is not recog-

nized by the ITBM, braking functions will

not be available), the GAIN setting will

illuminate and the correct type of trailer

must be selected from the instrument

cluster display options. 4. Push the UP or DOWN button on the

steering wheel until “TRAILER TOW” ap-

pears on the screen.

5. Push the RIGHT arrow on the steering wheel to enter “TRAILER TOW”.

6. Push the UP or DOWN buttons until the Trailer Brake Type appears on the screen.

7. Push the RIGHT arrow and then push the UP or DOWN buttons until the proper

Trailer Brake Type appears on the screen.

8. In a traffic-free environment, tow the trailer on a dry, level surface at a speed of 20–25 mph (30–40 km/h) and squeeze

the manual brake control lever

completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting;

if the trailer wheels turn freely, increase

the GAIN setting.

Repeat steps 8 and 9 until the GAIN setting

is at a point just below trailer wheel lockup. If

towing a heavier trailer, trailer wheel lockup

may not be attainable even with the maxi-

mum GAIN setting of 10.

Light Electric Heavy ElectricLight EOHHeavy EOH

Type of Trailer Brakes Electric Trailer Brakes Electric Trailer Brakes Electric over Hydraulic Trailer BrakesElectric over Hydraulic

Trailer Brakes

Load *Under 10,000 lbs *Above 10,000 lbs *Under 10,000 lbs *Above 10,000 lbs

* The suggested selection depends and may

change depending on the customer prefer-

ences for braking performance. Condition of

the trailer brakes, driving and road state may

also affect the selection. Display Messages

The trailer brake control interacts with the

instrument cluster display. Display mes-

sages, along with a single chime, will be

displayed when a malfunction is determined

in the trailer connection, trailer brake con- trol, or on the trailer. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

CAUTION!

Connecting a trailer that is not compatible

with the ITBM system may result in re-

STARTING AND OPERATING

194

Page 212 of 372

NOTE:

Always stow the spare tire with the valve stem

facing the ground. It is recommended that

you stow the flat or spare to avoid tangling the

loose cable.NOTE:

The winch mechanism is designed for use

with the extension tube only. Use of an air

wrench or other power tools is not recom-

mended and can damage the winch.

Preparations For Jacking

1. Park the vehicle on a firm, level surface.

Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic, pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2. Place the gear selector into PARK. On four-wheel drive vehicles, shift the trans-

fer case to the 4L position.

3. Turn on the Hazard Warning flasher.

4. Apply the parking brake.

5. Turn the ignition OFF. 6. Block both the front and rear of the wheel

diagonally opposite the jacking position.

For example, if the right front wheel is

being changed, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Lug Wrench/Spare Tire

1 — Lug Wrench 2 — Spare Tire

Wheel Blocked

IN CASE OF EMERGENCY

210

Page 216 of 372

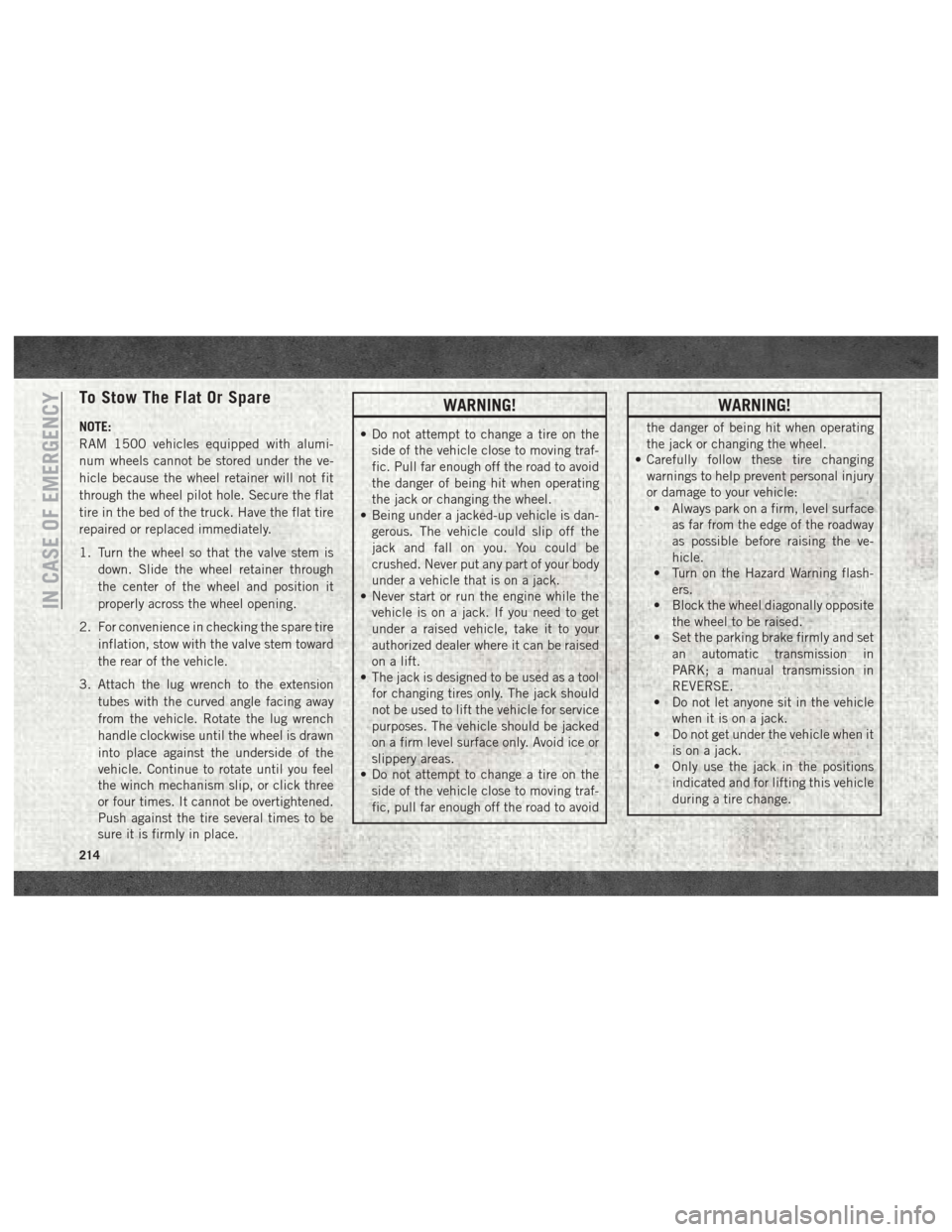

To Stow The Flat Or Spare

NOTE:

RAM 1500 vehicles equipped with alumi-

num wheels cannot be stored under the ve-

hicle because the wheel retainer will not fit

through the wheel pilot hole. Secure the flat

tire in the bed of the truck. Have the flat tire

repaired or replaced immediately.

1. Turn the wheel so that the valve stem isdown. Slide the wheel retainer through

the center of the wheel and position it

properly across the wheel opening.

2. For convenience in checking the spare tire inflation, stow with the valve stem toward

the rear of the vehicle.

3. Attach the lug wrench to the extension tubes with the curved angle facing away

from the vehicle. Rotate the lug wrench

handle clockwise until the wheel is drawn

into place against the underside of the

vehicle. Continue to rotate until you feel

the winch mechanism slip, or click three

or four times. It cannot be overtightened.

Push against the tire several times to be

sure it is firmly in place.

WARNING!

• Do not attempt to change a tire on theside of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack.

• Never start or run the engine while the

vehicle is on a jack. If you need to get

under a raised vehicle, take it to your

authorized dealer where it can be raised

on a lift.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

• Do not attempt to change a tire on the

side of the vehicle close to moving traf-

fic, pull far enough off the road to avoid

WARNING!

the danger of being hit when operating

the jack or changing the wheel.

• Carefully follow these tire changing

warnings to help prevent personal injury

or damage to your vehicle:• Always park on a firm, level surface

as far from the edge of the roadway

as possible before raising the ve-

hicle.

• Turn on the Hazard Warning flash-

ers.

• Block the wheel diagonally opposite

the wheel to be raised.

• Set the parking brake firmly and set

an automatic transmission in

PARK; a manual transmission in

REVERSE.

• Do not let anyone sit in the vehicle

when it is on a jack.

• Do not get under the vehicle when it

is on a jack.

• Only use the jack in the positions

indicated and for lifting this vehicle

during a tire change.

IN CASE OF EMERGENCY

214

Page 231 of 372

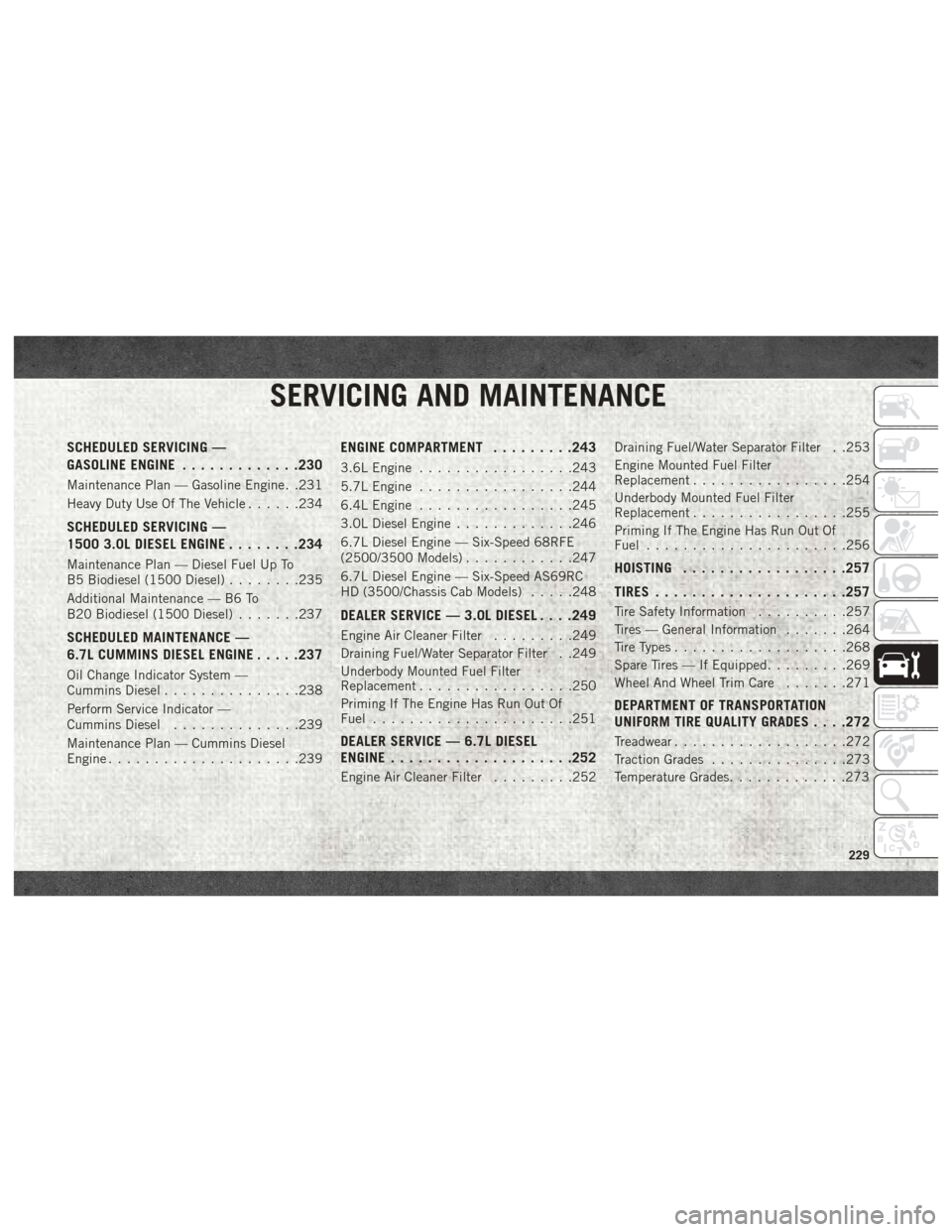

SERVICING AND MAINTENANCE

SCHEDULED SERVICING —

GASOLINE ENGINE.............230

Maintenance Plan — Gasoline Engine. .231

Heavy Duty Use Of The Vehicle ......234

SCHEDULED SERVICING —

1500 3.0L DIESEL ENGINE........234

Maintenance Plan — Diesel Fuel Up To

B5 Biodiesel (1500 Diesel) ........235

Additional Maintenance — B6 To

B20 Biodiesel (1500 Diesel) .......237

SCHEDULED MAINTENANCE —

6.7L CUMMINS DIESEL ENGINE .....237

Oil Change Indicator System —

Cummins Diesel...............238

Perform Service Indicator —

Cummins Diesel ..............239

Maintenance Plan — Cummins Diesel

Engine .....................239

ENGINE COMPARTMENT .........243

3.6L Engine.................243

5.7L Engine .................244

6.4L Engine .................245

3.0L Diesel Engine .............246

6.7L Diesel Engine — Six-Speed 68RFE

(2500/3500 Models) ............247

6.7L Diesel Engine — Six-Speed AS69RC

HD (3500/Chassis Cab Models) .....248

DEALER SERVICE — 3.0L DIESEL . . . .249

Engine Air Cleaner Filter.........249

Draining Fuel/Water Separator Filter . .249

Underbody Mounted Fuel Filter

Replacement .................250

Priming If The Engine Has Run Out Of

Fuel ......................251

DEALER SERVICE — 6.7L DIESEL

ENGINE ................... .252

Engine Air Cleaner Filter.........252Draining Fuel/Water Separator Filter . .253

Engine Mounted Fuel Filter

Replacement

.................254

Underbody Mounted Fuel Filter

Replacement .................255

Priming If The Engine Has Run Out Of

Fuel ......................256

HOISTING ................. .257

TIRES .................... .257

Tire Safety Information..........257

Tires — General Information .......264

Tire Types ...................268

Spare Tires — If Equipped .........269

Wheel And Wheel Trim Care .......271

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES . . . .272

Treadwear...................272

Traction Grades ...............273

Temperature Grades .............273

SERVICING AND MAINTENANCE

229

Page 242 of 372

Mileage or time passed (whichever comes first):7,500

15,000

22,500

30,000

37,500

45,000

52,500

60,000

67,500

75,000

82,500

90,000

97,500

105,000

112,500

120,000

127,500

135,000

142,500

150,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

Or Kilometers:

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

192,000

204,000

216,000

228,000

240,000

Inspect the front suspension, tie rod ends and

boot seals for cracks or leaks and all parts for

damage, wear, improper looseness or end

play; replace if necessary. XX XX X X XX X X

Inspect the brake linings. XXX XX X

Inspect and adjust parking brake. XXX XX X

Inspect drive belt; replace as necessary. XXX XX X

Inspect wheel bearings. XX XX X

Additional Maintenance

Replace cabin air filter. XXX XX X

Replace engine fuel filter element. X X X X X X X X X X

Replace chassis mounted fuel filter element. X X X X X X X X X X

Inspect the front and rear axle surfaces. If

gear oil leakage is suspected, check the fluid

level. If using your vehicle for police, taxi,

fleet, off-road or frequent trailer towing

change the axle fluid. *

Inspect the transfer case fluid (4x4), change

for any of the following: police, taxi, fleet, or

frequent trailer towing. XX XX X

Change the transfer case fluid (4x4). XX

SERVICING AND MAINTENANCE

240