stop start RAM 1500 2021 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 210 of 496

208STARTING AND OPERATING

AUX CAMERA — IF EQUIPPED

Your vehicle may be equipped with one or two

AUX Cameras, which display images from the

trailer on the touchscreen.

Activation

The AUX Camera is activated any of the

following ways:

By first pressing the Backup Camera or

Surround View Camera (if equipped) button

on the touchscreen, followed by the AUX

button located in the upper left corner of the

rearview display

Pressing the AUX button in the Apps menu

Pressing the AUX button when the vehicle is

in REVERSE

If equipped with two AUX Cameras, you can

switch between each camera by pressing the

AUX1 or AUX2 buttons on the Trailer Camera

display. AUX1 Camera Button

AUX2 Camera Button

Deactivation

The AUX Camera is deactivated when the

following situations occur:

The “X” in the upper right corner of the touch -

screen is pressed. This will return the display

back to the previously displayed screen.

The vehicle speed exceeds 8 mph (13 km/h)

for 10 seconds.

The vehicle is shifted into PARK.

The ignition is placed in the OFF position. NOTE:

If the AUX button is pressed and no AUX

Camera is connected, the touchscreen will

display a blue screen along with the message

“Camera System Unavailable.” The screen

can be exited out by pressing the “X” in the

upper right hand corner. This will return the

display back to the previously displayed

screen.

Zoom View is not available with the AUX

Camera feature.

The display will always default to the Trailer

Camera display (AUX 1).

REFUELING THE VEHICLE — GASOLINE

ENGINE

The capless fuel filler is located on the left side

of the vehicle.

The capless system is sealed by two flapper

doors.

CAUTION!

To avoid vehicle damage, Surround View

should only be used as a parking aid. The

Surround View camera is unable to view

every obstacle or object in your drive path.

To avoid vehicle damage, the vehicle must

be driven slowly when using Surround View

to be able to stop in time when an obstacle

is seen. It is recommended that the driver

look frequently over his/her shoulder when

using Surround View.

21_DT_OM_EN_USC_t.book Page 208

Page 214 of 496

212STARTING AND OPERATING

(Continued)

(Continued)

2. Insert DEF fill adapter/nozzle into DEF tank filler neck.

NOTE:

The DEF gauge may take up to five seconds

to update after adding a gallon or more of

(DEF) to the DEF tank. If you have a fault

related to the DEF system, the gauge may not

update to the new level. See an authorized

dealer for service.

The DEF gauge may also not immediately

update after a refill if the temperature of the

DEF fluid is below 12°F (-11°C). The DEF line

heater will possibly warm up the DEF fluid

and allow the gauge to update after a period

of run time. Under very cold conditions, it is

possible that the gauge may not reflect the

new fill level for several drives.

Refilling With Nozzles

You can fill up at any DEF distributor.

Proceed as follows:

Insert the DEF nozzle in the filler, start

refilling and stop refilling at the first

shut-off (the shut-off indicates that the

DEF tank is full). Do not proceed with the

refilling, to prevent spillage of DEF.

Extract the nozzle. Refilling With Containers

Proceed as follows:

Check the expiration date.

Read the advice for use on the label

before pouring the content of the bottle

into the DEF tank.

If systems which cannot be screwed in

(e.g. tanks) are used for refilling, after the

indication appears on the instrument

panel display Ú

page 114 fill the DEF

tank with no more than 2 Gallons (8

liters).

If containers which can be screwed to the

filler are used, the reservoir is full when

the DEF level in the container stops

pouring out. Do not proceed further.

CAUTION!

To avoid DEF spillage, and possible

damage to the DEF tank from overfilling, do

not “top off” the DEF tank after filling.

DO NOT OVERFILL. DEF will freeze below

12ºF (-11ºC). The DEF system is designed

to work in temperatures below the DEF

freezing point, however, if the tank is over -

filled and freezes, the system could be

damaged.

When DEF is spilled, clean the area imme -

diately with water and use an absorbent

material to soak up the spills on the ground.

Do not attempt to start your engine if DEF is

accidentally added to the diesel fuel tank

as it can result in severe damage to your

engine, including but not limited to failure

of the fuel pump and injectors.

CAUTION! (Continued)

21_DT_OM_EN_USC_t.book Page 212

Page 215 of 496

STARTING AND OPERATING213

3. Stop filling the DEF tank immediately when

any of the following happen: DEF stops

flowing from the fill bottle into the DEF tank,

DEF splashes out the filler neck, or a DEF

pump nozzle automatically shuts off.

4. Reinstall cap onto DEF tank.

Filling The Def Tank In Cold Climates

Your vehicle is equipped with an automatic DEF

heating system. This allows the DEF injection

system to operate properly at temperatures below 12°F (-11°C). If your vehicle is not in

operation for an extended period of time with

temperatures below 12°F (-11°C), the DEF in

the tank may freeze. Do not overfill the DEF

tank. If the tank is overfilled and freezes, it

could be damaged.

Extra care should be taken when filling with

portable containers to avoid overfilling. Keep an

eye on the DEF gauge in your instrument

cluster. You may safely add a maximum of

2 gallons (7.6 Liters) when your DEF gauge is

reading at the half mark.

VEHICLE LOADING

GROSS VEHICLE WEIGHT RATING

(GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear Gross

Axle Weight Rating (GAWR). Total load must be

limited so GVWR and front and rear GAWR are

not exceeded.

PAYLOAD

The payload of a vehicle is defined as the

allowable load weight a truck can carry,

including the weight of the driver, all

passengers, options and cargo.

GROSS AXLE WEIGHT RATING (GAWR)

The GAWR is the maximum permissible load on

the front and rear axles. The load must be

distributed in the cargo area so that the GAWR

of each axle is not exceeded.

Each axle GAWR is determined by the

components in the system with the lowest load

carrying capacity (axle, springs, tires or wheels).

Heavier axles or suspension components

sometimes specified by purchasers for

increased durability does not necessarily

increase the vehicle's GVWR.

TIRE SIZE

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

Never add anything other than DEF to the

tank – especially any form of hydrocarbon

such as diesel fuel, fuel system additives,

gasoline, or any other petroleum-based

product. Even a very small amount of these,

less than 100 parts per million or less than

1 oz. per 78 gallons (295 liters) will contam -

inate the entire DEF system and will require

replacement. If owners use a container,

funnel or nozzle when refilling the tank, it

should either be new or one that is has only

been used for adding DEF. Mopar provides

an attachable nozzle with its DEF for this

purpose.

CAUTION! (Continued)

4

21_DT_OM_EN_USC_t.book Page 213

Page 221 of 496

STARTING AND OPERATING219

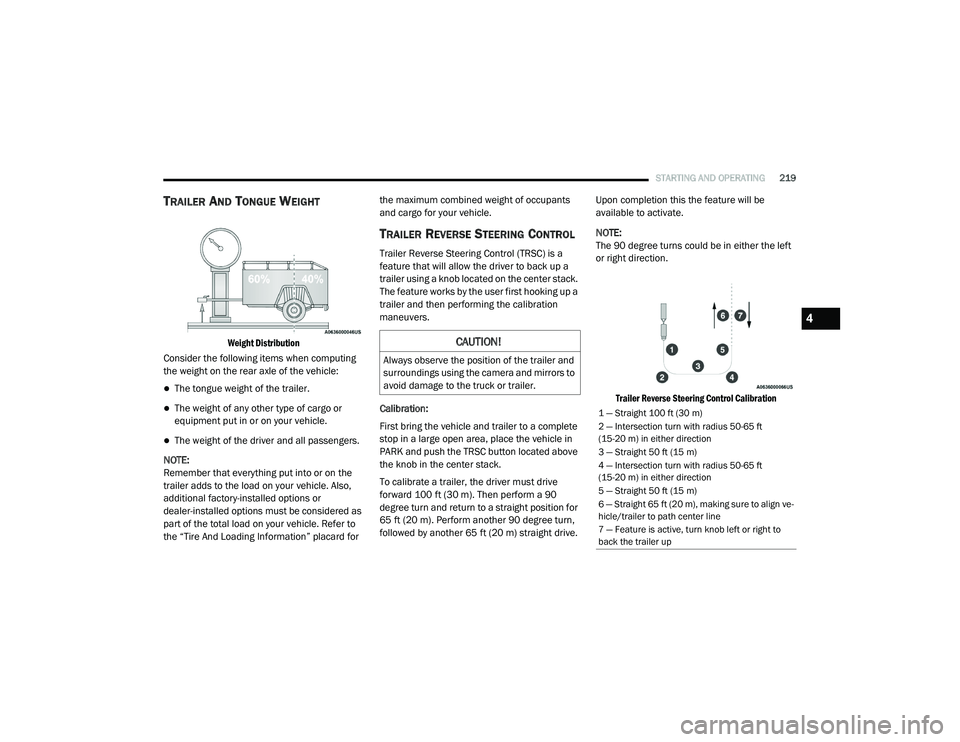

TRAILER AND TONGUE WEIGHT

Weight Distribution

Consider the following items when computing

the weight on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or

equipment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:

Remember that everything put into or on the

trailer adds to the load on your vehicle. Also,

additional factory-installed options or

dealer-installed options must be considered as

part of the total load on your vehicle. Refer to

the “Tire And Loading Information” placard for the maximum combined weight of occupants

and cargo for your vehicle.

TRAILER REVERSE STEERING CONTROL

Trailer Reverse Steering Control (TRSC) is a

feature that will allow the driver to back up a

trailer using a knob located on the center stack.

The feature works by the user first hooking up a

trailer and then performing the calibration

maneuvers.

Calibration:

First bring the vehicle and trailer to a complete

stop in a large open area, place the vehicle in

PARK and push the TRSC button located above

the knob in the center stack.

To calibrate a trailer, the driver must drive

forward 100 ft (30 m). Then perform a 90

degree turn and return to a straight position for

65 ft (20 m). Perform another 90 degree turn,

followed by another 65 ft (20 m) straight drive. Upon completion this the feature will be

available to activate.

NOTE:

The 90 degree turns could be in either the left

or right direction.

Trailer Reverse Steering Control Calibration

CAUTION!

Always observe the position of the trailer and

surroundings using the camera and mirrors to

avoid damage to the truck or trailer.

1 — Straight 100 ft (30 m)

2 — Intersection turn with radius 50-65 ft

(15-20 m) in either direction

3 — Straight 50 ft (15 m)

4 — Intersection turn with radius 50-65 ft

(15-20 m) in either direction

5 — Straight 50 ft (15 m)

6 — Straight 65 ft (20 m), making sure to align ve -

hicle/trailer to path center line

7 — Feature is active, turn knob left or right to

back the trailer up

4

21_DT_OM_EN_USC_t.book Page 219

Page 222 of 496

220STARTING AND OPERATING

Once calibrated the driver can shift to PARK,

push the button on top of the TRSC knob and

activate the feature. The knob is then turned

either to the left or right depending on what

direction the driver wants the trailer to go.

Trailer Reverse Steering Control Knob

NOTE:

When steering the trailer with the knob, remove

hands from the steering wheel.

There is also a holdover state where if during an

active trailer steering maneuver, the driver

shifts to NEURAL or DRIVE to straighten the

trailer, the driver may shift back to REVERSE

and not need to reactivate the feature. However

the feature will cancel after 10 seconds or when

the vehicle speed reaches 8 mph (12 km/h). Instrument Cluster Messages:

“Drive forward to calibrate trailer” will display

when a trailer is not calibrated and the

vehicle is at standstill while the button is

pushed.

“Calibrating trailer” will display when the

trailer is not calibrated and the vehicle is

moving while the button is pushed.

“To activate trailer steering shift to P” will

display when the trailer is calibrated success

-

fully and the vehicle is not in PARK.

“Trailer Steering ready, shift to reverse” will

display when the button is pushed, trailer is

calibrated and the vehicle is in PARK.

“Trailer steering active” will display after the

driver shifts to REVERSE and indicates the

feature is active.

“Trailer Steering Unavailable” will display if

there is a fault in the system preventing acti -

vation, the driver’s door is open, the driver’s

seat belt is unbuckled, or the tailgate is open. Other reasons the feature may cancel:

The driver overrides steering by placing

hands on the steering wheel.

Trailer tracking is lost.

If the trailer angle becomes excessive, the

brakes apply bringing the vehicle to a stop

and then applying the parking brake.

Trailer steering button is pushed while active.

Vehicle speed goes over 8 mph (12 km/h).

Driver door is open and seat belt is

unbuckled.

Transmission shifted to PARK.

Trailer Memory

The trailer steering system can remember up to

five trailers, so recalibration will not be

necessary.

To store a trailer to memory, calibrate the trailer

and then allow the vehicle to be off for a period

of time. The next time the vehicle is started,

place the vehicle in DRIVE and drive a short

distance. The trailer system can then be

activated.

21_DT_OM_EN_USC_t.book Page 220

Page 224 of 496

222STARTING AND OPERATING

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h)

when towing while using a full size spare tire.

Proper tire inflation pressures are essential

to the safe and satisfactory operation of your

vehicle.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer.

Replacing tires with a higher load carrying

capacity will not increase the vehicle's GVWR

and GAWR limits.

For further information Ú page 443.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake

system or vacuum system of your vehicle

with that of the trailer.

An electronically actuated trailer brake

controller is required when towing a trailer

with electronically actuated brakes. When

towing a trailer equipped with a hydraulic

surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers

over 1,000 lbs (453 kg) and required for

trailers in excess of 2,000 lbs (907 kg).

Vehicles with trailers should not be parked

on a grade. When parking, apply the

parking brake on the tow vehicle. Put the

tow vehicle transmission in PARK. For

four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL. Always,

block or "chock" the trailer wheels.

GCWR must not be exceeded.

Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer

hitch utilized.

WARNING! (Continued)WARNING!

Do not connect trailer brakes to your

vehicle's hydraulic brake lines. It can over -

load your brake system and cause it to fail.

You might not have brakes when you need

them and could have an accident.

Towing any trailer will increase your stop -

ping distance. When towing, you should

allow for additional space between your

vehicle and the vehicle in front of you.

Failure to do so could result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lbs

(453 kg) loaded, it should have its own

brakes and they should be of adequate

capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake

pedal effort, and longer stopping distances.

21_DT_OM_EN_USC_t.book Page 222

Page 225 of 496

STARTING AND OPERATING223

Integrated Trailer Brake Module — If

Equipped

Your vehicle may have an Integrated Trailer

Brake Module (ITBM) for Electric and Electric

Over Hydraulic (EOH) trailer brakes.

NOTE:

This module has been designed and verified

with electric trailer brakes and new EOH

systems. Some previous EOH systems may not

be compatible with ITBM.

Integrated Trailer Brake Module (ITBM)

The user interface consists of the following:

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake

control power output to the trailer brakes in

0.5 increments. The GAIN setting can be

increased to a maximum of 10 or decreased to

a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer brake

control for the specific towing condition and

should be changed as towing conditions

change. Changes to towing conditions include

trailer load, vehicle load, road conditions and

weather.

Manual Brake Control Lever

Slide the manual brake control lever to the left

to activate power to the trailer's electric brakes

independent of the tow vehicle's brakes. If the

manual brake control lever is activated while

the brake is also applied, the greater of the two

inputs determines the power sent to the trailer

brakes. The trailer and the vehicle’s stop lamps will

come on when braking normally with the vehicle

brake pedal. Only the trailer stop lamps will

come on when the manual brake control lever is

applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical

connection status.

If no electrical connection is detected after the

ignition is turned on, pushing the GAIN

adjustment button or sliding the manual brake

control lever will display the GAIN setting for

10 seconds and the “Trailer Brake Status

Indicator Light” will not be displayed.

If a fault is detected in the trailer wiring or the

Integrated Trailer Brake Module (ITBM), the

“Trailer Brake Status Indicator Light” will flash.

1 — GAIN (-) Adjustment Button

2 — GAIN (+) Adjustment Button

3 — Manual Brake Control Lever

4

21_DT_OM_EN_USC_t.book Page 223

Page 227 of 496

STARTING AND OPERATING225

Display Messages

The trailer brake control interacts with the

instrument cluster display. Display messages,

along with a single chime, will be displayed

when a malfunction is determined in the trailer

connection, trailer brake control, or on the

trailer Úpage 114. NOTE:

An aftermarket controller may be available

for use with trailers with air or elec

-

tric-over-hydraulic trailer brake systems. To

determine the type of brakes on your trailer

and the availability of controllers, check with

your trailer manufacturer or dealer.

Removal of the ITBM will cause errors and it

may cause damage to the electrical system

and electronic modules of the vehicle. See

your authorized dealer if an aftermarket

module is to be installed.

Towing Requirements — Trailer Lights And

Wiring

Whenever you pull a trailer, regardless of the

trailer size, stoplights and turn signals on the

trailer are required for motoring safety.

The Trailer Tow Package may include a four-pin

and seven-pin wiring harness. Use a factory

approved trailer harness and connector.

NOTE:

Do not cut or splice wiring into the vehicle’s

wiring harness. The electrical connections are all complete to

the vehicle but you must connect the harness to

a trailer connector. Refer to the following

illustrations.

NOTE:

Disconnect trailer wiring connector from the

vehicle before launching a boat (or any other

device plugged into vehicle’s electrical

connect) into water.

Be sure to reconnect once clear from water

area.

Four-Pin Connector

WARNING!

Connecting a trailer that is not compatible

with the ITBM system may result in reduced

or complete loss of trailer braking. There may

be a increase in stopping distance or trailer

instability which could result in personal

injury.

CAUTION!

Connecting a trailer that is not compatible

with the ITBM system may result in reduced

or complete loss of trailer braking. There may

be a increase in stopping distance or trailer

instability which could result in damage to

your vehicle, trailer, or other property.

1 — Ground

2 — Park

3 — Left Stop/Turn

4 — Right Stop/Turn

4

21_DT_OM_EN_USC_t.book Page 225

Page 228 of 496

226STARTING AND OPERATING

Seven-Pin Connector

Trailer Light Check

This feature will run the trailer lights through a

sequence to check the trailer light function. It is

available in the Instrument Cluster under the

Trailer Tow menu Ú page 118.

When activated the feature will enable all of the

exterior lights sequentially for up to two minutes

for time to walk around and verify functionality. The following exterior lights will remain on for

the entirety of the sequence:

Park/Running Lamps

Side Marker Lamps (if equipped)

License Lamp

Signature Lamp (if equipped)

Low Beams

Fog Lamps (if equipped)

Daytime Running Lamps

During this time the following lights will

sequence, each activating for three seconds:

1. Brake and CHMSL (third brake light)

2. Left turn signal

3. Right turn signal

4. Reverse Lamps

5. High Beam

This light check sequence will continue for a

total of two minutes. The sequence will only activate if the following

conditions are met:

Vehicle is equipped with the Trailer Tow

Package

Vehicle is in PARK

Vehicle is not in motion

Ignition in ACC or RUN

Remote start is inactive

Brakes are not applied

Left turn signal is not applied

Right turn signal not applied

Hazard switch is not applied

The sequence will cancel if any of the following

conditions occur:

Brakes are applied

Vehicle is shifted from PARK

Vehicle is no longer stationary

Left turn signal activated from stalk

Right turn signal is activated from stalk

1 — Battery

2 — Backup Lamps

3 — Right Stop/Turn

4 — Electric Brakes

5 — Ground

6 — Left Stop/Turn

7 — Running Lamps

21_DT_OM_EN_USC_t.book Page 226

Page 229 of 496

STARTING AND OPERATING227

Hazard switch is activated

Any button on the key fob is pushed

Ignition button is pushed

High Beam stalk position is changed

Sequence is canceled in the instrument

cluster

TOWING TIPS

Before towing, practice turning, stopping, and

backing up the trailer in an area located away

from heavy traffic.

Automatic Transmission

The DRIVE range can be selected when towing.

The transmission controls include a drive

strategy to avoid frequent shifting when towing.

However, if frequent shifting does occur while in

DRIVE, select TOW/HAUL mode or select a lower

gear range (using the Electronic Range Select

(ERS) shift control).

NOTE:

Using TOW/HAUL mode or selecting a lower

gear range (using the ERS shift control) while

operating the vehicle under heavy loading

conditions will improve performance and extend transmission life by reducing excessive

shifting and heat build up. This action will also

provide better engine braking.

Tow/Haul Mode

To reduce potential for automatic transmission

overheating, activate TOW/HAUL mode when

driving in hilly areas, or select a lower gear

range (using the (ERS) shift control) on more

severe grades.

Cruise Control — If Equipped

Do not use on hilly terrain or with heavy

loads.

When using the Cruise Control, if you experi

-

ence speed drops greater than 10 mph

(16 km/h), disengage until you can get back

to cruising speed.

Use Cruise Control in flat terrain and with

light loads to maximize fuel efficiency.

Air Suspension System

To aid in attaching/detaching the trailer from

the vehicle, the air suspension system can be

used Ú page 165. NOTE:

The vehicle must remain in the engine running

position while attaching a trailer for proper

leveling of the air suspension system.

SNOWPLOW

Snowplow Prep Packages are available as a

factory installed option. These packages

include components necessary to equip your

vehicle with a snowplow.

NOTE:

Before installation of a snowplow it is highly

recommended that the owner/installer obtain

and follow the recommendations contained

within the current Body Builders Guide. See an

authorized dealer, installer or snowplow manu

-

facturer for this information. There are unique

electrical systems that must be connected to

properly ensure operator safety and prevent

overloading vehicle systems.

4

21_DT_OM_EN_USC_t.book Page 227