wheel RAM 1500 2022 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: 1500, Model: RAM 1500 2022Pages: 496, PDF Size: 18.03 MB

Page 376 of 496

374IN CASE OF EMERGENCY

SOS Call System Limitations

Vehicles sold in Mexico DO NOT have SOS Call

system capabilities.

SOS or other emergency line operators in Mexico

may not answer or respond to SOS system calls.

If the SOS Call system detects a malfunction, any

of the following may occur at the time the

malfunction is detected, and at the beginning of

each ignition cycle:

The overhead console lights located within the

ASSIST and SOS buttons will continuously illumi -

nate red.

The Device Screen will display the following

message: “Vehicle device requires service.

Please contact an authorized dealer.”

An In-Vehicle Audio message will state “Vehicle

device requires service. Please contact an

authorized dealer.” Even if the SOS Call system is fully functional,

factors beyond FCA US LLC’s control may prevent

or stop the SOS Call system operation. These

include, but are not limited to, the following

factors:

The ignition is in the OFF position

The vehicle’s electrical systems are not intact

The SOS Call system software and/or hardware

are damaged during a crash

The vehicle battery loses power or becomes

disconnected during a vehicle crash

LTE (voice/data) or 4G (data) network and/or

Global Positioning Satellite signals are unavail

-

able or obstructed

Equipment malfunction at the SOS operator

facility

Operator error by the SOS operator

LTE (voice/data) or 4G (data) network conges -

tion

Weather

Buildings, structures, geographic terrain, or

tunnels

WARNING!

Ignoring the overhead console light could

mean you will not have SOS Call services. If

the overhead console light is illuminated, have

an authorized dealer service the SOS Call

system immediately.

The Occupant Restraint Control module turns

on the air bag Warning Light on the instrument

panel if a malfunction in any part of the

system is detected. If the Air Bag Warning

Light is illuminated, have an authorized dealer

service the Occupant Restraint Control system

immediately.

WARNING!

ALWAYS obey traffic laws and pay attention to

the road. ALWAYS drive safely with your hands on

the steering wheel. You have full responsibility

and assume all risks related to the use of the

features and applications in this vehicle. Only

use the features and applications when it is safe

to do so. Failure to do so may result in an

accident involving serious injury or death.

22_DT_OM_EN_USC_t.book Page 374

Page 377 of 496

IN CASE OF EMERGENCY375

NOTE:

Your vehicle may be transmitting data as autho -

rized by the subscriber.

Never place anything on or near the vehicle’s

LTE (voice/data) or 4G (data) and GPS

antennas. You could prevent LTE (voice/data) or

4G (data) and GPS signal reception, which can

prevent your vehicle from placing an emergency

call. An operable LTE (voice/data) or 4G (data)

network connection and a GPS signal is

required for the SOS Call system to function

properly.

NOTE:Changes or modifications not expressly approved

by the party responsible for compliance could void

the user's authority to operate the equipment.

Automatic SOS — If Equipped

Automatic SOS is a hands-free safety service that

can immediately connect you with help in the event

that your vehicle’s airbags deploy. Please refer to

your provided radio supplement for complete

information.

JACKING AND TIRE CHANGING NOTE:If your vehicle is equipped with an air suspension

system, there is a feature which allows the auto -

matic leveling to be disabled to assist with

changing a tire. This feature can be activated

through the Uconnect system Ú page 253.

PREPARATIONS FOR JACKING

NOTE:

If your vehicle is equipped with Air Suspension, you

will need to enable Tire Jack Mode in the Uconnect

system Úpage 165 before changing the tire.

1. Park on a firm, level surface. Avoid ice or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake.

4. Shift the transmission into Park (P).

5. Turn the ignition OFF.

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid the danger of

being hit when operating the jack or changing

the wheel.

Being under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on

you. You could be crushed. Never put any part

of your body under a vehicle that is on a jack.

If you need to get under a raised vehicle, take

it to a service center where it can be raised on

a lift.

Never start or run the engine while the vehicle

is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

7

22_DT_OM_EN_USC_t.book Page 375

Page 378 of 496

376IN CASE OF EMERGENCY

6. Block both the front and rear wheel diagonally opposite of each jacking position. For example,

if the driver’s front wheel is being changed,

block the passenger’s rear wheel.

Wheel Blocked

NOTE:Passengers should not remain in the vehicle when

the vehicle is being raised or lifted.

JACK LOCATION

The jack and tools are stored under the front

passenger seat.

REMOVAL OF JACK AND TOOLS

To access the jack and tools, you must remove the

plastic access cover located on the side of the

front passenger’s seat. To remove the cover, pull

the front part of the cover (closest to the front of

the seat) toward you to release a locking tab. Once

the front of the cover is loose, slide the cover

toward the front of the seat until it is free from the

seat frame.

Pull Jack Access Cover From Front

Remove the jack and tools by turning the wing bolt

counterclockwise. After removing the wing bolt,

slide the assembly out from under the seat.

Jack And Tools

Fuel Funnel Location

22_DT_OM_EN_USC_t.book Page 376

Page 381 of 496

IN CASE OF EMERGENCY379

(Continued)

4. Rotate the lug wrench handle counter-

clockwise until the spare tire is on the ground

with enough cable slack to allow you to pull it

out from under the vehicle.

Rotating The Lug Wrench Handle

5. Pull the spare tire out from under the vehicle to gain access to the spare tire retainer.

Pulling The Spare Tire Out

6. Lift the spare tire with one hand to give

clearance to tilt the retainer at the end of the

cable.

7. Pull the retainer through the center of the wheel.

Disengaging The Retainer

JACKING INSTRUCTIONS

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the wheel

to be raised.

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with

the valve stem facing the ground.

WARNING!

7

22_DT_OM_EN_USC_t.book Page 379

Page 382 of 496

380IN CASE OF EMERGENCY

Jack Warning Label

1. Remove the spare tire, jack, and tools from the stored location.

2. Using the lug wrench, loosen the wheel nuts (but do not remove), by turning them counter -

clockwise one turn while the wheel is still on

the ground.

3. Assemble the jack and jacking tools. Connect the jack handle driver to the extension, then to

the lug wrench.

Assembled Jack And Tools

4. Placement for the front and rear jacking locations are critical. See below images for

proper jacking locations.

Jack / Extensions Placement

Front Jacking Location

When changing a front wheel, place the

scissor jack under the rear portion of the

lower control arm as shown. Access the

front jacking location from behind the front

tire.

Front Lifting Point

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the

Jacking Instructions for this vehicle.

22_DT_OM_EN_USC_t.book Page 380

Page 383 of 496

IN CASE OF EMERGENCY381

Front Jacking Location

Rear Jacking Location

Operate the jack using the extension with jack

hook and the lug wrench. The extension tubes

may be used but are not required.

When changing a rear wheel, assemble the ex -

tension with jack hook to the jack and connect

the extension tubes. Access the rear jacking lo -

cation from behind the rear tire. Place the jack

under the Jack Lifting Point located on the rear

axle lower control arm bracket. Then locate the

slot in the jack lift plate onto the rear axle Jack

Lifting Point. Attach the extension with jack

hook extending to the rear of the vehicle.

Rear Lifting Point

Rear Jacking Location

Connect the long extensions to the lug

wrench.

5. By rotating the lug wrench clockwise, raise the vehicle until the wheel just clears the ground

surface.

6. Remove the lug nuts and pull the wheel off. Install the spare wheel and lug nuts with the

cone shaped end of the lug nuts toward the

wheel. Hand tighten the lug nuts with the

vehicle lifted. To avoid the risk of forcing the

vehicle off the jack, do not fully tighten the lug

nuts until the vehicle has been completely

lowered.

CAUTION!

Before raising the wheel off the ground, make

sure that the jack will not damage surrounding

truck parts and adjust the jack position as

required.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

7

22_DT_OM_EN_USC_t.book Page 381

Page 384 of 496

382IN CASE OF EMERGENCY

7. Lower the vehicle to the ground and finish tightening the lug nuts. Push down on the

wrench handle for increased leverage. Tighten

the lug nuts in a star pattern until each lug nut

has been tightened twice Ú page 466. If in

doubt about the correct tightness, have them

checked with a torque wrench by an

authorized dealer or at a service station.

8. If your vehicle is equipped with a wheel center cap, install the cap and remove the wheel

blocks. Do not install chrome or aluminum

wheel center caps on the spare wheel. This

may result in cap damage.

9. Lower the jack to its fully closed position. Stow the replaced tire, and secure the jack and tools

in the proper location.

10. Adjust the tire pressure when possible.

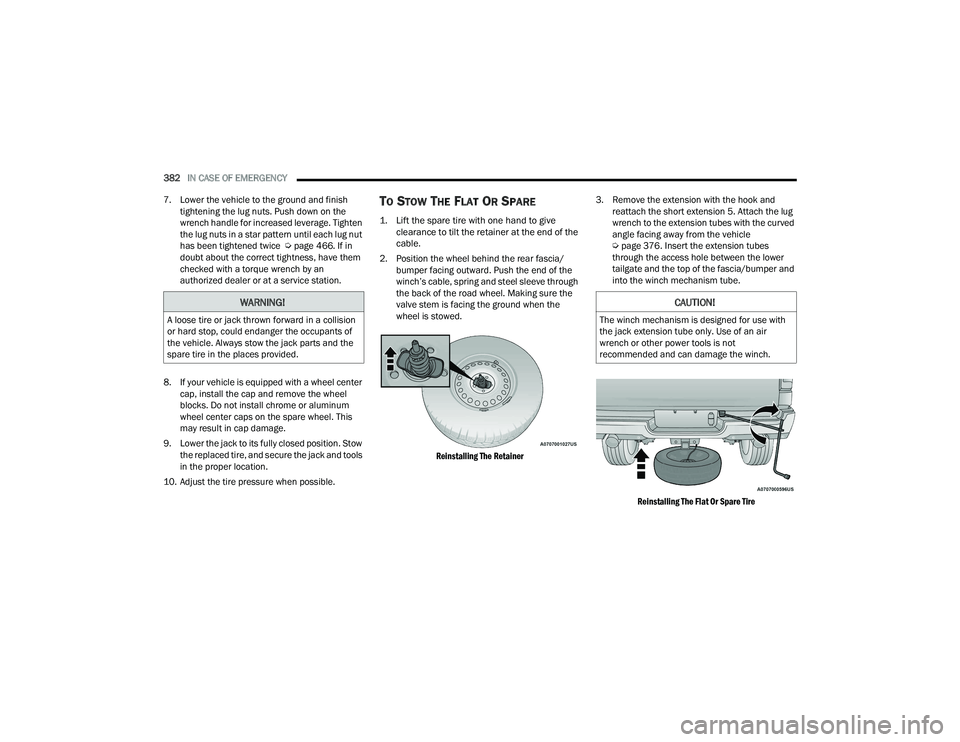

TO STOW THE FLAT OR SPARE

1. Lift the spare tire with one hand to give clearance to tilt the retainer at the end of the

cable.

2. Position the wheel behind the rear fascia/ bumper facing outward. Push the end of the

winch’s cable, spring and steel sleeve through

the back of the road wheel. Making sure the

valve stem is facing the ground when the

wheel is stowed.

Reinstalling The Retainer

3. Remove the extension with the hook and

reattach the short extension 5. Attach the lug

wrench to the extension tubes with the curved

angle facing away from the vehicle

Úpage 376. Insert the extension tubes

through the access hole between the lower

tailgate and the top of the fascia/bumper and

into the winch mechanism tube.

Reinstalling The Flat Or Spare Tire

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop, could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided.

CAUTION!

The winch mechanism is designed for use with

the jack extension tube only. Use of an air

wrench or other power tools is not

recommended and can damage the winch.

22_DT_OM_EN_USC_t.book Page 382

Page 385 of 496

IN CASE OF EMERGENCY383

4. Rotate the lug wrench handle clockwise until the wheel is drawn into place against the

underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip, or

click three or four times. It cannot be

overtightened. Push against the tire several

times to ensure it is firmly in place.

Rotating The Lug Wrench Handle

NOTE:Have the flat tire repaired or replaced immediately.

REINSTALLING THE JACK AND TOOLS

1. Tighten the jack all the way down by turning the jack turn-screw counterclockwise until the

jack is snug.

2. Position the jack and tool bag. Make sure the lug wrench is under the jack near the jack

turn-screw.

Jack And Tool Bag

3. Secure the tool bag straps to the jack.

Jack And Tools Tied

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

7

22_DT_OM_EN_USC_t.book Page 383

Page 391 of 496

IN CASE OF EMERGENCY389

4. Behind the Manual Park Release access cover is the orange tether strap. Pull the tether strap

out as far as it will go, then release it. The

tether and lever will remain outside of the trim

panel and the transmission should now be in

NEUTRAL, allowing the vehicle to be moved.

Manual Park Release Tether

To Reset The Manual Park Release:

1. Apply firm pressure to the brake pedal while

seated in the driver’s seat.

2. Pull the tether strap out again, then release it.

3. Allow the tether to retract with the lever back to its original position.

Manual Park Release Tether

4. Verify the transmission is in PARK.

5. Confirm that the tether has retracted fully and

reinstall the access cover. If the access cover

cannot be reinstalled, repeat steps 1 through

4.

NOTE:When the lever is locked in the released position

the access cover cannot be reinstalled.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Then shift

back and forth between DRIVE (D) and REVERSE

(R), while gently pressing the accelerator. Use the

least amount of accelerator pedal pressure that

will maintain the rocking motion, without spinning

the wheels or racing the engine.

7

22_DT_OM_EN_USC_t.book Page 389

Page 392 of 496

390IN CASE OF EMERGENCY

NOTE:Shifts between DRIVE and REVERSE can only be

achieved at wheel speeds of 5 mph (8 km/h) or

less. Whenever the transmission remains in

NEUTRAL (N) for more than two seconds, you must

press the brake pedal to engage DRIVE or

REVERSE.

Push the ESC OFF button to place the Electronic

Stability Control (ESC) system in “Partial OFF”

mode, before rocking the vehicle Ú page 314.

Once the vehicle has been freed, push the ESC OFF

button to restore “ESC On” mode.TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service.

If the transmission and drivetrain are operable,

disabled vehicles may also be towed as described

on Ú page 227.

NOTE:

Vehicles equipped with the Active-Level Four

Corner Air Suspension System must be placed in

Transport mode, before tying them down (from the

body) on a trailer or flatbed truck Ú page 165. If

the vehicle cannot be placed in Transport mode

(for example, engine will not run), tie-downs must

be fastened to the axles (not to the body). Failure

to follow these instructions may cause fault codes

to be set and/or cause loss of proper tie-down

tension.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after every

five rocking-motion cycles. This will minimize

overheating and reduce the risk of transmis -

sion failure during prolonged efforts to free a

stuck vehicle.

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin the

wheels faster than 15 mph (24 km/h), or

drivetrain damage may result.

Revving the engine or spinning the wheels too

fast may lead to transmission overheating and

failure. It can also damage the tires. Do not

spin the wheels above 30 mph (48 km/h)

while in gear (no transmission shifting occur -

ring).

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause damage, or even failure, of the axle and

tires. A tire could explode and injure someone.

Do not spin your vehicle's wheels faster than

30 mph (48 km/h) or for longer than 30

seconds continuously without stopping when

you are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

22_DT_OM_EN_USC_t.book Page 390