tire size RAM 1500 2022 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: 1500, Model: RAM 1500 2022Pages: 496, PDF Size: 18.03 MB

Page 326 of 496

324SAFETY

Automatic Trailer Detection

There are two modes of operation for the detection

of the trailer length:

Automatic Mode — When “Auto Mode” is

selected, the system will use the blind spot

sensors to automatically determine the pres -

ence and length of a trailer. The presence of a

trailer will be detected using the blind spot radar

within 90 seconds of forward movement of the

vehicle. The vehicle must be moving above

6 mph (10 km/h) to activate the feature. Once

the trailer has been detected, the system will

default to the maximum blind spot zone until the

length has been verified. You will see “Auto” in

the instrument panel cluster .

Maximum Mode — When “Max Mode” is

selected, the system will default to the

maximum blind spot zone regardless of what

size trailer is attached .

NOTE:Selected setting is stored when the ignition is

placed in the OFF position. To change this setting,

it must be selected through the Uconnect Settings

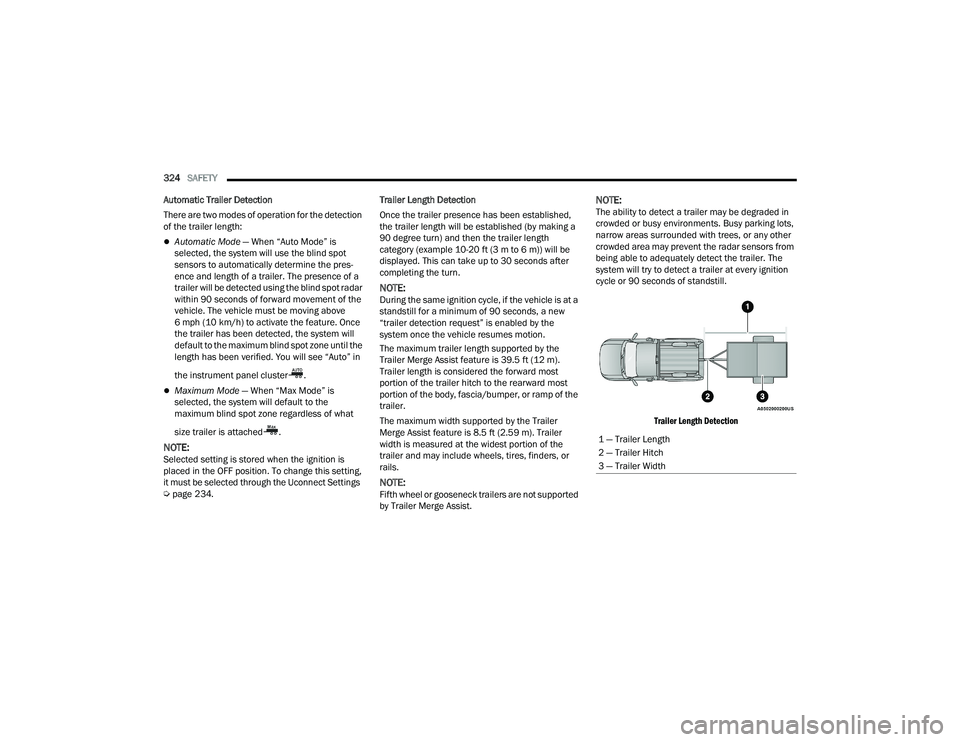

Ú page 234. Trailer Length Detection

Once the trailer presence has been established,

the trailer length will be established (by making a

90 degree turn) and then the trailer length

category (example 10-20 ft (3 m to 6 m)) will be

displayed. This can take up to 30 seconds after

completing the turn.

NOTE:During the same ignition cycle, if the vehicle is at a

standstill for a minimum of 90 seconds, a new

“trailer detection request” is enabled by the

system once the vehicle resumes motion.

The maximum trailer length supported by the

Trailer Merge Assist feature is 39.5 ft (12 m).

Trailer length is considered the forward most

portion of the trailer hitch to the rearward most

portion of the body, fascia/bumper, or ramp of the

trailer.

The maximum width supported by the Trailer

Merge Assist feature is 8.5 ft (2.59 m). Trailer

width is measured at the widest portion of the

trailer and may include wheels, tires, finders, or

rails.

NOTE:Fifth wheel or gooseneck trailers are not supported

by Trailer Merge Assist.

NOTE:The ability to detect a trailer may be degraded in

crowded or busy environments. Busy parking lots,

narrow areas surrounded with trees, or any other

crowded area may prevent the radar sensors from

being able to adequately detect the trailer. The

system will try to detect a trailer at every ignition

cycle or 90 seconds of standstill.

Trailer Length Detection

1 — Trailer Length

2 — Trailer Hitch

3 — Trailer Width

22_DT_OM_EN_USC_t.book Page 324

Page 331 of 496

SAFETY329

(Continued)

The TPMS will warn the driver of a low tire pressure

if the tire pressure falls below the low-pressure

warning limit for any reason, including low

temperature effects and natural pressure loss

through the tire Ú

page 480.

The TPMS will continue to warn the driver of low

tire pressure as long as the condition exists, and

will not turn off until the tire pressure is at or above

the recommended cold placard pressure. Once the

low TPMS Warning Light illuminates, increase the

tire pressure to the recommended cold placard

pressure in order for the TPMS Warning Light to

turn off. The system will automatically update and

the TPMS Warning Light will turn off once the

system receives the updated tire pressures. The

vehicle may need to be driven for up to 20 minutes

above 15 mph (24 km/h) in order for the TPMS to

receive this information.

NOTE:When filling warm tires, the tire pressure may need

to be increased up to an additional 4 psi (28 kPa)

above the recommended cold placard pressure in

order to turn the TPMS Warning Light off.

For example, your vehicle may have a

recommended cold (parked for more than three

hours) placard pressure of 30 psi (207 kPa). If the

ambient temperature is 68°F (20°C) and the

measured tire pressure is 27 psi (186 kPa), a

temperature drop to 20°F (-7°C) will decrease the

tire pressure to approximately 23 psi (158 kPa). This tire pressure is sufficiently low enough to turn

on the TPMS Warning Light. Driving the vehicle

may cause the tire pressure to rise to

approximately 27 psi (186 kPa), but the TPMS

Warning Light will still be on. In this situation, the

TPMS Warning Light will turn off only after the tires

are inflated to the vehicle’s recommended cold

placard pressure value.

NOTE:

The TPMS is not intended to replace normal tire

care and maintenance or to provide warning of

a tire failure or condition.

The TPMS should not be used as a tire pressure

gauge while adjusting your tire pressure, unless

your vehicle is equipped with a Tire Fill Alert

(TFA) system.

Driving on a significantly underinflated tire

causes the tire to overheat and can lead to tire

failure. Underinflation also reduces fuel effi

-

ciency and tire tread life, and may affect the

vehicle’s handling and stopping ability.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures

and warning have been established for the tire

size equipped on your vehicle. Undesirable

system operation or sensor damage may

result when using replacement equipment

that is not of the same size, type, and/or style.

Aftermarket wheels can cause sensor

damage.

Using aftermarket tire sealants may cause the

Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended

that you take your vehicle to an authorized

dealership to have your sensor function

checked.

After inspecting or adjusting the tire pressure

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the TPMS

sensor.

CAUTION!

6

22_DT_OM_EN_USC_t.book Page 329

Page 333 of 496

SAFETY331

NOTE:When filling warm tires, the tire pressure may need

to be increased up to an additional 4 psi (28 kPa)

above the recommended cold placard pressure in

order to turn the Tire Pressure Monitoring System

Warning Light off.

Service TPMS Warning

If a system fault is detected, the Tire Pressure

Monitoring System (TPMS) Warning Light will flash

on and off for 75 seconds and then remain on

solid. The system fault will also sound a chime. In

addition, the instrument cluster will display a

"SERVICE TPM SYSTEM" message for a minimum

of five seconds and then display dashes (--) in

place of the pressure value to indicate which

sensor is not being received.

If the ignition switch is cycled, this sequence will

repeat, providing the system fault still exists. If the

system fault no longer exists, the Tire Pressure

Monitoring System Warning Light will no longer

flash, and the "SERVICE TPM SYSTEM" message

will no longer display, and a pressure value will

display in place of the dashes. A system fault can

occur due to any of the following:

Signal interference due to electronic devices or

driving next to facilities emitting the same radio

frequencies as the Tire Pressure Monitoring

System sensors

Installing aftermarket window tinting that

contains materials that may block radio wave

signals

Accumulation of snow or ice around the wheels

or wheel housings

Using tire chains on the vehicle

Using wheels/tires not equipped with TPMS

sensors

A system fault may occur due to an incorrect TPMS

sensor location condition. When a system fault

occurs due to an incorrect TPMS sensor location,

the Tire Pressure Monitoring System (TPMS)

Warning Light will flash on and off for 75 seconds

and then remain on solid. The system fault will also

sound a chime. In addition, the instrument cluster

will display a Tire Pressure Temporarily Unavailable

message in place of the tire pressure display

screen. If the ignition switch is cycled, this

sequence will repeat, providing the system fault

still exists. If the system fault no longer exists, the

“Tire Pressure Monitoring System Warning Light”

will no longer flash and the tire pressure display

screen will be displayed showing the tire pressure

values the correct locations. Vehicles With Non-Matching Full Size Spare Or

Compact Spare

The non-matching full size spare or compact

spare tire does not have a TPMS sensor. There

-

fore, the TPMS will not monitor the pressure in

the non-matching full size spare or compact

spare tire.

If you install the non-matching full size spare or

compact spare tire in place of a road tire that

has a pressure below the low-pressure warning

limit, upon the next ignition switch cycle, the Tire

Pressure Monitoring System (TPMS) Warning

Light and a “LOW TIRE” message will remain on

and a chime will sound. In addition, the graphic

in the instrument cluster will still display a pres -

sure value in a different color and an “Inflate to

XX” message.

After driving the vehicle for up to 20 minutes

above 15 mph (24 km/h), the Tire Pressure

Monitoring System (TPMS) Warning Light will

flash on and off for 75 seconds and then remain

on solid. In addition, the instrument cluster will

display a "SERVICE TPM SYSTEM" message for a

minimum of five seconds and then display

dashes (--) in place of the pressure value.

6

22_DT_OM_EN_USC_t.book Page 331

Page 334 of 496

332SAFETY

For each subsequent ignition switch cycle, a

chime will sound, the Tire Pressure Monitoring

System (TPMS) Warning Light will flash on and

off for 75 seconds and then remain on solid,

and the instrument cluster will display a

"SERVICE TPM SYSTEM" message for a

minimum of five seconds and then display

dashes (--) in place of the pressure value.

Once you repair or replace the original road tire

and reinstall it on the vehicle in place of the

non-matching full size spare or compact spare,

the TPMS will update automatically. In addition,

the Tire Pressure Monitoring System (TPMS)

Warning Light will turn off and the graphic in the

instrument cluster will display a new pressure

value instead of dashes (--), as long as no tire

pressure is below the low-pressure warning limit

in any of the four active road tires. The vehicle

may need to be driven for up to 20 minutes

above 15 mph (24 km/h) in order for the TPMS

to receive this information.

Tire Fill Alert

This feature notifies the user when the placard tire

pressure is attained while inflating or deflating the

tire.

You may choose to disable or enable the Tire Fill

Alert feature through use of the Uconnect Settings

in the radio.

NOTE:

Only one tire can be filled at a time when using

the Tire Fill Alert system.

The Tire Fill Alert feature cannot be entered if an

existing TPMS fault is set to “active” or if the

system is in deactivation mode (if equipped).

The system will be activated when a positive

increase in tire pressure is detected by the TPMS

while inflating the tire. The ignition must be in the

RUN mode, with the transmission in PARK.

NOTE:It is not required to have the engine running to

enter Tire Fill Alert mode.

The hazard lamps will come on to confirm the

vehicle is in Tire Fill Alert mode.

When Tire Fill Alert mode is entered, the tire

pressure display screen will be displayed in the

instrument cluster.

If the hazard lamps do not come on while inflating

the tire, the TPMS sensor may be out of range

preventing the TPMS sensor signal from being

received. In this case, the vehicle may need to be

moved either forward or backward slightly to exit

the null spot. Operation:

The horn will sound once to let the user know

when to stop filling the tire, when it reaches

recommended pressure.

The horn will sound three times if the tire is over

-

filled and will continue to sound every five

seconds if the user continues to inflate the tire.

The horn will sound once again when enough air

is let out to reach proper inflation level.

The horn will also sound three times if the tire is

then underinflated and will continue to sound

every five seconds if the user continues to

deflate the tire.

Trailer Tire Pressure Monitoring System

(TTPMS) — If Equipped

The Trailer Tire Pressure Monitoring System

(TTPMS) is a feature that displays the trailer tire

pressure values and warns the driver of a low tire

pressure event based on the driver’s set target tire

pressure value, through TTPMS settings found in

the radio.

The TTPMS monitors the pressure of each tire and

warns the driver through the instrument cluster,

when either a low tire pressure condition falls

below 25% of the driver’s set pressure or if a

system malfunction occurs. The instrument cluster

will display the actual tire pressure or dashes for

each of the trailer tires in the correct trailer

position, based on trailer configuration.

22_DT_OM_EN_USC_t.book Page 332

Page 446 of 496

444SERVICING AND MAINTENANCE

TIRES

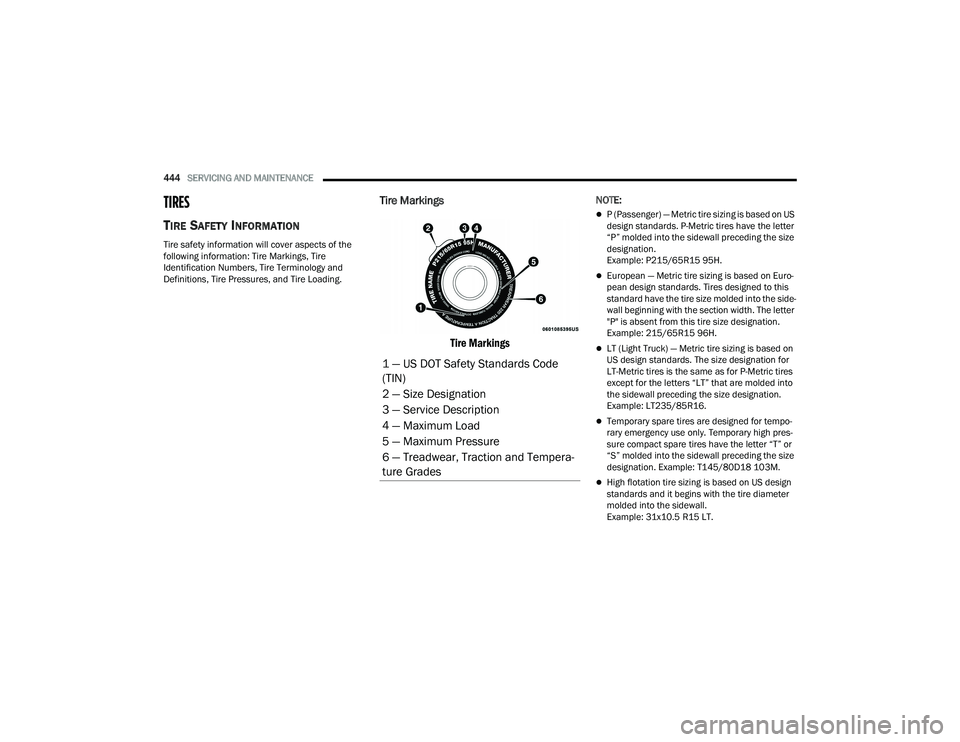

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter

“P” molded into the sidewall preceding the size

designation.

Example: P215/65R15 95H.

European — Metric tire sizing is based on Euro -

pean design standards. Tires designed to this

standard have the tire size molded into the side -

wall beginning with the section width. The letter

"P" is absent from this tire size designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on

US design standards. The size designation for

LT-Metric tires is the same as for P-Metric tires

except for the letters “LT” that are molded into

the sidewall preceding the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for tempo -

rary emergency use only. Temporary high pres -

sure compact spare tires have the letter “T” or

“S” molded into the sidewall preceding the size

designation. Example: T145/80D18 103M.

High flotation tire sizing is based on US design

standards and it begins with the tire diameter

molded into the sidewall.

Example: 31x10.5 R15 LT.

1 — US DOT Safety Standards Code

(TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera -

ture Grades

22_DT_OM_EN_USC_t.book Page 444

Page 447 of 496

SERVICING AND MAINTENANCE445

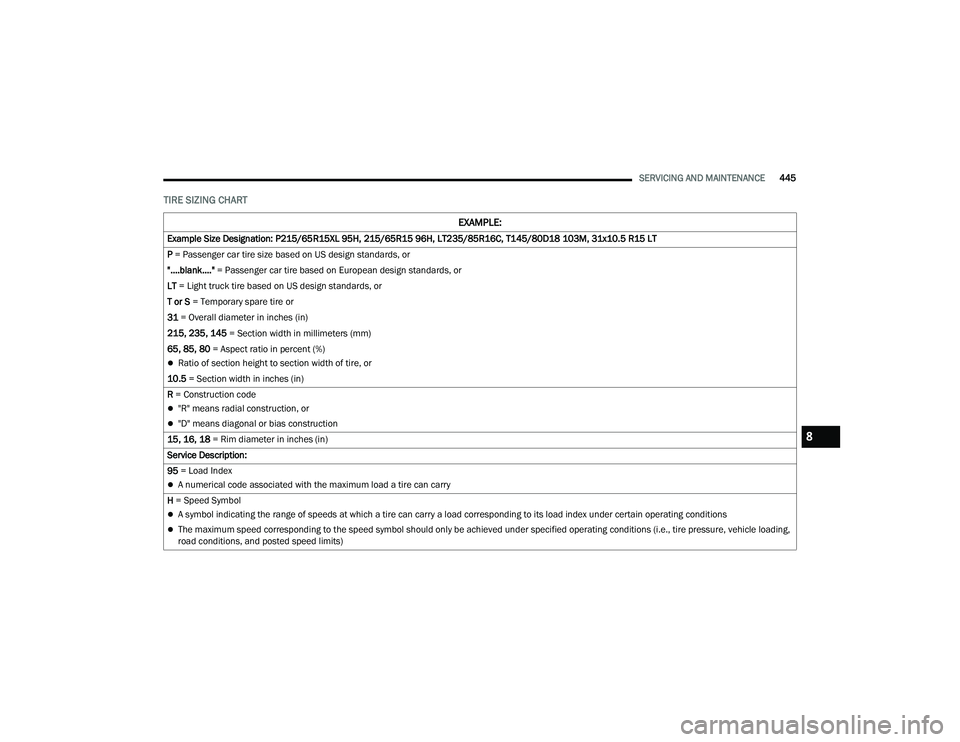

TIRE SIZING CHART

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

Service Description:

95 = Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading,

road conditions, and posted speed limits)

8

22_DT_OM_EN_USC_t.book Page 445

Page 448 of 496

446SERVICING AND MAINTENANCE

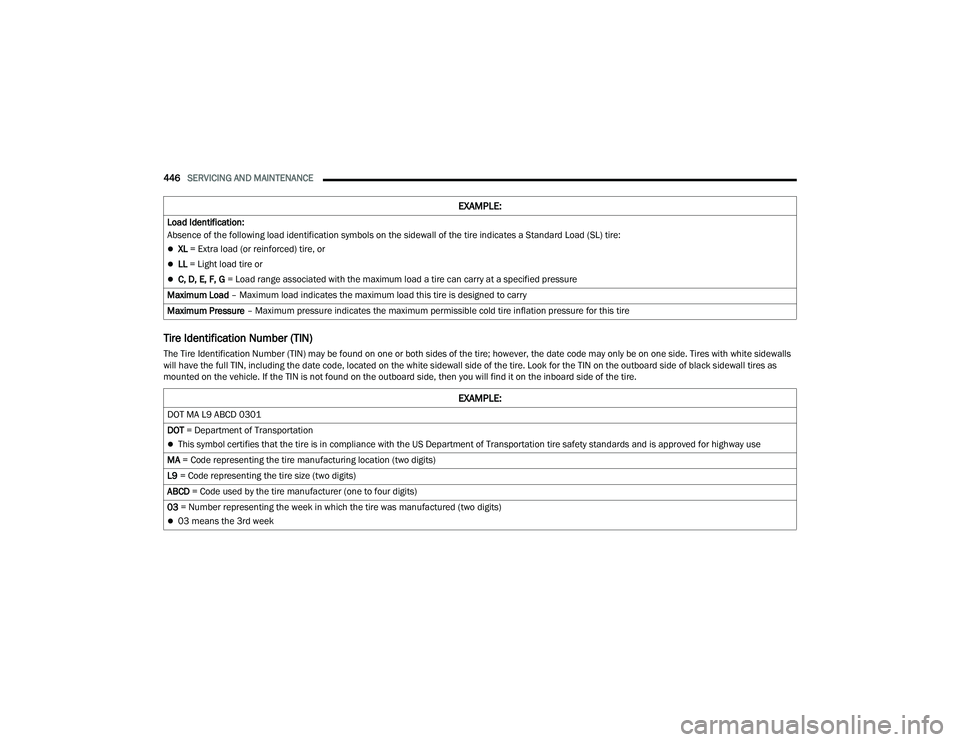

Tire Identification Number (TIN)

The Tire Identification Number (TIN) may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white sidewalls

will have the full TIN, including the date code, located on the white sidewall side of the tire. Look for the TIN on the outboard side of black sidewall tires as

mounted on the vehicle. If the TIN is not found on the outboard side, then you will find it on the inboard side of the tire.Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL

= Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

03 = Number representing the week in which the tire was manufactured (two digits)

03 means the 3rd week

22_DT_OM_EN_USC_t.book Page 446

Page 449 of 496

SERVICING AND MAINTENANCE447

Tire Terminology And Definitions

01 = Number representing the year in which the tire was manufactured (two digits)

01 means the year 2001

Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was manufactured. Example: 031 could

represent the 3rd week of 1981 or 1991

Term Definition

B-pillarThe vehicle B-pillar is the structural member of the body located behind the front door.

Cold Tire Inflation Pressure Cold tire inflation pressure is defined as the tire pressure after the vehicle has not been

driven for at least three hours, or driven less than 1 mile (1.6 km) after sitting for a minimum

of three hours. Inflation pressure is measured in units of PSI (pounds per square inch) or kPa

(kilopascals).

Maximum Inflation Pressure The maximum inflation pressure is the maximum permissible cold tire inflation pressure for

this tire. The maximum inflation pressure is molded into the sidewall.

Recommended Cold Tire Inflation Pressure The manufacturer’s recommended cold tire inflation pressure as shown on the tire placard.

Tire Placard A label permanently attached to the vehicle describing the vehicle’s loading capacity, the

original equipment tire sizes and the recommended cold tire inflation pressures.

EXAMPLE:

8

22_DT_OM_EN_USC_t.book Page 447

Page 450 of 496

448SERVICING AND MAINTENANCE

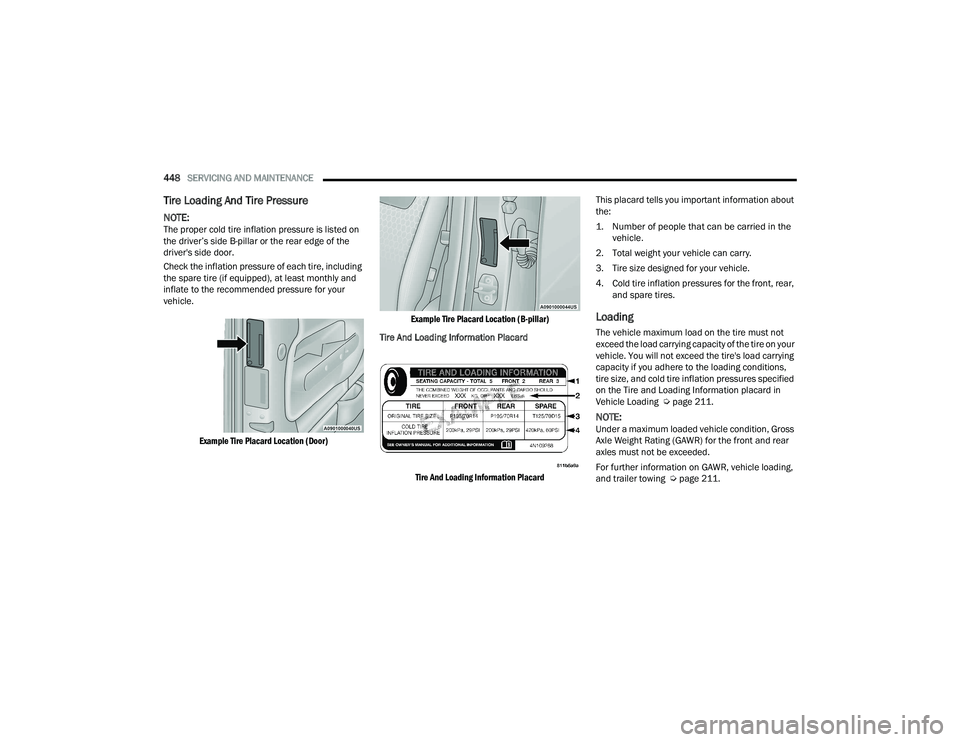

Tire Loading And Tire Pressure

NOTE:The proper cold tire inflation pressure is listed on

the driver’s side B-pillar or the rear edge of the

driver's side door.

Check the inflation pressure of each tire, including

the spare tire (if equipped), at least monthly and

inflate to the recommended pressure for your

vehicle.

Example Tire Placard Location (Door) Example Tire Placard Location (B-pillar)

Tire And Loading Information Placard

Tire And Loading Information Placard

This placard tells you important information about

the:

1. Number of people that can be carried in the

vehicle.

2. Total weight your vehicle can carry.

3. Tire size designed for your vehicle.

4. Cold tire inflation pressures for the front, rear, and spare tires.

Loading

The vehicle maximum load on the tire must not

exceed the load carrying capacity of the tire on your

vehicle. You will not exceed the tire's load carrying

capacity if you adhere to the loading conditions,

tire size, and cold tire inflation pressures specified

on the Tire and Loading Information placard in

Vehicle Loading Ú page 211.

NOTE:Under a maximum loaded vehicle condition, Gross

Axle Weight Rating (GAWR) for the front and rear

axles must not be exceeded.

For further information on GAWR, vehicle loading,

and trailer towing Ú page 211.

22_DT_OM_EN_USC_t.book Page 448

Page 451 of 496

SERVICING AND MAINTENANCE449

To determine the maximum loading conditions of

your vehicle, locate the statement “The combined

weight of occupants and cargo should never

exceed XXX kg or XXX lbs” on the Tire and Loading

Information placard. The combined weight of

occupants, cargo/luggage and trailer tongue

weight (if applicable) should never exceed the

weight referenced here.

Steps For Determining Correct Load

Limit—

(1) Locate the statement “The combined

weight of occupants and cargo should

never exceed XXX kg or XXX lbs.” on your

vehicle's placard.

(2) Determine the combined weight of

the driver and passengers that will be

riding in your vehicle.

(3) Subtract the combined weight of the

driver and passengers from XXX kg or

XXX lbs. (4) The resulting figure equals the

available amount of cargo and luggage

load capacity. For example, if “XXX”

amount equals 1400 lbs. and there will

be five 150 lb passengers in your

vehicle, the amount of available cargo

and luggage load capacity is 650 lbs.

(1400-750 (5x150) = 650 lbs.)

(5) Determine the combined weight of

luggage and cargo being loaded on the

vehicle. That weight may not safely

exceed the available cargo and luggage

load capacity calculated in Step 4.

(6) If your vehicle will be towing a trailer,

load from your trailer will be transferred

to your vehicle. Consult this manual to

determine how this reduces the

available cargo and luggage load

capacity of your vehicle.

Metric Example For Load Limit

For example, if “XXX” amount equals 635 kg and

there will be five 68 kg passengers in your vehicle,

the amount of available cargo and luggage load

capacity is 295 kg (635-340 (5x68) = 295 kg) as

shown in step 4.

NOTE:

If your vehicle will be towing a trailer, load from

your trailer will be transferred to your vehicle.

The following table shows examples on how to

calculate total load, cargo/luggage, and towing

capacities of your vehicle with varying seating

configurations and number and size of occu

-

pants. This table is for illustration purposes only

and may not be accurate for the seating and

load carry capacity of your vehicle.

For the following example, the combined weight

of occupants and cargo should never exceed

865 lbs (392 kg).

8

22_DT_OM_EN_USC_t.book Page 449