oil RAM 1500 2022 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: 1500, Model: RAM 1500 2022Pages: 496, PDF Size: 18.03 MB

Page 444 of 496

442SERVICING AND MAINTENANCE

4. Disengage the side marker socket by rotating counterclockwise a quarter turn.

5. Pull the socket and bulb straight out from the housing.

6. Separate the bulb from the socket without twisting.

7. Reverse the procedure for installation of new bulb and covers.

FOG LAMPS — IF EQUIPPED

Please see an authorized dealer for service on LED

and Halogen front fog lamps.

Halogen

See below steps to replace:

1. Reach under and behind the front fascia/bumper to access the back of the front fog

lamp housing.

2. Disconnect the fog lamp wiring harness connector from the fog lamp bulb.

Fog Lamp Bulb

3. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the housing.

4. Pull the bulb straight out from the housing.

5. Reverse the procedure to install the bulb and cover.

REAR TAIL/STOP, TURN SIGNAL AND BACKUP

LAMPS

See below steps to replace:

1. Remove the two screws and push pin retainers that pass through the bed sheet

metal.

Tail Lamp Locations

2. Pull the outboard side of the lamp rearward far enough to unsnap the two receptacles on the

outboard side of the lamp housing from the

two plastic snap post retainers in the outer box

side panel.

CAUTION!

Do not contaminate the bulb glass by touching it

with your fingers or by allowing it to contact other

oily surfaces. Shortened bulb life will result.1 — Tail Lamp

2 — Fasteners

3 — Push - Pin Retainers

22_DT_OM_EN_USC_t.book Page 442

Page 445 of 496

SERVICING AND MAINTENANCE443

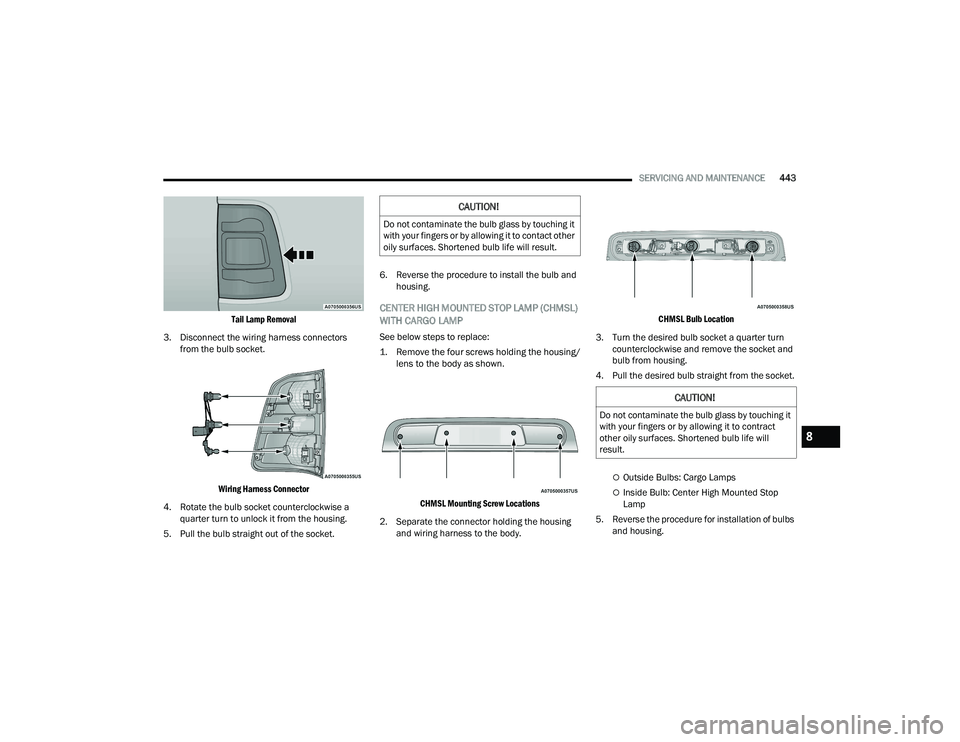

Tail Lamp Removal

3. Disconnect the wiring harness connectors from the bulb socket.

Wiring Harness Connector

4. Rotate the bulb socket counterclockwise a quarter turn to unlock it from the housing.

5. Pull the bulb straight out of the socket. 6. Reverse the procedure to install the bulb and

housing.

CENTER HIGH MOUNTED STOP LAMP (CHMSL)

WITH CARGO LAMP

See below steps to replace:

1. Remove the four screws holding the housing/lens to the body as shown.

CHMSL Mounting Screw Locations

2. Separate the connector holding the housing and wiring harness to the body.

CHMSL Bulb Location

3. Turn the desired bulb socket a quarter turn counterclockwise and remove the socket and

bulb from housing.

4. Pull the desired bulb straight from the socket.

Outside Bulbs: Cargo Lamps

Inside Bulb: Center High Mounted Stop

Lamp

5. Reverse the procedure for installation of bulbs and housing.

CAUTION!

Do not contaminate the bulb glass by touching it

with your fingers or by allowing it to contact other

oily surfaces. Shortened bulb life will result.

CAUTION!

Do not contaminate the bulb glass by touching it

with your fingers or by allowing it to contract

other oily surfaces. Shortened bulb life will

result.

8

22_DT_OM_EN_USC_t.book Page 443

Page 456 of 496

454SERVICING AND MAINTENANCE

Life Of Tire

The service life of a tire is dependent upon varying

factors including, but not limited to:

Driving style

Tire pressure - Improper cold tire inflation pres -

sures can cause uneven wear patterns to

develop across the tire tread. These abnormal

wear patterns will reduce tread life, resulting in

the need for earlier tire replacement

Distance driven

Performance tires, tires with a speed rating of V

or higher, and Summer tires typically have a

reduced tread life. Rotation of these tires per

the vehicle scheduled maintenance is highly

recommended

NOTE:Wheel Valve Stem must be replaced as well when

installing new tires due to wear and tear in existing

tires. Keep dismounted tires in a cool, dry place with as

little exposure to light as possible. Protect tires

from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of

many characteristics. They should be inspected

regularly for wear and correct cold tire inflation

pressures. The manufacturer strongly

recommends that you use tires equivalent to the

originals in size, quality and performance when

replacement is needed Ú

page 453. Refer to the

Tire and Loading Information placard or the

Vehicle Certification Label for the size designation

of your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

For more information relating to the Load Index

and Speed Symbol of a tire Ú page 445.

It is recommended to replace the two front tires or

two rear tires as a pair. Replacing just one tire can

seriously affect your vehicle’s handling. If you ever

replace a wheel, make sure that the wheel’s

specifications match those of the original wheels.

It is recommended you contact an authorized tire

dealer or original equipment dealer with any

questions you may have on tire specifications or

capability. Failure to use equivalent replacement

tires may adversely affect the safety, handling, and

ride of your vehicle.

WARNING!

Tires and the spare tire should be replaced after

six years, regardless of the remaining tread.

Failure to follow this warning can result in

sudden tire failure. You could lose control and

have a collision resulting in serious injury or

death.

WARNING!

Do not use a tire, wheel size, load rating, or

speed rating other than that specified for your

vehicle. Some combinations of unapproved

tires and wheels may change suspension

dimensions and performance characteristics,

resulting in changes to steering, handling, and

braking of your vehicle. This can cause unpre -

dictable handling and stress to steering and

suspension components. You could lose

control and have a collision resulting in

serious injury or death. Use only the tire and

wheel sizes with load ratings approved for

your vehicle.

Never use a tire with a smaller load index or

capacity, other than what was originally

equipped on your vehicle. Using a tire with a

smaller load index could result in tire over -

loading and failure. You could lose control and

have a collision.

Failure to equip your vehicle with tires having

adequate speed capability can result in

sudden tire failure and loss of vehicle control.

22_DT_OM_EN_USC_t.book Page 454

Page 465 of 496

SERVICING AND MAINTENANCE463

Special Care

If you drive on salted or dusty roads or if you

drive near the ocean, hose off the undercarriage

at least once a month.

It is important that the drain holes in the lower

edges of the doors, rocker panels, and trunk be

kept clear and open.

If you detect any stone chips or scratches in the

paint, touch them up immediately.

If your vehicle is damaged due to a collision or

similar cause that destroys the paint and protec -

tive coating, have your vehicle repaired as soon

as possible.

If you carry special cargo such as chemicals,

fertilizers, de-icer salt, etc., be sure that such

materials are well packaged and sealed.

If a lot of driving is done on gravel roads,

consider mud or stone shields behind each

wheel.

Use Mopar® Touch Up Paint on scratches as

soon as possible. An authorized dealer has

touch up paint to match the color of your

vehicle.

Spray-On Bedliner – If Equipped

During ownership, the shine and luster of the

Spray-On Bedliner can fade from oxidation, road

dirt, heavy-duty hauling and hard water stains.

Weathering and UV exposure will lead to fading.

To help maintain the appearance of your Spray-On

Bedliner, the manufacturer recommends you

periodically rinse all loose dirt from your truck bed

and clean your truck at least twice per year using

the Mopar® Spray-On Bedliner Conditioner

available at a local authorized dealer. To Help Maintain The Appearance Of Your

Spray-On Bedliner, Follow The Steps Below:

1. Rinse your truck bed out with water to remove any loose dirt and debris.

2. Mix a mild soap or detergent with water. Then apply solution with a soft cloth or brush.

3. Rinse bedliner with water.

4. Once dry, apply a small amount of Mopar® Spray-On Bedliner Conditioner to a moist towel

or sponge and wipe over the entire surface of

the truck bedliner.

Spray-On Bedliners are chemically-resistant to

many different types of chemicals (including

gasoline, oil, hydraulic fluids) for short periods of

time. If a spill occurs on your Spray-On Bedliner,

rinse the truck out as soon as possible to avoid

permanent damage.

CAUTION!

Do not use scouring pads, steel wool, a bristle

brush, metal polishes, or oven cleaner. These

products may damage the bumper’s protec -

tive finish. Such damage is not covered by the

New Vehicle Limited Warranty. Only car wash

soap, Mopar® Chrome Cleaner, or equivalent

is recommended.

Avoid products or automatic car washes that

use acidic solutions, strong alkaline additives,

or harsh brushes. Many aftermarket cleaners

and automatic car washes may damage the

bumper’s protective finish. Such damage is

not covered by the New Vehicle Limited

Warranty. Only car wash soap, Mopar®

Chrome Cleaner, or equivalent is recom -

mended.

WARNING!

Do not use silicon-based protection products to

clean your bedliner. Silicon-based products can

become slippery and may result in personal

injury.

8

22_DT_OM_EN_USC_t.book Page 463

Page 466 of 496

464SERVICING AND MAINTENANCE

Repairing The Spray-On Bedliner

While extremely tough, it is possible to damage a

Spray-On Bedliner. One common condition is when

loading a heavy pallet and dragging that pallet

across the floor of the bed. If a nail or sharp point

is exposed under the weight of the pallet a scratch

or tear is possible. While not covered by your new

vehicle warranty, a cosmetic fix to cover the metal

exposed by the scratch is required. To repair a tear

or gouge, follow the directions provided in the

Mopar® Quick Repair Kit.

INTERIORS

SEATS AND FABRIC PARTS

Use Mopar® Total Clean to clean fabric upholstery

and carpeting.

Stain Repel Fabric Cleaning Procedure — If

Equipped

Stain Repel seats may be cleaned in the following

manner:

Remove as much of the stain as possible by

blotting with a clean, dry towel.

Blot any remaining stain with a clean, damp

towel.

For tough stains, apply Mopar® Total Clean, or

a mild soap solution to a clean, damp cloth and

remove stain. Use a fresh, damp towel to

remove soap residue.

For grease stains, apply Mopar® Multi-Purpose

Cleaner to a clean, damp cloth and remove

stain. Use a fresh, damp towel to remove soap

residue.

Do not use any harsh solvents or any other form

of protectants on Stain Repel products.

Seat Belt Maintenance

Do not bleach, dye or clean the belts with chemical

solvents or abrasive cleaners. This will weaken the

fabric. If the belts need cleaning, use a mild soap solution

or lukewarm water. Do not remove the belts from

the vehicle to wash them. Dry with a soft cloth.

Sun damage can also weaken the fabric. Replace

the belts if they appear frayed or worn or if the

buckles do not work properly.

NOTE:If the belts retract slowly, inspect the upper turning

loop for soiling. If soiling is present, clean with a

wet soft cloth until all residue is removed.

WARNING!

Do not use volatile solvents for cleaning

purposes. Many are potentially flammable, and

if used in closed areas they may cause

respiratory harm.

WARNING!

A frayed or torn seat belt could rip apart in a

collision and leave you with no protection.

Inspect the seat belt system periodically,

checking for cuts, frays, or loose parts.

Damaged parts must be replaced immediately.

Do not disassemble or modify the seat belt

system. If your vehicle is involved in a collision,

or if you have questions regarding seat belt or

retractor conditions, take your vehicle to an

authorized FCA dealer or authorized FCA

Certified Collision Care Program facility for

inspection.

22_DT_OM_EN_USC_t.book Page 464

Page 467 of 496

SERVICING AND MAINTENANCE465

PLASTIC AND COATED PARTS

Use Mopar® Total Clean to clean vinyl upholstery.

Cleaning Plastic Instrument Cluster

Lenses

The lenses in front of the instruments in this

vehicle are molded in clear plastic. When cleaning

the lenses, care must be taken to avoid scratching

the plastic. Clean with a wet soft cloth. A mild soap solution

may be used, but do not use high alcohol content

or abrasive cleaners. If soap is used, wipe clean

with a clean damp cloth. Dry with a soft cloth.

LEATHER SURFACES

Mopar® Total Clean is specifically recommended

for leather upholstery.

Your leather upholstery can be best preserved by

regular cleaning with a damp soft cloth. Small

particles of dirt can act as an abrasive and damage

the leather upholstery and should be removed

promptly with a damp cloth. Stubborn soils can be

removed easily with a soft cloth and Mopar® Total

Clean. Care should be taken to avoid soaking your

leather upholstery with any liquid. Please do not

use polishes, oils, cleaning fluids, solvents,

detergents, or ammonia-based cleaners to clean

your leather upholstery.

NOTE:If equipped with light colored leather, it tends to

show any foreign material, dirt, and fabric dye

transfer more so than darker colors. The leather is

designed for easy cleaning, and the manufacturer

recommends Mopar® Total Clean leather cleaner

applied on a cloth to clean the leather seats as

needed.

GLASS SURFACES

All glass surfaces should be cleaned on a regular

basis with Mopar® Glass Cleaner, or any

commercial household-type glass cleaner. Never

use an abrasive type cleaner. Use caution when

cleaning the inside rear window equipped with

electric defrosters or windows equipped with radio

antennas. Do not use scrapers or other sharp

instruments that may scratch the elements.

When cleaning the rear view mirror, spray cleaner

on the towel or cloth that you are using. Do not

spray cleaner directly on the mirror.

CAUTION!

Direct contact of air fresheners, insect repel

-

lents, suntan lotions, or hand sanitizers to the

plastic, painted, or decorated surfaces of the

interior may cause permanent damage. Wipe

away immediately.

Damage caused by these type of products

may not be covered by your New Vehicle

Limited Warranty.

CAUTION!

Do not use Alcohol and Alcohol-based and/or

Ketone based cleaning products to clean leather

upholstery, as damage to the upholstery may

result.

8

22_DT_OM_EN_USC_t.book Page 465

Page 468 of 496

466

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the

instrument panel, visible through the windshield.

Vehicle Identification Number

NOTE:It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for example,

repeated brake applications with the engine off),

the brakes will still function. However, you will

experience a substantial increase in braking effort

to stop the vehicle.

If either the front or rear hydraulic system lose

normal braking capability, the remaining system

will still function with some loss of overall braking

effectiveness. This will be evident by increased

pedal travel during application, greater pedal force

required to slow or stop, and the Brake Warning

Light and the ABS Warning Light will activate

during brake use.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug

nuts/bolts and clean or remove any dirt or oil

before tightening.

NOTE:Do not oil wheel studs. For chrome wheels, do not

substitute with chrome plated wheel nuts.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Lug Nut/

Bolt

Torque Lug Nut/

Bolt Type**Lug

Nut/Bolt

SizeLug Nut/

Bolt

Socket

Size

130 Ft-Lb

(176 N·m) ConeM14 x

1.5022 mm

22_DT_OM_EN_USC_t.book Page 466

Page 472 of 496

470TECHNICAL SPECIFICATIONS

Diesel fuel is seldom completely free of water. To

prevent fuel system trouble, drain the

accumulated water from the fuel/water separator

filter using the fuel/water separator drain provided

on the fuel filter housing. If you buy good quality

fuel and follow the cold weather advice above, fuel

conditioners should not be required in your vehicle.

If available in your area, a high cetane “premium”

diesel fuel may offer improved cold-starting and

warm-up performance.

DIESEL FUEL SPECIFICATIONS

This diesel engine has been developed to take

advantage of the high energy content and

generally lower cost Number 2 Ultra Low Sulfur

diesel fuel or Number 2 Ultra Low Sulfur Climatized

diesel fuels.

NOTE:

If you accidentally fill the fuel tank with gasoline

or DEF on your diesel vehicle, do not start the

engine. Damage to the engine and fuel system

could occur. Please call an authorized dealer for

service.

A maximum blend of 5% biodiesel meeting

ASTM specification D-975 may be used with

your diesel engine without any adjustments to

regular service schedules.

Commercially available fuel additives are not

necessary for the proper operation of your

diesel engine.

Number 1 Ultra Low Sulfur diesel fuel should

only be used where extended arctic conditions

(-10°F or -23°C) exist.

BIODIESEL FUEL REQUIREMENTS

A maximum blend of 5% biodiesel meeting ASTM

specification D975 is recommended for use with

your diesel engine. If frequent operation with

Biodiesel blends that are between 6% and 20%

(B6–B20) is desired, the maintenance schedule is

subject to shorter intervals.

The oil and filter change along with fuel filter

replacement is subject to shorter intervals when

operating your engine on biodiesel greater than

5%. Do not use biodiesel greater than 20%. For regular use of biodiesel blends between 6%

and 20% (B6–B20) it is important that you

understand and comply with these requirements.

For further direction Ú

page 402.

Biodiesel is a fuel produced from renewable

resources typically derived from animal fat,

rapeseed oil (Rapeseed Methyl Ester (RME) base),

or soybean oil (Soy Methyl Ester (SME or SOME)

base).

Biodiesel fuel has inherent limitations which

require that you understand and adhere to the

following requirements if you use blends of

Biodiesel between 6% and 20% (B6–B20). There

are no unique restrictions for the use of B5.

CAUTION!

If the Water in Fuel Indicator Light remains on,

DO NOT START engine before you drain the water

from the fuel filter(s) to avoid engine damage

Ú page 412.

CAUTION!

Failure to comply with Oil Change requirements

for vehicles operating on biodiesel blends

between 6% and 20% (B6–B20) will result in

premature engine wear. Such wear is not

covered by the New Vehicle Limited Warranty.

CAUTION!

Use of blends greater than 20% is not approved.

Use of blends greater than 20% can result in

engine damage. Such damage is not covered by

the New Vehicle Limited Warranty.

22_DT_OM_EN_USC_t.book Page 470

Page 473 of 496

TECHNICAL SPECIFICATIONS471

Biodiesel Fuel Properties — Low Ambient

Temperatures

Biodiesel fuel may gel or solidify at low ambient

temperatures, which may pose problems for both

storage and operation. Precautions can be

necessary at low ambient temperatures, such as

storing the fuel in a heated building or a heated

storage tank, or using cold temperature additives.

Fuel Quality — Must Comply With ASTM

Standards

The quality of Biodiesel fuel may vary widely. Only

fuel produced by a BQ9000 supplier to the

following specifications may be blended to meet

Biodiesel blend B6 – B20 fuel meeting ASTM

specification D-7467: Petrodiesel fuel meeting ASTM specification D-975

and Biodiesel fuel (B100) meeting ASTM

specification D-6751

Fuel Oxidation Stability — Must Use Fuel

Within Six Months Of Manufacture

Biodiesel fuel has poor oxidation stability which

can result in long term storage problems. Fuel

produced to approved ASTM standards, if stored

properly, provides for protection against fuel

oxidation for up to six months.

Fuel Water Separation — Must Use

Mopar® Approved Fuel Filter Elements

Biodiesel fuel has a natural affinity to water and

water accelerates microbial growth. Your Mopar®

filtration system is designed to provide adequate

fuel water separation capabilities.

Fuel In Oil Dilution — Must Adhere To

Required Oil Change Interval

Fuel dilution of lubricating oil has been observed

with the use of Biodiesel fuel. Fuel in oil must not

exceed 5%. To ensure this limit is met your oil

change interval must be maintained with in the

suggested schedule. The regular use of biodiesel

between 6% and 20% requires intervals shorter

than the outlined 10,000 miles (16,100 km) and

must not exceed the suggested schedule. When

routinely operating on biodiesel between 6% and

20%, oil and filter replacement intervals must not

exceed 8,000 Miles (12,900 km) or six months,

which ever comes first.

Biodiesel Fuel Filter Change Intervals

The use of biodiesel requires more frequent fuel

filter change intervals. When operating on

biodiesel between 6% and 20%, fuel filter

replacement intervals should be every second oil

change, and must not exceed 16,000 miles

(25,750 km).

NOTE:Under no circumstances should oil change

intervals exceed 8,000 miles (12,875 km) or six

months, if regular operation occurs with 6% - 20%

biodiesel blends. Under no circumstances should

fuel filter replacement intervals exceed every

second oil change and must not exceed

16,000 miles (25,750 km), if regular operation

occurs with 6% - 20% biodiesel blends. Failure to

comply with these oil change and fuel filter require

-

ments for vehicles operating on biodiesel blends

up to B20 may result in premature engine wear.

Such wear is not covered by the New Vehicle

Limited Warranty. The engine may suffer severe

damage if operated with concentrations of

biodiesel higher than 20%.

CAUTION!

In the event that the vehicle is filled with

biodiesel and not used for more than a month,

the fuel should either be used up by driving (up

to quarter tank) and filled with standard diesel

blends with less than 5% that is normally

available. This will help prevent the fuel filter

clogging and potential damage to the fuel

injection system due to degraded biodiesel,

which is not covered by the New Vehicle Limited

Warranty.

9

22_DT_OM_EN_USC_t.book Page 471

Page 474 of 496

472TECHNICAL SPECIFICATIONS

FLUID CAPACITIES

USMetric

Fuel (Approximate)

1500 Regular Cab Shortbed/Crew Quad Cab Models 23 Gallons87 Liters

1500 Regular Cab Shortbed/Crew Quad Cab Models 26 Gallons98 Liters

1500 Regular Cab Longbed/Crew Quad Cab Models (Optional) 33 Gallons121 Liters

Engine Oil With Filter

3.6L Engine 5 Quarts4.7 Liters

5.7L Engine 7 Quarts6.6 Liters

Cooling System

3.6L Engine 13.7 Quarts13 Liters

3.6L Motor Generator Unit 1.8 Quarts1.7 Liters

5.7L Engine 18.3 Quarts17.3 Liters

US Metric

Fuel (Approximate)

3.0L Turbo Diesel Engine 26 Gallons98.5 Liters

Diesel Exhaust Fluid Tank

Tradesman/Rebel Models 5.14 Gallons19.5 Liters

All Other Models 5.74 Gallons21.7 Liters

22_DT_OM_EN_USC_t.book Page 472