trailer RAM 1500 2022 Repair Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: 1500, Model: RAM 1500 2022Pages: 496, PDF Size: 18.03 MB

Page 334 of 496

332SAFETY

For each subsequent ignition switch cycle, a

chime will sound, the Tire Pressure Monitoring

System (TPMS) Warning Light will flash on and

off for 75 seconds and then remain on solid,

and the instrument cluster will display a

"SERVICE TPM SYSTEM" message for a

minimum of five seconds and then display

dashes (--) in place of the pressure value.

Once you repair or replace the original road tire

and reinstall it on the vehicle in place of the

non-matching full size spare or compact spare,

the TPMS will update automatically. In addition,

the Tire Pressure Monitoring System (TPMS)

Warning Light will turn off and the graphic in the

instrument cluster will display a new pressure

value instead of dashes (--), as long as no tire

pressure is below the low-pressure warning limit

in any of the four active road tires. The vehicle

may need to be driven for up to 20 minutes

above 15 mph (24 km/h) in order for the TPMS

to receive this information.

Tire Fill Alert

This feature notifies the user when the placard tire

pressure is attained while inflating or deflating the

tire.

You may choose to disable or enable the Tire Fill

Alert feature through use of the Uconnect Settings

in the radio.

NOTE:

Only one tire can be filled at a time when using

the Tire Fill Alert system.

The Tire Fill Alert feature cannot be entered if an

existing TPMS fault is set to “active” or if the

system is in deactivation mode (if equipped).

The system will be activated when a positive

increase in tire pressure is detected by the TPMS

while inflating the tire. The ignition must be in the

RUN mode, with the transmission in PARK.

NOTE:It is not required to have the engine running to

enter Tire Fill Alert mode.

The hazard lamps will come on to confirm the

vehicle is in Tire Fill Alert mode.

When Tire Fill Alert mode is entered, the tire

pressure display screen will be displayed in the

instrument cluster.

If the hazard lamps do not come on while inflating

the tire, the TPMS sensor may be out of range

preventing the TPMS sensor signal from being

received. In this case, the vehicle may need to be

moved either forward or backward slightly to exit

the null spot. Operation:

The horn will sound once to let the user know

when to stop filling the tire, when it reaches

recommended pressure.

The horn will sound three times if the tire is over

-

filled and will continue to sound every five

seconds if the user continues to inflate the tire.

The horn will sound once again when enough air

is let out to reach proper inflation level.

The horn will also sound three times if the tire is

then underinflated and will continue to sound

every five seconds if the user continues to

deflate the tire.

Trailer Tire Pressure Monitoring System

(TTPMS) — If Equipped

The Trailer Tire Pressure Monitoring System

(TTPMS) is a feature that displays the trailer tire

pressure values and warns the driver of a low tire

pressure event based on the driver’s set target tire

pressure value, through TTPMS settings found in

the radio.

The TTPMS monitors the pressure of each tire and

warns the driver through the instrument cluster,

when either a low tire pressure condition falls

below 25% of the driver’s set pressure or if a

system malfunction occurs. The instrument cluster

will display the actual tire pressure or dashes for

each of the trailer tires in the correct trailer

position, based on trailer configuration.

22_DT_OM_EN_USC_t.book Page 332

Page 335 of 496

SAFETY333

The TTPMS can support up to 12 trailer tires per

configured trailer on up to four configurable trailers

Ú page 234.

Trailer Tire Pressure Monitoring System

Trailer Tire Pressure Sensor Pairing

In order use this feature, the provided tire pressure

sensors must be installed in the desired trailer

tires and the sensors must be paired to the truck.

If the target trailer requires more than the provided

four sensors, additional sensors can be purchased

at an authorized Ram dealership.

With the sensors installed and the trailer near or

connected to your Ram truck, initiate the pairing

process by entering the settings menu in the radio

and selecting trailer. Select the desired trailer

profile to pair to, open the “Tire Pressure” menu,

and hit “Setup All Tires” Ú page 234.

NOTE:The vehicle may not be driven until the pairing

process is complete.

Trailer Tire Pressure Settings

Trailer Tire Pressure Pairing

Follow the on screen prompts to select the number

of axles (1 - 3), the number of trailer tires (2, 4, 6,

8, or 12), and the set trailer tire pressure. The

range is selectable anywhere between 25-125 psi

(172-862 kPa).

Once psi (kPa) is programmed, the pairing screen

appears. Tire sensors must be paired in order

shown. Starting with Tire 1, deflate tire by 5 psi (34

kPa) and wait for a horn chirp. It may take up to

three minutes for the chirp to occur, indicating that

the sensor has paired. Repeat process on each

tire, in order, until complete. Do not exit the pairing

screen until process is complete. If pairing was

unsuccessful, a double horn chirp will sound, and

a prompt on the touchscreen will allow you to retry

the procedure; “Retry” will only appear when setup

fails. Each tire must be successfully paired during

a single pairing process to receive the success

screen.

NOTE:If the pairing process times out after three minutes

of no communication with a sensor, a double horn

chip will occur indicating the pairing has failed and

a message will display on the radio indicating the

process was unsuccessful. Under certain circum

-

stances, the double horn chirp may continue to

happen every three minutes indicating the failed

pairing. If this happens, the horn chirping may be

canceled by cycling the ignition button OFF and

then back to RUN position.

6

22_DT_OM_EN_USC_t.book Page 333

Page 336 of 496

334SAFETY

Tire Pressure Monitoring System Low Pressure

Warnings

When a tire pressure low in one or more of the

active road tires is detected, the instrument cluster

will display a message stating “Trailer Tire

Pressure Low”. The instrument cluster will then

display the TTPMS graphic showing the pressure

values of each tire with the low tire pressure values

in a different color.

Should this occur, you should stop as soon as

possible and inflate the tires with a low pressure

condition (those in a different color in the

instrument cluster graphic) to the customer

programmed target tire pressure value as shown

at the top of the TTPMS instrument cluster graphic.

Once the tire(s) are inflated, the system will

automatically update the graphic display in the

instrument cluster, returning to its original color.

The vehicle may need to be driven for up to

10 minutes above 15 mph (24 km/h) in order for

the TTPMS to receive the updated information.

Service TTPMS Warning

If a system fault is detected, the instrument cluster

will display a “Trailer Tire Pressure System Service

Required” message for a minimum of five seconds. Once the system fault is corrected the "Trailer Tire

Pressure System Service Required" message will

no longer be displayed. The vehicle may need to be

driven for up to 10 minutes above 15 mph

(24 km/h) in order for the TTPMS to receive the

trailer tire pressure information.

Trailer Tire Pressure System Not Configured

A “Trailer Tire Pressure System Not Configured”

message will be displayed in the instrument

cluster on the TTPMS instrument cluster graphic

when a trailer number is selected that has not had

trailer tire pressure sensors paired. To correct this

condition, see Ú

page 234.

Trailer Sensors Detected Do Not Match Active

Trailer

The “Trailer Sensors Detected Do Not Match Active

Trailer” message will be displayed in the

instrument cluster when the trailer sensors being

received by the TTPMS module do not match the

trailer sensors paired to the current trailer number

selected. This message will be displayed when the

sensors being received completely match the

sensors paired to another trailer number

configured in the TTPMS module.

To correct this condition, the correct trailer number

must be selected in the radio Ú page 234.

OCCUPANT RESTRAINT SYSTEMS

Some of the most important safety features in your

vehicle are the restraint systems:

OCCUPANT RESTRAINT SYSTEMS

F

EATURES

Seat Belt Systems

Supplemental Restraint Systems (SRS) Air Bags

Child Restraints

Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on others. If

you are not sure, ask an authorized dealer.

IMPORTANT SAFETY PRECAUTIONS

Please pay close attention to the information in

this section. It tells you how to use your restraint

system properly, to keep you and your passengers

as safe as possible.

22_DT_OM_EN_USC_t.book Page 334

Page 392 of 496

390IN CASE OF EMERGENCY

NOTE:Shifts between DRIVE and REVERSE can only be

achieved at wheel speeds of 5 mph (8 km/h) or

less. Whenever the transmission remains in

NEUTRAL (N) for more than two seconds, you must

press the brake pedal to engage DRIVE or

REVERSE.

Push the ESC OFF button to place the Electronic

Stability Control (ESC) system in “Partial OFF”

mode, before rocking the vehicle Ú page 314.

Once the vehicle has been freed, push the ESC OFF

button to restore “ESC On” mode.TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service.

If the transmission and drivetrain are operable,

disabled vehicles may also be towed as described

on Ú page 227.

NOTE:

Vehicles equipped with the Active-Level Four

Corner Air Suspension System must be placed in

Transport mode, before tying them down (from the

body) on a trailer or flatbed truck Ú page 165. If

the vehicle cannot be placed in Transport mode

(for example, engine will not run), tie-downs must

be fastened to the axles (not to the body). Failure

to follow these instructions may cause fault codes

to be set and/or cause loss of proper tie-down

tension.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after every

five rocking-motion cycles. This will minimize

overheating and reduce the risk of transmis -

sion failure during prolonged efforts to free a

stuck vehicle.

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin the

wheels faster than 15 mph (24 km/h), or

drivetrain damage may result.

Revving the engine or spinning the wheels too

fast may lead to transmission overheating and

failure. It can also damage the tires. Do not

spin the wheels above 30 mph (48 km/h)

while in gear (no transmission shifting occur -

ring).

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause damage, or even failure, of the axle and

tires. A tire could explode and injure someone.

Do not spin your vehicle's wheels faster than

30 mph (48 km/h) or for longer than 30

seconds continuously without stopping when

you are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

22_DT_OM_EN_USC_t.book Page 390

Page 395 of 496

393

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, and extremely hot or cold ambient

temperatures will influence when the “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km).An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, the

message can be reset by referring to the steps

described under Instrument Cluster Display

Ú

page 114.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for fleet

customers. Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual wear

or damage. Rotate tires at the first sign of irreg

-

ular wear, even if it occurs before the oil indi -

cator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and fill as needed.

Check function of all interior and exterior lights.

8

22_DT_OM_EN_USC_t.book Page 393

Page 397 of 496

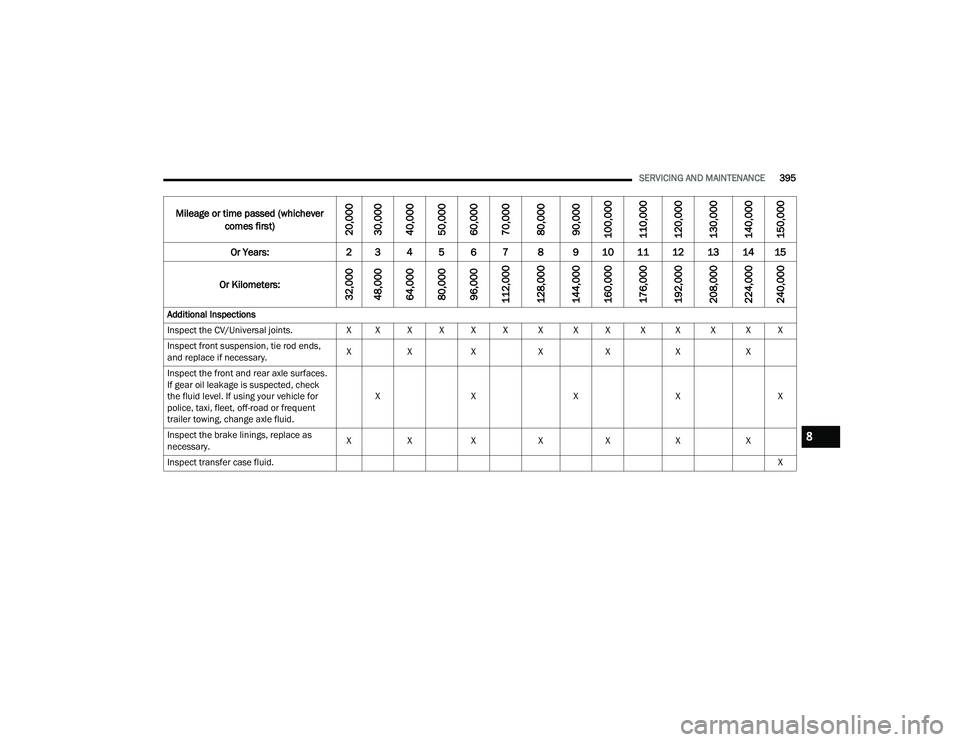

SERVICING AND MAINTENANCE395

Mileage or time passed (whichever

comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X X X X X X X X

Inspect front suspension, tie rod ends,

and replace if necessary. X

X X XX XX

Inspect the front and rear axle surfaces.

If gear oil leakage is suspected, check

the fluid level. If using your vehicle for

police, taxi, fleet, off-road or frequent

trailer towing, change axle fluid. X

X XXX

Inspect the brake linings, replace as

necessary. X

X X XX XX

Inspect transfer case fluid. X

8

22_DT_OM_EN_USC_t.book Page 395

Page 398 of 496

396SERVICING AND MAINTENANCE

Additional Maintenance

Replace cabin air filter. To be replaced every 12,000 mi (19,000 km).

For severe dusty driving conditions,

inspect and replace the Evaporative

System Fresh Air Filter as necessary;

replacement may be more frequent

depending on conditions. X X X X X X X X X X X X X X

Replace engine air cleaner. XX XXX

If equipped with Stop/Start, replace

accessory drive belt with OEM grade

Mopar® belt. X

Replace spark plugs.

1X

Flush and replace the engine coolant at

10 years or 150,000 miles (240,000 km)

whichever comes first. X

X

Inspect the transfer case fluid, change for

any of the following: police, taxi, fleet, or

frequent trailer towing. X

X

Mileage or time passed (whichever

comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

22_DT_OM_EN_USC_t.book Page 396

Page 400 of 496

398SERVICING AND MAINTENANCE

SCHEDULED SERVICING — DIESEL ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, extremely hot or cold ambient

temperatures will influence when the “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km). An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, the

message can be reset by referring to the steps

described under Instrument Cluster Display

Ú

page 114.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km) or

12 months, whichever comes first. Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check the tire inflation pressures and look for

unusual wear or damage.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering, and

fill as needed.

Check function of all interior and exterior lights.

22_DT_OM_EN_USC_t.book Page 398

Page 402 of 496

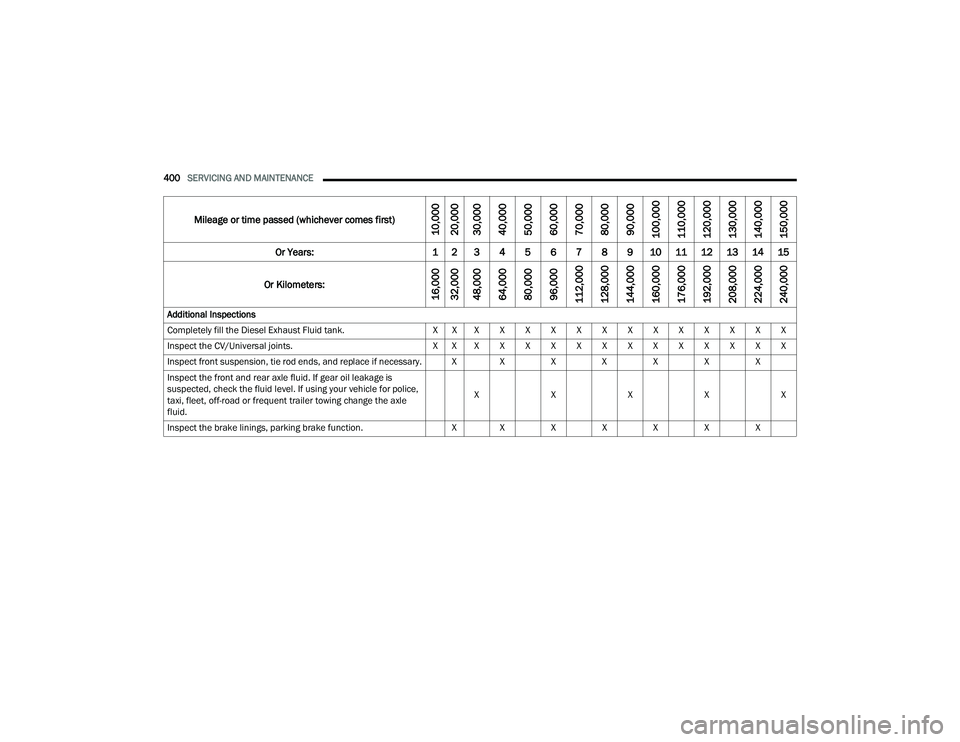

400SERVICING AND MAINTENANCE

Mileage or time passed (whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Completely fill the Diesel Exhaust Fluid tank. X X X X X X X X X X X X X X X

Inspect the CV/Universal joints. X X X X X X X X X X X X X X X

Inspect front suspension, tie rod ends, and replace if necessary. X X X X X X X Inspect the front and rear axle fluid. If gear oil leakage is

suspected, check the fluid level. If using your vehicle for police,

taxi, fleet, off-road or frequent trailer towing change the axle

fluid. X

XXXX

Inspect the brake linings, parking brake function. X X X X X X X

22_DT_OM_EN_USC_t.book Page 400

Page 404 of 496

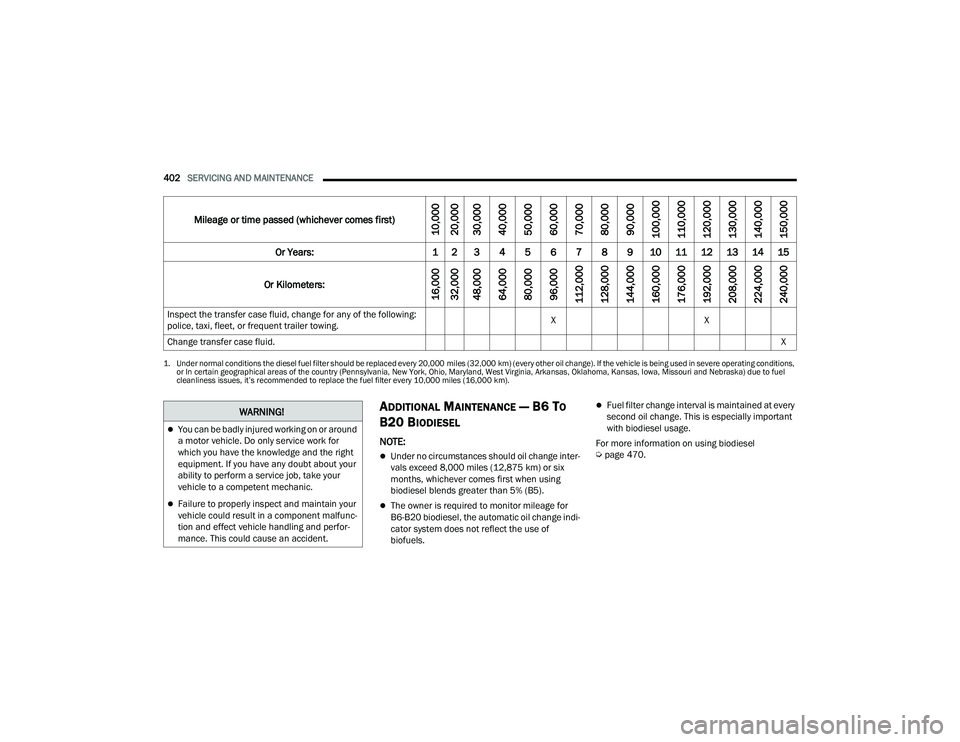

402SERVICING AND MAINTENANCE

ADDITIONAL MAINTENANCE — B6 TO

B20 B

IODIESEL

NOTE:

Under no circumstances should oil change inter -

vals exceed 8,000 miles (12,875 km) or six months, whichever comes first when using

biodiesel blends greater than 5% (B5).

The owner is required to monitor mileage for

B6-B20 biodiesel, the automatic oil change indi -

cator system does not reflect the use of

biofuels.

Fuel filter change interval is maintained at every

second oil change. This is especially important

with biodiesel usage.

For more information on using biodiesel

Ú page 470.

Inspect the transfer case fluid, change for any of the following:

police, taxi, fleet, or frequent trailer towing.

X

X

Change transfer case fluid. X

1. Under normal conditions the diesel fuel filter should be replaced every 20,000 miles (32,000 km) (every other oil change). If the vehicle is being used in severe operating conditions,

or In certain geographical areas of the country (Pennsylvania, New York, Ohio, Maryland, West Virginia, Arkansas, Oklahoma, Kansas, Iowa, Missouri and Nebraska) due to fuel

cleanliness issues, it’s recommended to replace the fuel filter every 10,000 miles (16,000 km).

Mileage or time passed (whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

WARNING!

You can be badly injured working on or around

a motor vehicle. Do only service work for

which you have the knowledge and the right

equipment. If you have any doubt about your

ability to perform a service job, take your

vehicle to a competent mechanic.

Failure to properly inspect and maintain your

vehicle could result in a component malfunc -

tion and effect vehicle handling and perfor -

mance. This could cause an accident.

22_DT_OM_EN_USC_t.book Page 402