oil change Ram 2500 2017 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2017, Model line: 2500, Model: Ram 2500 2017Pages: 228, PDF Size: 1.35 MB

Page 82 of 228

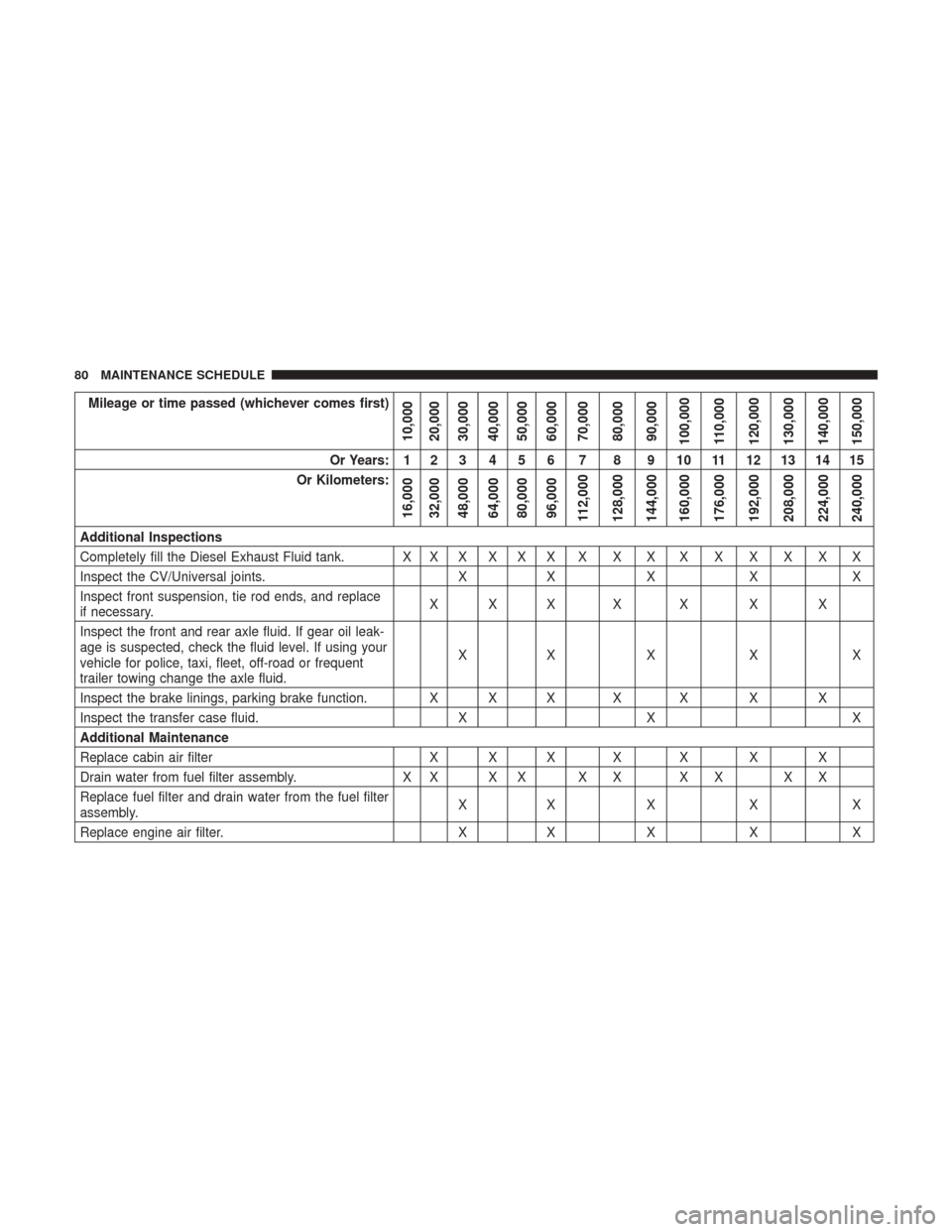

Mileage or time passed (whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Completely fill the Diesel Exhaust Fluid tank. X X X X X X X X X X X X X X X

Inspect the CV/Universal joints. XX X X X

Inspect front suspension, tie rod ends, and replace

if necessary. XXX X X X X

Inspect the front and rear axle fluid. If gear oil leak-

age is suspected, check the fluid level. If using your

vehicle for police, taxi, fleet, off-road or frequent

trailer towing change the axle fluid. XX X X X

Inspect the brake linings, parking brake function. X X X X X X X

Inspect the transfer case fluid. XX X

Additional Maintenance

Replace cabin air filter X X X X X X X

Drain water from fuel filter assembly. X X X X X X X X X X

Replace fuel filter and drain water from the fuel filter

assembly. XX X X X

Replace engine air filter. XX X X X

80 MAINTENANCE SCHEDULE

Page 84 of 228

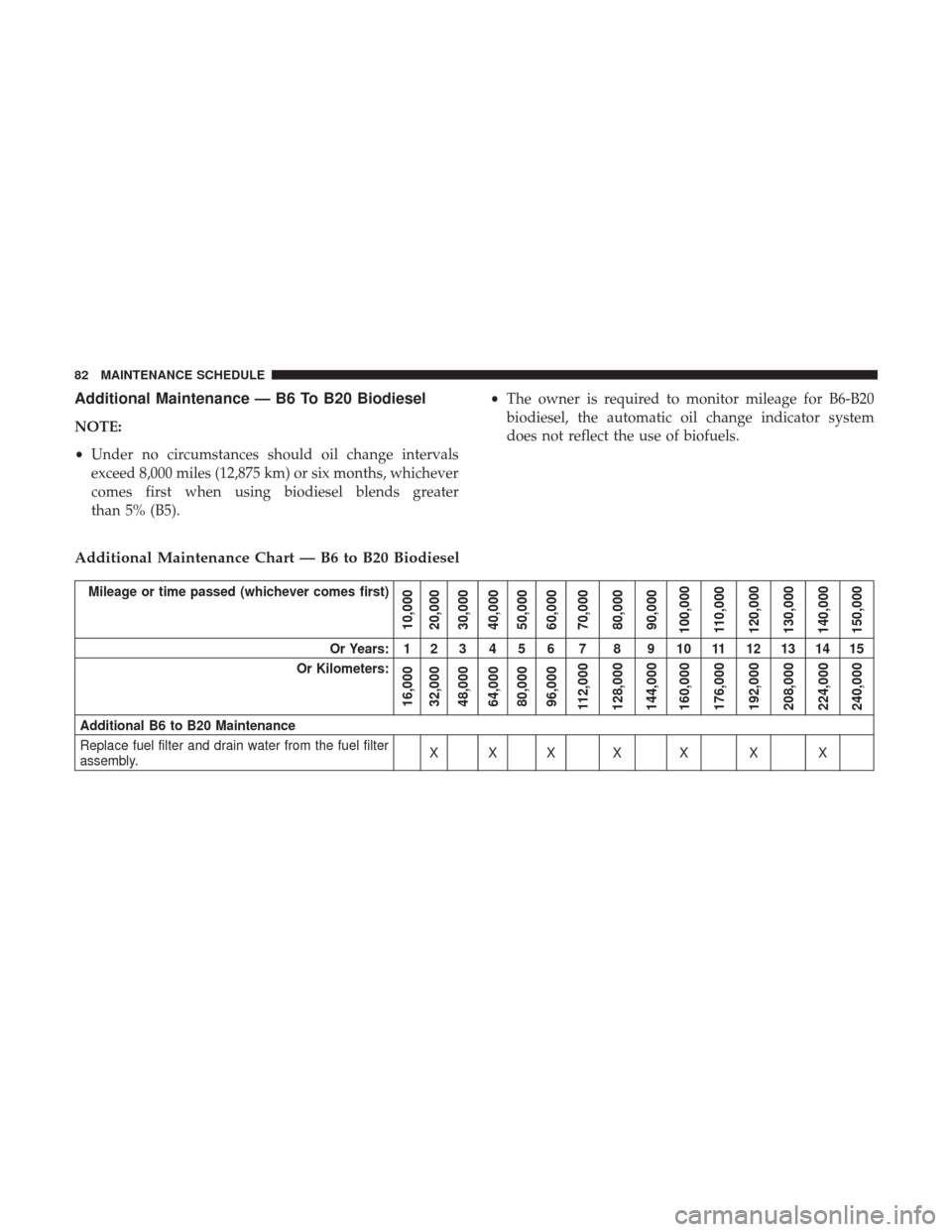

Additional Maintenance — B6 To B20 Biodiesel

NOTE:

•Under no circumstances should oil change intervals

exceed 8,000 miles (12,875 km) or six months, whichever

comes first when using biodiesel blends greater

than 5% (B5). •

The owner is required to monitor mileage for B6-B20

biodiesel, the automatic oil change indicator system

does not reflect the use of biofuels.

Additional Maintenance Chart — B6 to B20 Biodiesel

Mileage or time passed (whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional B6 to B20 Maintenance

Replace fuel filter and drain water from the fuel filter

assembly. XXX X X X X

82 MAINTENANCE SCHEDULE

Page 113 of 228

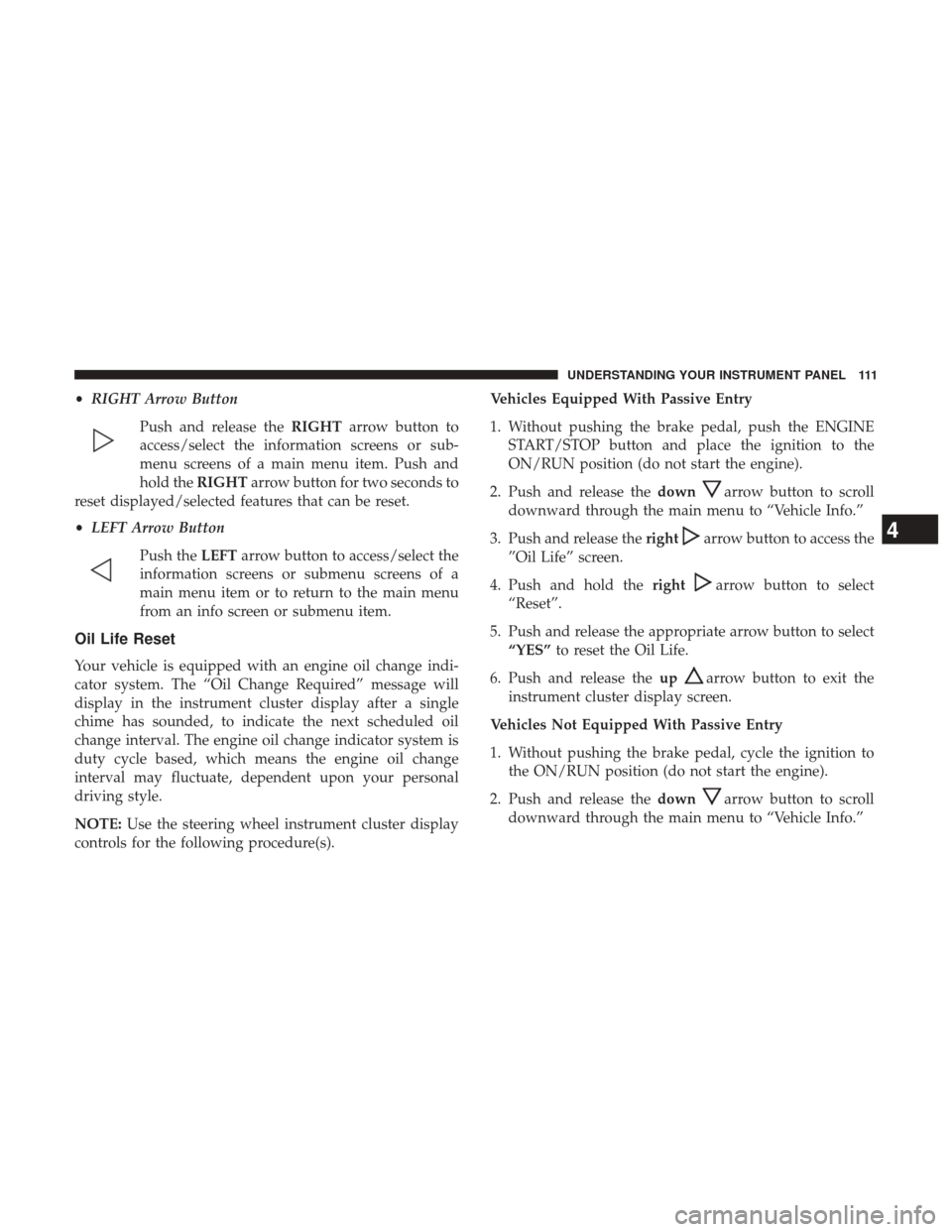

•RIGHT Arrow Button

Push and release the RIGHTarrow button to

access/select the information screens or sub-

menu screens of a main menu item. Push and

hold the RIGHTarrow button for two seconds to

reset displayed/selected features that can be reset.

• LEFT Arrow Button

Push the LEFTarrow button to access/select the

information screens or submenu screens of a

main menu item or to return to the main menu

from an info screen or submenu item.

Oil Life Reset

Your vehicle is equipped with an engine oil change indi-

cator system. The “Oil Change Required” message will

display in the instrument cluster display after a single

chime has sounded, to indicate the next scheduled oil

change interval. The engine oil change indicator system is

duty cycle based, which means the engine oil change

interval may fluctuate, dependent upon your personal

driving style.

NOTE: Use the steering wheel instrument cluster display

controls for the following procedure(s). Vehicles Equipped With Passive Entry

1. Without pushing the brake pedal, push the ENGINE

START/STOP button and place the ignition to the

ON/RUN position (do not start the engine).

2. Push and release the down

arrow button to scroll

downward through the main menu to “Vehicle Info.”

3. Push and release the right

arrow button to access the

”Oil Life” screen.

4. Push and hold the right

arrow button to select

“Reset”.

5. Push and release the appropriate arrow button to select “YES” to reset the Oil Life.

6. Push and release the up

arrow button to exit the

instrument cluster display screen.

Vehicles Not Equipped With Passive Entry

1. Without pushing the brake pedal, cycle the ignition to the ON/RUN position (do not start the engine).

2. Push and release the down

arrow button to scroll

downward through the main menu to “Vehicle Info.”

4

UNDERSTANDING YOUR INSTRUMENT PANEL 111

Page 135 of 228

Engine Warm-Up

Avoid full throttle operation when the engine is cold. When

starting a cold engine, bring the engine up to operating

speed slowly to allow the oil pressure to stabilize as the

engine warms up.

NOTE:High-speed, no-load running of a cold engine can

result in excessive white smoke and poor engine perfor-

mance. No-load engine speeds should be kept under 1,200

RPM during the warm-up period, especially in cold ambi-

ent temperature conditions.

Your vehicle is equipped with a turbo speed limiter, this

feature limits the engine speed to 1,200 RPM when engine

coolant temperatures are below 70°F (21°C). This feature is

designed to protect the turbocharger from damage and will

only operate in PARK or NEUTRAL.

If temperatures are below 32°F (0°C), operate the engine at

moderate speeds for five minutes before full loads are

applied.

NOTE: If ambient temperatures are low and the coolant

temperature is below 180°F (82°C), the engine idle speed

will slowly increase to 1,000 RPM after two minutes of idle,

if the following conditions are met:

• Foot is off brake pedal and throttle pedal. •

Automatic transmission is in PARK.

• Vehicle speed is 0 mph (0 km/h).

• Applying the throttle will cancel fast idle.

• Operating the exhaust brake at idle will greatly improve

warm up rate and will help keep the engine close to

operating temperature during extended idle.

Engine Idling

Avoid prolonged idling, long periods of idling may be

harmful to your engine because combustion chamber tem-

peratures can drop so low that the fuel may not burn

completely. Incomplete combustion allows carbon and

varnish to form on piston rings, engine valves, and injector

nozzles. Also, the unburned fuel can enter the crankcase,

diluting the oil and causing rapid wear to the engine.

If the engine is allowed to idle or the truck is driven on low

engine speed drive cycles for more than 2 hours, the

system will automatically enter an emissions operating

mode that will increase the engine idle speed to 900 RPM

(1050 RPM for Chassis Cab). While in this mode, which is

designed to help maintain the diesel particulate filter, the

engine idle speed will return to normal when the brake

pedal is applied. A small change in engine tone or a slight

change in engine performance while accelerating may also5

STARTING AND OPERATING 133

Page 139 of 228

Do Not Operate The Engine With Low Oil Pressure

When the engine is at normal operating temperature, the

minimum oil pressures required are:

Idle 700 to 800 RPM 10 psi (69 kPa)

Full speed and load 30 psi (207 kPa)

CAUTION!

If oil pressure falls to less than normal readings, shut

the engine off immediately. Failure to do so could

result in immediate and severe engine damage.

Do Not Operate The Engine With Failed Parts

All engine failures give some warning before the parts fail.

Be on the alert for changes in performance, sounds, and

visual evidence that the engine requires service. Some

important clues are:

•Engine misfiring or vibrating severely.

• Sudden loss of power.

• Unusual engine noises. •

Fuel, oil or coolant leaks.

• Sudden change, outside the normal operating range, in

the engine operating temperature.

• Excessive smoke.

• Oil pressure drop.

ENGINE BLOCK HEATER — IF EQUIPPED

The engine block heater warms engine coolant and permits

quicker starts in cold weather. Connect the heater cord to a

ground-fault interrupter protected 110–115 Volt AC electri-

cal outlet with a grounded, three-wire extension cord.

The engine block heater cord is routed under the hood to

the right side and can be located just behind the grille near

the headlamp.

NOTE: The engine block heater cord is a factory installed

option. If your vehicle is not equipped, heater cords are

available from your authorized MOPAR dealer.

The block heater must be plugged in at least one hour to

have an adequate warming effect on the coolant.5

STARTING AND OPERATING 137

Page 160 of 228

NOTE:

•If you accidentally fill the fuel tank with gasoline on

your diesel vehicle, Do not start the vehicle. If you

restart your vehicle you risk damaging the engine and

fuel system. Please call your local dealer for service.

• A maximum blend of 5% biodiesel meeting ASTM

specification D-975 may be used with your Cummins

diesel engine. (Chassis Cab models not configured with

B20 capability.)

• A maximum blend of 20% biodiesel meeting ASTM

specification D-7467 may be used with your Cummins

diesel engine. (Pickup models and Chassis Cab models

configured with B20 Capability.)

• In addition, commercially available fuel additives are

not necessary for the proper operation of your Cummins

diesel engine. However, if seasonably adjusted fuel is

not available and you are operating below 20°F (-6°C),

MOPAR Premium Diesel Fuel Treatment (or equivalent)

may be beneficial to avoid fuel gelling.

• No. 1 Ultra Low Sulfur diesel fuel should only be used

where extended arctic conditions (-10°F or -23°C) exist.Bio-Diesel Fuel Requirements

Chassis Cab Models

A maximum blend of 5% biodiesel meeting ASTM specifi-

cation D975 may be used with your Cummins diesel

engine. If operation with biodiesel blends greater than 5%

but not greater than 20% (B6-B20) is desired, the truck must

first be reconfigured by an authorized Ram dealer and the

provisions in the following section must be adhered to.

Pickup Models And Chassis Cab Models Ordered

With B20 Option

Your vehicle has been validated and approved for the use

of biodiesel in blends up to 20% (B20) provided that you

comply with the requirements outlined below. It is impor-

tant that you understand and comply with these require-

ments. Failure to comply with Oil Change requirements for

vehicles operating on biodiesel blends up to B20 will result

in premature engine wear. Such wear is not covered by the

New Vehicle Limited Warranty.

Biodiesel is a fuel produced from renewable resources

typically derived from animal fat, rapeseed oil (Rapeseed

Methyl Ester (RME) base), or soybean oil (Soy Methyl Ester

(SME or SOME) base). Biodiesel fuel has inherent limita-

tions which require that you understand and adhere to the

158 STARTING AND OPERATING

Page 161 of 228

following requirements if you use blends of biodiesel

greater then 5% but not greater than 20% (B6-B20). There

are no unique restrictions for the use of B5. Use of blends

greater than 20% is not approved. Use of blends greater

than 20% can result in engine damage. Such damage is not

covered by the New Vehicle Limited Warranty.

Fuel Quality — Must Comply With ASTM

Standards

The quality of biodiesel fuel may vary widely. Only fuel

produced by a BQ9000 supplier to the following specifica-

tions may be blended to meet biodiesel blend (B6–B20) fuel

meeting ASTM specification D-7467:

•Pretrodiesel fuel meeting ASTM specification D-975 and

biodiesel fuel (B100) meeting ASTM specification

D-6751.

Fuel Oxidation Stability — Must Use Fuel Within

Six Months Of Manufacture

Biodiesel fuel has poor oxidation stability which can result

in long term storage problems. Fuel produced to approved

ASTM standards, if stored properly, provides for protec-

tion against fuel oxidation for up to six months.

Fuel Water Separation — Must Use MOPAR/

Cummins Approved Fuel Filter Elements

You must use MOPAR/Cummins approved fuel filter

elements in both your engine mounted filter and frame

mounted filter.

Biodiesel fuel has a natural affinity to water and water

accelerates microbial growth. Your MOPAR/Cummins fil-

tration system is designed to provide adequate fuel water

separation capabilities.

Bio-Diesel Fuel Properties — Low Ambient

Temperatures

Biodiesel fuel may gel or solidify at low ambient tempera-

tures, which may pose problems for both storage and opera-

tion. Precautions can be necessary at low ambient tempera-

tures, such as storing the fuel in a heated building or a heated

storage tank, or using cold temperature additives.

Fuel In Oil Dilution — Must Adhere To Required

Oil Change Interval

Fuel dilution of lubricating oil has been observed with the

use of biodiesel fuel. Fuel in oil must not exceed 5%. To

ensure this limit is met your oil change interval must be

maintained to the following schedule:

5

STARTING AND OPERATING 159

Page 162 of 228

•Ram PickUp 2500/3500 Only — 15,000 Miles*

• Ram 3500/4500/5500 Chassis Cab — 12,500 Miles*

(*unless otherwise notified with a oil service message)

CAUTION!

•Under no circumstances should oil change intervals

exceed 15,000 miles (24 000 km) pickup or 12,500 miles

(20 000 km) chassis cab if operation occurs with greater

than 5% biodiesel blends. Oil change intervals should

not exceed 6 months in either case. Failure to comply

with these Oil Change requirements for vehicles op-

erating on biodiesel blends up to B20 may result in

premature engine wear. Such wear is not covered by

the New Vehicle Limited Warranty.

• B20 Biodiesel capable: The engine may suffer severe

damage if operated with concentrations of Biodiesel

higher than 20%.

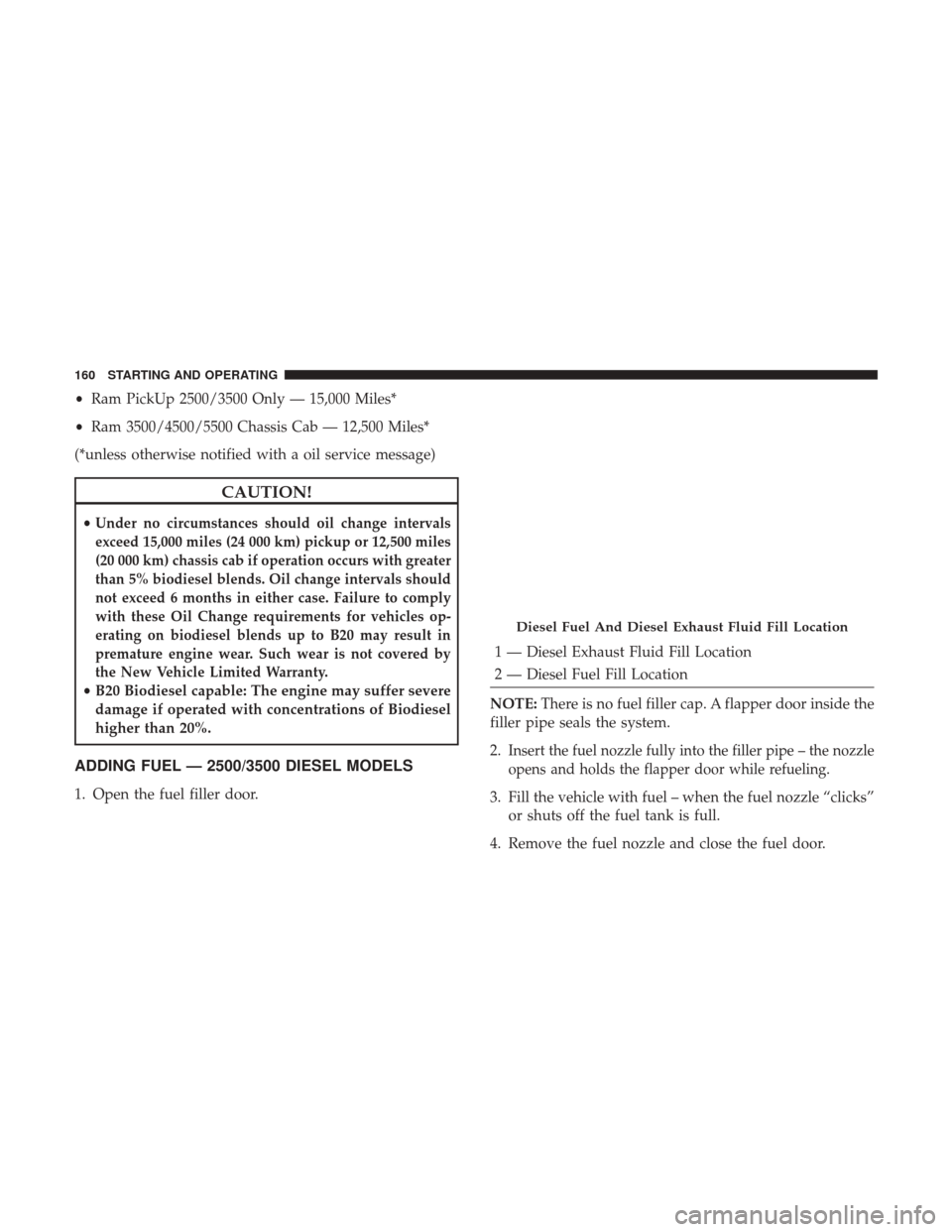

ADDING FUEL — 2500/3500 DIESEL MODELS

1. Open the fuel filler door.

1 — Diesel Exhaust Fluid Fill Location

2 — Diesel Fuel Fill Location

NOTE: There is no fuel filler cap. A flapper door inside the

filler pipe seals the system.

2.

Insert the fuel nozzle fully into the filler pipe – the nozzle

opens and holds the flapper door while refueling.

3. Fill the vehicle with fuel – when the fuel nozzle “clicks” or shuts off the fuel tank is full.

4. Remove the fuel nozzle and close the fuel door.

Diesel Fuel And Diesel Exhaust Fluid Fill Location

160 STARTING AND OPERATING

Page 179 of 228

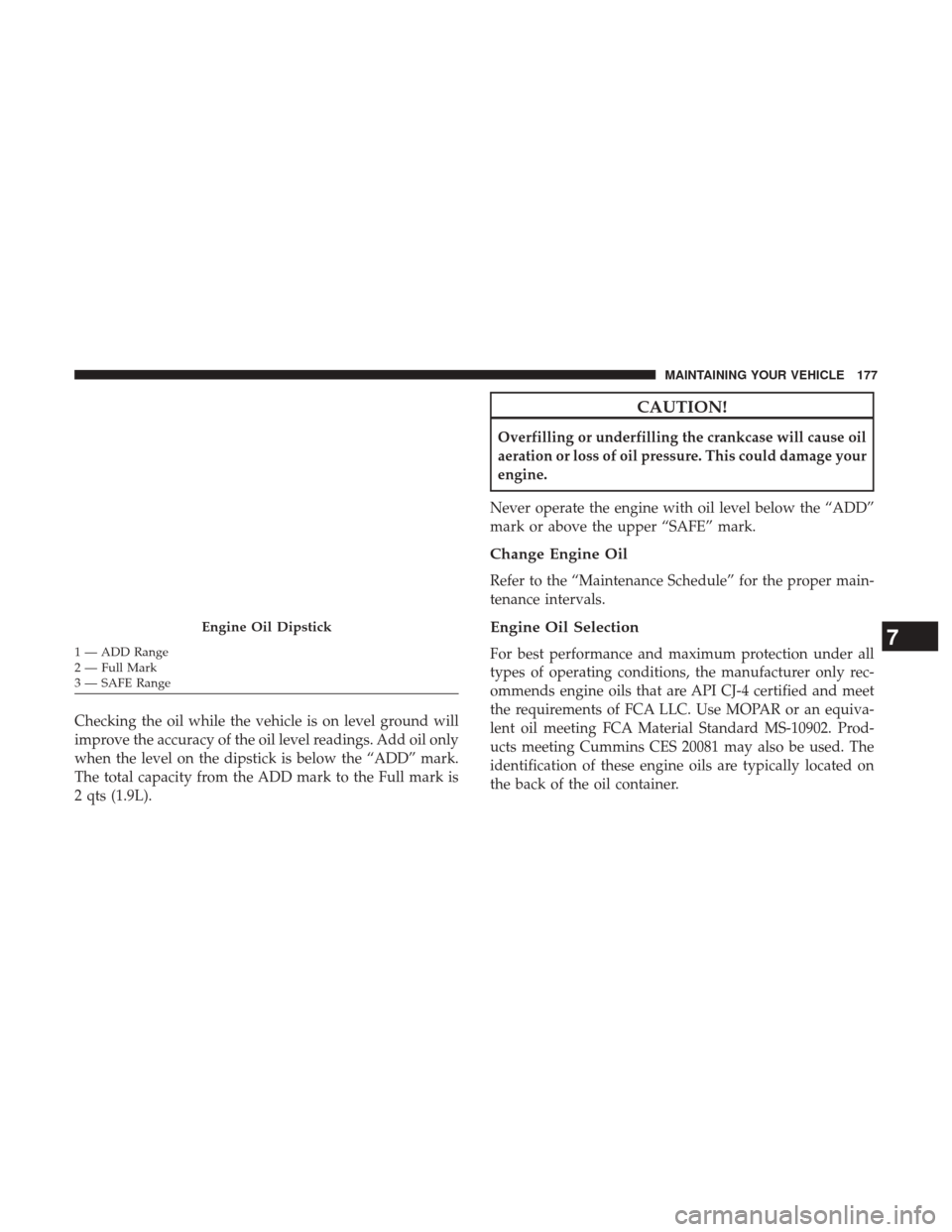

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings. Add oil only

when the level on the dipstick is below the “ADD” mark.

The total capacity from the ADD mark to the Full mark is

2 qts (1.9L).

CAUTION!

Overfilling or underfilling the crankcase will cause oil

aeration or loss of oil pressure. This could damage your

engine.

Never operate the engine with oil level below the “ADD”

mark or above the upper “SAFE” mark.

Change Engine Oil

Refer to the “Maintenance Schedule” for the proper main-

tenance intervals.

Engine Oil Selection

For best performance and maximum protection under all

types of operating conditions, the manufacturer only rec-

ommends engine oils that are API CJ-4 certified and meet

the requirements of FCA LLC. Use MOPAR or an equiva-

lent oil meeting FCA Material Standard MS-10902. Prod-

ucts meeting Cummins CES 20081 may also be used. The

identification of these engine oils are typically located on

the back of the oil container.

Engine Oil Dipstick

1 — ADD Range

2—FullMark

3 — SAFE Range7

MAINTAINING YOUR VEHICLE 177

Page 180 of 228

American Petroleum Institute (API) Engine Oil

Identification Symbol

This symbol means that the oil has been

certified by the American Petroleum In-

stitute (API). The manufacturer only rec-

ommends API Certified engine oils.

Oils with a high ash content may produce damaging

deposits on cylinder head valves and/or aftertreatment

system damage. A maximum sulfated ash content of 1.00

mass % is recommended for all oil used in the engine.

The same oil change interval is to be followed for synthetic

oil as for petroleum based oil. Also, synthetic oil must meet

the same performance specifications as petroleum oil.

CAUTION!

Do not use chemical flushes in your engine oil as the

chemicals can damage your engine. Such damage is not

covered by the New Vehicle Limited Warranty.

Engine Oil Viscosity (SAE Grade)

In ambient temperatures above 0°F (-18°C), we recommend

you use SAE 15W-40 engine oil such as MOPAR, Shell

Rotella and Shell Rimula that meets FCA Material Standard

MS-10902 and the API CJ-4 engine oil category is required.

Products meeting Cummins CES 20081 may also be used.

The identification of these engine oils is typically located

on the back of the oil container.

In ambient temperatures below 0°F (-18°C), SAE 5W-40 we

recommend you use syntheticengine oil such as MOPAR,

Shell Rotella and Shell Rimula that meets FCA Material

Standard MS-10902 and the API CJ-4 engine oil category is

required.

CAUTION!

Failure to use SAE 5W-40 synthetic engine oil in

ambient temperatures below 0°F (-18°C) could result in

severe engine damage.

178 MAINTAINING YOUR VEHICLE