Battery Ram 2500 2017 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2017, Model line: 2500, Model: Ram 2500 2017Pages: 734, PDF Size: 7.3 MB

Page 635 of 734

ENGINE COMPARTMENT — 3.6L

1 — Air Cleaner Filter

2 — Engine Oil Dipstick

3 — Engine Oil Fill

4 — Brake Fluid Reservoir

5 — Battery6 — Washer Fluid Reservoir

7 — Power Distribution Center (Fuses)

8 — Coolant Pressure Cap

9 — Engine Coolant Reservoir

7

MAINTAINING YOUR VEHICLE 633

Page 636 of 734

ENGINE COMPARTMENT — 5.7L

1 — Air Cleaner Filter7 — Washer Fluid Reservoir

2 — Automatic Transmission Dipstick (6-Speed Trans Only) 8 — Power Distribution Center (Fuses)

3 — Engine Oil Fill 9 — Power Steering Fluid Reservoir (2500/3500 Models Only)

4 — Engine Oil Dipstick 10 — Coolant Pressure Cap

5 — Brake Fluid Reservoir 11 — Engine Coolant Reservoir

6 — Battery 634 MAINTAINING YOUR VEHICLE

Page 637 of 734

ENGINE COMPARTMENT — 6.4L

1 — Coolant Pressure Bottle6 — Battery

2 — Transmission Dipstick 7 — Power Distribution Center (Fuses)

3 — Engine Oil Fill 8 — Washer Solvent

4 — Engine Oil Dipstick 9 — Power Steering Fluid Reservoir

5 — Brake Fluid Reservoir 10 — Air Cleaner Filter

7

MAINTAINING YOUR VEHICLE 635

Page 639 of 734

WARNING!(Continued)

vehicle control could occur that may result in an

accident involving serious injury or death.

• Access, or allow others to access, information

stored in your vehicle systems, including personal

information.

For further information, refer to “Privacy Practices — If

Equipped With Uconnect 8.4 Radio” and “Uconnect Cy-

berSecurity” in “All About Uconnect Access” in your

Owner ’s Manual Radio Supplement and “Cybersecurity”

in “Understanding Your Instrument Panel”.

Loose Fuel Filler Cap Message

If the vehicle diagnostic system determines that

the fuel filler cap is loose, improperly installed,

or damaged, a loose gascap indicator will dis-

play in the instrument cluster telltale display

area. Refer to “Instrument Cluster Display” in “Under-

standing Your Instrument Panel” for further information.

Tighten the fuel filler cap properly and push the SELECT

button to turn off the message. If the problem continues,

the message will appear the next time the vehicle is started. A loose, improperly installed, or damaged fuel filler cap

may also turn on the Malfunction Indicator Light (MIL).

EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS

In some localities, it may be a legal requirement to pass an

inspection of your vehicle’s emissions control system.

Failure to pass could prevent vehicle registration.

For states that require an Inspection and Mainte-

nance (I/M), this check verifies the “Malfunction

Indicator Light (MIL)” is functioning and is not on

when the engine is running, and that the OBD II system is

ready for testing.

Normally, the OBD II system will be ready. The OBD II

system may notbe ready if your vehicle was recently

serviced, or recently had a dead battery or a battery

replacement. If the OBD II system should be determined

not ready for the I/M test, your vehicle may fail the test.

7

MAINTAINING YOUR VEHICLE 637

Page 640 of 734

Your vehicle has a simple ignition actuated test, which you

can use prior to going to the test station. To check if your

vehicle’s OBD II system isready, you must do the follow-

ing:

1. Cycle the ignition to the ON mode, but do not crank or start the engine.

NOTE: If you crank or start the engine, you will have to

start this test over.

2. As soon as you cycle the ignition to the ON mode, you will see the “Malfunction Indicator Light (MIL)” symbol

come on as part of a normal bulb check.

3. Approximately 15 seconds later, one of two things will happen:

• The MIL will flash for about 10 seconds and then return

to being fully illuminated until you cycle the ignition

OFF or start the engine. This means that your vehicle’s

OBD II system is not readyand you should notproceed

to the I/M station. •

The MIL will not flash at all and will remain fully

illuminated until you place the ignition in the off posi-

tion or start the engine. This means that your vehicle’s

OBD II system is readyand you can proceed to the I/M

station.

If your OBD II system is not ready,you should see your

authorized dealer or repair facility. If your vehicle was

recently serviced or had a battery failure or replacement,

you may need to do nothing more than drive your vehicle

as you normally would in order for your OBD II system to

update. A recheck with the above test routine may then

indicate that the system is now ready.

Regardless of whether your vehicle’s OBD II system is

ready or not, if the MIL is illuminated during normal

vehicle operation you should have your vehicle serviced

before going to the I/M station. The I/M station can fail

your vehicle because the MIL is on with the engine

running.

638 MAINTAINING YOUR VEHICLE

Page 650 of 734

Maintenance-Free Battery

Your vehicle is equipped with a maintenance-free battery.

You will never have to add water, nor is periodic mainte-

nance required.

WARNING!

•Battery fluid is a corrosive acid solution and can

burn or even blind you. Do not allow battery fluid to

contact your eyes, skin, or clothing. Do not lean over

a battery when attaching clamps. If acid splashes in

eyes or on skin, flush the area immediately with

large amounts of water. Refer to “Jump-Starting

Procedures” in “What To Do In Emergencies” for

further information.

• Battery gas is flammable and explosive. Keep flame

or sparks away from the battery. Do not use a booster

battery or any other booster source with an output

greater than 12 Volts. Do not allow cable clamps to

touch each other.

• Battery posts, terminals, and related accessories con-

tain lead and lead compounds. Wash hands after

handling.

CAUTION!

• It is essential when replacing the cables on the

battery that the positive cable is attached to the

positive post and the negative cable is attached to the

negative post. Battery posts are marked positive (+)

and negative (-) and are identified on the battery

case. Cable clamps should be tight on the terminal

posts and free of corrosion.

• If a “fast charger” is used while the battery is in the

vehicle, disconnect both vehicle battery cables before

connecting the charger to the battery. Do not use a

“fast charger” to provide starting voltage.

648 MAINTAINING YOUR VEHICLE

Page 682 of 734

Power Distribution Center

The Power Distribution Center is located in the engine

compartment near the battery. This center contains car-

tridge fuses, micro fuses, relays, and circuit breakers. A

description of each fuse and component may be stamped

on the inside cover, otherwise the cavity number of each

fuse is stamped on the inside cover that corresponds to the

following chart.

Power Distribution Center Location

680 MAINTAINING YOUR VEHICLE

Page 686 of 734

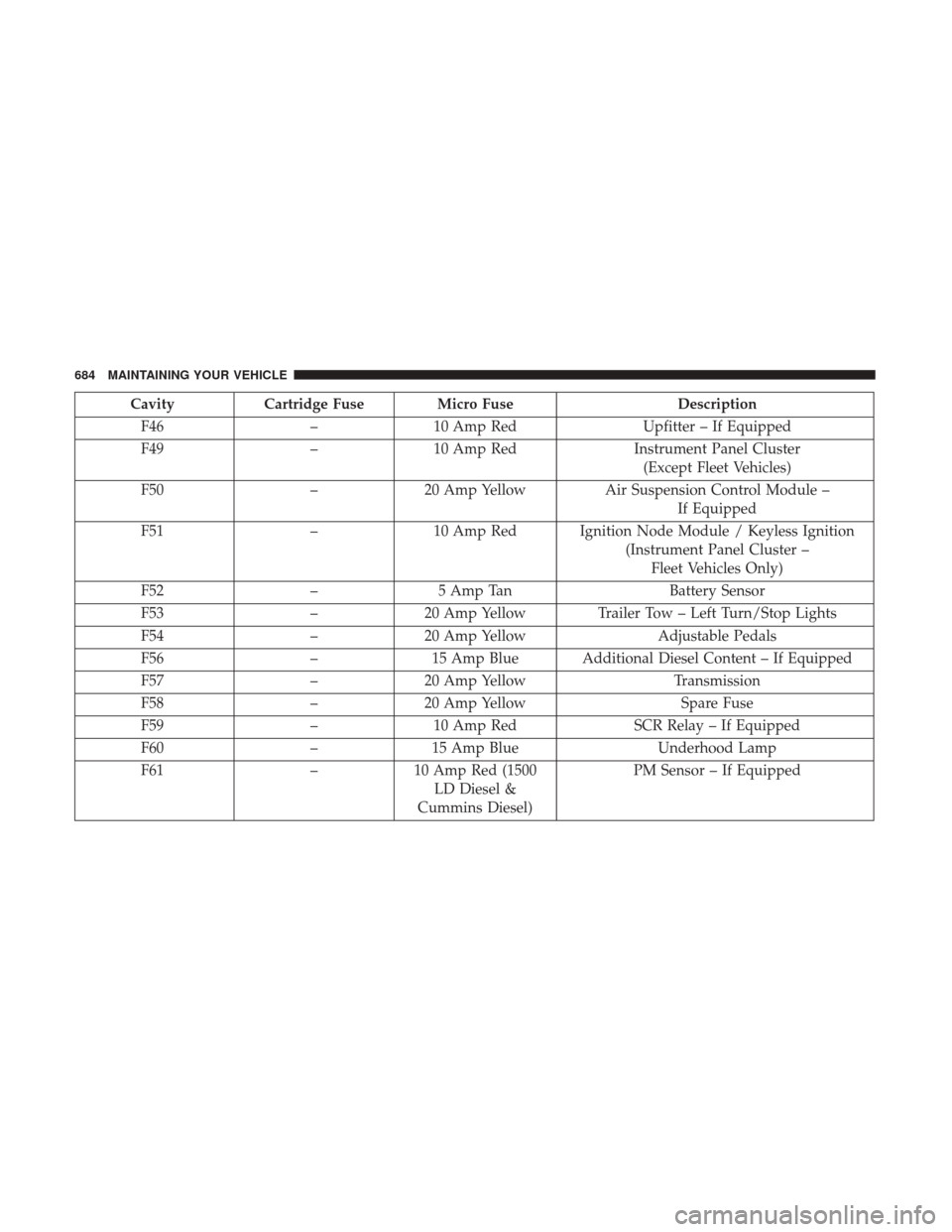

CavityCartridge Fuse Micro Fuse Description

F46 –10 Amp Red Upfitter – If Equipped

F49 –10 Amp Red Instrument Panel Cluster

(Except Fleet Vehicles)

F50 –20 Amp Yellow Air Suspension Control Module –

If Equipped

F51 –10 Amp Red Ignition Node Module / Keyless Ignition

(Instrument Panel Cluster –Fleet Vehicles Only)

F52 –5 Amp Tan Battery Sensor

F53 –20 Amp Yellow Trailer Tow – Left Turn/Stop Lights

F54 –20 Amp Yellow Adjustable Pedals

F56 –15 Amp Blue Additional Diesel Content – If Equipped

F57 –20 Amp Yellow Transmission

F58 –20 Amp Yellow Spare Fuse

F59 –10 Amp Red SCR Relay – If Equipped

F60 –15 Amp Blue Underhood Lamp

F61 –10 Amp Red (1500

LD Diesel &

Cummins Diesel) PM Sensor – If Equipped

684 MAINTAINING YOUR VEHICLE

Page 690 of 734

CAUTION!

•When installing the power distribution center cover,

it is important to ensure the cover is properly posi-

tioned and fully latched. Failure to do so may allow

water to get into the power distribution center and

possibly result in an electrical system failure.

• When replacing a blown fuse, it is important to use

only a fuse having the correct amperage rating. The

use of a fuse with a rating other than indicated may

result in a dangerous electrical system overload. If a

properly rated fuse continues to blow, it indicates a

problem in the circuit that must be corrected.

VEHICLE STORAGE

If you are storing your vehicle for more than 21 days, we

recommend that you take the following steps to minimize

the drain on your vehicle’s battery:

• Disconnect the negative cable from battery.

• Any time you store your vehicle or keep it out of service

(i.e., vacation) for two weeks or more, run the air

conditioning system at idle for about five minutes in the

fresh air and high blower setting. This will ensure

adequate system lubrication to minimize the possibility

of compressor damage when the system is started again.

REPLACEMENT BULBS

All of the inside bulbs are brass or glass-wedge base.

Aluminum base bulbs are not approved.

Interior Bulbs

Bulb Number

Overhead Console Lamps TS 212–9

Dome Lamp 7679

For lighted switches, see your authorized dealer for

replacement instructions.

688 MAINTAINING YOUR VEHICLE

Page 692 of 734

BULB REPLACEMENT

NOTE:Lens fogging can occur under certain atmospheric

conditions. This will usually clear as atmospheric condi-

tions change to allow the condensation to change back into

a vapor. Turning the lamps on will usually accelerate the

clearing process.

Base Quad / Premium Bi-Halogen: Low Beam

Headlamp, High Beam Headlamp, Front Park And

Turn — If Equipped

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Remove the six plastic push-in fasteners that secure the upper radiator seal to the grille support and both fender

ledges.

4. Remove the two plastic push-in rivets that secure the upper radiator seal to the radiator.

5. Remove the upper radiator seal from the vehicle. 6. Remove the two headlamp assembly attachment screws.

7. Reach into the front wheel house ahead of the front

wheel, remove the fastener, and lift the cover over the

access hole in the front of the wheel house splash shield.

Access to the rear of the lamp can be gained through this

access hole.

Headlamp Assembly Attachment Screw Locations

690 MAINTAINING YOUR VEHICLE