lock Ram 2500 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 2500, Model: Ram 2500 2018Pages: 700, PDF Size: 8.86 MB

Page 431 of 700

Repeat steps 8 and 9 until the GAIN setting is at a point just

below trailer wheel lockup. If towing a heavier trailer,trailer wheel lockup may not be attainable even with the

maximum GAIN setting of 10.

Light Electric Heavy Electric Light EOH

Heavy EOH

Type of Trailer Brakes Electric Trailer Brakes Electric Trailer Brakes Electric over Hydrau- lic Trailer BrakesElectric over Hydrau-

lic Trailer Brakes

Load *Under 10,000 lbs *Above 10,000 lbs *Under 10,000 lbs *Above 10,000 lbs

* The suggested selection depends and may change de-

pending on the customer preferences for braking perfor-

mance. Condition of the trailer brakes, driving and road

state may also affect the selection.

Display Messages

The trailer brake control interacts with the instrument

cluster display. Display messages, along with a single

chime, will be displayed when a malfunction is determined

in the trailer connection, trailer brake control, or on the

trailer. Refer to “Instrument Cluster Display” in “Getting

To Know Your Instrument Panel” for further information.

CAUTION!

Connecting a trailer that is not compatible with the

ITBM system may result in reduced or complete loss of

trailer braking. There may be a increase in stopping

distance or trailer instability which could result in

damage to your vehicle, trailer, or other property.

WARNING!

Connecting a trailer that is not compatible with the

ITBM system may result in reduced or complete loss of

trailer braking. There may be a increase in stopping

distance or trailer instability which could result in

personal injury.

6

STARTING AND OPERATING 429

Page 445 of 700

WARNING!(Continued)

•Failure to follow these warnings may result in inju-

ries that are serious or fatal to you, your passengers,

and others around you.

CAUTION!

•Always check the depth of the standing water before

driving through it. Never drive through standing

water that is deeper than the bottom of the tire rims

mounted on the vehicle.

• Determine the condition of the road or the path that

is under water and if there are any obstacles in the

way before driving through the standing water.

• Do not exceed 5 mph (8 km/h) when driving through

standing water. This will minimize wave effects.

• Driving through standing water may cause damage

to your vehicle’s drivetrain components. Always in-

spect your vehicle’s fluids (i.e., engine oil, transmis-

sion, axle, etc.) for signs of contamination (i.e., fluid

that is milky or foamy in appearance) after driving

through standing water. Do not continue to operate

the vehicle if any fluid appears contaminated, as this

(Continued)

CAUTION! (Continued)

may result in further damage. Such damage is not

covered by the New Vehicle Limited Warranty.

• Getting water inside your vehicle’s engine can cause

it to lock up and stall out, and cause serious internal

damage to the engine. Such damage is not covered by

the New Vehicle Limited Warranty.

Off-Road Driving Tips

Care should be taken when attempting to climb steep hills

or driving diagonally across a hill or slope. If natural

obstacles force you to travel diagonally up or down a hill,

choose a mild angle and keep as little side tilt as possible.

Keep the vehicle moving and make turns slowly and

cautiously.

If you must back down a hill, back straight down using

REVERSE gear. Never back down in NEUTRAL or diago-

nally across the hill.

When driving over sand, mud, and other soft terrain, shift

to low gear and drive steadily. Apply the accelerator slowly

to avoid spinning the wheels.

Do not reduce the tire pressures for this type of driving.

6

STARTING AND OPERATING 443

Page 456 of 700

Replacing Exterior Bulbs

Base Quad / Premium Bi-Halogen: Low Beam

Headlamp, High Beam Headlamp, Front Park And

Turn — If Equipped

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Remove the six plastic push-in fasteners that secure theupper radiator seal to the grille support and both fender

ledges.

4. Remove the two plastic push-in rivets that secure the upper radiator seal to the radiator.

5. Remove the upper radiator seal from the vehicle.

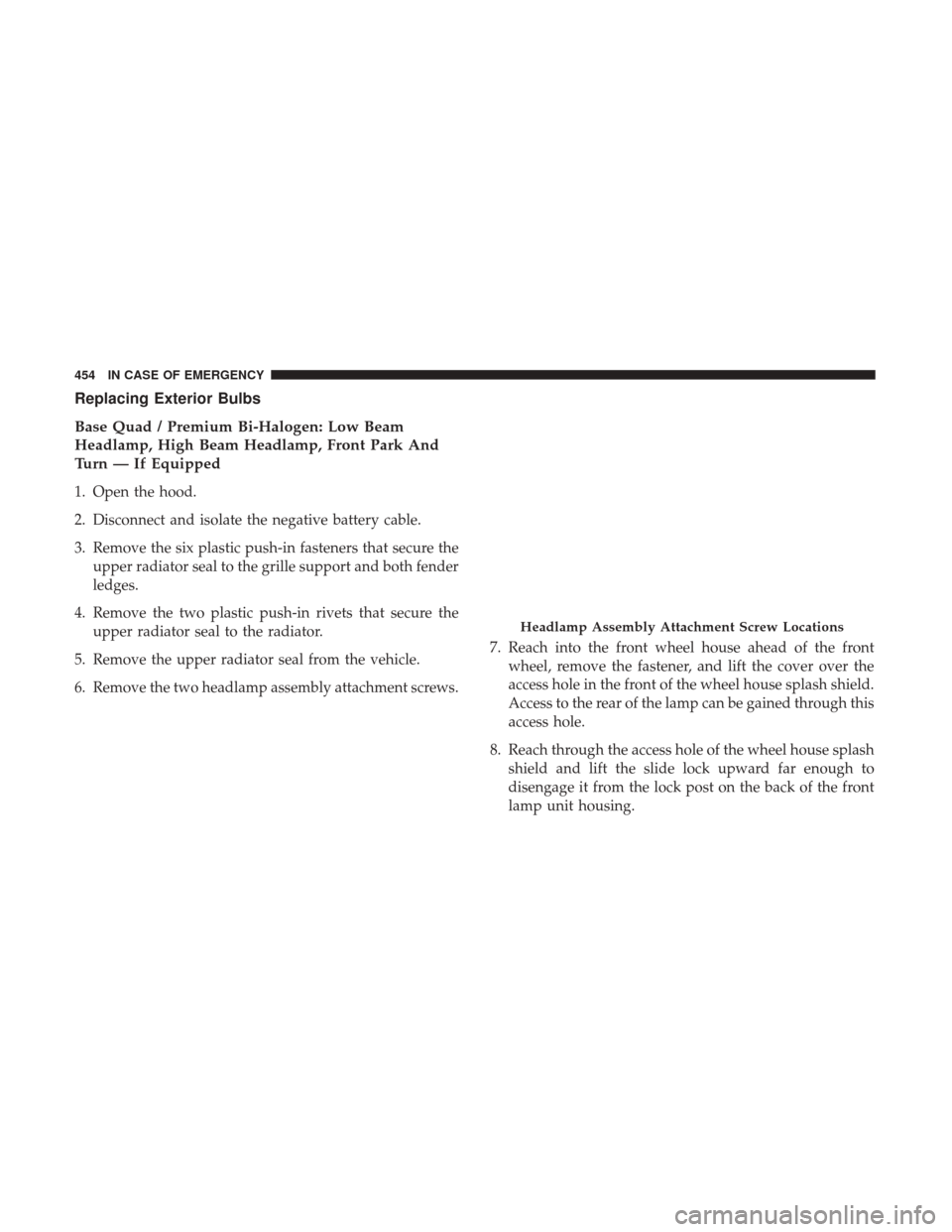

6. Remove the two headlamp assembly attachment screws. 7. Reach into the front wheel house ahead of the front

wheel, remove the fastener, and lift the cover over the

access hole in the front of the wheel house splash shield.

Access to the rear of the lamp can be gained through this

access hole.

8. Reach through the access hole of the wheel house splash shield and lift the slide lock upward far enough to

disengage it from the lock post on the back of the front

lamp unit housing.

Headlamp Assembly Attachment Screw Locations

454 IN CASE OF EMERGENCY

Page 457 of 700

9. Remove the headlamp assembly. Grasp the outboardedge of the lamp and pull it straight forward to disen-

gage the ball stud from the plastic grommet.

10. Disconnect the wiring harness connectors from the bulb socket.

11. Replace bulb(s) as necessary.

CAUTION!

• Do not contaminate the bulb glass by touching it

with your fingers or by allowing it to contact other

oily surfaces. Shortened bulb life will result.

• Always use the correct bulb size and type for replace-

ment. An incorrect bulb size or type may overheat

and cause damage to the lamp, the bulb socket, or the

lamp wiring.

NOTE: There are access covers over both headlamp bulb

access holes in the quad front lamp unit housing (if

equipped). These covers MUST be reinstalled after the bulb

has been replaced.

Fog Lamps — If Equipped

1. Reach under and behind the front bumper to access the back of the front fog lamp housing.

2. Disconnect the fog lamp wiring harness connector from the fog lamp bulb.

3. Rotate the bulb counterclockwise ¼ turn to unlock the bulb from the housing.

4. Pull the bulb straight out from the housing.

Slide Lock

7

IN CASE OF EMERGENCY 455

Page 458 of 700

CAUTION!

Do not contaminate the bulb glass by touching it with

your fingers or by allowing it to contact other oily

surfaces. Shortened bulb life will result.

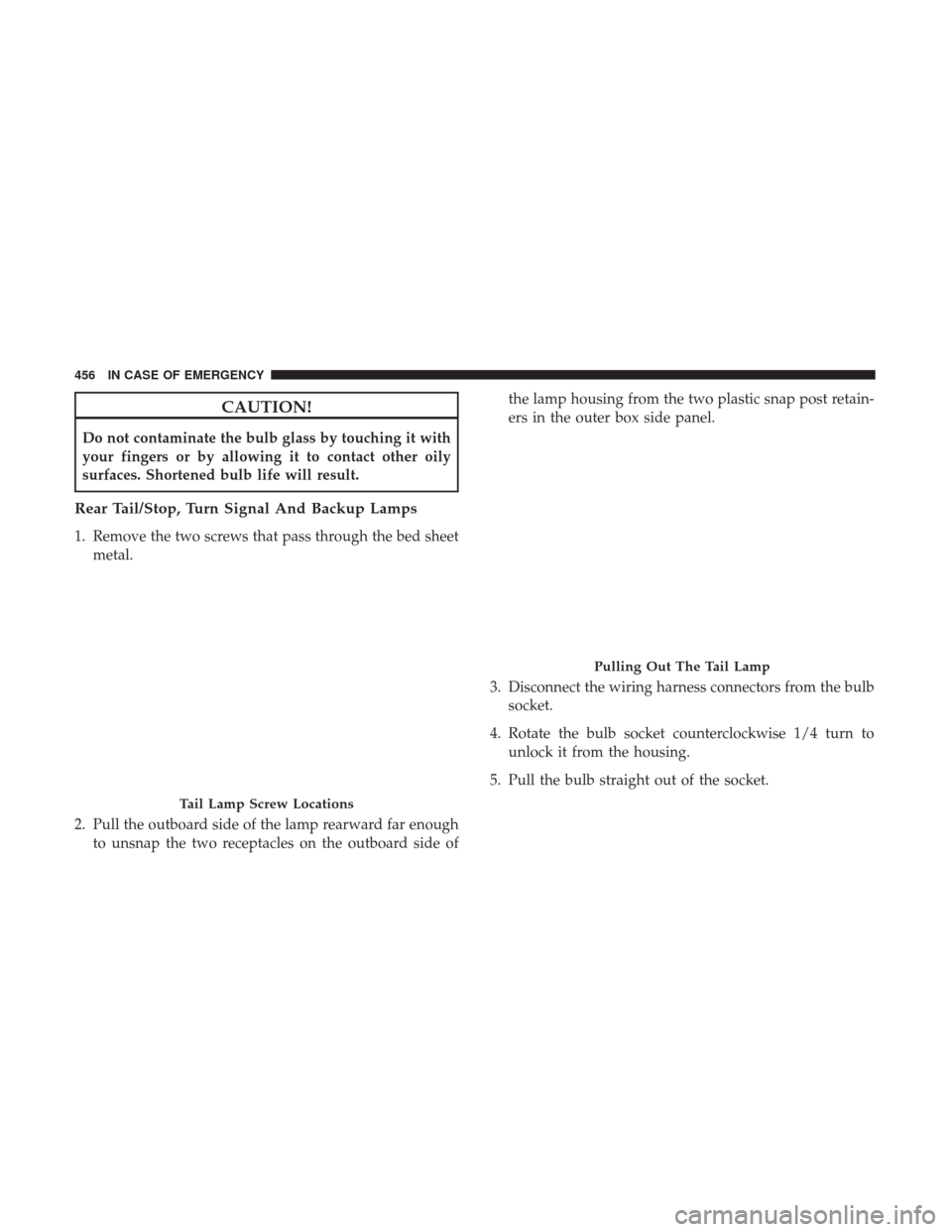

Rear Tail/Stop, Turn Signal And Backup Lamps

1. Remove the two screws that pass through the bed sheetmetal.

2. Pull the outboard side of the lamp rearward far enough to unsnap the two receptacles on the outboard side of the lamp housing from the two plastic snap post retain-

ers in the outer box side panel.

3. Disconnect the wiring harness connectors from the bulb socket.

4. Rotate the bulb socket counterclockwise 1/4 turn to unlock it from the housing.

5. Pull the bulb straight out of the socket.

Tail Lamp Screw Locations

Pulling Out The Tail Lamp

456 IN CASE OF EMERGENCY

Page 462 of 700

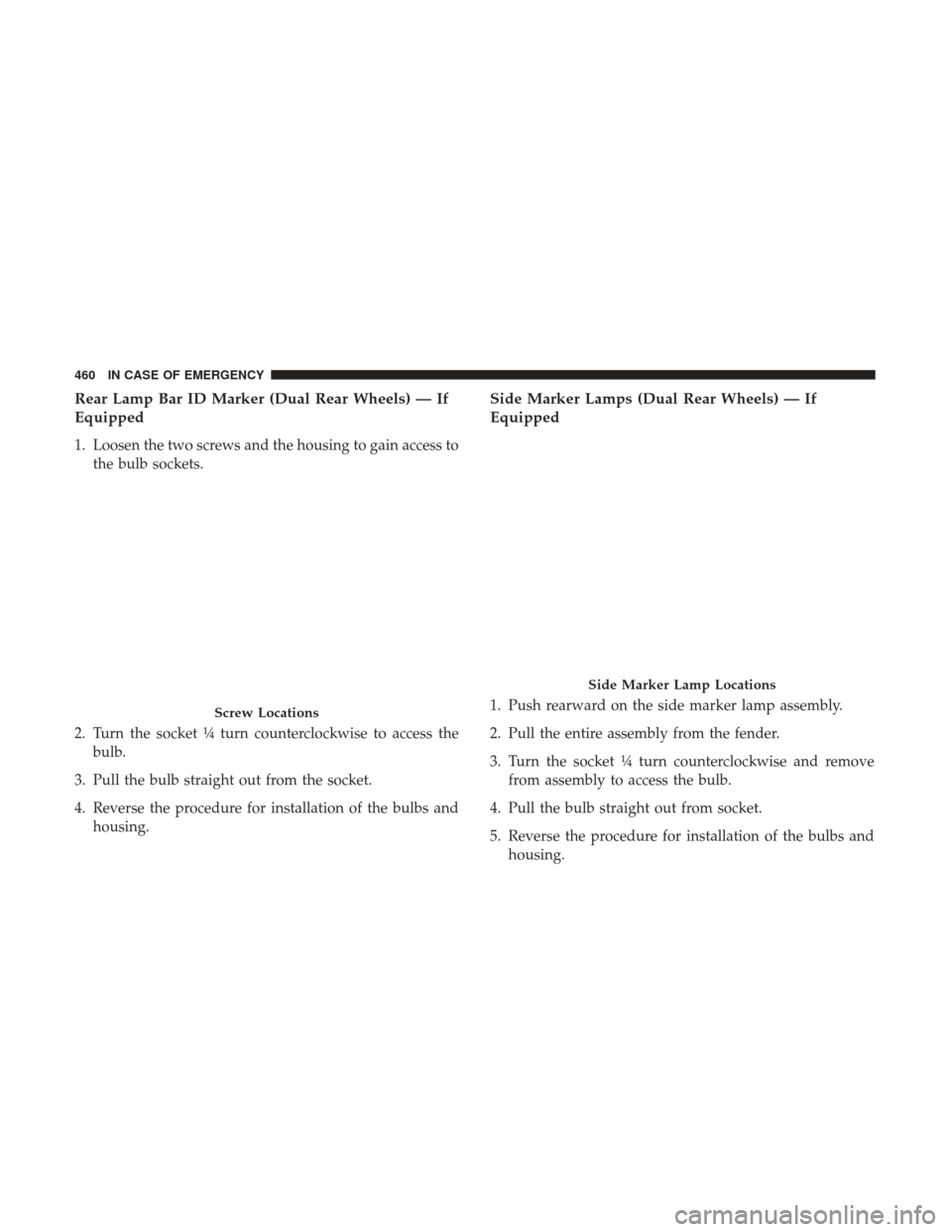

Rear Lamp Bar ID Marker (Dual Rear Wheels) — If

Equipped

1. Loosen the two screws and the housing to gain access tothe bulb sockets.

2. Turn the socket ¼ turn counterclockwise to access the bulb.

3. Pull the bulb straight out from the socket.

4. Reverse the procedure for installation of the bulbs and housing.

Side Marker Lamps (Dual Rear Wheels) — If

Equipped

1. Push rearward on the side marker lamp assembly.

2. Pull the entire assembly from the fender.

3. Turn the socket ¼ turn counterclockwise and removefrom assembly to access the bulb.

4. Pull the bulb straight out from socket.

5. Reverse the procedure for installation of the bulbs and housing.Screw Locations

Side Marker Lamp Locations

460 IN CASE OF EMERGENCY

Page 464 of 700

CavityCartridge Fuse Micro Fuse Description

F03 60 Amp Yellow –Rad Fan – If Equipped

F05 40 Amp Green –Compressor for Air Suspension – If

Equipped

F06 40 Amp Green –Antilock Brakes/Electronic Stability Control

Pump

F07 40 Amp Green –Starter Solenoid

F08 20 Amp Blue

(1500 LD/Cummins Diesel) –

Emissions Diesel – If Equipped

F09 40 Amp Green (Spe-

cial Services Vehicle& Cummins Diesel) –

Diesel Fuel Heater – If Equipped

F10 40 Amp Green –Body Controller / Exterior Lighting #2

F10 50 Amp Red –Body Controller / Exterior Lighting #2 – If

Equipped with Stop/Start

F11 30 Amp Pink –Integrated Trailer Brake Module – If

Equipped

F12 40 Amp Green –Body Controller #3 / Power Locks

F13 40 Amp Green –Blower Motor

F14 40 Amp Green –Body Controller #4 / Interior Lighting

F16 30 Amp Pink –Smart Bar – If Equipped

462 IN CASE OF EMERGENCY

Page 465 of 700

CavityCartridge Fuse Micro Fuse Description

F19 20 Amp Blue

(1500 LD Diesel)

30 Amp Pink (Cum- mins Diesel) –

SCR – If Equipped

F20 30 Amp Pink –Passenger Door Module

F21 30 Amp Pink –Drive Train Control Module

F22 20 Amp Blue

30 Amp Pink (Cum- mins Diesel) –

Engine Control Module

F23 30 Amp Pink –Body Controller #1 / Interior Lighting

F24 30 Amp Pink –Driver Door Module

F25 30 Amp Pink – Front Wiper

F26 30 Amp Pink –Antilock Brakes / Stability Control Module /

Valves

F28 20 Amp Blue –Trailer Tow Backup Lights – If Equipped

F29 20 Amp Blue –Trailer Tow Parking Lights – If Equipped

F30 30 Amp Pink –Trailer Tow Receptacle

F31 30 Amp Pink

(1500 LD Diesel) –

Urea Heater Control – If Equipped

F32 –– Spare Fuse

F33 20 Amp Blue –Special Services Vehicle Only

7

IN CASE OF EMERGENCY 463

Page 468 of 700

CavityCartridge Fuse Micro Fuse Description

F71 –25 Amp Clear Amplifier

F72 –10 Amp Red PCM – If Equipped

F73 –20 Amp Yellow Fuel Transfer Pump (HD Only) – If

Equipped

F74 –20 Amp Yellow

(Gas Engine & 1500 LD Diesel) Brake Vacuum Pump Gas/Diesel – If

Equipped

F75 –10 Amp Red Coolant Temperature Valve Actuator

F76 –10 Amp Red Antilock Brakes / Electronic Stability Control

F77 –10 Amp Red Drivetrain Control Module/Front Axle

Disconnect Module

F78 –10 Amp Red Engine Control Module / Electric Power

Steering

F79 –15 Amp Blue Clearance Lights

F80 –10 Amp Red Universal Garage Door Opener / Compass

F81 –20 Amp Yellow Trailer Tow Right Turn / Stop Lights

F82 –10 Amp Red Steering Column Control Module /

Cruise Control

F84 –15 Amp Blue Switch Bank / Instrument Cluster

F85 –10 Amp Red Airbag Module

F86 –10 Amp Red Airbag Module

466 IN CASE OF EMERGENCY

Page 471 of 700

If your vehicle is not equipped with a touchscreen, this

feature can be activated through the instrument cluster

display. Refer to “Instrument Cluster Display” in “Getting

To Know Your Instrument Panel” for further information.

Jack Location

The jack and jack tools are stored under the front passenger

seat.

Removal Of Jack And Tools (1500 Series)

To access the jack and jack tools, you must remove the

plastic access cover located on the side of the front passen-

ger ’s seat. To remove the cover, pull the front part of the

cover (closest to the front of the seat) toward you to release

a locking tab. Once the front of the cover is loose, slide the

cover toward the front of the seat until it is free from the

seat frame.

Jack Access Cover

7

IN CASE OF EMERGENCY 469