Ram 2500 2018 Owner's Manual

Manufacturer: RAM, Model Year: 2018, Model line: 2500, Model: Ram 2500 2018Pages: 700, PDF Size: 8.86 MB

Page 531 of 700

American Petroleum Institute (API) Engine Oil

Identification Symbol

This symbol means that the oil has

been certified by the American Pe-

troleum Institute (API). The manu-

facturer only recommends API Cer-

tified engine oils.

This symbol certifies 0W-20, 5W-20,

0W-30, 5W-30 and 10W-30 engine

oils.

CAUTION!

Do not use chemical flushes in your engine oil as the

chemicals can damage your engine. Such damage is not

covered by the New Vehicle Limited Warranty.

Engine Oil Viscosity — 3.6L Engines (1500 Models

Only)

Mopar SAE 5W-20 engine oil approved to FCA Material

Standard MS-6395 or equivalent Pennzoil or Shell Helix is

recommended for all operating temperatures. This engine

oil improves low temperature starting and vehicle fuel

economy.The engine oil filler cap also shows the recommended

engine oil viscosity for your vehicle. For information on

engine oil filler cap location, refer to “Engine Compart-

ment” in “Servicing And Maintenance” for further infor-

mation.

NOTE:

Mopar SAE 5W-30 engine oil approved to FCA

Material Standard MS-6395 may be used when SAE 5W-20

engine oil meeting MS-6395 is not available.

Engine Oil Viscosity (SAE Grade) — 5.7L Engine

(1500/2500/3500 Models)

Mopar SAE 5W-20 engine oil approved to FCA Material

Standard MS-6395 such as Pennzoil, Shell Helix or equiva-

lent is recommended for all operating temperatures. This

engine oil improves low temperature starting and vehicle

fuel economy.

The engine oil filler cap also shows the recommended

engine oil viscosity for your engine. For information on

engine oil filler cap location, refer to the “Engine Compart-

ment” illustration in this section.

Lubricants which do not have both the engine oil certifi-

cation mark and the correct SAE viscosity grade number

should not be used.

8

SERVICING AND MAINTENANCE 529

Page 532 of 700

Engine Oil Viscosity (SAE Grade) — 6.4L Engine

Use Mopar SAE 0W-40 engine oil approved to FCA Mate-

rial Standard MS-12633 such as Pennzoil Ultra equivalent

is recommended for all operating temperatures.

The engine oil filler cap also shows the recommended

engine oil viscosity for your engine. For information on

engine oil filler cap location, refer to the “Engine Compart-

ment” illustration in this section.

Lubricants which do not have both the engine oil certifi-

cation mark and the correct SAE viscosity grade number

should not be used.

Synthetic Engine Oils

You may use synthetic engine oils provided the recom-

mended oil quality requirements are met, and the recom-

mended maintenance intervals for oil and filter changes are

followed.

Synthetic engine oils which do not have both the engine oil

certification mark and the correct SAE viscosity grade

number should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against the addi-

tion of any additives (other than leak detection dyes) to the

engine oil. Engine oil is an engineered product and its

performance may be impaired by supplemental additives.

Disposing Of Used Engine Oil And Oil Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service station

or governmental agency for advice on how and where used

oil and oil filters can be safely discarded in your area.

Engine Oil Filter

The engine oil filter should be replaced with a new filter at

every engine oil change.

Engine Oil Filter Selection

This manufacturer’s engines have a full-flow type dispos-

able oil filter. Use a filter of this type for replacement. The

quality of replacement filters varies considerably. Only

high quality filters should be used to assure most efficient

service. Mopar engine oil filters are high quality oil filters

and are recommended.

530 SERVICING AND MAINTENANCE

Page 533 of 700

Engine Air Cleaner Filter

Refer to the “Maintenance Plan” in this section for the

proper maintenance intervals.

NOTE:Be sure to follow the “Severe Duty Conditions”

maintenance interval if applicable.

WARNING!

The air induction system (air cleaner, hoses, etc.) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

cleaner, hoses, etc.) unless such removal is necessary

for repair or maintenance. Make sure that no one is

near the engine compartment before starting the ve-

hicle with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in serious

personal injury.

Engine Air Cleaner Filter Selection

The quality of replacement engine air cleaner filters varies

considerably. Only high quality filters should be used to

assure most efficient service. Mopar engine air cleaner

filters are a high quality filter and are recommended.

Engine Air Cleaner Filter Inspection and

Replacement

Inspect engine air cleaner filter for dirt and or debris, if you

find evidence of either dirt or debris you should change

your air cleaner filter.

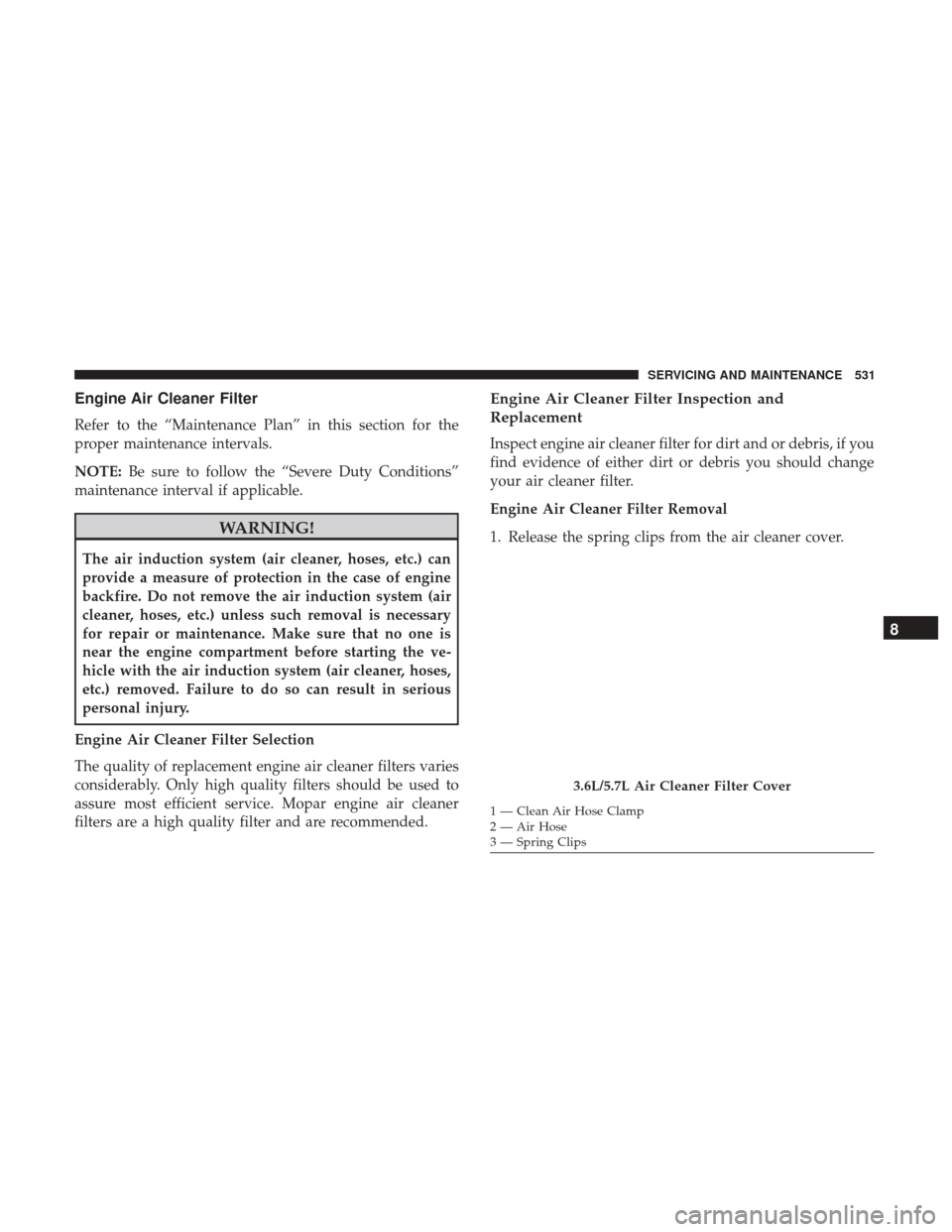

Engine Air Cleaner Filter Removal

1. Release the spring clips from the air cleaner cover.

3.6L/5.7L Air Cleaner Filter Cover

1 — Clean Air Hose Clamp

2 — Air Hose

3 — Spring Clips

8

SERVICING AND MAINTENANCE 531

Page 534 of 700

2. Lift the air cleaner cover to access the air cleaner filter. 3. Remove the air cleaner filter element from the housingassembly.

6.4L Air Cleaner Filter Cover

1 — Clean Air Hose Clamp

2 — Spring Clips

Open Air Cleaner Filter Assembly

1 — Air Cleaner Cover

2 — Air Cleaner Filter

532 SERVICING AND MAINTENANCE

Page 535 of 700

Engine Air Cleaner Filter Installation

NOTE:Inspect and clean the housing if dirt or debris is

present before replacing the air filter element.

1. Install the air cleaner filter element into the housing assembly with the air cleaner filter inspection surface

facing downward. 2. Install the air cleaner cover onto the housing assembly

locating tabs.

3. Latch the spring clips and lock the air cleaner cover to the housing assembly.

Air Conditioner Maintenance

For best possible performance, your air conditioner should

be checked and serviced by an authorized dealer at the

start of each warm season. This service should include

cleaning of the condenser fins and a performance test.

Drive belt tension should also be checked at this time.

WARNING!

•Use only refrigerants and compressor lubricants ap-

proved by the manufacturer for your air conditioning

system. Some unapproved refrigerants are flam-

mable and can explode, injuring you. Other unap-

proved refrigerants or lubricants can cause the sys-

tem to fail, requiring costly repairs. Refer to

Warranty Information Book, for further warranty

information.

• The air conditioning system contains refrigerant un-

der high pressure. To avoid risk of personal injury or

(Continued)

Air Cleaner Filter

1 — Air Cleaner Filter

2 — Air Cleaner Filter Inspection Surface

8

SERVICING AND MAINTENANCE 533

Page 536 of 700

WARNING!(Continued)

damage to the system, adding refrigerant or any

repair requiring lines to be disconnected should be

done by an experienced technician.

CAUTION!

Do not use chemical flushes in your air conditioning

system as the chemicals can damage your air condition-

ing components. Such damage is not covered by the

New Vehicle Limited Warranty.

Refrigerant Recovery And Recycling R-134a — If

Equipped

R-134a Air Conditioning Refrigerant is a hydrofluoro-

carbon (HFC) that is an ozone-friendly substance. The

manufacturer recommends that air conditioning service be

performed by an authorized dealer or other service facili-

ties using recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C system PAG

compressor oil and refrigerants.

Refrigerant Recovery And Recycling — R–1234yf

R–1234yf Air Conditioning Refrigerant is a hydrofluo-

roolefin (HFO) that is endorsed by the Environmental

Protection Agency and is an ozone-friendly substance with

a low global-warming potential. The manufacturer recom-

mends that air conditioning service be performed by an

authorized dealer using recovery and recycling equipment.

NOTE: Use only manufacturer approved A/C system

PAG compressor oil, and refrigerants.

Cabin Filter Replacement (A/C Air Filter)

Refer to the “Maintenance Plan” for the proper mainte-

nance intervals.

WARNING!

Do not remove the cabin air filter while the vehicle is

running, or while the ignition is in the ACC or ON/

RUN mode. With the cabin air filter removed and the

blower operating, the blower can contact hands and

may propel dirt and debris into your eyes, resulting in

personal injury.

534 SERVICING AND MAINTENANCE

Page 537 of 700

The cabin air filter is located in the fresh air inlet behind the

glove compartment. Perform the following procedure to

replace the filter:

1. Open the glove compartment and remove all contents.

2. With the glove compartment door open, remove theglove compartment tension tether and tether clip by

sliding the clip toward the face of the glove compart-

ment door. Lift the clip out of glove compartment door

and release into dash panel.

3. There are glove compartment travel stops on both sidesof the glove compartment door, push inward on both

sides of the glove compartment to release the glove

compartment travel stops.

Right Side Of Glove Compartment

1 — Glove Compartment Tension Tether

2 — Glove Compartment Door

8

SERVICING AND MAINTENANCE 535

Page 538 of 700

4. Disengage the glove compartment door from its hingesby opening the glove compartment past the travel stop

and pulling it toward you. 5. Remove the filter cover by pushing in on the finger tabs

on each end of the filter cover.

Glove Compartment

1 — Glove Compartment Travel Stops

2 — Glove Compartment Tension Tether

3 — Glove Compartment DoorFilter Cover

536 SERVICING AND MAINTENANCE

Page 539 of 700

6. Remove the cabin air filter by pulling it straight out ofthe housing.

Finger TabsFinger Tab8

SERVICING AND MAINTENANCE 537

Page 540 of 700

7. Install the cabin air filter with the arrow on the filterpointing toward the floor. When installing the filter

cover, press on each end until you hear an audible click.

CAUTION!

The cabin air filter is identified with an arrow to

indicate airflow direction through the filter. Failure to

properly install the filter will result in the need to

replace it more often. 8. Reinstall the glove compartment on the hinges.

9. Pull the tension tether outward and reinstall the glove

compartment past the travel stops by pushing in on the

glove compartment sides.

Cabin Air Filter

Glove Compartment Installation

538 SERVICING AND MAINTENANCE