air condition Ram 2500 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 2500, Model: Ram 2500 2018Pages: 372, PDF Size: 7.1 MB

Page 177 of 372

Normal Ride Height (NRH)– This is the stan-

dard position of the suspension and is meant

for normal driving. It will automatically adjust

to maintain the rear ride height as conditions

change.

Alternate Trailer Height (ATH) – Lowers the

vehicle approximately 1 in (25 mm) for a

level truck, to be used as required while

trailer towing. It will automatically adjust to

maintain the rear ride height as conditions

change.

Trailer Decoupling/Unloading - The air suspen-

sion system will load level (lower/exhaust

only) for up to 10 minutes after the vehicle is

turned off. This allows for easy removal of a trailer and/or load from the back of the truck

by maintaining the ride height. After 10 min-

utes you will need to turn the ignition to the

run position for the air suspension to main-

tain ride height. If the air suspension system

is disabled using the settings menu (Tire Jack

Mode, Transport Mode or Alignment Mode)

the system will remain disabled when the

vehicle is turned off. Reactivating the air

suspension can be accomplished via the set-

tings menu or driving the vehicle above

5 mph (8 km/h) for Tire Jack Mode or Align-

ment Mode and 16 mph (26 km/h) for Trans-

port Mode.

NOTE:

• Most 3500 models will not lower to Alter-

nate Trailer Height (ATH) when unloaded.

• Refer to “Trailer Towing” in “Starting And Operating” for further information.

Ignition OFF Behavior

For a predetermined amount of time after the

ignition is off the air suspension may adjust

to maintain a proper appearance.

Refer to your Owner’s Manual for further

information.

WARNING!

The air suspension system uses a high

pressure volume of air to operate the sys-

tem. To avoid personal injury or damage to

the system, see your authorized dealer for

service.

Air Suspension Modes

The air suspension system has multiple

modes to protect the system in unique situa-

tions:

Tire/Jack Mode

To assist with changing a tire, the air suspen-

sion system has a feature which allows the

automatic leveling to be disabled. This mode

is intended to be enabled with engine run-

ning. Refer to “Instrument Cluster Display”

in “Getting To Know Your Instrument Panel”

or “Uconnect Settings” in “Multimedia” if

equipped with a touch screen radio, in your

Owner’s Manual for further information.

NOTE:

This mode is intended to be enabled with

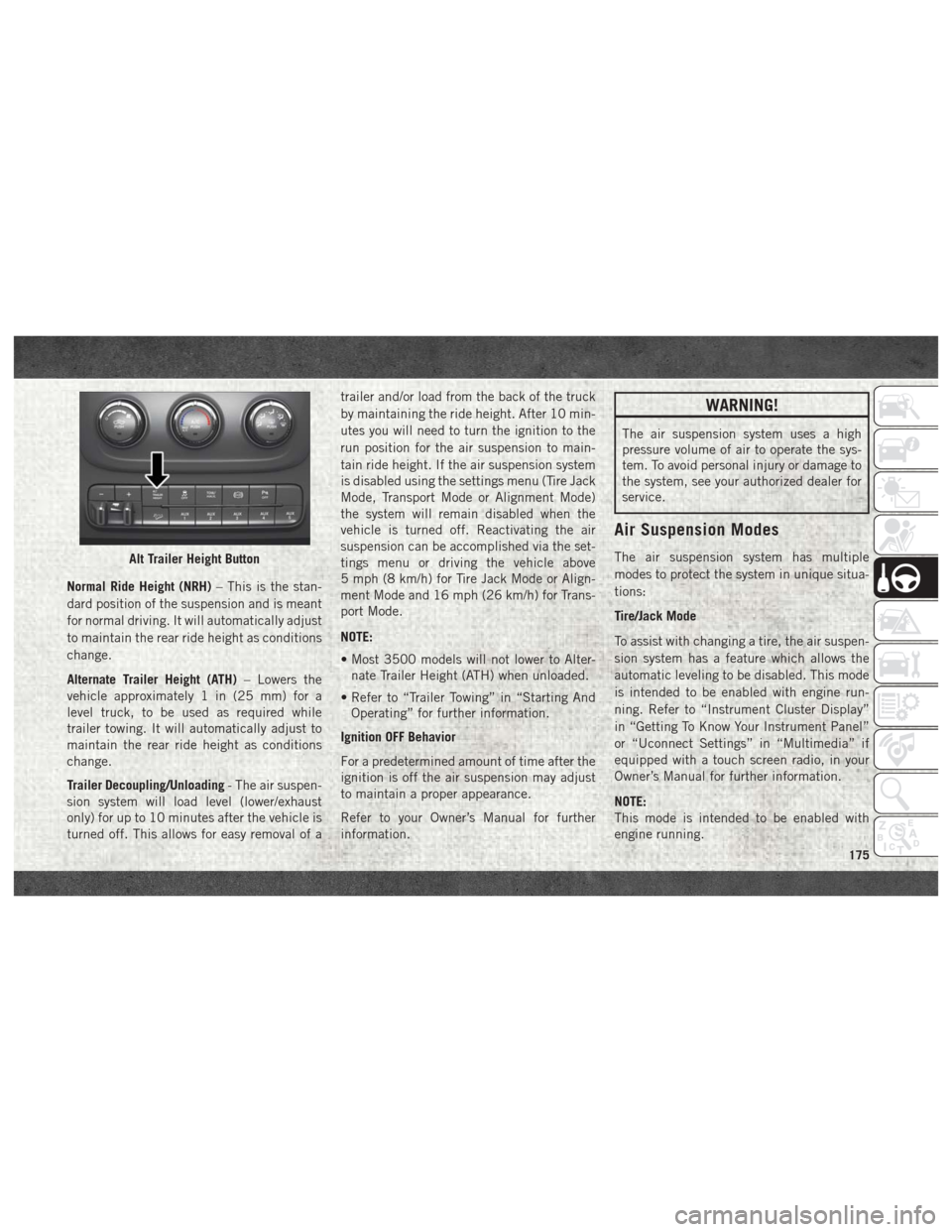

engine running.Alt Trailer Height Button

175

Page 198 of 372

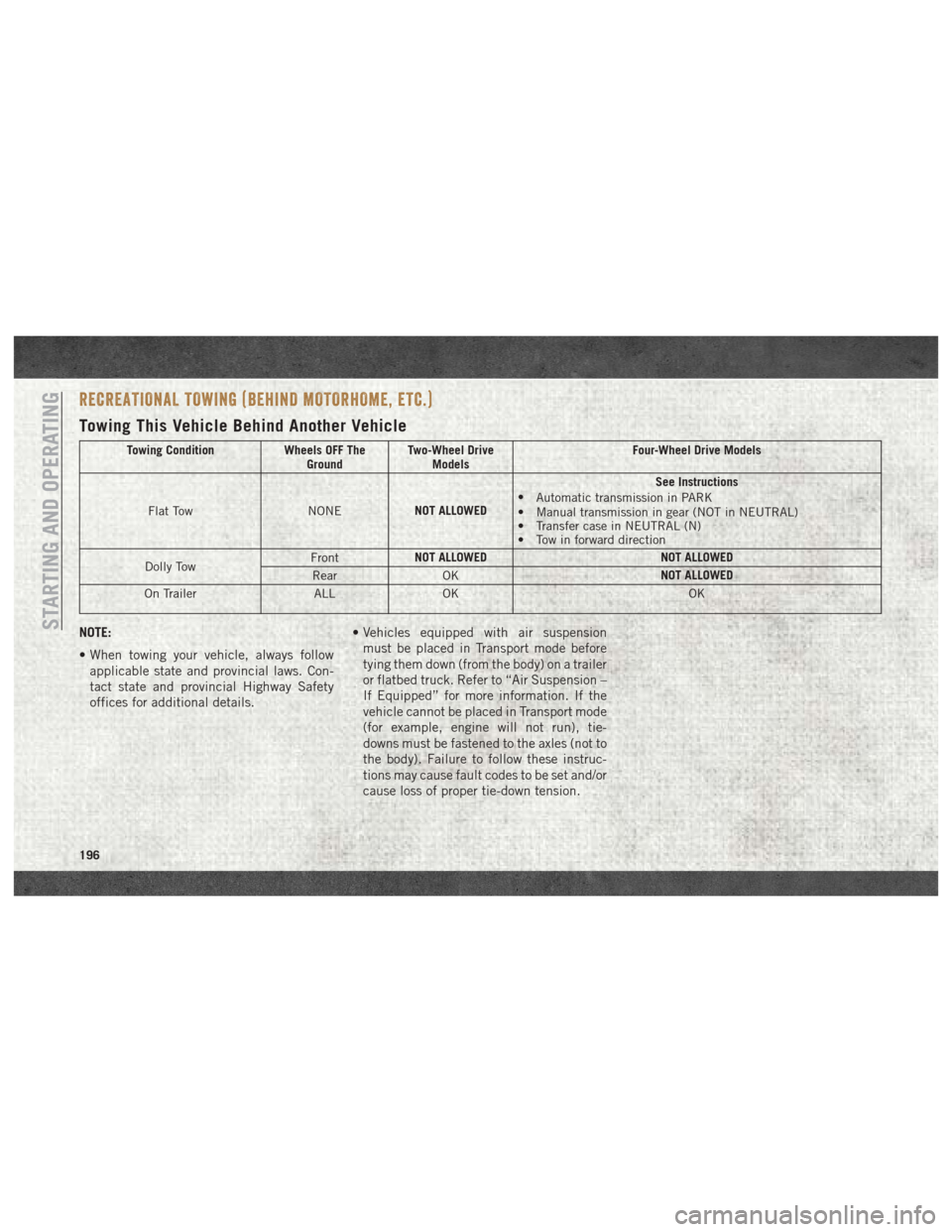

RECREATIONAL TOWING (BEHIND MOTORHOME, ETC.)

Towing This Vehicle Behind Another Vehicle

Towing ConditionWheels OFF The

Ground Two-Wheel Drive

Models Four-Wheel Drive Models

Flat Tow NONENOT ALLOWED See Instructions

• Automatic transmission in PARK

• Manual transmission in gear (NOT in NEUTRAL)

• Transfer case in NEUTRAL (N)

• Tow in forward direction

Dolly Tow Front

NOT ALLOWED

NOT ALLOWED

Rear OK NOT ALLOWED

On Trailer ALLOK OK

NOTE:

• When towing your vehicle, always follow

applicable state and provincial laws. Con-

tact state and provincial Highway Safety

offices for additional details. • Vehicles equipped with air suspension

must be placed in Transport mode before

tying them down (from the body) on a trailer

or flatbed truck. Refer to “Air Suspension –

If Equipped” for more information. If the

vehicle cannot be placed in Transport mode

(for example, engine will not run), tie-

downs must be fastened to the axles (not to

the body). Failure to follow these instruc-

tions may cause fault codes to be set and/or

cause loss of proper tie-down tension.STARTING AND OPERATING

196

Page 208 of 372

CavityCartridge Fuse Micro Fuse Description

F52 –5 Amp Tan Battery Sensor

F53 –20 Amp Yellow Trailer Tow – Left Turn/Stop Lights

F54 –20 Amp Yellow Adjustable Pedals

F56 –15 Amp Blue Additional Diesel Content – If Equipped

F57 –20 Amp Yellow Transmission

F58 –20 Amp Yellow Spare Fuse

F59 –10 Amp Red SCR Relay – If Equipped

F60 –15 Amp Blue Underhood Lamp

F61 –10 Amp Red (1500 LD Die-

sel & Cummins Diesel) PM Sensor – If Equipped

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils (Gas), Urea Heater (Cummins Diesel)

F64 –25 Amp Clear Fuel Injectors / Powertrain

F65 –– Spare Fuse

F66 –10 Amp Red Sunroof / Passenger Window Switches / Rain Sensor

F67 –10 Amp Red CD / DVD / Bluetooth Hands-free Module – If Equipped

F69 –15 Amp Blue Mod SCR 12V (Cummins Diesel) – If Equipped

F70 –30 Amp Green Fuel Pump Motor

F71 –25 Amp Clear Amplifier

F72 –10 Amp Red PCM – If Equipped

F73 –20 Amp Yellow Fuel Transfer Pump (HD Only) – If Equipped

F74 –20 Amp Yellow (Gas Engine

& 1500 LD Diesel) Brake Vacuum Pump Gas/Diesel – If Equipped

IN CASE OF EMERGENCY

206

Page 222 of 372

WARNING!

personal injury. Only use the specific

ground point, do not use any other exposed

metal parts.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a

few minutes, and then start the engine in

the vehicle with the discharged battery.

CAUTION!

Do not connect jumper cable to any of the

fuses on the positive battery terminal. The

resulting electrical current will blow the

fuse.

6. Once the engine is started, remove the jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative (-)end of the

jumper cable from the engine ground of

the vehicle with the discharged battery. 2. Disconnect the opposite end of the nega-

tive (-)jumper cable from the negative (-)

post of the booster battery.

3. Disconnect the positive (+)end of the

jumper cable from the positive (+)post of

the booster battery.

4. Disconnect the opposite end of the posi- tive (+)jumper cable from the positive (+)

post of the vehicle with the discharged

battery.

If frequent jump starting is required to start

your vehicle you should have the battery and

charging system inspected at an authorized

dealer.

CAUTION!

Accessories plugged into the vehicle

power outlets draw power from the vehi-

cle’s battery, even when not in use (i.e.,

cellular devices, etc.). Eventually, if

plugged in long enough without engine

operation, the vehicle’s battery will dis-

charge sufficiently to degrade battery life

and/or prevent the engine from starting.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can

reduce the potential for overheating by taking

the appropriate action.

• On the highways — slow down.

• In city traffic — while stopped, place the transmission in NEUTRAL, but do not in-

crease the engine idle speed while prevent-

ing vehicle motion with the brakes.

NOTE:

There are steps that you can take to slow

down an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off. The A/C system adds heat to the engine

cooling system and turning the A/C off can

help remove this heat.

• You can also turn the temperature control to maximum heat, the mode control to floor

and the blower control to high. This allows

the heater core to act as a supplement to

the radiator and aids in removing heat from

the engine cooling system.

IN CASE OF EMERGENCY

220

Page 223 of 372

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never try to open a cooling system

pressure cap when the radiator or coolant

bottle is hot.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop

the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer

drops back into the normal range. If the

pointer remains on HOT (H), and you hear

continuous chimes, turn the engine off

immediately and call for service.

GEAR SELECTOR OVERRIDE —

6-SPEED TRANSMISSION

If a malfunction occurs and the gear selector

cannot be moved out of the PARK position,

you can use one of the following procedures

to temporarily move the gear selector.

Column Gear Selector — If

Equipped

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Tilt the steering wheel to the full upposition.

4. Press and maintain firm pressure on the brake pedal.

5. Insert a screwdriver or similar tool into the access port (ringed circle) on the bottom

of the steering column, and push and hold

the override release lever up. 6. Move the gear selector to the NEUTRAL

position.

7. The vehicle may then be started in NEUTRAL.

Shift Lock Manual Override Access Port

221

Page 227 of 372

TOWING A DISABLED VEHICLE

This section describes procedures for towing

a disabled vehicle using a commercial towing

service. If the transmission and drivetrain are

operable, disabled vehicles may also be

towed as described under “Recreational Tow-

ing” in the “Starting And Operating” section.NOTE:

Vehicles equipped with air suspension must

be placed in Transport mode, before tying

them down (from the body) on a trailer or

flatbed truck. Refer to "Air Suspension" in

"Starting And Operating" for more informa-

tion. If the vehicle cannot be placed in Trans-

port mode (for example, engine will not run),

tie-downs must be fastened to the axles (not

to the body). Failure to follow these instruc-

tions may cause fault codes to be set and/or

cause loss of proper tie-down tension.

Towing Condition Wheels OFF The Ground

2WD Models4WD Models

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max

• 15 miles (24 km) maxdistance •

Auto Transmission in PARK

• Manual Transmission in gear

(NOT NEUTRAL)

• Transfer Case in NEUTRAL

• Tow in FORWARDdirection

Wheel Lift Or Dolly Tow Front

NOT ALLOWED

Rear OK

NOT ALLOWED

Flatbed ALL

BEST METHOD BEST METHOD

CAUTION!

• Do not use sling type equipment when

towing. Vehicle damage may occur.

CAUTION!

•When securing the vehicle to a flat bed

truck, do not attach to front or rear sus-

CAUTION!

pension components. Damage to your ve-

hicle may result from improper towing.

225

Page 233 of 372

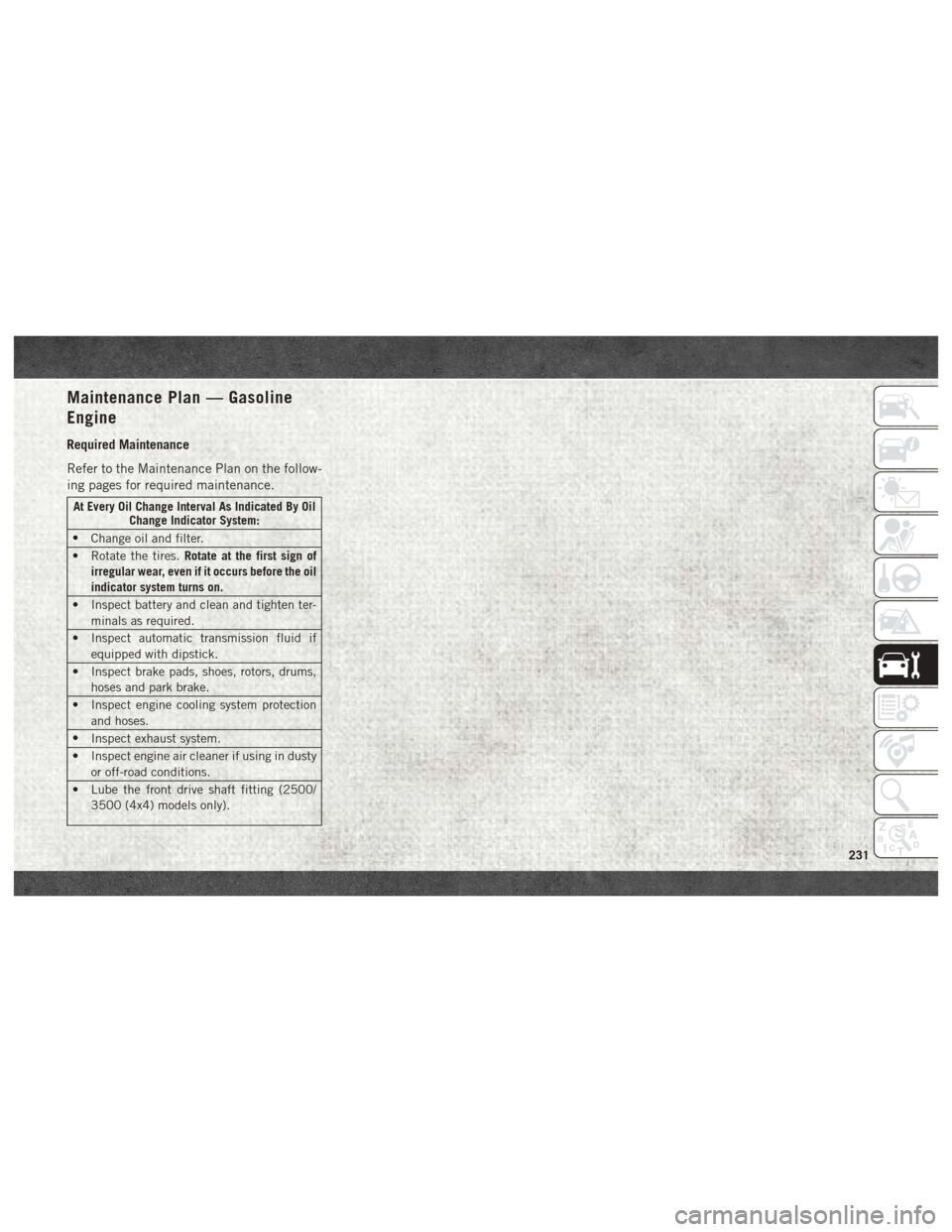

Maintenance Plan — Gasoline

Engine

Required Maintenance

Refer to the Maintenance Plan on the follow-

ing pages for required maintenance.

At Every Oil Change Interval As Indicated By OilChange Indicator System:

• Change oil and filter.

• Rotate the tires. Rotate at the first sign of

irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect battery and clean and tighten ter- minals as required.

• Inspect automatic transmission fluid if equipped with dipstick.

• Inspect brake pads, shoes, rotors, drums, hoses and park brake.

• Inspect engine cooling system protection and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or off-road conditions.

• Lube the front drive shaft fitting (2500/ 3500 (4x4) models only).

231

Page 237 of 372

Maintenance Plan — Diesel Fuel

Up To B5 Biodiesel (1500 Diesel)

Required Maintenance

Refer to the Maintenance Schedules on the

following pages for required maintenance.

At Every Oil Change Interval As Indicated By OilChange Indicator System:

• Change oil and filter.

•

Completely fill the Diesel Exhaust Fluid tank.

• Drain water from fuel filter assembly.

• Rotate the tires. Rotate at the first sign of

irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect battery and clean and tighten ter- minals as required.

• Inspect brake pads, shoes, rotors, drums, hoses and park brake.

• Inspect engine cooling system protection and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or off-road conditions.

At Every Second Oil Change Interval As Indi-cated By Oil Change Indicator System:

• Change fuel filter.

235

Page 253 of 372

5. Remove bottom cover using a strapwrench. Rotate counterclockwise for re-

moval. Remove the used o-ring and dis-

card it.

6. Remove the used filter cartridge from the housing and dispose of it according to

your local regulations.

7. Wipe the sealing surfaces of the lid and housing clean.

8. Install a new o-ring into the ring groove on the filter housing and lubricate with clean

engine oil.

NOTE:

WIF (Water In Fuel) sensor is re-usable. Ser-

vice kit comes with new o-ring for filter can-

ister and WIF sensor.

Priming If The Engine Has Run Out

Of Fuel

WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure

WARNING!

fuel spray can cause serious injury or

death.

1. Add a substantial amount of fuel to the tank, approximately 2 to 5 gal (8L to

19L).

2. Press ignition switch twice without your foot on brake to put vehicle in Run posi-

tion. This will activate the in tank fuel

pump for approximately 30 seconds. Re-

peat this process twice.

3. Start the engine using the “Normal Start- ing” procedure. Refer to “Starting The

Engine” in “Starting and Operating” for

further information.

CAUTION!

The starter motor will engage for approxi-

mately 30 seconds at a time. Allow two

minutes between cranking intervals.

NOTE:

The engine may run rough until the air is

forced from all the fuel lines.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable un-

der certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system.

NOTE:

• Use of biodiesel mixture in excess of 20% can negatively impact the fuel filter's abil-

ity to separate water from the fuel, resulting

in high pressure fuel system corrosion or

damage.

• In addition, commercially available fuel ad- ditives are not necessary for the proper

operation of your diesel engine.

• For extreme cold conditions, "Mopar Pre- mium Diesel Fuel Treatment" is recom-

mended to assist with cold starting.

251

Page 254 of 372

DEALER SERVICE — 6.7L DIESEL

ENGINE

Your authorized dealer has the qualified ser-

vice personnel, special tools, and equipment

to perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals be-

fore attempting any procedure yourself.

NOTE:

Intentional tampering with emissions control

systems may void your warranty and could

result in civil penalties being assessed

against you.

WARNING!

You can be badly injured working on or

around a motor vehicle. Only do service

work for which you have the knowledge

and the proper equipment. If you have any

doubt about your ability to perform a ser-

vice job, take your vehicle to a competent

mechanic.

Engine Air Cleaner Filter

CAUTION!

All air entering the engine intake must be

filtered. The abrasive particles in unfil-

tered air will cause rapid wear to engine

components.

WARNING!

The air induction system (air cleaner,

hoses, etc.) provides a measure of protec-

tion. Do not remove the air induction sys-

tem (air cleaner, hoses, etc.) unless such

removal is necessary for repair or mainte-

nance. Make sure that no one is near the

engine compartment before starting the

vehicle with the air induction system (air

cleaner, hoses, etc.) removed. Failure to

do so can result in serious personal injury.

The condition of the air cleaner filter is moni-

tored by the Engine Control Module. The

“SERVICE AIR FILTER” message will display

in the instrument cluster when service is required. Refer to “Instrument Cluster Dis-

play” in “Getting To Know Your Instrument

Panel” for further information.

The “SERVICE AIR FILTER” message could

be displayed periodically. This is because

engine air flow requirements change based

on driving conditions. As the filter becomes

more restrictive and air flow requirements

increase the “SERVICE AIR FILTER” mes-

sage will be displayed. The message may not

be displayed in subsequent drive cycles if the

same conditions are not met. The air filter

element should be replaced within 250 miles

(402 km) from the first time this message is

displayed to ensure proper engine operation

during all driving conditions.

CAUTION!

Driving with a restricted air filter can

cause engine damage. Driving in dusty

environments for extended periods will

lead to rapid air filter plugging. Action

should be taken as soon as the “SERVICE

AIR FILTER” message is displayed.

SERVICING AND MAINTENANCE

252