oil filter Ram 2500 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 2500, Model: Ram 2500 2018Pages: 372, PDF Size: 7.1 MB

Page 249 of 372

6.7L Diesel Engine — Six-Speed 68RFE (2500/3500 Models)

1 — Battery7 — Aux Power Distribution Center

2 — Engine Coolant Reservoir 8 — Power Distribution Center

3 — Automatic Transmission Dipstick 9 — Washer Fluid Reservoir

4 — Engine Oil Fill 10 — Power Steering Fluid Reservoir

5 — Engine Oil Dipstick 11 — Air Cleaner Filter

6 — Brake Fluid Reservoir

247

Page 250 of 372

6.7L Diesel Engine — Six-Speed AS69RC HD (3500/Chassis Cab Models)

1 — Battery

2 — Engine Coolant Reservoir

3 — Engine Oil Fill

4 — Engine Oil Dipstick

5 — Automatic Transmission Dipstick

6 — Brake Fluid Reservoir7 — Aux Power Distribution Center

8 — Power Distribution Center

9 — Washer Fluid Reservoir

10 — Power Steering Fluid Reservoir

11 — Air Cleaner Filter

SERVICING AND MAINTENANCE

248

Page 253 of 372

5. Remove bottom cover using a strapwrench. Rotate counterclockwise for re-

moval. Remove the used o-ring and dis-

card it.

6. Remove the used filter cartridge from the housing and dispose of it according to

your local regulations.

7. Wipe the sealing surfaces of the lid and housing clean.

8. Install a new o-ring into the ring groove on the filter housing and lubricate with clean

engine oil.

NOTE:

WIF (Water In Fuel) sensor is re-usable. Ser-

vice kit comes with new o-ring for filter can-

ister and WIF sensor.

Priming If The Engine Has Run Out

Of Fuel

WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure

WARNING!

fuel spray can cause serious injury or

death.

1. Add a substantial amount of fuel to the tank, approximately 2 to 5 gal (8L to

19L).

2. Press ignition switch twice without your foot on brake to put vehicle in Run posi-

tion. This will activate the in tank fuel

pump for approximately 30 seconds. Re-

peat this process twice.

3. Start the engine using the “Normal Start- ing” procedure. Refer to “Starting The

Engine” in “Starting and Operating” for

further information.

CAUTION!

The starter motor will engage for approxi-

mately 30 seconds at a time. Allow two

minutes between cranking intervals.

NOTE:

The engine may run rough until the air is

forced from all the fuel lines.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable un-

der certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system.

NOTE:

• Use of biodiesel mixture in excess of 20% can negatively impact the fuel filter's abil-

ity to separate water from the fuel, resulting

in high pressure fuel system corrosion or

damage.

• In addition, commercially available fuel ad- ditives are not necessary for the proper

operation of your diesel engine.

• For extreme cold conditions, "Mopar Pre- mium Diesel Fuel Treatment" is recom-

mended to assist with cold starting.

251

Page 257 of 372

6. Remove the used filter cartridge from thehousing and dispose of according to your

local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

9. Remove new filter cartridge from plastic bag and install into housing.

NOTE:

Do not remove cartridge from bag until

you reach this step in order to keep car-

tridge clean.

10. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter

housing with fuel.

11. Install lid onto housing and tighten to 22.5 ft lbs (30.5 N.m). Do not over-

tighten the lid.

12. Prime the engine using the procedure in “Priming If The Engine Has Run Out Of

Fuel.” Then start the engine and confirm

there are no leaks.Underbody Mounted Fuel Filter

Replacement

NOTE:

• Using a fuel filter that does not meet themanufacturer's filtration and water separat-

ing requirements can severely impact fuel

system life and reliability.

• The underbody mounted filter housing will cause the engine not to run if:

1. No filter is installed.

CAUTION!

• Diesel fuel will damage blacktop paving surfaces. Drain the filter into an appro-

priate container.

• Do not prefill the fuel filter when install-

ing a new fuel filter. There is a possibility

debris could be introduced into the fuel

filter during this action. It is best to

install the filter dry and allow the in-tank

lift pump to prime the fuel system.

1. Ensure engine is turned off. 2. Place drain pan under the fuel filter drain

hose.

3. Open the water drain valve 1 full turn counterclockwise and completely drain

fuel and water into the approved

container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for re-

moval. Remove used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your

local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

NOTE:

WIF sensor is re-usable. Service kit comes

with new o-ring for filter canister and WIF

sensor.

255

Page 280 of 372

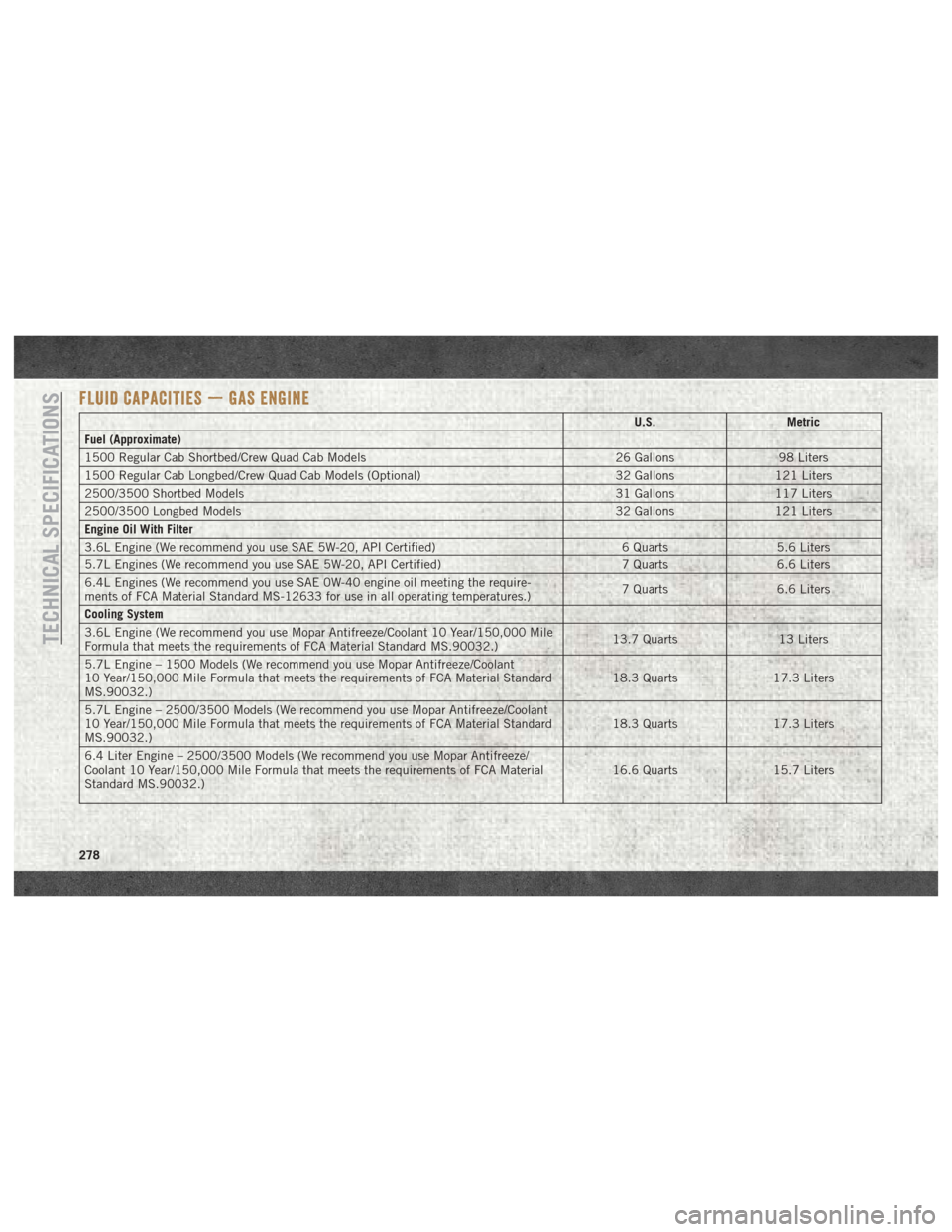

FLUID CAPACITIES — GAS ENGINE

U.S.Metric

Fuel (Approximate)

1500 Regular Cab Shortbed/Crew Quad Cab Models 26 Gallons98 Liters

1500 Regular Cab Longbed/Crew Quad Cab Models (Optional) 32 Gallons121 Liters

2500/3500 Shortbed Models 31 Gallons117 Liters

2500/3500 Longbed Models 32 Gallons121 Liters

Engine Oil With Filter

3.6L Engine (We recommend you use SAE 5W-20, API Certified) 6 Quarts5.6 Liters

5.7L Engines (We recommend you use SAE 5W-20, API Certified) 7 Quarts6.6 Liters

6.4L Engines (We recommend you use SAE 0W-40 engine oil meeting the require-

ments of FCA Material Standard MS-12633 for use in all operating temperatures.) 7 Quarts

6.6 Liters

Cooling System

3.6L Engine (We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile

Formula that meets the requirements of FCA Material Standard MS.90032.) 13.7 Quarts

13 Liters

5.7L Engine – 1500 Models (We recommend you use Mopar Antifreeze/Coolant

10 Year/150,000 Mile Formula that meets the requirements of FCA Material Standard

MS.90032.) 18.3 Quarts

17.3 Liters

5.7L Engine – 2500/3500 Models (We recommend you use Mopar Antifreeze/Coolant

10 Year/150,000 Mile Formula that meets the requirements of FCA Material Standard

MS.90032.) 18.3 Quarts

17.3 Liters

6.4 Liter Engine – 2500/3500 Models (We recommend you use Mopar Antifreeze/

Coolant 10 Year/150,000 Mile Formula that meets the requirements of FCA Material

Standard MS.90032.) 16.6 Quarts

15.7 Liters

TECHNICAL SPECIFICATIONS

278

Page 281 of 372

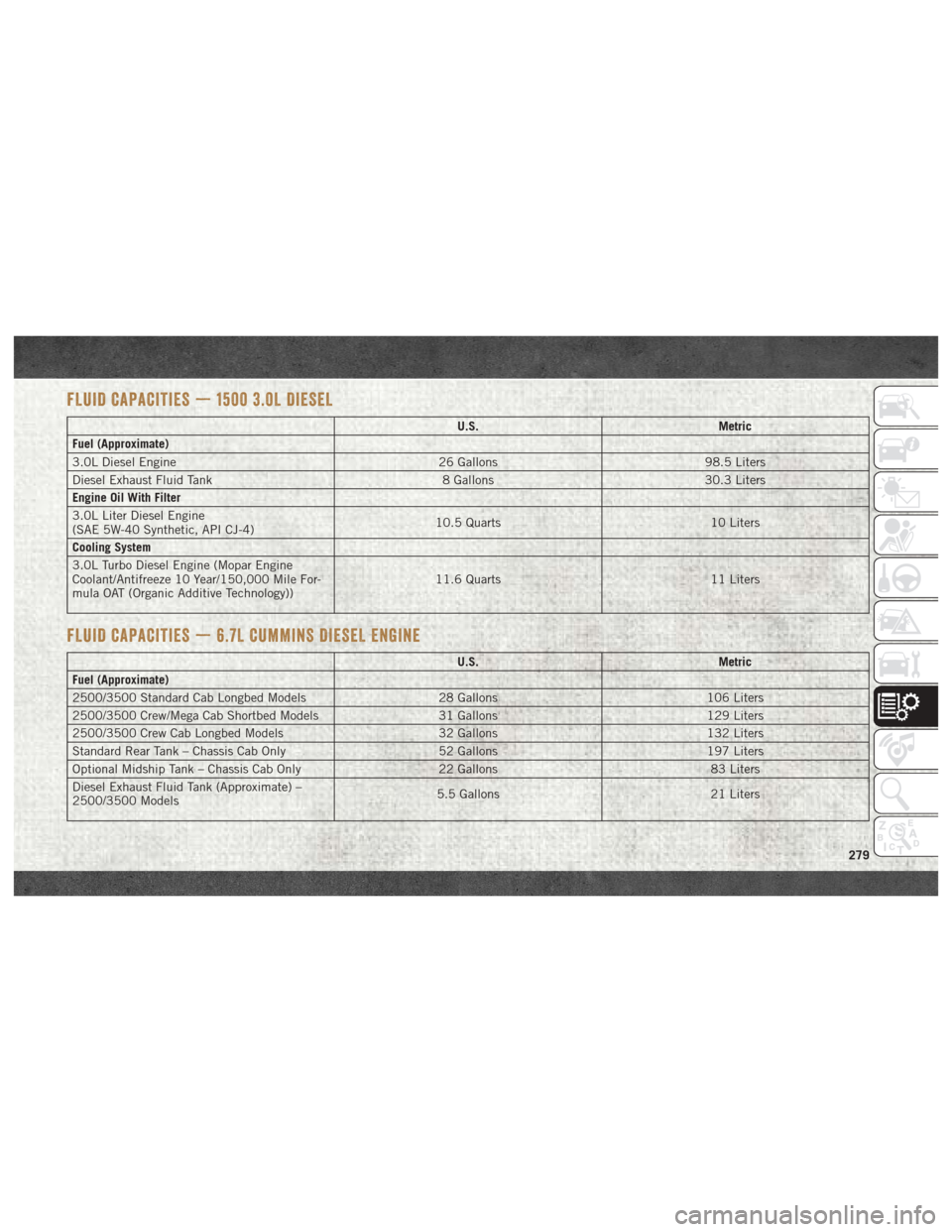

FLUID CAPACITIES — 1500 3.0L DIESEL

U.S.Metric

Fuel (Approximate)

3.0L Diesel Engine 26 Gallons98.5 Liters

Diesel Exhaust Fluid Tank 8 Gallons30.3 Liters

Engine Oil With Filter

3.0L Liter Diesel Engine

(SAE 5W-40 Synthetic, API CJ-4) 10.5 Quarts

10 Liters

Cooling System

3.0L Turbo Diesel Engine (Mopar Engine

Coolant/Antifreeze 10 Year/150,000 Mile For-

mula OAT (Organic Additive Technology)) 11.6 Quarts

11 Liters

FLUID CAPACITIES — 6.7L CUMMINS DIESEL ENGINE

U.S.Metric

Fuel (Approximate)

2500/3500 Standard Cab Longbed Models 28 Gallons106 Liters

2500/3500 Crew/Mega Cab Shortbed Models 31 Gallons129 Liters

2500/3500 Crew Cab Longbed Models 32 Gallons132 Liters

Standard Rear Tank – Chassis Cab Only 52 Gallons197 Liters

Optional Midship Tank – Chassis Cab Only 22 Gallons83 Liters

Diesel Exhaust Fluid Tank (Approximate) –

2500/3500 Models 5.5 Gallons

21 Liters

279

Page 282 of 372

U.S.Metric

Diesel Exhaust Fluid Tank (Approximate) –

Chassis Cab 9 Gallons

34 Liters

Engine Oil With Filter

6.7L Turbo Diesel Engine 12 Quarts11.4 Liters

Cooling System

6.7L Turbo Diesel Engine (Mopar Engine

Coolant/Antifreeze 10 Year/150,000 Mile For-

mula) 5.7 Gallons

21.4 Liters

FLUIDS AND LUBRICANTS — GAS ENGINE

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile

Formula OAT (Organic Additive Technology).

Engine Oil – 3.6L Engine We recommend you use API Certified SAE 5W-20 Engine Oil, meeting the

requirements of FCA Material Standard MS-6395 such as Mopar, Penn-

zoil, and Shell Helix. Refer to your engine oil filler cap for correct SAE

grade.

Mopar SAE 5W-30 engine oil approved to FCA Material Standard MS-

6395 may be used when SAE 5W-20 engine oil meeting MS-6395 is not

available.

Engine Oil – 5.7L Engine We recommend you use API Certified SAE 5W-20 Engine Oil, meeting the

requirements of FCA Material Standard MS-6395 such as Mopar, Penn-

zoil, and Shell Helix. Refer to your engine oil filler cap for correct SAE

grade.

TECHNICAL SPECIFICATIONS

280

Page 283 of 372

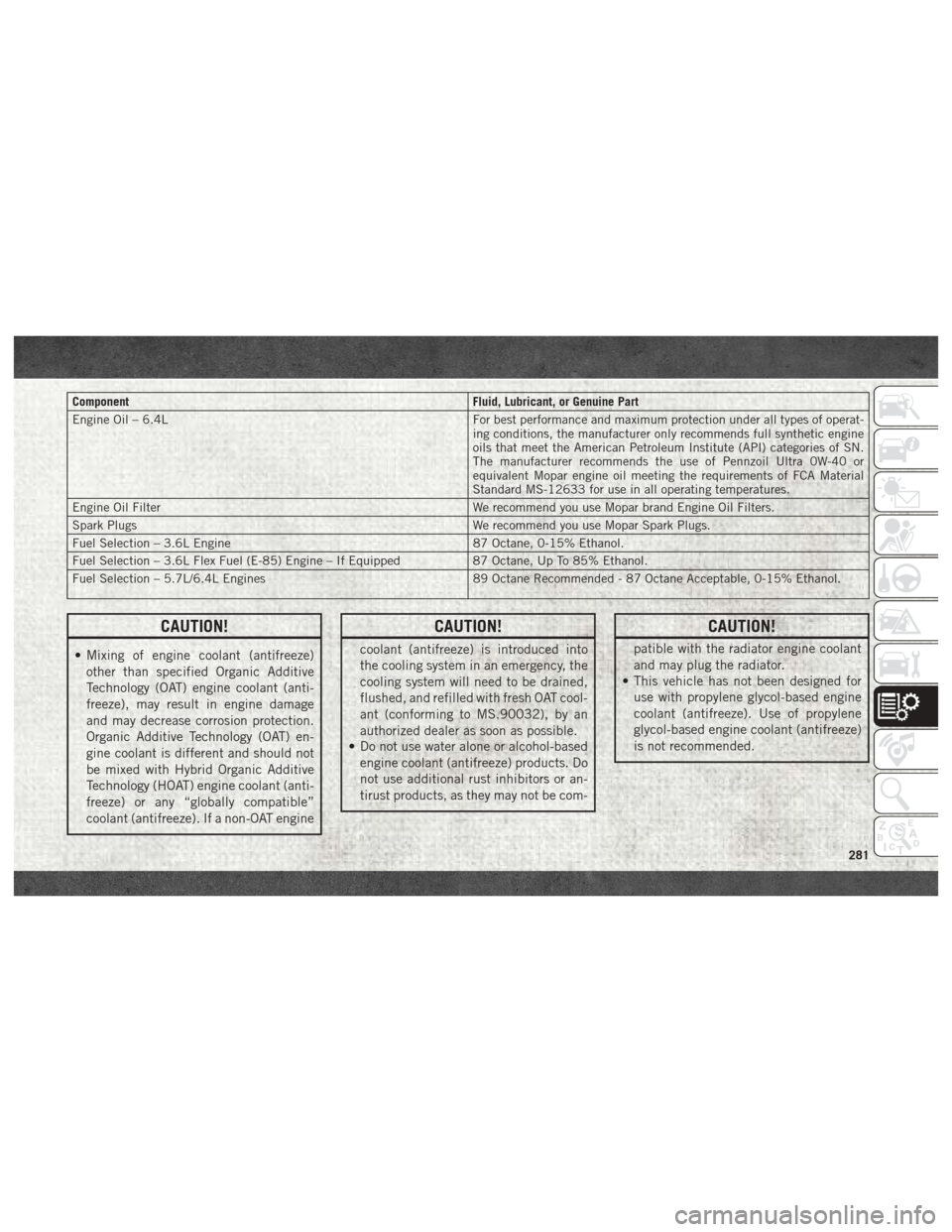

ComponentFluid, Lubricant, or Genuine Part

Engine Oil – 6.4L For best performance and maximum protection under all types of operat-

ing conditions, the manufacturer only recommends full synthetic engine

oils that meet the American Petroleum Institute (API) categories of SN.

The manufacturer recommends the use of Pennzoil Ultra 0W-40 or

equivalent Mopar engine oil meeting the requirements of FCA Material

Standard MS-12633 for use in all operating temperatures.

Engine Oil Filter We recommend you use Mopar brand Engine Oil Filters.

Spark Plugs We recommend you use Mopar Spark Plugs.

Fuel Selection – 3.6L Engine 87 Octane, 0-15% Ethanol.

Fuel Selection – 3.6L Flex Fuel (E-85) Engine – If Equipped 87 Octane, Up To 85% Ethanol.

Fuel Selection – 5.7L/6.4L Engines 89 Octane Recommended - 87 Octane Acceptable, 0-15% Ethanol.

CAUTION!

• Mixing of engine coolant (antifreeze)

other than specified Organic Additive

Technology (OAT) engine coolant (anti-

freeze), may result in engine damage

and may decrease corrosion protection.

Organic Additive Technology (OAT) en-

gine coolant is different and should not

be mixed with Hybrid Organic Additive

Technology (HOAT) engine coolant (anti-

freeze) or any “globally compatible”

coolant (antifreeze). If a non-OAT engine

CAUTION!

coolant (antifreeze) is introduced into

the cooling system in an emergency, the

cooling system will need to be drained,

flushed, and refilled with fresh OAT cool-

ant (conforming to MS.90032), by an

authorized dealer as soon as possible.

• Do not use water alone or alcohol-based

engine coolant (antifreeze) products. Do

not use additional rust inhibitors or an-

tirust products, as they may not be com-

CAUTION!

patible with the radiator engine coolant

and may plug the radiator.

• This vehicle has not been designed for

use with propylene glycol-based engine

coolant (antifreeze). Use of propylene

glycol-based engine coolant (antifreeze)

is not recommended.

281

Page 285 of 372

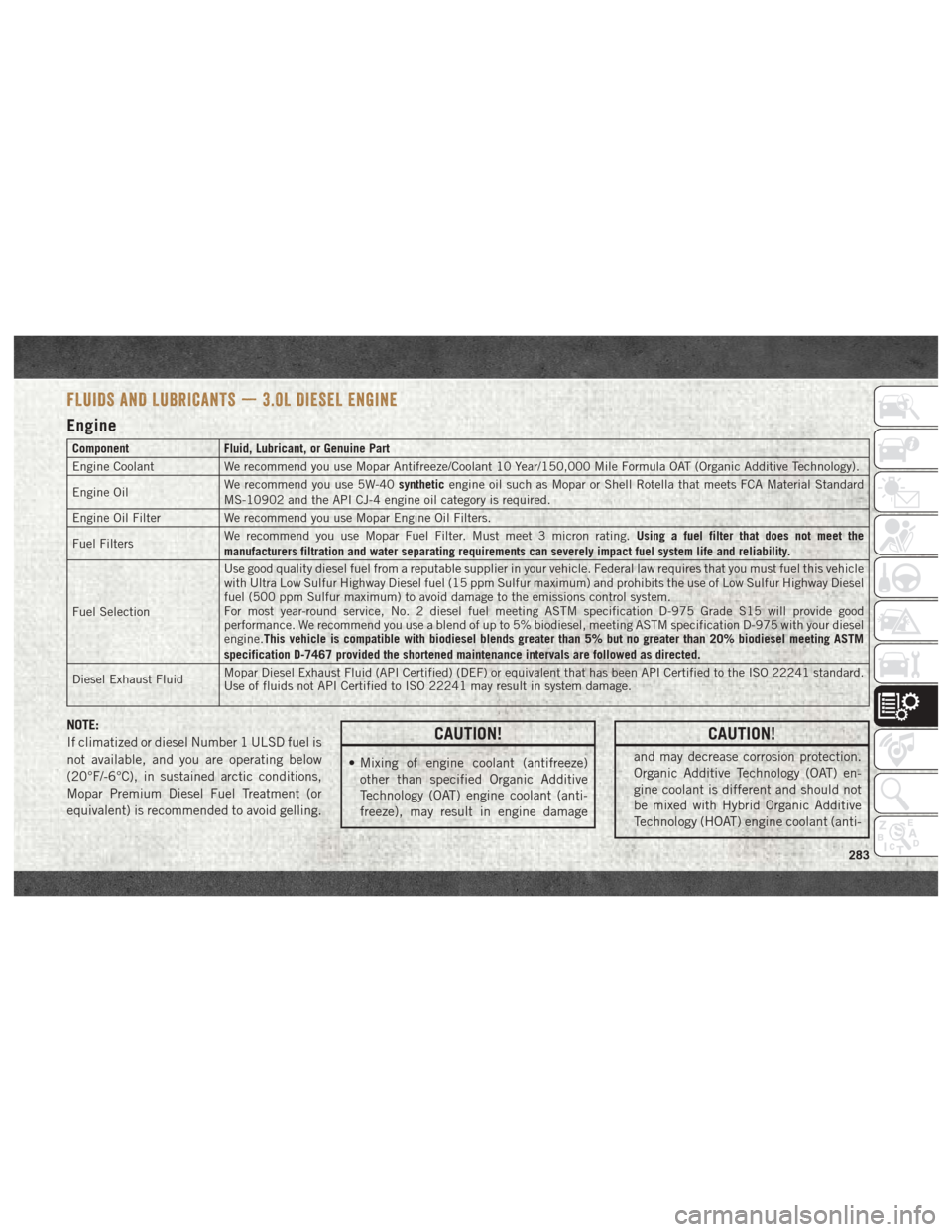

FLUIDS AND LUBRICANTS — 3.0L DIESEL ENGINE

Engine

ComponentFluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula OAT (Organic Additive Technology).

Engine Oil We recommend you use 5W-40

syntheticengine oil such as Mopar or Shell Rotella that meets FCA Material Standard

MS-10902 and the API CJ-4 engine oil category is required.

Engine Oil Filter We recommend you use Mopar Engine Oil Filters.

Fuel Filters We recommend you use Mopar Fuel Filter. Must meet 3 micron rating.

Using a fuel filter that does not meet the

manufacturers filtration and water separating requirements can severely impact fuel system life and reliability.

Fuel Selection Use good quality diesel fuel from a reputable supplier in your vehicle. Federal law requires that you must fuel this vehicle

with Ultra Low Sulfur Highway Diesel fuel (15 ppm Sulfur maximum) and prohibits the use of Low Sulfur Highway Diesel

fuel (500 ppm Sulfur maximum) to avoid damage to the emissions control system.

For most year-round service, No. 2 diesel fuel meeting ASTM specification D-975 Grade S15 will provide good

performance. We recommend you use a blend of up to 5% biodiesel, meeting ASTM specification D-975 with your diesel

engine.This vehicle is compatible with biodiesel blends greater than 5% but no greater than 20% biodiesel meeting ASTM

specification D-7467 provided the shortened maintenance intervals are followed as directed.

Diesel Exhaust Fluid Mopar Diesel Exhaust Fluid (API Certified) (DEF) or equivalent that has been API Certified to the ISO 22241 standard.

Use of fluids not API Certified to ISO 22241 may result in system damage.

NOTE:

If climatized or diesel Number 1 ULSD fuel is

not available, and you are operating below

(20°F/-6°C), in sustained arctic conditions,

Mopar Premium Diesel Fuel Treatment (or

equivalent) is recommended to avoid gelling.CAUTION!

• Mixing of engine coolant (antifreeze)

other than specified Organic Additive

Technology (OAT) engine coolant (anti-

freeze), may result in engine damage

CAUTION!

and may decrease corrosion protection.

Organic Additive Technology (OAT) en-

gine coolant is different and should not

be mixed with Hybrid Organic Additive

Technology (HOAT) engine coolant (anti-

283

Page 287 of 372

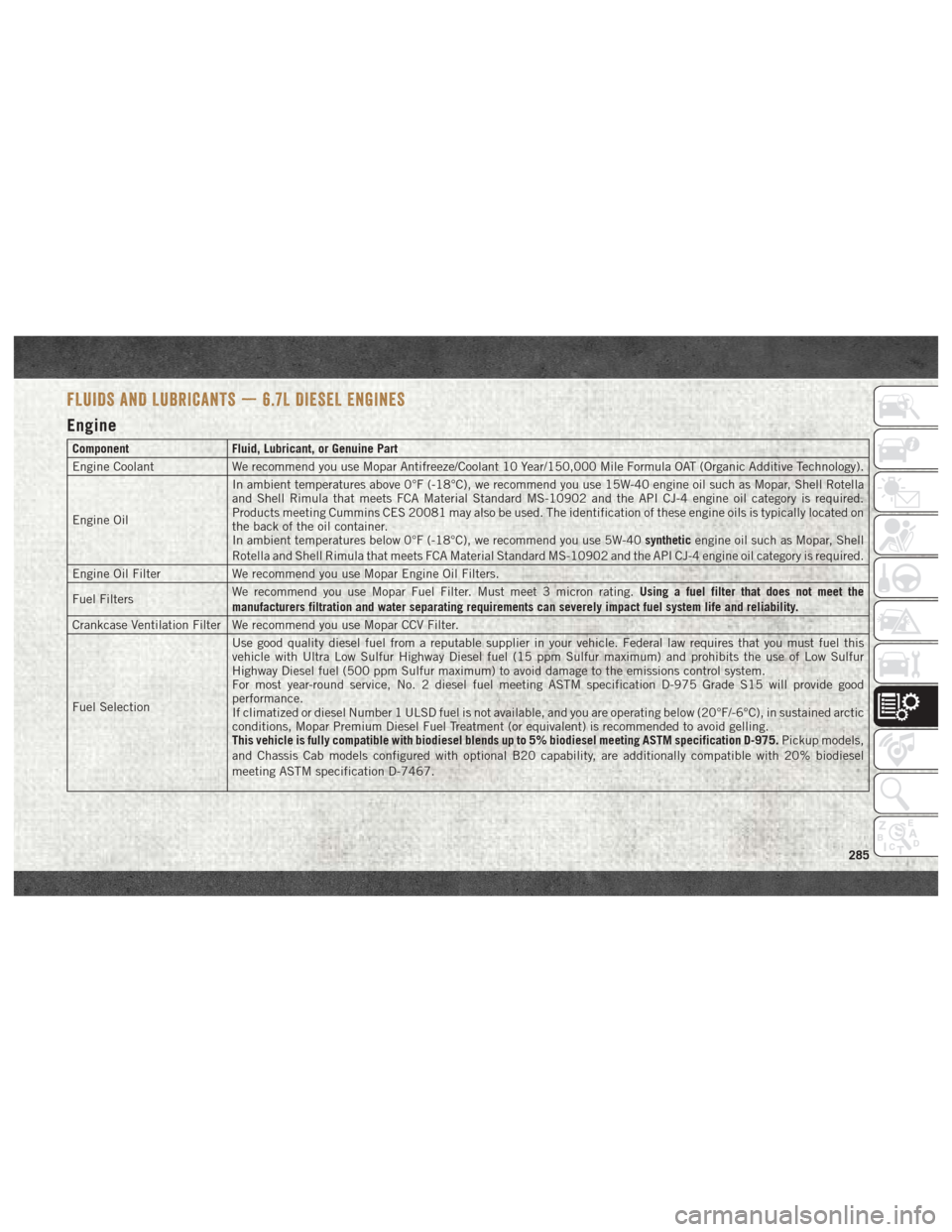

FLUIDS AND LUBRICANTS — 6.7L DIESEL ENGINES

Engine

ComponentFluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula OAT (Organic Additive Technology).

Engine Oil In ambient temperatures above 0°F (-18°C), we recommend you use 15W-40 engine oil such as Mopar, Shell Rotella

and Shell Rimula that meets FCA Material Standard MS-10902 and the API CJ-4 engine oil category is required.

Products meeting Cummins CES 20081 may also be used. The identification of these engine oils is typically located on

the back of the oil container.

In ambient temperatures below 0°F (-18°C), we recommend you use 5W-40

syntheticengine oil such as Mopar, Shell

Rotella and Shell Rimula that meets FCA Material Standard MS-10902 and the API CJ-4 engine oil category is required.

Engine Oil Filter We recommend you use Mopar Engine Oil Filters.

Fuel Filters We recommend you use Mopar Fuel Filter. Must meet 3 micron rating.

Using a fuel filter that does not meet the

manufacturers filtration and water separating requirements can severely impact fuel system life and reliability.

Crankcase Ventilation Filter We recommend you use Mopar CCV Filter.

Fuel Selection Use good quality diesel fuel from a reputable supplier in your vehicle. Federal law requires that you must fuel this

vehicle with Ultra Low Sulfur Highway Diesel fuel (15 ppm Sulfur maximum) and prohibits the use of Low Sulfur

Highway Diesel fuel (500 ppm Sulfur maximum) to avoid damage to the emissions control system.

For most year-round service, No. 2 diesel fuel meeting ASTM specification D-975 Grade S15 will provide good

performance.

If climatized or diesel Number 1 ULSD fuel is not available, and you are operating below (20°F/-6°C), in sustained arctic

conditions, Mopar Premium Diesel Fuel Treatment (or equivalent) is recommended to avoid gelling.

This vehicle is fully compatible with biodiesel blends up to 5% biodiesel meeting ASTM specification D-975.

Pickup models,

and Chassis Cab models configured with optional B20 capability, are additionally compatible with 20% biodiesel

meeting ASTM specification D-7467.

285