lock Ram 2500 2018 Manual Online

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 2500, Model: Ram 2500 2018Pages: 372, PDF Size: 7.1 MB

Page 216 of 372

To Stow The Flat Or Spare

NOTE:

RAM 1500 vehicles equipped with alumi-

num wheels cannot be stored under the ve-

hicle because the wheel retainer will not fit

through the wheel pilot hole. Secure the flat

tire in the bed of the truck. Have the flat tire

repaired or replaced immediately.

1. Turn the wheel so that the valve stem isdown. Slide the wheel retainer through

the center of the wheel and position it

properly across the wheel opening.

2. For convenience in checking the spare tire inflation, stow with the valve stem toward

the rear of the vehicle.

3. Attach the lug wrench to the extension tubes with the curved angle facing away

from the vehicle. Rotate the lug wrench

handle clockwise until the wheel is drawn

into place against the underside of the

vehicle. Continue to rotate until you feel

the winch mechanism slip, or click three

or four times. It cannot be overtightened.

Push against the tire several times to be

sure it is firmly in place.

WARNING!

• Do not attempt to change a tire on theside of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack.

• Never start or run the engine while the

vehicle is on a jack. If you need to get

under a raised vehicle, take it to your

authorized dealer where it can be raised

on a lift.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

• Do not attempt to change a tire on the

side of the vehicle close to moving traf-

fic, pull far enough off the road to avoid

WARNING!

the danger of being hit when operating

the jack or changing the wheel.

• Carefully follow these tire changing

warnings to help prevent personal injury

or damage to your vehicle:• Always park on a firm, level surface

as far from the edge of the roadway

as possible before raising the ve-

hicle.

• Turn on the Hazard Warning flash-

ers.

• Block the wheel diagonally opposite

the wheel to be raised.

• Set the parking brake firmly and set

an automatic transmission in

PARK; a manual transmission in

REVERSE.

• Do not let anyone sit in the vehicle

when it is on a jack.

• Do not get under the vehicle when it

is on a jack.

• Only use the jack in the positions

indicated and for lifting this vehicle

during a tire change.

IN CASE OF EMERGENCY

214

Page 217 of 372

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or

inflated, are securely stowed,

spares must be stowed with the

valve stem facing the ground.

• Raising the vehicle higher than nec-

essary can make the vehicle less

stable. It could slip off the jack and

hurt someone near it. Raise the ve-

hicle only enough to remove the

tire.

• To avoid the risk of forcing the ve-

hicle off the jack, do not fully

tighten the wheel bolts until the

vehicle has been lowered. Failure to

follow this warning may result in

personal injury.

• To avoid possible personal injury,

handle the wheel covers with care to

avoid contact with any sharp edges.

WARNING!

• A loose tire or jack thrown forward ina collision or hard stop could en-

danger the occupants of the ve-

hicle. Always stow the jack parts

and the spare tire in the places

provided.

• A loose tire thrown forward in a

collision or hard stop could injure

the occupants in the vehicle. Have

the deflated (flat) tire repaired or

replaced immediately.

CAUTION!

• Do not attempt to raise the vehicle byjacking on locations other than those

indicated in the Jacking Instructions for

this vehicle.

• Before raising the wheel off the ground,

make sure that the jack will not damage

surrounding truck parts and adjust the

jack position as required.

• Use a back and forth motion to remove

the hub cap. Do not use a twisting mo-

CAUTION!

tion when removing the hub cap, dam-

age to the hub cap; finish may occur.

• The rear hubcaps on the dual rear wheel

has two pry off notches. Make sure that

the hook of the jack handle driver is

located squarely in the cap notch before

attempting to pull off.

Reinstalling The Jack And Tools

1500 Series Trucks

1. Tighten the jack all the way down by turning the jack turn-screw clockwise un-

til the jack is snug.

215

Page 218 of 372

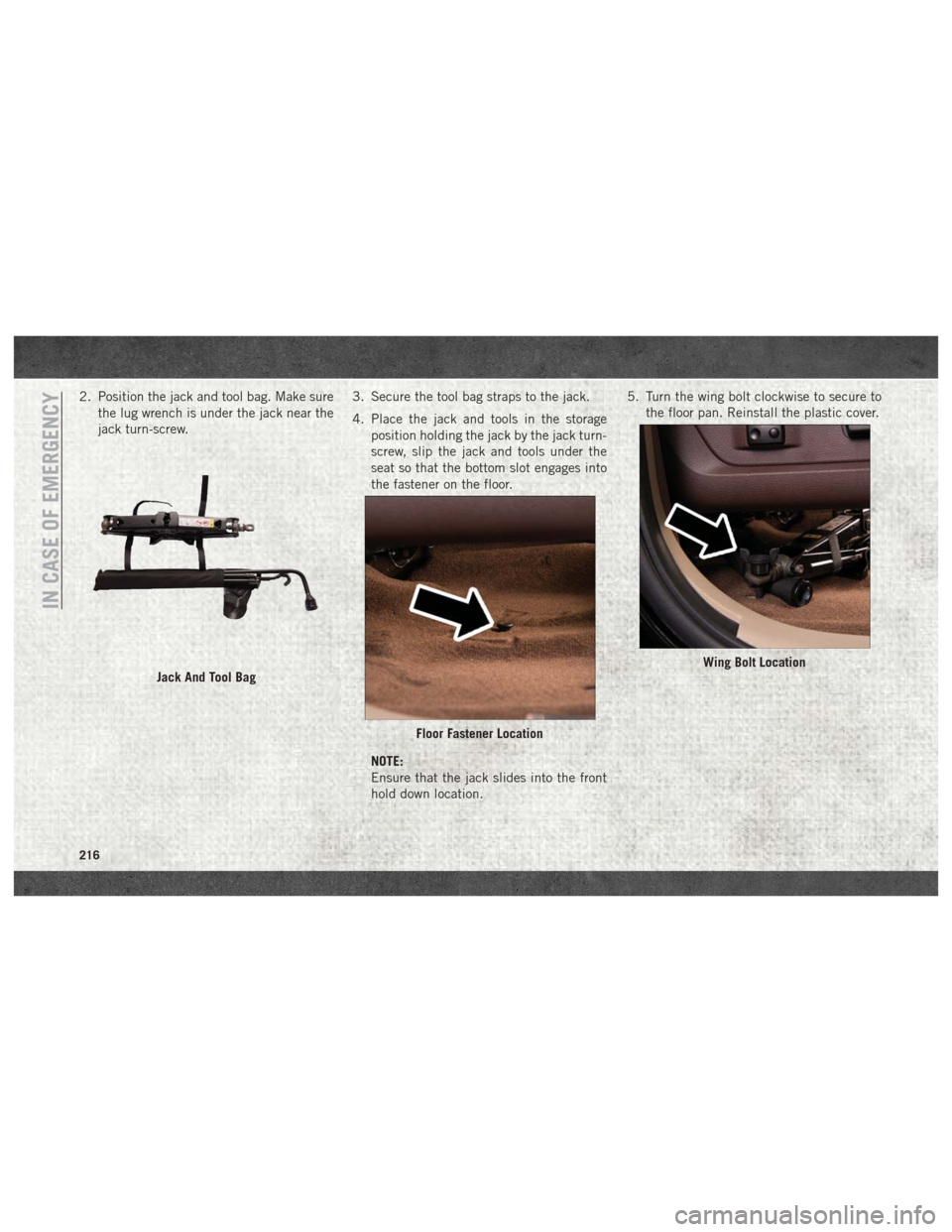

2. Position the jack and tool bag. Make surethe lug wrench is under the jack near the

jack turn-screw. 3. Secure the tool bag straps to the jack.

4. Place the jack and tools in the storage

position holding the jack by the jack turn-

screw, slip the jack and tools under the

seat so that the bottom slot engages into

the fastener on the floor.

NOTE:

Ensure that the jack slides into the front

hold down location. 5. Turn the wing bolt clockwise to secure to

the floor pan. Reinstall the plastic cover.

Jack And Tool Bag

Floor Fastener Location

Wing Bolt Location

IN CASE OF EMERGENCY

216

Page 219 of 372

2500/3500 Series Trucks

1. Tighten the jack all the way down byturning the jack turn-screw clockwise un-

til the jack is snug.

2. Position the jack and tools into bracket assembly. Make sure the lug wrench is

under the jack near the jack turn-screw.

Snap tools into bracket assembly clips.

Install the jack into bracket assembly and

turn screw until jack is snug into bracket

assembly.

3. Place the jack and tool bracket assembly in the storage position holding the jack by

the jack turn-screw, slip the jack and tools

under the seat so that the bottom slot

engages into the fastener on the floor. NOTE:

Ensure that the jack and tool bracket

assembly slides into the front hold down

location.

4. Turn the wing bolt clockwise to secure to the floor pan. Reinstall the plastic cover.Hub Caps/Wheel Covers — If

Equipped

The hub caps must be removed before raising

the vehicle off the ground.

CAUTION!

Use extreme caution when removing the

front and rear center caps. Damage can

occur to the center cap and/or the wheel if

screwdriver type tools are used. A pulling

motion, not a pry off motion, is recom-

mended to remove the caps.

For single rear wheel (SRW) models, use the

flat blade on the end of the lug wrench to pull

the hub cap off. Insert the blade end into the

pull off notch and carefully pull the hub cap

off with a back and forth motion.

On 3500 models with dual rear wheels

(DRW), you must first remove the hub caps.

The jack handle driver has a hook at one end

that will fit in the pull off notch of the rear

hub caps. Position the hook and pull straight

out on the ratchet firmly. The hub cap should

pop off. The wheel skins can now be removed.

For the front hub cap, use the flat blade on

Floor Fastener Location

217

Page 221 of 372

NOTE:

The positive battery post may be covered with

a protective cap if equipped. Lift up on the

cap to gain access to the positive battery

post. Do not jump off fuses. Only jump di-

rectly off positive post which has a positive

(+)symbol on or around the post.

WARNING!

• Take care to avoid the radiator cooling

fan whenever the hood is raised. It can

start anytime the ignition switch is ON.

You can be injured by moving fan blades.

• Remove any metal jewelry such as rings,

watch bands and bracelets that could

make an inadvertent electrical contact.

You could be seriously injured.

• Batteries contain sulfuric acid that can

burn your skin or eyes and generate

hydrogen gas which is flammable and

explosive. Keep open flames or sparks

away from the battery.

1. Apply the parking brake, shift the auto- matic transmission into PARK and turn

the ignition to LOCK. 2. Turn off the heater, radio, and all unnec-

essary electrical accessories.

3. If using another vehicle to jump start the battery, park the vehicle within the jumper

cables reach, apply the parking brake and

make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other

as this could establish a ground connec-

tion and personal injury could result.

Jump Starting Procedure

WARNING!

Failure to follow this jump starting proce-

dure could result in personal injury or

property damage due to battery explosion.

CAUTION!

Failure to follow these procedures could

result in damage to the charging system of

the booster vehicle or the discharged ve-

hicle.

Connecting The Jumper Cables

1. Connect the positive (+)end of the jumper

cable to the positive (+)post of the dis-

charged vehicle.

NOTE:

Do not jump off fuses. Only jump directly off

positive post.

2. Connect the opposite end of the positive (+) jumper cable to the positive (+)post of

the booster battery.

3. Connect the negative (-)end of the jumper

cable to the negative (-)post of the

booster battery.

4. Connect the opposite end of the negative (-)jumper cable to a good engine ground

(exposed metal part of the discharged

vehicle’s engine) away from the battery

and the fuel injection system.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause

the battery to explode and could result in

219

Page 223 of 372

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never try to open a cooling system

pressure cap when the radiator or coolant

bottle is hot.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop

the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer

drops back into the normal range. If the

pointer remains on HOT (H), and you hear

continuous chimes, turn the engine off

immediately and call for service.

GEAR SELECTOR OVERRIDE —

6-SPEED TRANSMISSION

If a malfunction occurs and the gear selector

cannot be moved out of the PARK position,

you can use one of the following procedures

to temporarily move the gear selector.

Column Gear Selector — If

Equipped

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Tilt the steering wheel to the full upposition.

4. Press and maintain firm pressure on the brake pedal.

5. Insert a screwdriver or similar tool into the access port (ringed circle) on the bottom

of the steering column, and push and hold

the override release lever up. 6. Move the gear selector to the NEUTRAL

position.

7. The vehicle may then be started in NEUTRAL.

Shift Lock Manual Override Access Port

221

Page 225 of 372

Follow these steps to activate the Manual

Park Release:

1. Firmly apply the parking brake.

2. Using a small screwdriver or similar tool,remove the Manual Park Release access

cover, which is just above the parking

brake release handle, below and to the left

of the steering column.

3. Press and maintain firm pressure on the brake pedal. 4. Using the screwdriver or similar tool, push

the Manual Park Release lever locking tab

(just below the middle of the lever) to the

right.

5. While holding the locking tab in the disengaged position, pull the tether strap

to rotate the lever rearward, until it locks

in place pointing towards the driver's seat.

Release the locking tab and verify that the

Manual Park Release lever is locked in the

released position. 6. The vehicle is now out of PARK and can be

towed. Release the parking brake only

when the vehicle is securely connected to

a tow vehicle.

To Reset The Manual Park Release:

1. Push the locking tab to the right, to unlock the lever.

Manual Park Release Access Cover

Manual Park Release Lever Locking Tab

Manual Park Release Tether

223

Page 226 of 372

2. Rotate the Manual Park Release leverforward to its original position, until the

locking tab snaps into place to secure the

lever.

3. Pull gently on the tether strap to confirm that the lever is locked in its stowed

position.

4. Re-install the access cover.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand,

or snow, it can often be moved using a rock-

ing motion. Turn the steering wheel right and

left to clear the area around the front wheels.

Then shift back and forth between DRIVE

and REVERSE (with automatic transmission)

or SECOND GEAR and REVERSE (with

manual transmission), while gently pressing

the accelerator. Use the least amount of ac-

celerator pedal pressure that will maintain

the rocking motion, without spinning the

wheels or racing the engine. NOTE:

For trucks equipped with 8-speed automatic

transmission: Shifts between DRIVE and RE-

VERSE can only be achieved at wheel speeds

of 5 mph (8 km/h) or less. Whenever the

transmission remains in NEUTRAL for more

than two seconds, you must press the brake

pedal to engage DRIVE or REVERSE.

NOTE:

Push the "ESC Off" switch, to place the Elec-

tronic Stability Control (ESC) system in "Par-

tial Off" mode, before rocking the vehicle.

Refer to “Electronic Brake Control” in

“Safety” in the Owner’s Manual for further

information. Once the vehicle has been

freed, push the "ESC Off" switch again to

restore "ESC On" mode.

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure,

of the axle and tires. A tire could explode

and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

WARNING!

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

CAUTION!

• Racing the engine or spinning the

wheels may lead to transmission over-

heating and failure. Allow the engine to

idle with the transmission in NEUTRAL

for at least one minute after every five

rocking-motion cycles. This will mini-

mize overheating and reduce the risk of

clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by shift- ing between DRIVE/2nd gear and RE-

VERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain

damage may result.

• Revving the engine or spinning the wheels too fast may lead to transmission

overheating and failure. It can also dam-

age the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

IN CASE OF EMERGENCY

224

Page 252 of 372

nate and an audible chime will be heard. At

this point, you should stop the engine and

drain the water from the filter housing.

CAUTION!

If the “Water In Fuel Indicator Light” re-

mains on, DO NOT START the engine be-

fore you drain water from the fuel filter to

avoid engine damage.

If the “Water In Fuel Indicator Light” comes

on and a single chime is heard while you are

driving, or with the ignition in the ON posi-

tion, there may be a problem with your water

separator wiring or sensor. See your autho-

rized dealer for service.

Upon proper draining of the water from the

fuel filter, the “Water In Fuel Indicator Light”

will remain illuminated for approximately

10 seconds. If the water was drained while

the engine was running, the “Water In Fuel

Indicator Light” may remain on for approxi-

mately three minutes. NOTE:

Care should be taken in disposing of used

fluids from your vehicle. Used fluids, indis-

criminately discarded, can present a problem

to the environment. Contact an authorized

dealer, service station, or government agency

for advice on recycling programs and for

where used fluids and filters can be properly

disposed of in your area.

Drain the fuel/water separator filter when the

“Water In Fuel Indicator Light” is ON. Within

10 minutes of vehicle shutdown, turn the

filter drain valve (located on the bottom of the

filter housing) counterclockwise to drain fuel/

water, then turn the ignition switch to the ON

position, and allow any accumulated water to

drain. Leave the drain valve open until all

water and contaminants have been removed.

When clean fuel is visible, close the drain

valve by turning it clockwise, and turn the

ignition switch to OFF.

If more than two ounces or 60 milliliters of

fuel have been drained, follow the directions

for “Priming If The Engine Has Run Out Of

Fuel.”

Underbody Mounted Fuel Filter

Replacement

NOTE:

Using a fuel filter that does not meet the

manufacturer's filtration and water separat-

ing requirements can severely impact fuel

system life and reliability.

CAUTION!

• Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

• Do not prefill the fuel filter when install-

ing a new fuel filter. There is a possibility

debris could be introduced into the fuel

filter during this action. It is best to

install the filter dry and allow the in-tank

lift pump to prime the fuel system.

1. Turn engine off.

2. Place a drain pan under the fuel filter assembly.

3. Open the water drain valve, and let any accumulated water drain.

4. Close the water drain valve.

SERVICING AND MAINTENANCE

250

Page 253 of 372

5. Remove bottom cover using a strapwrench. Rotate counterclockwise for re-

moval. Remove the used o-ring and dis-

card it.

6. Remove the used filter cartridge from the housing and dispose of it according to

your local regulations.

7. Wipe the sealing surfaces of the lid and housing clean.

8. Install a new o-ring into the ring groove on the filter housing and lubricate with clean

engine oil.

NOTE:

WIF (Water In Fuel) sensor is re-usable. Ser-

vice kit comes with new o-ring for filter can-

ister and WIF sensor.

Priming If The Engine Has Run Out

Of Fuel

WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure

WARNING!

fuel spray can cause serious injury or

death.

1. Add a substantial amount of fuel to the tank, approximately 2 to 5 gal (8L to

19L).

2. Press ignition switch twice without your foot on brake to put vehicle in Run posi-

tion. This will activate the in tank fuel

pump for approximately 30 seconds. Re-

peat this process twice.

3. Start the engine using the “Normal Start- ing” procedure. Refer to “Starting The

Engine” in “Starting and Operating” for

further information.

CAUTION!

The starter motor will engage for approxi-

mately 30 seconds at a time. Allow two

minutes between cranking intervals.

NOTE:

The engine may run rough until the air is

forced from all the fuel lines.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable un-

der certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system.

NOTE:

• Use of biodiesel mixture in excess of 20% can negatively impact the fuel filter's abil-

ity to separate water from the fuel, resulting

in high pressure fuel system corrosion or

damage.

• In addition, commercially available fuel ad- ditives are not necessary for the proper

operation of your diesel engine.

• For extreme cold conditions, "Mopar Pre- mium Diesel Fuel Treatment" is recom-

mended to assist with cold starting.

251