lug pattern Ram 2500 2019 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2019, Model line: 2500, Model: Ram 2500 2019Pages: 696, PDF Size: 13.89 MB

Page 181 of 696

GETTING TO KNOW YOUR INSTRUMENT PANEL 179

What to do when an electrical load reduction action

message is present (“Battery Saver On” or “Battery Saver

Mode”)

During a trip:

• Reduce power to unnecessary loads if possible:•Turn off redundant lights (interior or exterior).

•Check what may be plugged in to power outlets +12V,115V AC, USB ports.

•Check HVAC settings (blower, temperature).

•Check the audio settings (volume).

After a trip:

• Check if any aftermarket equipment was installed (addi -

tional lights, upfitter electrical accessories, audio systems,

alarms) and review specifications if any (load and Ignition

Off Draw currents).

• Evaluate the latest driving cycles (distance, driving time and parking time).

• The vehicle should have service performed if the message is still present during consecutive trips and the evaluation

of the vehicle and driving pattern did not help to identify

the cause.WARNING LIGHTS AND MESSAGES

The warning/indicator lights will illuminate in the instru-

ment panel together with a dedicated message and/or

acoustic signal when applicable. These indications are indic -

ative and precautionary and as such must not be considered

as exhaustive. Always refer to the information in this chapter

in the event of a failure indication. All active telltales will

display first if applicable. The system check menu may

appear different based upon equipment options and current

vehicle status. Some telltales are optional and may not

appear.

Red Warning Lights

— Seat Belt Reminder Warning Light

This warning light indicates when the driver or passenger

seat belt is unbuckled. When the ignition is first placed in the

ON/RUN or ACC/ON/RUN position and if the driver’s

seat belt is unbuckled, a chime will sound and the light will

turn on. When driving, if the driver or front passenger seat

belt remains unbuckled, the Seat Belt Reminder Light will

flash or remain on continuously and a chime will sound.

Refer to “Occupant Restraint Systems” in “Safety” for

further information.

3

Page 484 of 696

482 IN CASE OF EMERGENCY

Dual Rear Wheel Jack Placement

6. Finish tightening the lug nuts. Push down on the lug wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. For the correct lug nut

torque refer to “Torque Specifications” in “Technical

Specifications”. If in doubt about the correct tightness,

have them checked with a torque wrench by an autho -

rized dealer or service station. 7. Install the wheel center cap and remove the wheel blocks.

Do not install chrome or aluminum wheel center caps on

the spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. Stow the replaced tire, jack, and tools as previously described.

NOTE:

The bottle jack will not lower by turning the dial (thumb -

wheel) by hand, it may be necessary to use the jack driver in

order to lower the jack

9. Adjust the tire pressure when possible.

NOTE:

Do not oil wheel studs. For chrome wheels, do not substitute

with chrome plated lug nuts.

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop, could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided.

Page 568 of 696

566 TECHNICAL SPECIFICATIONS

NOTE:

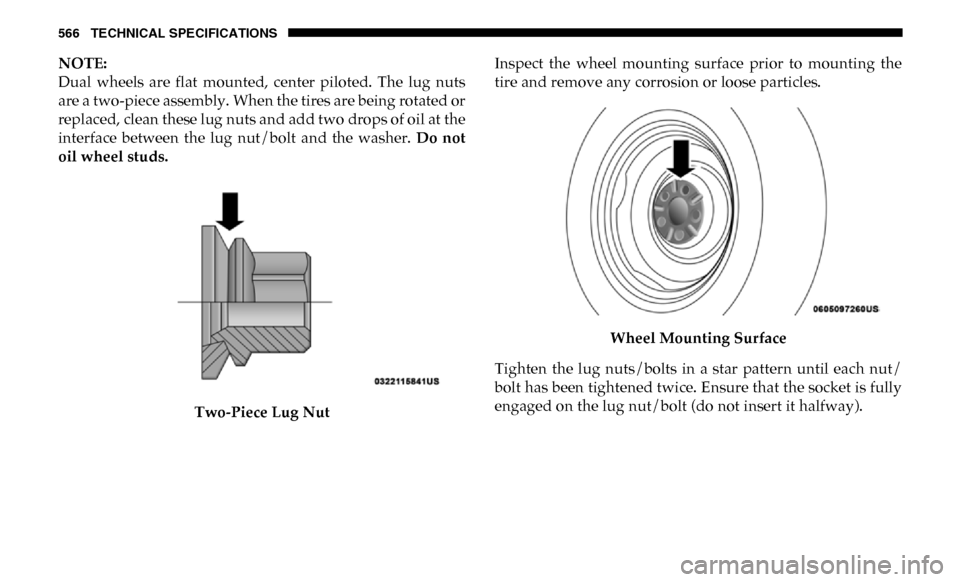

Dual wheels are flat mounted, center piloted. The lug nuts

are a two-piece assembly. When the tires are being rotated or

replaced, clean these lug nuts and add two drops of oil at the

interface between the lug nut/bolt and the washer. Do not

oil wheel studs.

Two-Piece Lug Nut

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until each nut/

bolt has been tightened twice. Ensure that the socket is fully

engaged on the lug nut/bolt (do not insert it halfway).

Page 569 of 696

TECHNICAL SPECIFICATIONS 567

After 25 miles (40 km), check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly seated against

the wheel.Four And Five Lug Nuts/Bolts Torque PatternFUEL REQUIREMENTS

6.4L Engine

Do not use E-85 flex fuel or ethanol blends greater than 15%

in this engine. This engines is designed to meet all emissions regu -

lations and provide satisfactory fuel economy and

performance when using high quality unleaded

gasoline having a posted octane number range of 87 to 89 as

specified by the (R+M)/2 method. The use of 89 octane

“Plus” gasoline is recommended for optimum performance

and fuel economy.

While operating on gasoline with an octane number of 87,

hearing a light knocking sound from the engine is not a cause

for concern. However, if the engine is heard making a heavy

knocking sound, see your dealer immediately. Use of gaso -

line with an octane number lower than 87 can cause engine

failure and may void or not be covered by the New Vehicle

Limited Warranty.

Poor quality gasoline can cause problems such as hard

starting, stalling, and hesitations. If you experience these

symptoms, try another brand of gasoline before considering

service for the vehicle.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts/bolts fully until the vehicle has

been lowered. Failure to follow this warning may result

in personal injury.8