service interval Ram 2500 2020 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 417 of 553

SERVICING AND MAINTENANCE415

(Continued)

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning,

keep the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever

necessary, install ONLY the correct type ther -

mostat. Other designs may result in unsatis -

factory engine coolant (antifreeze)

performance, poor gas mileage, and

increased emissions.

Charge Air Cooler — Inter-Cooler

The charge air cooler is positioned below the

radiator and the air conditioner condenser. Air

enters the engine through the air cleaner and

passes through the turbocharger, where it is

pressurized. This pressurized air rapidly

reaches high temperature. The air is then

directed through a hose to the charge air cooler

and through another hose to the intake mani -

fold of the engine. The air entering the engine

has been cooled by about 50° to 100°F (10° to

38°C). This cooling process enables more effi -

cient burning of fuel resulting in fewer emis -

sions.

To guarantee optimum performance of the

system, keep the surfaces of the charge air

cooler, condenser and radiator clean and free of debris. Periodically check the hoses leading

to and from the charge air cooler for cracks or

loose clamps resulting in loss of pressure and

reduced engine performance.

Brake System

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the “Mainte

-

nance Plan” in this section for the proper main -

tenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood

service or immediately if the brake system

warning lamp indicates system failure. If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the

top of the master cylinder area before removing

cap.

With disc brakes the fluid level can be expected

to fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by

a leak and a system check should be

conducted.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder reser -

voir.

7

20_DJD2_OM_EN_USC_t.book Page 415

Page 420 of 553

418SERVICING AND MAINTENANCE

8. Reinsert the dipstick. Check for leaks.

Release the parking brake.

NOTE:

If it is necessary to check the transmission

below the operating temperature, the fluid level

should be between the two COLD (lower) holes

on the dipstick with the fluid at 68-86°F /

20-30°C. Only use the COLD region of the

dipstick as a rough reference when setting the

fluid level after a transmission service or fluid

change. Re-check the fluid level, and adjust as

required, once the transmission reaches

normal operating temperature.Fluid And Filter Changes — Eight-Speed

Transmission

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not

required. However, change the fluid and filter if

the fluid becomes contaminated (with water,

etc.), or if the transmission is disassembled for

any reason.

Fluid And Filter Changes — Six Speed

Transmission

Refer to the “Maintenance Plan” for the proper

maintenance intervals.

In addition, change the fluid and filters if the

fluid becomes contaminated (with water, etc.),

or if the transmission is disassembled for any

reason.

Rear Axle And 4x4 Front Driving Axle Fluid

Level

For normal service, periodic fluid level checks

are not required. When the vehicle is serviced

for other reasons the exterior surfaces of the

axle assembly should be inspected. If gear oil

leakage is suspected inspect the fluid level.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. This

inspection should be made with the vehicle in a

level position.

For all 2500/3500 Model axles, the fluid level

should be 1/4 in ± 1/4 in (6.4 mm ± 6.4 mm)

below the fill hole on the 9.25 in front, 11.5 in

rear axle, and 12.0 in rear axle.

Drain And Refill

Refer to the “Maintenance Plan” for the proper

maintenance intervals.

Lubricant Selection

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

NOTE:

The presence of water in the gear lubricant will

result in corrosion and possible failure of differ -

ential components. Operation of the vehicle in

CAUTION!

If the fluid temperature is below 50°F (10°C)

it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough

to produce an accurate reading. Run the

engine at idle, in PARK, to warm the fluid.

CAUTION!

If the fluid temperature is below 50°F (10°C)

it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough

to produce an accurate reading. Run the

engine at idle, in PARK, to warm the fluid.

20_DJD2_OM_EN_USC_t.book Page 418

Page 421 of 553

SERVICING AND MAINTENANCE419

water, as may be encountered in some

off-highway types of service, will require

draining and refilling the axle to avoid damage.

Limited-Slip Differentials DO REQUIRE limited

slip oil additive (friction modifiers).

NOTE:

Slight noise and mild shuddering may be

evident while turning a vehicle with limited slip

differential on concrete or dry pavement. These

conditions should be considered normal opera -

tion of the limited slip differential.

Transfer Case

Selection Of Lubricant

Use only the manufacturer's recommended

fluid. Refer to “Fluids And Lubricants” in “Tech -

nical Specifications” for further information.

Fluid Level Check

This fluid level can be checked by removing the

filler plug. The fluid level should be to the

bottom edge of the filler plug hole with the

vehicle in a level position.

Drain And Refill

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

Noise Control System Required

Maintenance & Warranty

All vehicles built over 10,000 lbs. (4,535 kg)

Gross Vehicle Weight Rating and manufactured

for sale and use in the United States are

required to comply with the Federal Govern -

ment's Exterior Noise Regulations. These vehi -

cles can be identified by the Noise Emission

Control Label located in the operator's compart -

ment.

Required Maintenance For Noise Control

Systems

The following maintenance services must be

performed every six months or 7,500 miles

(12,000 km) whichever comes first, to ensure

proper operation of the noise control systems.

In addition, inspection and service should be

performed anytime a malfunction is observed or

suspected. Proper maintenance of the entire

vehicle will help the effectiveness of the noise

control systems.

Exhaust System

Inspect the entire exhaust system for leaks and

damaged parts. Devices such as hangers,

clamps, and U-bolts should be tight and in good

condition. Damaged components, burned or

blown out mufflers, burned or rusted out

exhaust pipes should be replaced according to

the procedures and specifications outlined in

the appropriate service manual.

Air Cleaner Assembly

Inspect air cleaner housing for proper assembly

and fit. Make certain that the air cleaner is prop -

erly positioned and that the cover is tight. Check

all hoses leading to the air cleaner for tightness.

7

20_DJD2_OM_EN_USC_t.book Page 419

Page 452 of 553

450TECHNICAL SPECIFICATIONS

Bio-Diesel Fuel Properties — Low Ambient

Temperatures

Biodiesel fuel may gel or solidify at low ambient

temperatures, which may pose problems for

both storage and operation. Precautions can be

necessary at low ambient temperatures, such

as storing the fuel in a heated building or a

heated storage tank, or using cold temperature

additives.

Fuel In Oil Dilution — Must Adhere To

Required Oil Change Interval

Fuel dilution of lubricating oil has been

observed with the use of biodiesel fuel. Fuel in

oil must not exceed 5%. To ensure this limit is

met your oil change interval must be main -

tained to the following schedule:

Ram PickUp 2500/3500 Only — 15,000 Miles*

(*unless otherwise notified with a oil service

message)

CAUTION!

Under no circumstances should oil change

intervals exceed 15,000 miles (24 000 km)

pickup or 12,500 miles (20 000 km)

chassis cab if operation occurs with greater

than 5% biodiesel blends. Oil change inter -

vals should not exceed 6 months in either

case. Failure to comply with these Oil

Change requirements for vehicles operating

on biodiesel blends up to B20 may result in

premature engine wear. Such wear is not

covered by the New Vehicle Limited

Warranty.

B20 Biodiesel capable: The engine may

suffer severe damage if operated with

concentrations of Biodiesel higher than

20%.

20_DJD2_OM_EN_USC_t.book Page 450

Page 547 of 553

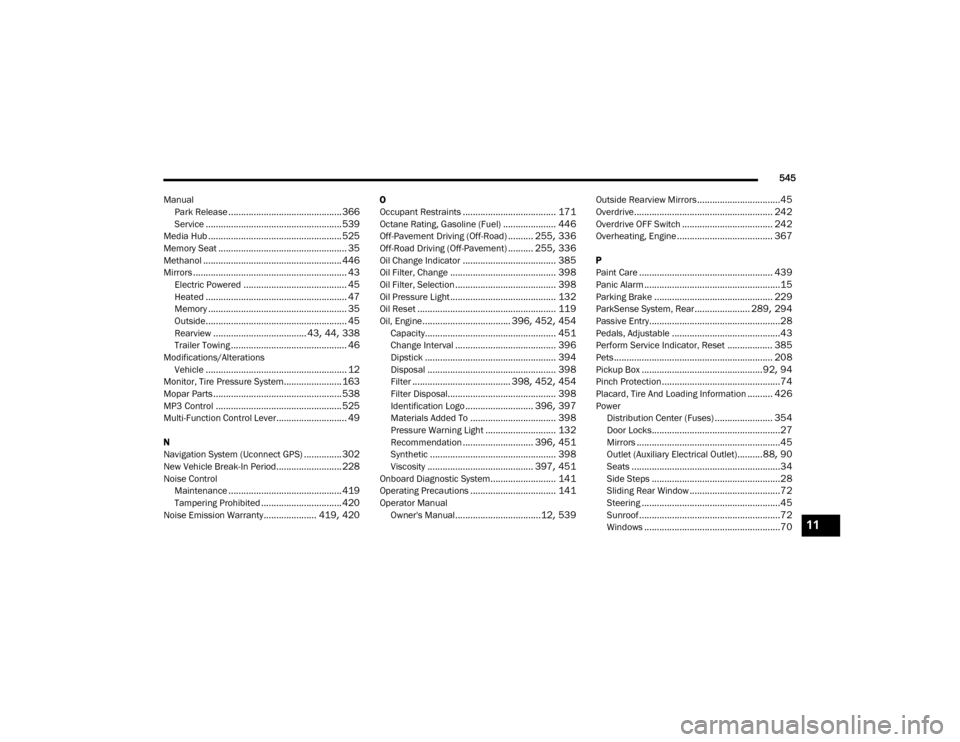

545

Manual Park Release

............................................. 366

Service...................................................... 539

Media Hub..................................................... 525

Memory Seat................................................... 35

Methanol....................................................... 446

Mirrors............................................................. 43Electric Powered......................................... 45

Heated........................................................ 47

Memory....................................................... 35Outside........................................................ 45

Rearview..................................... 43, 44, 338

Trailer Towing.............................................. 46

Modifications/AlterationsVehicle

........................................................ 12Monitor, Tire Pressure System....................... 163

Mopar Parts................................................... 538

MP3 Control.................................................. 525

Multi-Function Control Lever............................ 49

N

Navigation System (Uconnect GPS)

............... 302

New Vehicle Break-In Period.......................... 228

Noise ControlMaintenance............................................. 419

Tampering Prohibited................................ 420

Noise Emission Warranty..................... 419, 420

O

Occupant Restraints

..................................... 171

Octane Rating, Gasoline (Fuel)..................... 446

Off-Pavement Driving (Off-Road).......... 255, 336

Off-Road Driving (Off-Pavement).......... 255, 336

Oil Change Indicator..................................... 385

Oil Filter, Change.......................................... 398Oil Filter, Selection........................................ 398

Oil Pressure Light.......................................... 132

Oil Reset....................................................... 119Oil, Engine................................... 396, 452, 454

Capacity.................................................... 451

Change Interval........................................ 396

Dipstick.................................................... 394

Disposal................................................... 398Filter....................................... 398, 452, 454

Filter Disposal........................................... 398

Identification Logo........................... 396, 397

Materials Added To.................................. 398Pressure Warning Light............................ 132

Recommendation............................ 396, 451

Synthetic.................................................. 398

Viscosity.......................................... 397, 451

Onboard Diagnostic System.......................... 141

Operating Precautions.................................. 141

Operator ManualOwner's Manual

..................................12, 539

Outside Rearview Mirrors.................................45

Overdrive....................................................... 242

Overdrive OFF Switch.................................... 242

Overheating, Engine...................................... 367

P

Paint Care

..................................................... 439

Panic Alarm......................................................15

Parking Brake............................................... 229

ParkSense System, Rear...................... 289, 294Passive Entry....................................................28

Pedals, Adjustable...........................................43

Perform Service Indicator, Reset.................. 385

Pets............................................................... 208

Pickup Box................................................92, 94

Pinch Protection...............................................74

Placard, Tire And Loading Information.......... 426

PowerDistribution Center (Fuses)

....................... 354

Door Locks...................................................27

Mirrors.........................................................45

Outlet (Auxiliary Electrical Outlet)..........88, 90

Seats...........................................................34

Side Steps...................................................28Sliding Rear Window....................................72

Steering.......................................................45

Sunroof........................................................72

Windows......................................................7011

20_DJD2_OM_EN_USC_t.book Page 545