fuel Ram 2500 2020 Repair Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 359 of 553

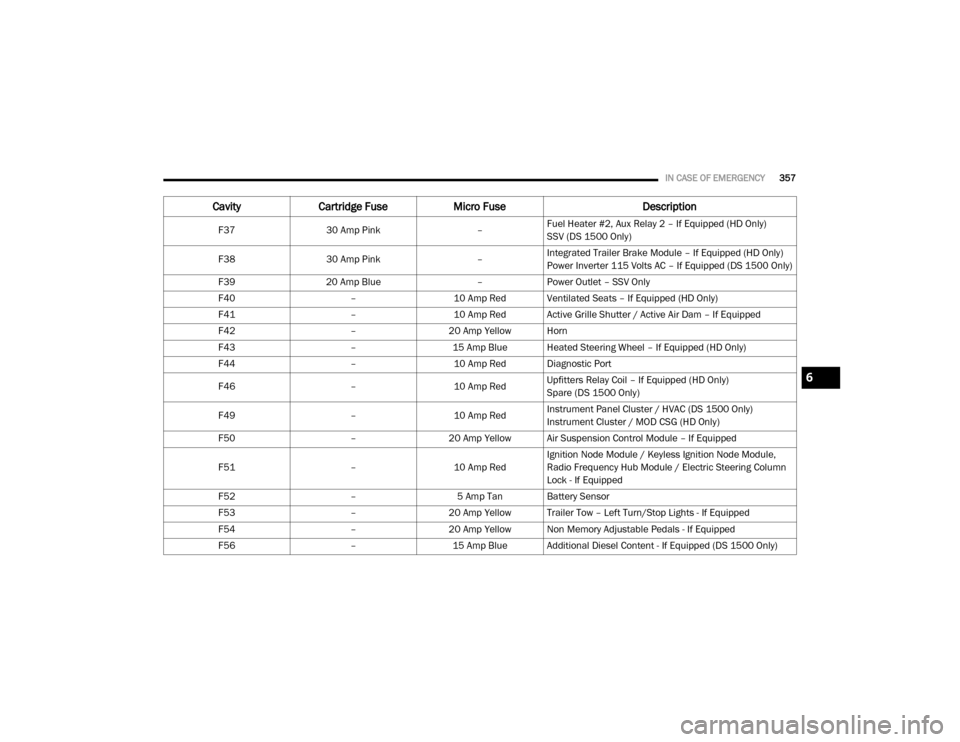

IN CASE OF EMERGENCY357

F3730 Amp Pink –Fuel Heater #2, Aux Relay 2 – If Equipped (HD Only)

SSV (DS 1500 Only)

F38 30 Amp Pink –Integrated Trailer Brake Module – If Equipped (HD Only)

Power Inverter 115 Volts AC – If Equipped (DS 1500 Only)

F39 20 Amp Blue –Power Outlet – SSV Only

F40 –10 Amp Red Ventilated Seats – If Equipped (HD Only)

F41 –10 Amp Red Active Grille Shutter / Active Air Dam – If Equipped

F42 –20 Amp Yellow Horn

F43 –15 Amp Blue Heated Steering Wheel – If Equipped (HD Only)

F44 –10 Amp Red Diagnostic Port

F46 –10 Amp RedUpfitters Relay Coil – If Equipped (HD Only)

Spare (DS 1500 Only)

F49 –10 Amp RedInstrument Panel Cluster / HVAC (DS 1500 Only)

Instrument Cluster / MOD CSG (HD Only)

F50 –20 Amp Yellow Air Suspension Control Module – If Equipped

F51 –10 Amp RedIgnition Node Module / Keyless Ignition Node Module,

Radio Frequency Hub Module / Electric Steering Column

Lock - If Equipped

F52 –5 Amp Tan Battery Sensor

F53 –20 Amp Yellow Trailer Tow – Left Turn/Stop Lights - If Equipped

F54 –20 Amp Yellow Non Memory Adjustable Pedals - If Equipped

F56 –15 Amp Blue Additional Diesel Content - If Equipped (DS 1500 Only)

CavityCartridge Fuse Micro Fuse Description

6

20_DJD2_OM_EN_USC_t.book Page 357

Page 360 of 553

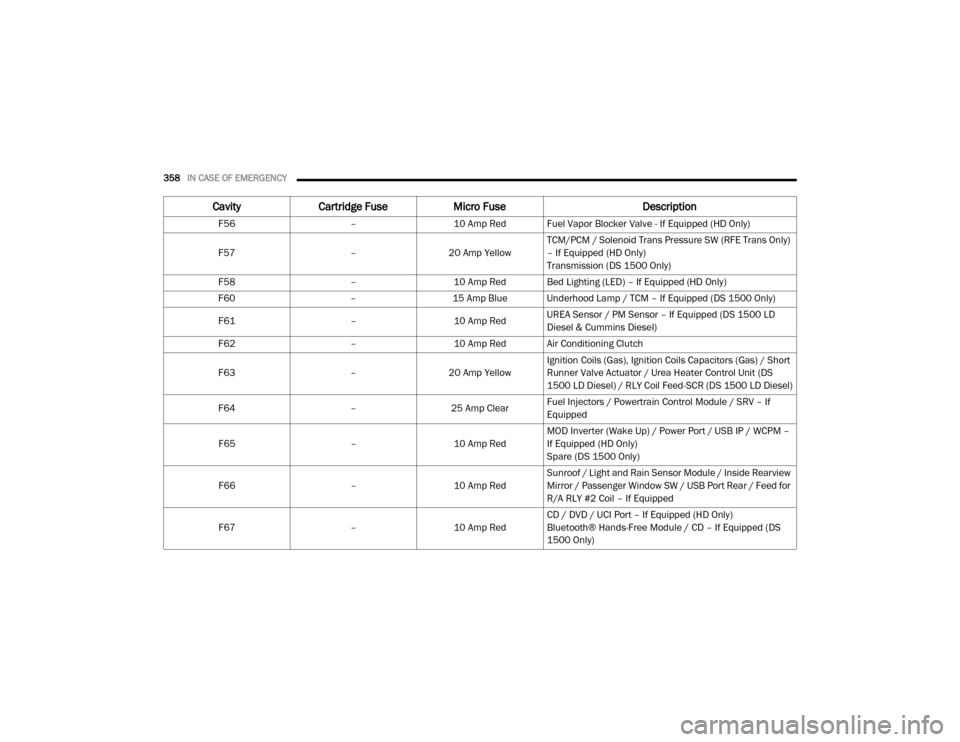

358IN CASE OF EMERGENCY

F56 –10 Amp Red Fuel Vapor Blocker Valve - If Equipped (HD Only)

F57 –20 Amp Yellow TCM/PCM / Solenoid Trans Pressure SW (RFE Trans Only)

– If Equipped (HD Only)

Transmission (DS 1500 Only)

F58 –10 Amp Red Bed Lighting (LED) – If Equipped (HD Only)

F60 –15 Amp Blue Underhood Lamp / TCM – If Equipped (DS 1500 Only)

F61 –10 Amp RedUREA Sensor / PM Sensor – If Equipped (DS 1500 LD

Diesel & Cummins Diesel)

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils (Gas), Ignition Coils Capacitors (Gas) / Short

Runner Valve Actuator / Urea Heater Control Unit (DS

1500 LD Diesel) / RLY Coil Feed-SCR (DS 1500 LD Diesel)

F64 –25 Amp ClearFuel Injectors / Powertrain Control Module / SRV – If

Equipped

F65 –10 Amp RedMOD Inverter (Wake Up) / Power Port / USB IP / WCPM –

If Equipped (HD Only)

Spare (DS 1500 Only)

F66 –10 Amp RedSunroof / Light and Rain Sensor Module / Inside Rearview

Mirror / Passenger Window SW / USB Port Rear / Feed for

R/A RLY #2 Coil – If Equipped

F67 –10 Amp RedCD / DVD / UCI Port – If Equipped (HD Only)

Bluetooth® Hands-Free Module / CD – If Equipped (DS

1500 Only)

Cavity

Cartridge Fuse Micro Fuse Description

20_DJD2_OM_EN_USC_t.book Page 358

Page 361 of 553

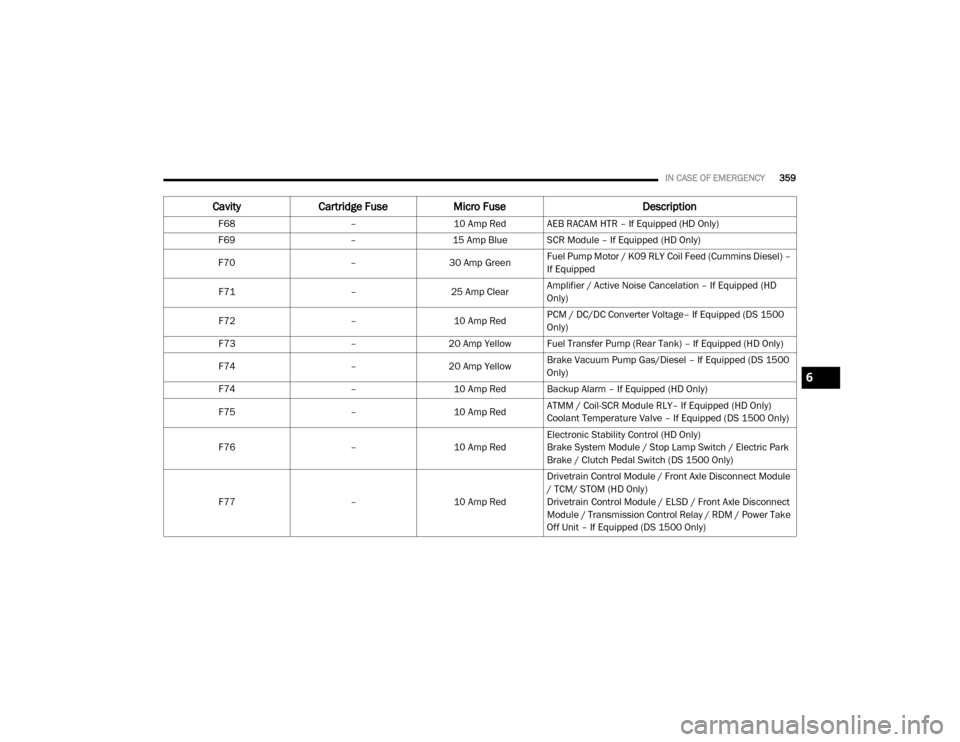

IN CASE OF EMERGENCY359

F68 –10 Amp Red AEB RACAM HTR – If Equipped (HD Only)

F69 –15 Amp Blue SCR Module – If Equipped (HD Only)

F70 –30 Amp GreenFuel Pump Motor / K09 RLY Coil Feed (Cummins Diesel) –

If Equipped

F71 –25 Amp ClearAmplifier / Active Noise Cancelation – If Equipped (HD

Only)

F72 –10 Amp RedPCM / DC/DC Converter Voltage– If Equipped (DS 1500

Only)

F73 –20 Amp Yellow Fuel Transfer Pump (Rear Tank) – If Equipped (HD Only)

F74 –20 Amp Yellow Brake Vacuum Pump Gas/Diesel – If Equipped (DS 1500

Only)

F74 –10 Amp Red Backup Alarm – If Equipped (HD Only)

F75 –10 Amp RedATMM / Coil-SCR Module RLY– If Equipped (HD Only)

Coolant Temperature Valve – If Equipped (DS 1500 Only)

F76 –10 Amp RedElectronic Stability Control (HD Only)

Brake System Module / Stop Lamp Switch / Electric Park

Brake / Clutch Pedal Switch (DS 1500 Only)

F77 –10 Amp RedDrivetrain Control Module / Front Axle Disconnect Module

/ TCM/ STOM (HD Only)

Drivetrain Control Module / ELSD / Front Axle Disconnect

Module / Transmission Control Relay / RDM / Power Take

Off Unit – If Equipped (DS 1500 Only)

Cavity

Cartridge Fuse Micro Fuse Description

6

20_DJD2_OM_EN_USC_t.book Page 359

Page 366 of 553

364IN CASE OF EMERGENCY

1. Connect the positive

(+) end of the jumper

cable to the positive (+)

post of the

discharged vehicle.

NOTE:

Do not jump off fuses. Only jump directly off

positive post.

2. Connect the opposite end of the positive (+)

jumper cable to the positive (+) post of the

booster battery.

3. Connect the negative (-) end of the jumper

cable to the negative (-) post of the booster

battery.

4. Connect the opposite end of the negative (-)

jumper cable to a good engine ground

(exposed metal part of the discharged vehicle’s engine) away from the battery and

the fuel injection system.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, remove the jumper cables in the reverse sequence. Disconnecting The Jumper Cables

1. Disconnect the negative

(-)

end of the

jumper cable from the engine ground of

the vehicle with the discharged battery.

2. Disconnect the opposite end of the negative (-) jumper cable from the negative (-) post of

the booster battery.

3. Disconnect the positive (+) end of the

jumper cable from the positive (+) post of

the booster battery.

4. Disconnect the opposite end of the positive (+) jumper cable from the positive (+) post

of the vehicle with the discharged battery.

If frequent jump starting is required to start your

vehicle you should have the battery and

charging system inspected at an authorized

dealer.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause the

battery to explode and could result in

personal injury. Only use the specific ground

point, do not use any other exposed metal

parts.

CAUTION!

Do not connect jumper cable to any of the

fuses on the positive battery terminal. The

resulting electrical current will blow the fuse.

20_DJD2_OM_EN_USC_t.book Page 364

Page 382 of 553

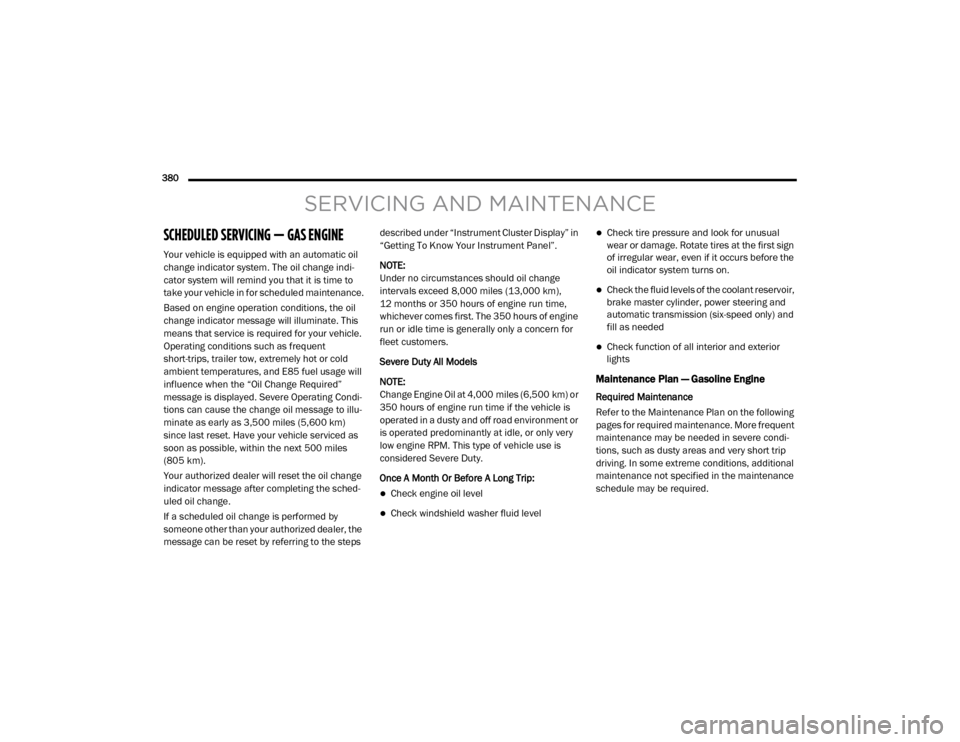

380

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GAS ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indi-

cator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will

influence when the “Oil Change Required”

message is displayed. Severe Operating Condi-

tions can cause the change oil message to illu -

minate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles

(805 km).

Your authorized dealer will reset the oil change

indicator message after completing the sched -

uled oil change.

If a scheduled oil change is performed by

someone other than your authorized dealer, the

message can be reset by referring to the steps described under “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel”.

NOTE:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

NOTE:

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominantly at idle, or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, power steering and

automatic transmission (six-speed only) and

fill as needed

Check function of all interior and exterior

lights

Maintenance Plan — Gasoline Engine

Required Maintenance

Refer to the Maintenance Plan on the following

pages for required maintenance. More frequent

maintenance may be needed in severe condi

-

tions, such as dusty areas and very short trip

driving. In some extreme conditions, additional

maintenance not specified in the maintenance

schedule may be required.

20_DJD2_OM_EN_USC_t.book Page 380

Page 386 of 553

384SERVICING AND MAINTENANCE

Heavy Duty Use Of The Vehicle

Change engine oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominately at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

SCHEDULED SERVICING— DIESEL ENGINE

Required Maintenance Intervals

Refer to the maintenance plan on the following

pages for the required maintenance intervals.

More frequent maintenance may be needed in

severe conditions, such as dusty areas and very

short trip driving. In some extreme conditions,

additional maintenance not specified in the

maintenance schedule may be required.

At Each Stop For Fuel

Check the engine oil level at least 30 minutes

after a fully warmed engine is shut off. Checking

the oil level while the vehicle is on level ground

will improve the accuracy of the oil level

reading. Add oil only when the level is at or

below the ADD or MIN mark. Once A Month

Inspect the batteries, and clean and tighten

the terminals as required.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and automatic trans-

mission, and add as needed.

At Each Oil Change

Change the engine oil filter.

Inspect the exhaust system.

Inspect engine air filter. Replace the engine

air filter cleaner, if necessary.

Inspect the CV/Universal joints.

Check the coolant level, hoses, and clamps.

Inspect front end, and lubricate — If equipped

with serviceable fittings.

Inspect and replace the Evaporative System

Fresh Air Filter as necessary, replacement

may be more frequent if vehicle is operated

in extreme dusty conditions.

WARNING!

You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge and

the right equipment. If you have any doubt

about your ability to perform a service job,

take your vehicle to a competent mechanic.

Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an acci -

dent.

CAUTION!

Failure to perform the required maintenance

items may result in damage to the vehicle.

20_DJD2_OM_EN_USC_t.book Page 384

Page 387 of 553

SERVICING AND MAINTENANCE385

Inspection and service should also be

performed anytime a malfunction is observed or

suspected. Retain all receipts.

NOTE:

Using white lithium grease, lubricate the door

hinge pivot joints twice a year to prevent prema-

ture wear.

Oil Change Indicator System — Cummins

Diesel

Your vehicle is equipped with an engine oil

change indicator system. This system will alert

you when it is time to change your engine oil by

displaying the words “Oil Change Due” in your

instrument cluster display. The oil change

reminder will remind the owner to change the

engine oil every 15,000 miles (24,000 km) or

500 hours, whichever comes first, except for the

Chassis Cab models configured with optional

B20 capability that are using greater than 5%

levels of biodiesel, which are 12,500 miles

(20,000 km) or 400 hours, whichever comes

first. Failure to change the engine oil per the

maintenance schedule can result in internal

engine damage. Your authorized dealer will reset the oil change

indicator message after completing the sched

-

uled oil change. If a scheduled oil change is

performed by someone other than your autho -

rized dealer, the message can be reset by refer -

ring to the steps described under “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

Replace the engine oil and oil filter every

15,000 miles (24,000 km) or 12 months, or

sooner if prompted by the oil change indicator

system. Under no circumstances should oil

change intervals exceed 15,000 miles

(24,000 km) or 12 months, whichever comes

first.

NOTE:

Under no circumstances should oil change

intervals exceed 15,000 miles (24,000 km)

or 12 months or 500 hours, whichever

comes first.

Replace the engine oil and oil filter every

12,500 miles (20,000 km) or 400 hours,

whichever comes first when running greater

than 5% levels of biodiesel (Chassis Cab

models configured with optional B20 capa -

bility). If Chassis Cab models configured with optional

B20 capability are operated with greater than

5% levels of biodiesel, the oil change interval

must not exceed 12,500 miles (20,000 km) or

400 hours, whichever comes first under any

circumstances. See the Fuel Requirements

section for more information regarding opera

-

tion with biodiesel blend (B6-B20) fuel meeting

ASTM specification D-7467.

Perform Service Indicator — Cummins

Diesel

Your vehicle will require emissions mainte -

nance at a set interval. To help remind you

when this maintenance is due, the instrument

cluster will display “Perform Service”. When the

“Perform Service” message is displayed on the

instrument cluster it is necessary to have the

emissions maintenance performed. Emissions

maintenance may include replacing the Closed

Crankcase Ventilation (CCV) filter element. The

procedure for clearing and resetting the

“Perform Service” indicator message is located

in the appropriate Service Information.

7

20_DJD2_OM_EN_USC_t.book Page 385

Page 390 of 553

388SERVICING AND MAINTENANCE

Replace engine fuel filter

element. X X X X X X X X X X

Replace chassis mounted fuel

filter element. X X X X X X X X X X

Inspect the front and rear axle

surfaces. If gear oil leakage is

suspected, check the fluid level.

If using your vehicle for police,

taxi, fleet, off-road or frequent

trailer towing change the axle

fluid.

3

Inspect the transfer case fluid

(4x4), change for any of the

following: police, taxi, fleet, or

frequent trailer towing. X

XXX X

Change the transfer case fluid

(4x4). X

X

Mileage or time passed

(whichever comes first):

7,500

15,000

22,500

30,000

37,500

45,000

52,500

60,000

67,500

75,000

82,500

90,000

97,500

105,000

112,500

120,000

127,500

135,000

142,500

150,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

Or Kilometers:

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

192,000

204,000

216,000

228,000

240,000

20_DJD2_OM_EN_USC_t.book Page 388

Page 396 of 553

394SERVICING AND MAINTENANCE

Checking Oil Level — Gas Engine

To ensure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals, such as every fuel stop. The best time

to check the engine oil level is about five

minutes after a fully warmed up engine is shut

off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings. Always maintain the oil level within

the SAFE zone on the dipstick. Adding one quart

of oil when the reading is at the bottom of the

SAFE zone will result in a reading at the top of

the safe zone on these engines.

Checking Oil Level — Diesel Engine

To ensure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals. The best time to check the oil level is

before starting the engine after it has been parked overnight. When checking oil after oper

-

ating the engine, first ensure the engine is at full

operating temperature, then wait for

30 minutes after engine shutdown to check the

oil.

Engine Oil Dipstick

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings. Add oil only when the level on the

dipstick is below the “ADD” mark. The total

capacity from the ADD mark to the Full mark is

2 qts (1.9L). Never operate the engine with oil level below

the “ADD” mark or above the upper “SAFE”

mark.

Adding Washer Fluid

The fluid reservoir is located under the hood

and should be checked for fluid level at regular

intervals. Fill the reservoir with windshield

washer solvent only (not radiator antifreeze).

When refilling the washer fluid reservoir, take

some washer fluid and apply it to a cloth or

towel and wipe the wiper blades clean. This will

help blade performance.

To prevent freeze-up of your windshield washer

system in cold weather, select a solution or

mixture that meets or exceeds the temperature

range of your climate. This rating information

can be found on most washer fluid containers.

CAUTION!

Overfilling or underfilling will cause oil

aeration or loss of oil pressure. This could

damage your engine.

1 — ADD Range

2 — Full Mark

3 — SAFE Range

CAUTION!

Overfilling or underfilling the crankcase will

cause oil aeration or loss of oil pressure. This

could damage your engine.

20_DJD2_OM_EN_USC_t.book Page 394

Page 405 of 553

SERVICING AND MAINTENANCE403

Accessory Drive Belt Inspection

When inspecting accessory drive belts, small

cracks that run across ribbed surface of belt

from rib to rib, are considered normal. These

are not a reason to replace belt. However,

cracks running along a rib (not across) are not

normal. Any belt with cracks running along a rib

must be replaced. Also have the belt replaced if

it has excessive wear, frayed cords or severe

glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has sepa -

rated from belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between

two ribs)

Belt slips

“Groove jumping" (belt does not maintain

correct position on pulley)

Belt broken (note: identify and correct

problem before new belt is installed)

Noise (objectionable squeal, squeak, or

rumble is heard or felt while drive belt is in

operation) Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools, we recommend having your

vehicle serviced at an authorized dealer.

Draining Fuel/Water Separator Filter —

Diesel Engine

There are two fuel filter assemblies. One is

located on the driver's side of the engine. The

best access to this water drain valve is from

under the hood. The second one is on the under

body, located in front of the rear axle above the

drive shaft on pick-up models. The Chassis Cab

models second filter location is on the frame

behind the front axle. The best access to this

water drain valve is from under the vehicle.

WARNING!

Do not attempt to inspect an accessory

drive belt with vehicle running.

When working near the radiator cooling fan,

disconnect the fan motor lead. The fan is

temperature controlled and can start at any

time regardless of ignition mode. You could

be injured by the moving fan blades.

You can be badly injured working on or

around a motor vehicle. Only do service

work for which you have the knowledge and

the proper equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a compe

-

tent mechanic.

CAUTION!

Do not drain the fuel/water separator filter

when the engine is running.

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

7

20_DJD2_OM_EN_USC_t.book Page 403