light Ram 3500 2014 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2014, Model line: 3500, Model: Ram 3500 2014Pages: 360, PDF Size: 2.02 MB

Page 86 of 360

Trailer Brake Status Indicator Light

This light indicates the trailer electrical connection status.

If no electrical connection is detected after the ignition is

turned on, pressing the GAIN adjustment button or

sliding the manual brake control lever will display the

GAIN setting for 10 seconds and the “Trailer Brake Status

Indicator Light” will not be displayed.

If a fault is detected in the trailer wiring or the Integrated

Trailer Brake Module (ITBM), the “Trailer Brake Status

Indicator Light” will flash.

GAIN Adjustment Buttons (+/-)

Pressing these buttons will adjust the brake control

power output to the trailer brakes in 0.5 increments. The

GAIN setting can be increased to a maximum of 10 or

decreased to a minimum of 0 (no trailer braking).GAIN

The GAIN setting is used to set the trailer brake control

for the specific towing condition and should be changed

as towing conditions change. Changes to towing condi-

tions include trailer load, vehicle load, road conditions

and weather.

Adjusting GAIN

NOTE:This should only be performed in a traffic free

environment at speeds of approximately 20–25 mph

(30–40 km/h).

1. Make sure the trailer brakes are in good working

condition, functioning normally and properly ad-

justed. See your trailer dealer if necessary.

2. Hook up the trailer and make the electrical connec-

tions according to the trailer manufacturer’s instruc-

tions.

84 STARTING AND OPERATING

Page 87 of 360

3. When a trailer with electric/EOH brakes is plugged

in, the trailer connected message should appear in the

EVIC (if the connection is not recognized by the ITBM,

braking functions will not be available), the GAIN

setting will illuminate and the correct type of trailer

must be selected from the EVIC options.

4. Press the UP or DOWN button on the steering wheel

until “TRAILER TOW” appears on the screen.

5. Press the RIGHT arrow on the steering wheel to enter

“TRAILER TOW”.

6. Press the UP or DOWN buttons until Trailer Brake

Type appears on the screen.

NOTE: 1500 Models Only— Light Electric and Heavy

Electric will only be available due to the tow capacities of

the vehicle.7. Press the RIGHT arrow and then press the UP or

DOWN buttons until the proper Trailer Brake Type

appears on the screen.

8. In a traffic-free environment, tow the trailer on a dry,

level surface at a speed of 20–25 mph (30–40 km/h)

and squeeze the manual brake control lever com-

pletely.

9. If the trailer wheels lockup (indicated by squealing

tires), reduce the GAIN setting; if the trailer wheels

turn freely, increase the GAIN setting.

Repeat steps 8 and 9 until the GAIN setting is at a point

just below trailer wheel lockup. If towing a heavier

trailer, trailer wheel lockup may not be attainable even

with the maximum GAIN setting of 10.

4

STARTING AND OPERATING 85

Page 88 of 360

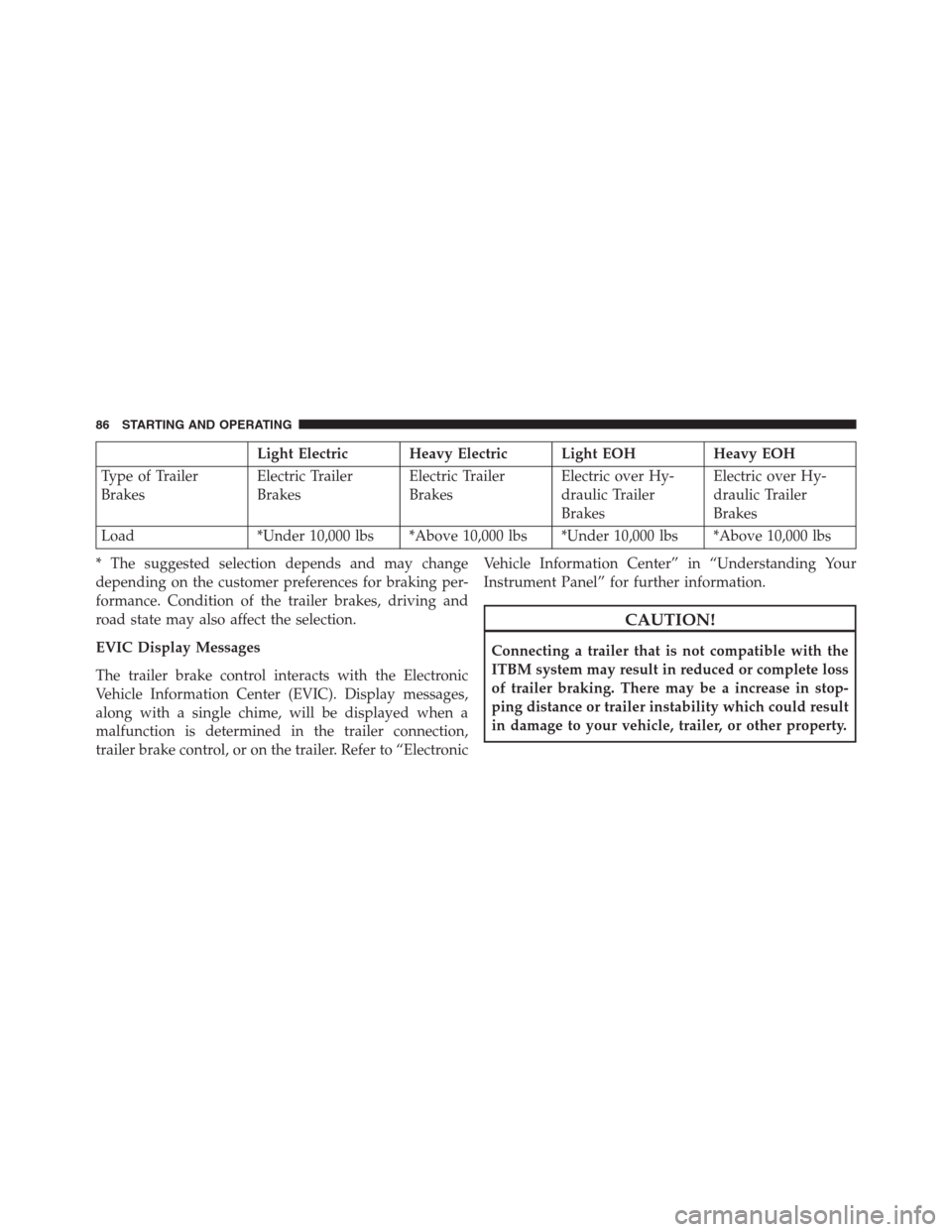

Light Electric Heavy Electric Light EOH Heavy EOH

Type of Trailer

BrakesElectric Trailer

BrakesElectric Trailer

BrakesElectric over Hy-

draulic Trailer

BrakesElectric over Hy-

draulic Trailer

Brakes

Load *Under 10,000 lbs *Above 10,000 lbs *Under 10,000 lbs *Above 10,000 lbs

* The suggested selection depends and may change

depending on the customer preferences for braking per-

formance. Condition of the trailer brakes, driving and

road state may also affect the selection.

EVIC Display Messages

The trailer brake control interacts with the Electronic

Vehicle Information Center (EVIC). Display messages,

along with a single chime, will be displayed when a

malfunction is determined in the trailer connection,

trailer brake control, or on the trailer. Refer to “ElectronicVehicle Information Center” in “Understanding Your

Instrument Panel” for further information.

CAUTION!

Connecting a trailer that is not compatible with the

ITBM system may result in reduced or complete loss

of trailer braking. There may be a increase in stop-

ping distance or trailer instability which could result

in damage to your vehicle, trailer, or other property.

86 STARTING AND OPERATING

Page 89 of 360

WARNING!

Connecting a trailer that is not compatible with the

ITBM system may result in reduced or complete loss

of trailer braking. There may be a increase in stop-

ping distance or trailer instability which could result

in personal injury.

NOTE:

•An aftermarket controller may be available for use

with trailers with air or electric-over-hydraulic trailer

brake systems. To determine the type of brakes on

your trailer and the availability of controllers, check

with your trailer manufacturer or dealer.

•Removal of the ITBM will cause errors and it may

cause damage to the electrical system and electronic

modules of the vehicle. See your authorized dealer if

an aftermarket module is to be installed.

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-

pin wiring harness. Use a factory approved trailer har-

ness and connector.

NOTE:Do not cut or splice wiring into the vehicles

wiring harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector.

Refer to the following illustrations.

4

STARTING AND OPERATING 87

Page 91 of 360

Towing Tips

Before setting out on a trip, practice turning, stopping

and backing the trailer up in an area away from heavy

traffic.

Automatic Transmission

The DRIVE range can be selected when towing. The

transmission controls include a drive strategy to avoid

frequent shifting when towing. However, if frequent

shifting does occur while in DRIVE, select TOW/HAUL

mode or select a lower gear range (using the Electronic

Range Select (ERS) shift control).

NOTE:Using TOW/HAUL mode or selecting a lower

gear range (using the ERS shift control) while operating

the vehicle under heavy loading conditions will improve

performance and extend transmission life by reducing

excessive shifting and heat build up. This action will also

provide better engine braking.When towing a loaded trailer up steep grades at low

speeds (20 mph [32 km/h] or below), holding your

vehicle in first gear (using the ERS shift control) can help

to avoid transmission overheating.

Tow/Haul Mode

To reduce potential for automatic transmission overheat-

ing, activate TOW/HAUL mode when driving in hilly

areas, or select a lower gear range (using the Electronic

Range Select (ERS) shift control) on more severe grades.

Electronic Speed Control — If Equipped

•Do not use in hilly terrain or with heavy loads.

•When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

•Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

4

STARTING AND OPERATING 89

Page 96 of 360

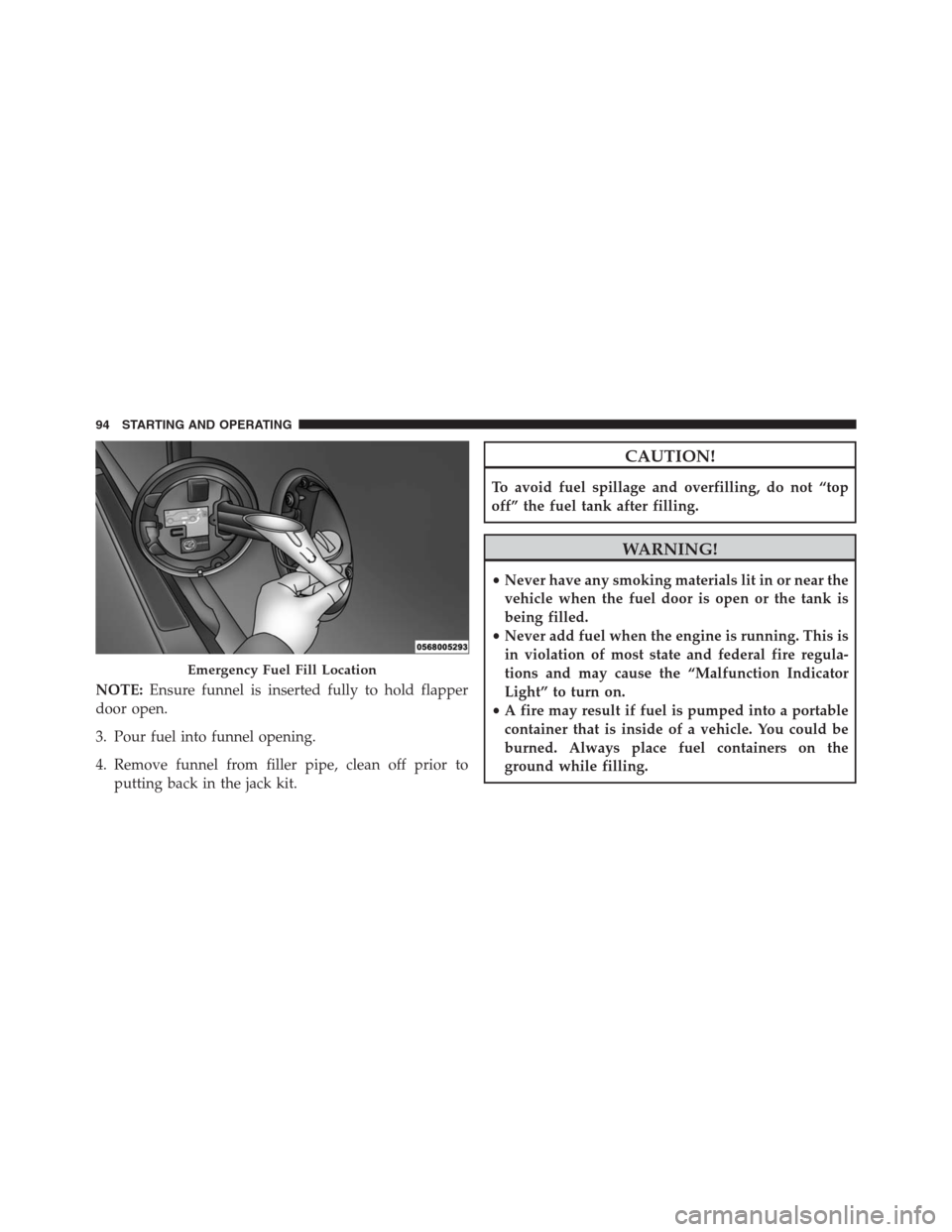

NOTE:Ensure funnel is inserted fully to hold flapper

door open.

3. Pour fuel into funnel opening.

4. Remove funnel from filler pipe, clean off prior to

putting back in the jack kit.

CAUTION!

To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

•Never have any smoking materials lit in or near the

vehicle when the fuel door is open or the tank is

being filled.

•Never add fuel when the engine is running. This is

in violation of most state and federal fire regula-

tions and may cause the “Malfunction Indicator

Light” to turn on.

•A fire may result if fuel is pumped into a portable

container that is inside of a vehicle. You could be

burned. Always place fuel containers on the

ground while filling.

Emergency Fuel Fill Location

94 STARTING AND OPERATING

Page 105 of 360

mark. The total capacity from the MIN mark to the MAX

mark is 1.3 qts (1.2 L).

CAUTION!

Overfilling or underfilling the crankcase will cause

oil aeration or loss of oil pressure. This could damage

your engine.

NOTE:It is possible for your oil level to be slightly

higher than a previous check. This would be due to diesel

fuel that may temporarily be in the crankcase due to

operation of the diesel particulate filter regeneration

strategy. This fuel will evaporate out under normal

operation.

Never operate the engine with oil level below the “MIN”

mark or above the upper “MAX” mark.

Change Engine Oil

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Engine Oil Viscosity (SAE Grade)

CAUTION!

Your vehicle is equipped with an advanced technol-

ogy Diesel Engine and an emission device designed

to limit Diesel Particulate Emissions from being

released into the atmosphere. The durability of your

engine and life expectancy of this diesel particulate

filter emission device is highly dependent on the use

of the correct engine oil.

5

MAINTAINING YOUR VEHICLE 103

Page 108 of 360

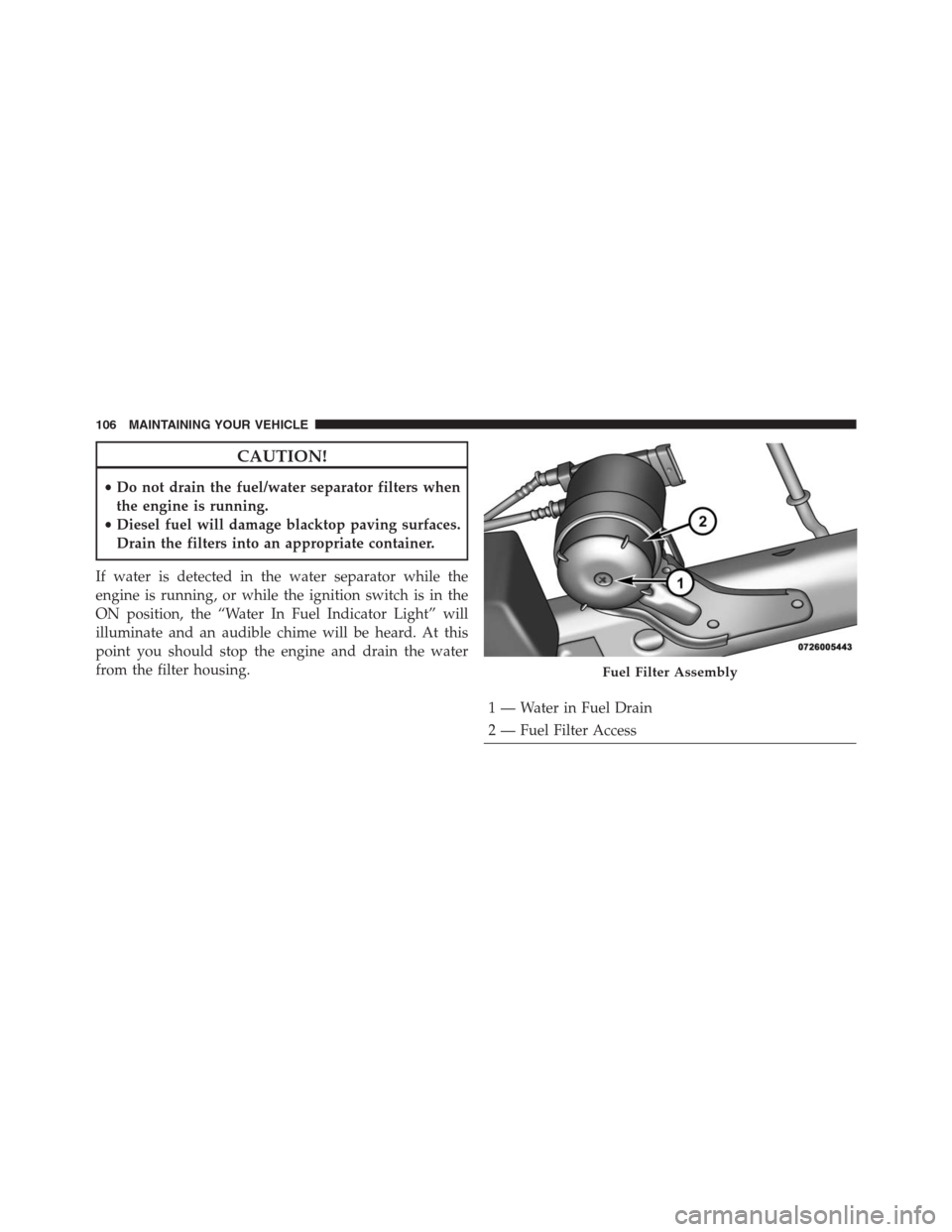

CAUTION!

•Do not drain the fuel/water separator filters when

the engine is running.

•Diesel fuel will damage blacktop paving surfaces.

Drain the filters into an appropriate container.

If water is detected in the water separator while the

engine is running, or while the ignition switch is in the

ON position, the “Water In Fuel Indicator Light” will

illuminate and an audible chime will be heard. At this

point you should stop the engine and drain the water

from the filter housing.

1 — Water in Fuel Drain

2 — Fuel Filter Access

Fuel Filter Assembly

106 MAINTAINING YOUR VEHICLE

Page 109 of 360

CAUTION!

If the “Water In Fuel Indicator Light” remains on, DO

NOT START the engine before you drain water from

the fuel filters to avoid engine damage.

If the “Water In Fuel Indicator Light” comes on and a

single chime is heard while you are driving, or with the

ignition in the ON position, there may be a problem with

your water separator wiring or sensor. See your autho-

rized dealer for service.

Upon proper draining of the water from the fuel filter, the

“Water In Fuel Indicator Light” will remain illuminated

for approximately 10 seconds. If the water was drained

while the engine was running, the “Water In Fuel Indi-

cator Light” may remain on for approximately three

minutes.NOTE:Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately dis-

carded, can present a problem to the environment. Con-

tact an authorized dealer, service station, or government

agency for advice on recycling programs and for where

used fluids and filters can be properly disposed of in

your area.

Drain the fuel/water separator filter when the “Water In

Fuel Indicator Light” is ON. Within 10 minutes of vehicle

shutdown, turn the filter drain valve (located on the

bottom of the filter housing) counterclockwise to drain

fuel/water, then turn the ignition switch to the ON

position, and allow any accumulated water to drain.

Leave the drain valve open until all water and contami-

nants have been removed. When clean fuel is visible,

close the drain valve by turning it clockwise, and turn the

ignition switch to OFF.

5

MAINTAINING YOUR VEHICLE 107

Page 120 of 360

•Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

•Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

•Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine coolant (antifreeze)

performance, poor gas mileage, and increased emis-

sions.

Charge Air Cooler — Inter-Cooler

The charge air cooler is positioned in front of the radiator

and the air conditioner condenser. Air enters the engine

through the air cleaner and passes through the turbo-

charger, where it is pressurized. This pressurized air

rapidly reaches high temperature. The air is then directed

through a hose to the charge air cooler and throughanother hose to the intake manifold of the engine. This

cooling process enables more efficient burning of fuel

resulting in fewer emissions.

To guarantee optimum performance of the system, keep

the surfaces of the charge air cooler, condenser and

radiator clean and free of debris. Periodically check the

hoses leading to and from the charge air cooler for cracks

or loose clamps resulting in loss of pressure and reduced

engine performance.

Brake System

Brake Master Cylinder — Brake Fluid Level Check

The fluid level of the master cylinder should be checked

when performing under the hood service, or immedi-

ately if the “Brake System Warning Light” indicates

system failure.

The brake master cylinder has a translucent plastic

reservoir. On the outboard side of the reservoir, there is a

118 MAINTAINING YOUR VEHICLE