Ram 3500 2016 Owner's Manual

Manufacturer: RAM, Model Year: 2016,

Model line: 3500,

Model: Ram 3500 2016

Pages: 919, PDF Size: 6.67 MB

Ram 3500 2016 Owner's Manual

3500 2016

Ram

Ram

https://www.carmanualsonline.info/img/34/12586/w960_12586-0.png

Ram 3500 2016 Owner's Manual

Trending: oil dipstick, bulb, remove seats, rear view mirror, catalytic converter, change wheel, clock setting

Page 761 of 919

WARNING!(Continued)

•If working on or near a roadway, be extremely

careful of motor traffic.

• To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

Jack Warning Label

Lug Wrench Adaptor Shown In Jack And Tools

Assembly

6

WHAT TO DO IN EMERGENCIES 759

Page 762 of 919

1. Remove the spare wheel, jack, and tools from storage.

2. Using the lug wrench, loosen, but do not remove, thewheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground. Changing

a dually tire requires the lug wrench adapter.

NOTE: If your vehicle is equipped with hub caps/wheel

covers they must be removed before raising the vehicle

off the ground. Refer to ”Hub Caps/Wheel Covers — If

Equipped” in this section.

Lug Wrench Adapter

760 WHAT TO DO IN EMERGENCIES

Page 763 of 919

3. Placement of the jack:

Front Jacking Location

When changing the front wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle as close tothe tire as possible with the drive tubes extending to the

front. Connect the jack tube extension and wheel wrench.

Rear Jacking Location

When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

Lug Wrench Adapter And Wrench

Front Jacking Location

6

WHAT TO DO IN EMERGENCIES 761

Page 764 of 919

extension tube. Place the jack under the axle between the

spring and the shock absorber with the drive tubes

extending to the rear.

Connect the jack tube extension and wheel wrench.CAUTION!

Before raising the wheel off the ground, make sure

that the jack will not damage surrounding truck parts

and adjust the jack position as required.

NOTE: If the bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to use the

jack drive tube in order to lower the jack.

4. By rotating the wheel wrench clockwise, raise the vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

Rear Jacking Location

762 WHAT TO DO IN EMERGENCIES

Page 765 of 919

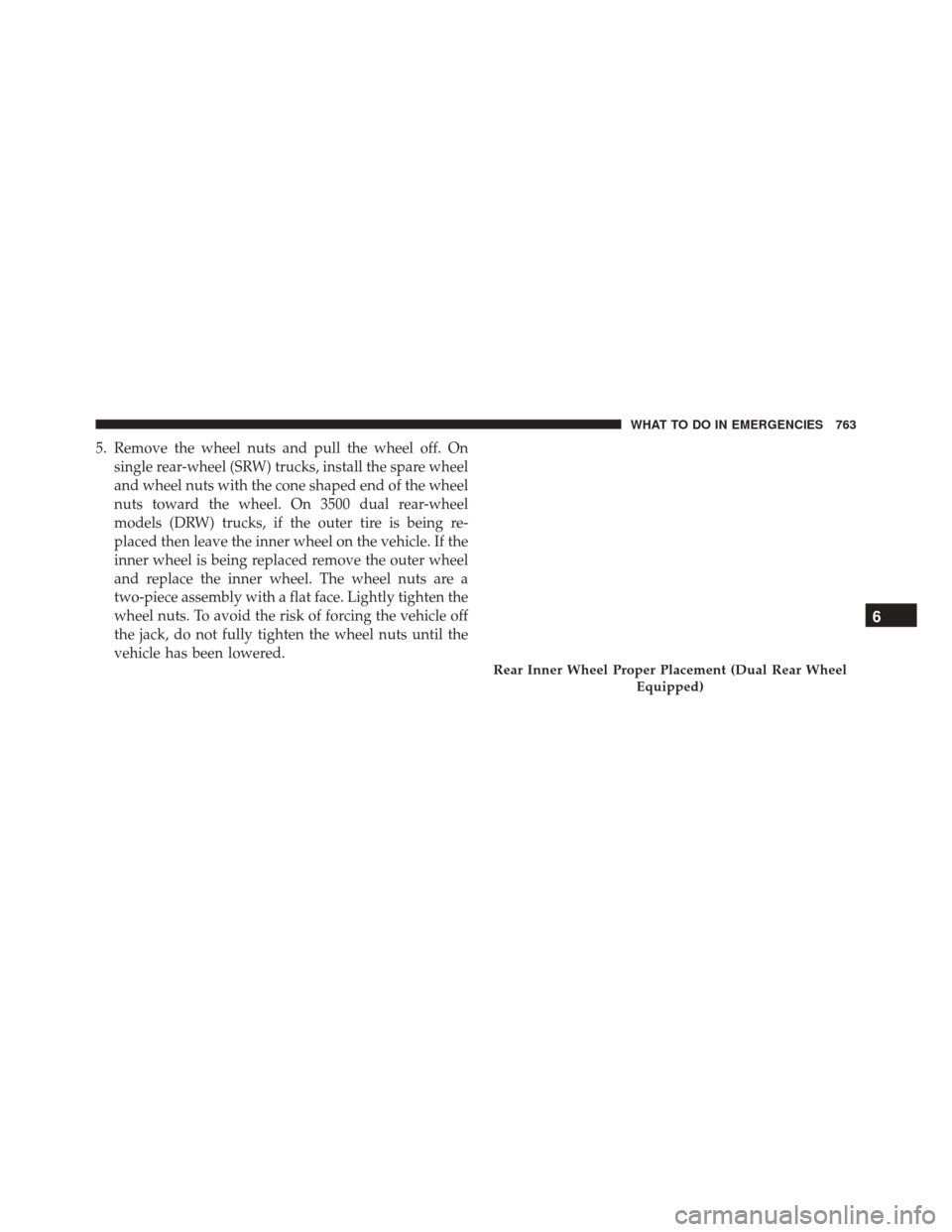

5. Remove the wheel nuts and pull the wheel off. Onsingle rear-wheel (SRW) trucks, install the spare wheel

and wheel nuts with the cone shaped end of the wheel

nuts toward the wheel. On 3500 dual rear-wheel

models (DRW) trucks, if the outer tire is being re-

placed then leave the inner wheel on the vehicle. If the

inner wheel is being replaced remove the outer wheel

and replace the inner wheel. The wheel nuts are a

two-piece assembly with a flat face. Lightly tighten the

wheel nuts. To avoid the risk of forcing the vehicle off

the jack, do not fully tighten the wheel nuts until the

vehicle has been lowered.

Rear Inner Wheel Proper Placement (Dual Rear Wheel

Equipped)

6

WHAT TO DO IN EMERGENCIES 763

Page 766 of 919

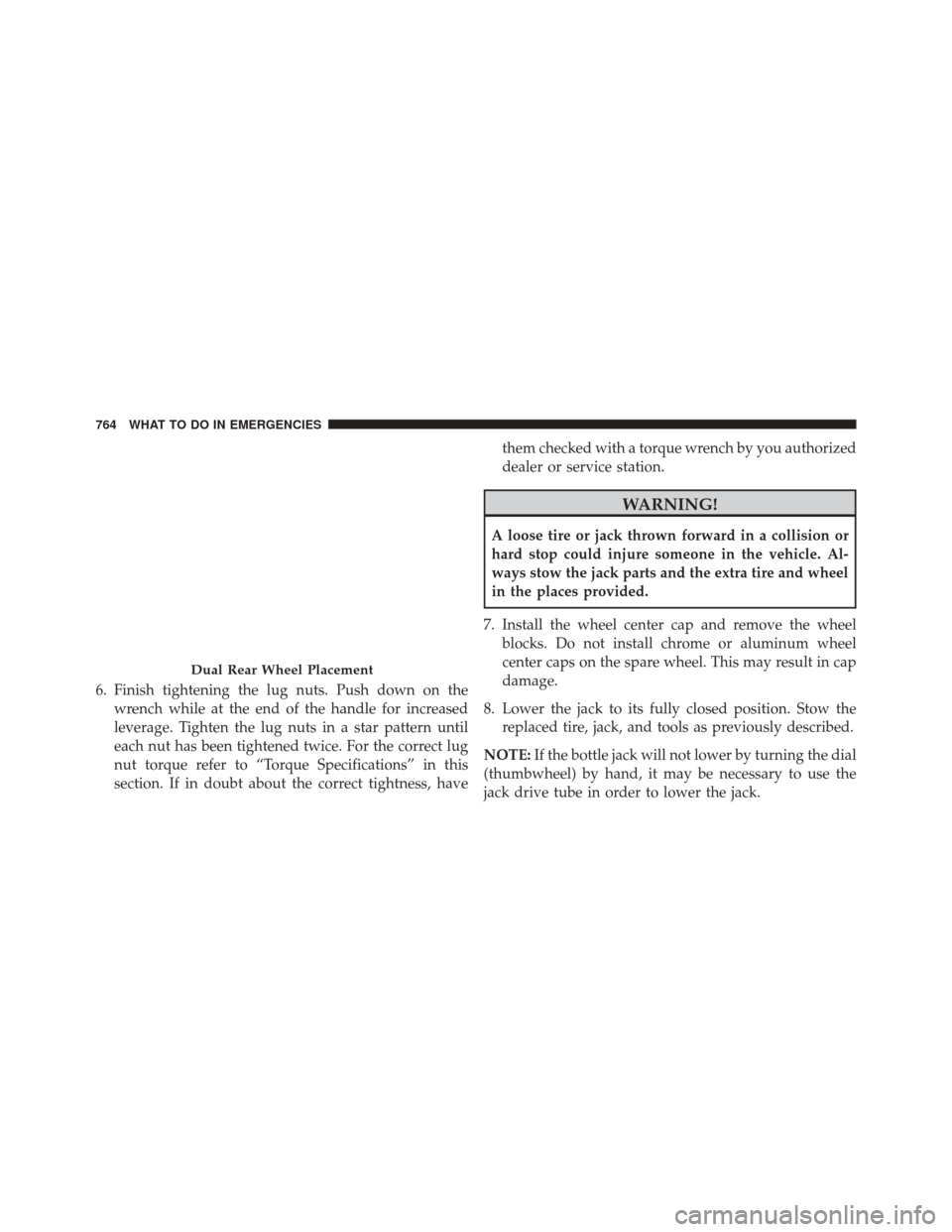

6. Finish tightening the lug nuts. Push down on thewrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. For the correct lug

nut torque refer to “Torque Specifications” in this

section. If in doubt about the correct tightness, have them checked with a torque wrench by you authorized

dealer or service station.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack parts and the extra tire and wheel

in the places provided.

7. Install the wheel center cap and remove the wheel blocks. Do not install chrome or aluminum wheel

center caps on the spare wheel. This may result in cap

damage.

8. Lower the jack to its fully closed position. Stow the replaced tire, jack, and tools as previously described.

NOTE: If the bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to use the

jack drive tube in order to lower the jack.

Dual Rear Wheel Placement

764 WHAT TO DO IN EMERGENCIES

Page 767 of 919

9. Adjust the tire pressure when possible.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

To Stow The Flat Or Spare

NOTE: Have the flat tire repaired or replaced immedi-

ately.

WARNING!

A loose tire thrown forward in a collision or hard

stop could injure the occupants in the vehicle. Have

the deflated (flat) tire repaired or replaced immedi-

ately.

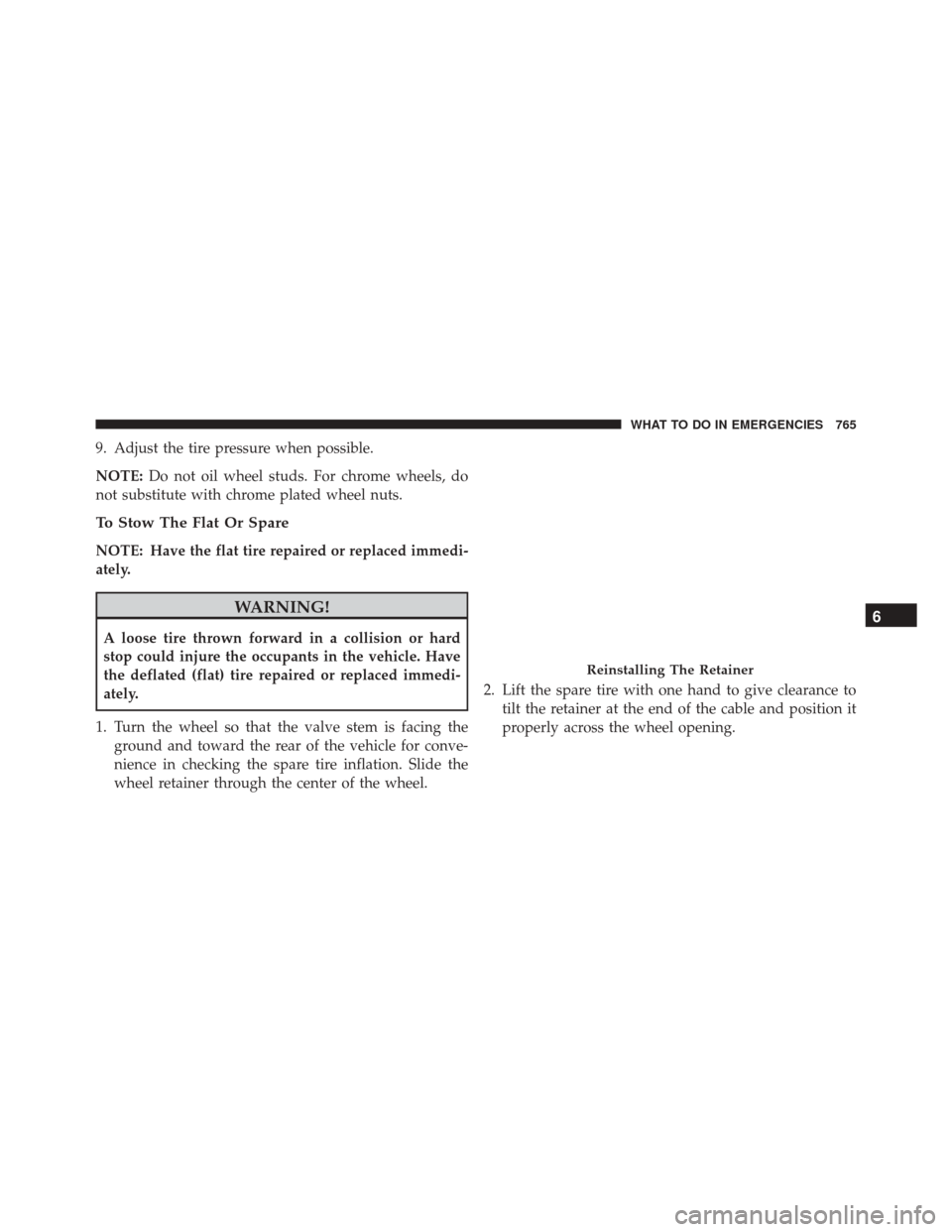

1. Turn the wheel so that the valve stem is facing the ground and toward the rear of the vehicle for conve-

nience in checking the spare tire inflation. Slide the

wheel retainer through the center of the wheel. 2. Lift the spare tire with one hand to give clearance to

tilt the retainer at the end of the cable and position it

properly across the wheel opening.

Reinstalling The Retainer

6

WHAT TO DO IN EMERGENCIES 765

Page 768 of 919

3. Attach the wheel wrench to the jack extension tubewith the curved angle facing away from the vehicle.

Insert the tube through the access hole between the

lower tailgate and the top of the bumper and into the

winch mechanism tube. 4. Rotate the wheel wrench handle clockwise until the

wheel is drawn into place against the underside of the

vehicle. Continue to rotate until you feel the winch

Pushing The Retainer Through The Center Of The

Wheel And Positioning ItWheel Wrench And Jack Extension Tube Assembled And In Position

766 WHAT TO DO IN EMERGENCIES

Page 769 of 919

mechanism slip, or click three or four times. It cannot

be overtightened. Push against the tire several times to

ensure it is firmly in place.NOTE:

The winch mechanism is designed for use with

the jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

Reinstalling The Jack And Tools (2500 And 3500

Series)

1. Tighten the jack all the way down by turning the jack turn-screw counterclockwise until the jack is snug.

2. Position the jack and tools into bracket assembly. Make sure the lug wrench is under the jack near the

jack turn-screw. Snap tools into bracket assembly clips.

Install the jack into bracket assembly and turn the

jack-turn-screw clockwise until jack is snug into

bracket assembly.

Rotating The Wheel Wrench Handle

6

WHAT TO DO IN EMERGENCIES 767

Page 770 of 919

3. Place the jack and tool bracket assembly in the storageposition holding the jack by the jack turn-screw, slip

the jack and tools under the seat so that the bottom slot

engages into the fastener on the floor. NOTE:

Ensure that the jack and tool bracket assembly

slides into the front hold down location.

Jack And Tools Bracket AssemblyJack Hold Down Fastener

768 WHAT TO DO IN EMERGENCIES

Trending: clock, radiator, steering, washer fluid, recommended oil, brakes, child lock