tailgate Ram 3500 2017 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2017, Model line: 3500, Model: Ram 3500 2017Pages: 734, PDF Size: 7.3 MB

Page 220 of 734

4. Rotate the handles to the horizontal position to secureinto place.WARNING!

To reduce the risk of potential injury or property

damage:

•Cargo must be secured.

• Do not exceed cargo load rating of your vehicle.

• Secure all loads to truck utilizing cargo tie downs.

• Extender should not be used as cargo tie down.

• When vehicle is in motion do not exceed 150 lbs

(68 kg) load on the tailgate.

• The bed extender is not intended for off road use.

• When not in use, the extender/divider should be in

stowed or divider position with the tailgate closed.

• When in use all handles are to be in the locked

position.

Locking Tab

218 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 222 of 734

To remove the cleats from the utility rail, remove the end

cap screw located in the center of the end cap, using a #T30

Torx head driver. Remove the end cap and slide the cleat

off the end of the rail.SLIDE-IN CAMPERS

Camper Applications

Certain truck models are not recommended for slide-in

campers. To determine if your vehicle is excluded, please

refer to the “Consumer Information Truck-Camper Load-

ing” document available from your authorized dealer. For

safety reasons, follow all instructions in this important

document.

NOTE:When a cap or pickup camper is installed on a

vehicle, an alternate Center High-Mounted Stop Light

(CHMSL) must be provided.

EASY-OFF TAILGATE

To simplify mounting of a camper unit with an overhang,

the tailgate can be removed.

NOTE: If your vehicle is equipped with a rear camera or

Remote Keyless Entry, the electrical connector must be

disconnected prior to removing the tailgate.

Utility Rail End Cap

220 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 223 of 734

Disconnecting The Rear Camera Or Remote

Keyless Entry — If Equipped

1. Open the tailgate to access the rear camera or RemoteKeyless Entry connector bracket located on the rear sill. 2. Remove the connector bracket from the sill by pushing

inward in the locking tab.

3. Disconnect the chassis wiring harness, ensuring the connector bracket does not fall into the sill.

4. Connect the chassis plug and bracket (provided in the glove compartment) to the chassis wiring harness and

insert the bracket back into the sill.

5. Connect the tailgate plug (provided in the glove com- partment) to the tailgate wiring harness to ensure that

the terminals do not corrode.

Connector Bracket

Locking Tab

3

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 221

Page 224 of 734

6. Tape the tailgate harness and bracket against theforward-facing surface of the tailgate. This will prevent

damaging the connector and bracket when storing or

reinstalling the tailgate.

Removing The Tailgate

1. Disconnect the wiring harness for the rear camera andor power locks (if equipped), refer to “Disconnecting the

Rear Camera — If Equipped” in this section.

2. Unlatch the tailgate and remove the support cables by releasing the lock tang from the pivot.

NOTE: Make sure tailgate is supported when removing

support cables. 3. Position the tailgate on a 45 degree angle.

4. Raise the right side of the tailgate until the right side

pivot clears the hanger bracket.

5. Slide the entire tailgate to the right to free the left side pivot.

6. Remove the tailgate from the vehicle.

NOTE: Do not carry the tailgate loose in the truck pickup

box.

Locking Tang

222 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 225 of 734

WARNING!

To avoid inhaling carbon monoxide, which is deadly,

the exhaust system on vehicles equipped with “Cap or

Slide-In Campers” should extend beyond the over-

hanging camper compartment and be free of leaks.

Locking Tailgate

The lock is located next to the tailgate handle. The tailgate

can be locked using the vehicle key or by locking the truck

with the key fob if equipped with remote keyless entry.

TRI-FOLD TONNEAU COVER — IF EQUIPPED

Your vehicle may be equipped with a Tri-Fold Tonneau

Cover which consists of different features:

•Easy Tri-Fold cover

• Tonneau fore aft locator

• Crosscar inside bed locator

• Front and rear clamps

• Stowage strap

• Locking Capability NOTE:

The Tonneau Cover can be folded up and secured

at the front of the box without removing completely.

Tri-Fold Tonneau Cover Removal

To remove the Tonneau Cover follow the following steps:

1. Lower the tailgate to gain access to the first set of two Tonneau Cover clamps located on the driver and pas-

senger underside of the Tonneau Cover.

Clamped Position

NOTE: If clamp wire is damaged replace immediately.

3

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 223

Page 590 of 734

Removing The Spare Tire

1. Remove the spare tire before attempting to jack up thetruck. Attach the wheel wrench to the jack extension

tube with the curved angle facing away from the

vehicle. Insert the tube through the access hole between

the lower tailgate and the top of the bumper and into the

winch mechanism tube. 2. Rotate the wheel wrench handle counterclockwise until

the spare tire is on the ground with enough cable slack

to allow you to pull it out from under the vehicle.

Inserting The Jack Extension Tube Into The Access Hole

Rotating The Wheel Wrench Handle

588 WHAT TO DO IN EMERGENCIES

Page 599 of 734

2. Lift the spare tire with one hand to give clearance to tiltthe retainer at the end of the cable and position it

properly across the wheel opening. 3. Attach the wheel wrench to the jack extension tube with

the curved angle facing away from the vehicle. Insert the

tube through the access hole between the lower tailgate

and the top of the bumper and into the winch mecha-

nism tube.

Pushing The Retainer Through The Center Of The Wheel

And Positioning It

Wheel Wrench And Jack Extension Tube AssembledAnd In Position

6

WHAT TO DO IN EMERGENCIES 597

Page 606 of 734

WARNING!

After using the jack and tools, always reinstall them in

the original carrier and location. While driving you

may experience abrupt stopping, rapid acceleration or

sharp turns. A loose jack, tools, bracket or other objects

in the vehicle may move around with force, resulting

in serious injury.

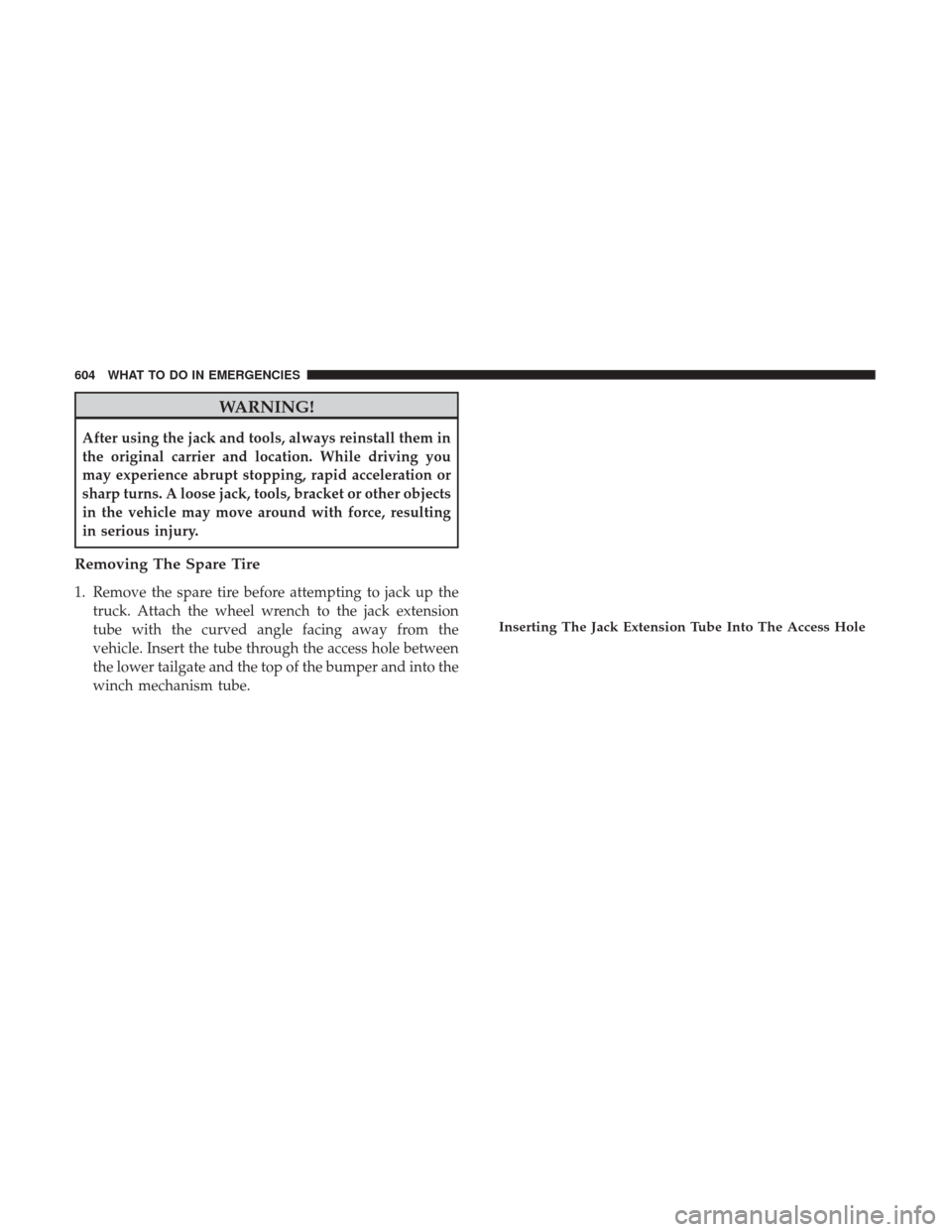

Removing The Spare Tire

1. Remove the spare tire before attempting to jack up thetruck. Attach the wheel wrench to the jack extension

tube with the curved angle facing away from the

vehicle. Insert the tube through the access hole between

the lower tailgate and the top of the bumper and into the

winch mechanism tube.

Inserting The Jack Extension Tube Into The Access Hole

604 WHAT TO DO IN EMERGENCIES

Page 616 of 734

2. Lift the spare tire with one hand to give clearance to tiltthe retainer at the end of the cable and position it

properly across the wheel opening. 3. Attach the wheel wrench to the jack extension tube with

the curved angle facing away from the vehicle. Insert the

tube through the access hole between the lower tailgate

and the top of the bumper and into the winch mecha-

nism tube.

Pushing The Retainer Through The Center Of The Wheel

And Positioning It

Wheel Wrench And Jack Extension Tube AssembledAnd In Position

614 WHAT TO DO IN EMERGENCIES

Page 658 of 734

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should be

lubricated periodically with a lithium based grease, such as

MOPAR Spray White Lube to assure quiet, easy operation

and to protect against rust and wear. Prior to the applica-

tion of any lubricant, the parts concerned should be wiped

clean to remove dust and grit; after lubricating excess oil

and grease should be removed. Particular attention should

also be given to hood latching components to ensure

proper function. When performing other underhood ser-

vices, the hood latch, release mechanism and safety catch

should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as MOPAR Lock

Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use washer

fluid when using the wipers to remove salt or dirt from a

dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending

on geographical area and frequency of use. Poor perfor-

mance of blades may be present with chattering, marks,

water lines or wet spots. If any of these conditions are

present, clean the wiper blades or replace as necessary.

656 MAINTAINING YOUR VEHICLE