battery Ram 3500 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 3500, Model: Ram 3500 2018Pages: 372, PDF Size: 7.1 MB

Page 221 of 372

NOTE:

The positive battery post may be covered with

a protective cap if equipped. Lift up on the

cap to gain access to the positive battery

post. Do not jump off fuses. Only jump di-

rectly off positive post which has a positive

(+)symbol on or around the post.

WARNING!

β’ Take care to avoid the radiator cooling

fan whenever the hood is raised. It can

start anytime the ignition switch is ON.

You can be injured by moving fan blades.

β’ Remove any metal jewelry such as rings,

watch bands and bracelets that could

make an inadvertent electrical contact.

You could be seriously injured.

β’ Batteries contain sulfuric acid that can

burn your skin or eyes and generate

hydrogen gas which is flammable and

explosive. Keep open flames or sparks

away from the battery.

1. Apply the parking brake, shift the auto- matic transmission into PARK and turn

the ignition to LOCK. 2. Turn off the heater, radio, and all unnec-

essary electrical accessories.

3. If using another vehicle to jump start the battery, park the vehicle within the jumper

cables reach, apply the parking brake and

make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other

as this could establish a ground connec-

tion and personal injury could result.

Jump Starting Procedure

WARNING!

Failure to follow this jump starting proce-

dure could result in personal injury or

property damage due to battery explosion.

CAUTION!

Failure to follow these procedures could

result in damage to the charging system of

the booster vehicle or the discharged ve-

hicle.

Connecting The Jumper Cables

1. Connect the positive (+)end of the jumper

cable to the positive (+)post of the dis-

charged vehicle.

NOTE:

Do not jump off fuses. Only jump directly off

positive post.

2. Connect the opposite end of the positive (+) jumper cable to the positive (+)post of

the booster battery.

3. Connect the negative (-)end of the jumper

cable to the negative (-)post of the

booster battery.

4. Connect the opposite end of the negative (-)jumper cable to a good engine ground

(exposed metal part of the discharged

vehicleβs engine) away from the battery

and the fuel injection system.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause

the battery to explode and could result in

219

Page 222 of 372

WARNING!

personal injury. Only use the specific

ground point, do not use any other exposed

metal parts.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a

few minutes, and then start the engine in

the vehicle with the discharged battery.

CAUTION!

Do not connect jumper cable to any of the

fuses on the positive battery terminal. The

resulting electrical current will blow the

fuse.

6. Once the engine is started, remove the jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative (-)end of the

jumper cable from the engine ground of

the vehicle with the discharged battery. 2. Disconnect the opposite end of the nega-

tive (-)jumper cable from the negative (-)

post of the booster battery.

3. Disconnect the positive (+)end of the

jumper cable from the positive (+)post of

the booster battery.

4. Disconnect the opposite end of the posi- tive (+)jumper cable from the positive (+)

post of the vehicle with the discharged

battery.

If frequent jump starting is required to start

your vehicle you should have the battery and

charging system inspected at an authorized

dealer.

CAUTION!

Accessories plugged into the vehicle

power outlets draw power from the vehi-

cleβs battery, even when not in use (i.e.,

cellular devices, etc.). Eventually, if

plugged in long enough without engine

operation, the vehicleβs battery will dis-

charge sufficiently to degrade battery life

and/or prevent the engine from starting.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can

reduce the potential for overheating by taking

the appropriate action.

β’ On the highways β slow down.

β’ In city traffic β while stopped, place the transmission in NEUTRAL, but do not in-

crease the engine idle speed while prevent-

ing vehicle motion with the brakes.

NOTE:

There are steps that you can take to slow

down an impending overheat condition:

β’ If your air conditioner (A/C) is on, turn it off. The A/C system adds heat to the engine

cooling system and turning the A/C off can

help remove this heat.

β’ You can also turn the temperature control to maximum heat, the mode control to floor

and the blower control to high. This allows

the heater core to act as a supplement to

the radiator and aids in removing heat from

the engine cooling system.

IN CASE OF EMERGENCY

220

Page 224 of 372

Center Console Gear Selector β

If Equipped

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Using a small screwdriver or similar tool,remove the gear selector override access

cover (located to the right of the gear

selector).

4. Press and maintain firm pressure on the brake pedal.

5. Insert the screwdriver or similar tool into the access hole, and push and hold the

override release lever down. 6. Move the gear selector to the NEUTRALposition.

7. The vehicle may then be started in NEUTRAL.

8. Reinstall the gear selector override access cover.

MANUAL PARK RELEASE β 8 SPEED

TRANSMISSION

WARNING!

Always secure your vehicle by fully apply-

ing the parking brake before activating the

Manual Park Release. In addition, you

should be seated in the driverβs seat with

your foot firmly on the brake pedal when

activating the Manual Park Release. Acti-

vating the Manual Park Release will allow

your vehicle to roll away if it is not secured

by the parking brake, or by proper connec-

tion to a tow vehicle. Activating the

Manual Park Release on an unsecured

vehicle could lead to serious injury or

death for those in or around the vehicle.

In order to push or tow the vehicle in cases

where the transmission will not shift out of

PARK (such as a dead battery), a Manual

Park Release is available.

Gear Selector Override Access Cover

IN CASE OF EMERGENCY

222

Page 233 of 372

Maintenance Plan β Gasoline

Engine

Required Maintenance

Refer to the Maintenance Plan on the follow-

ing pages for required maintenance.

At Every Oil Change Interval As Indicated By OilChange Indicator System:

β’ Change oil and filter.

β’ Rotate the tires. Rotate at the first sign of

irregular wear, even if it occurs before the oil

indicator system turns on.

β’ Inspect battery and clean and tighten ter- minals as required.

β’ Inspect automatic transmission fluid if equipped with dipstick.

β’ Inspect brake pads, shoes, rotors, drums, hoses and park brake.

β’ Inspect engine cooling system protection and hoses.

β’ Inspect exhaust system.

β’ Inspect engine air cleaner if using in dusty or off-road conditions.

β’ Lube the front drive shaft fitting (2500/ 3500 (4x4) models only).

231

Page 237 of 372

Maintenance Plan β Diesel Fuel

Up To B5 Biodiesel (1500 Diesel)

Required Maintenance

Refer to the Maintenance Schedules on the

following pages for required maintenance.

At Every Oil Change Interval As Indicated By OilChange Indicator System:

β’ Change oil and filter.

β’

Completely fill the Diesel Exhaust Fluid tank.

β’ Drain water from fuel filter assembly.

β’ Rotate the tires. Rotate at the first sign of

irregular wear, even if it occurs before the oil

indicator system turns on.

β’ Inspect battery and clean and tighten ter- minals as required.

β’ Inspect brake pads, shoes, rotors, drums, hoses and park brake.

β’ Inspect engine cooling system protection and hoses.

β’ Inspect exhaust system.

β’ Inspect engine air cleaner if using in dusty or off-road conditions.

At Every Second Oil Change Interval As Indi-cated By Oil Change Indicator System:

β’ Change fuel filter.

235

Page 245 of 372

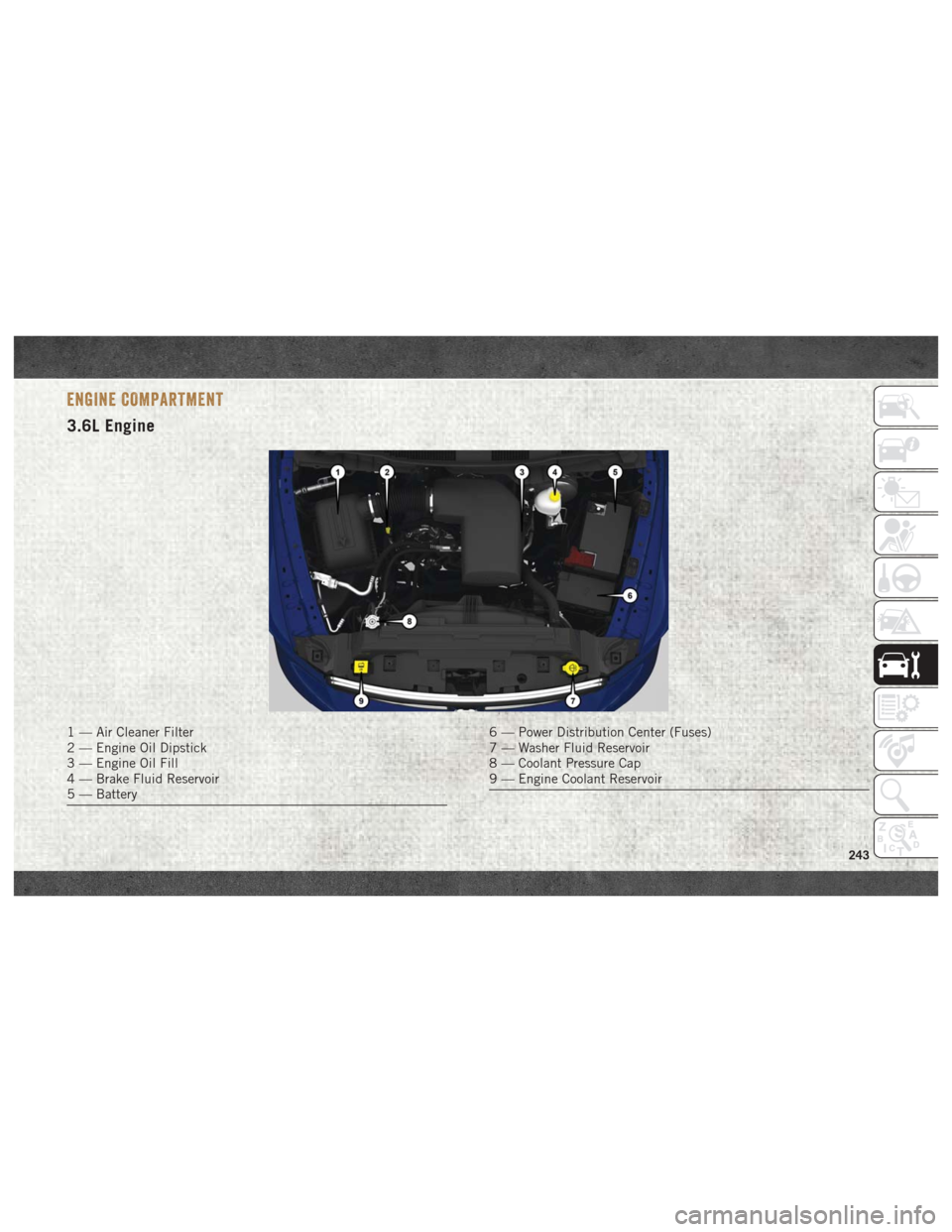

ENGINE COMPARTMENT

3.6L Engine

1 β Air Cleaner Filter

2 β Engine Oil Dipstick

3 β Engine Oil Fill

4 β Brake Fluid Reservoir

5 β Battery6 β Power Distribution Center (Fuses)

7 β Washer Fluid Reservoir

8 β Coolant Pressure Cap

9 β Engine Coolant Reservoir

243

Page 246 of 372

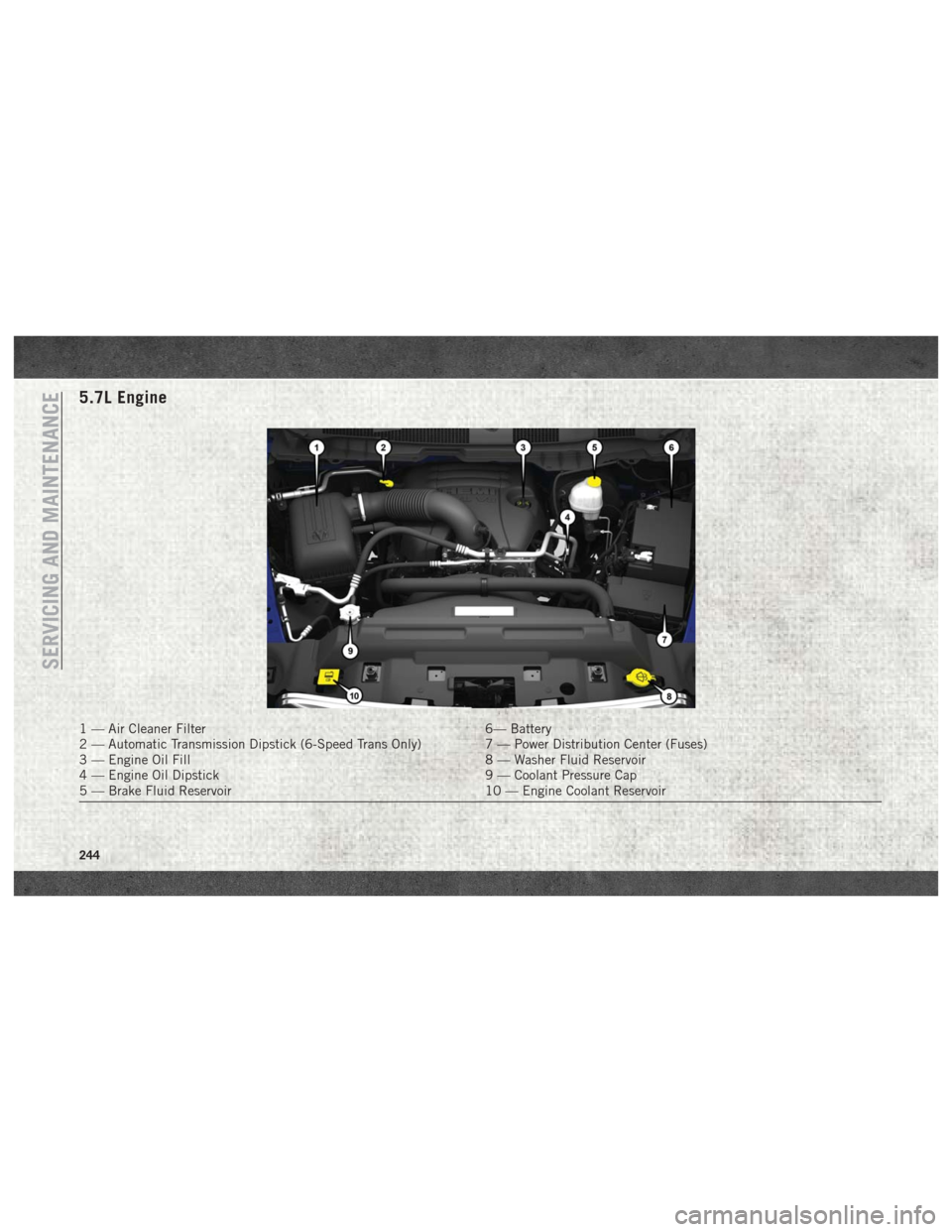

5.7L Engine

1 β Air Cleaner Filter6β Battery

2 β Automatic Transmission Dipstick (6-Speed Trans Only) 7 β Power Distribution Center (Fuses)

3 β Engine Oil Fill 8 β Washer Fluid Reservoir

4 β Engine Oil Dipstick 9 β Coolant Pressure Cap

5 β Brake Fluid Reservoir 10 β Engine Coolant Reservoir

SERVICING AND MAINTENANCE

244

Page 247 of 372

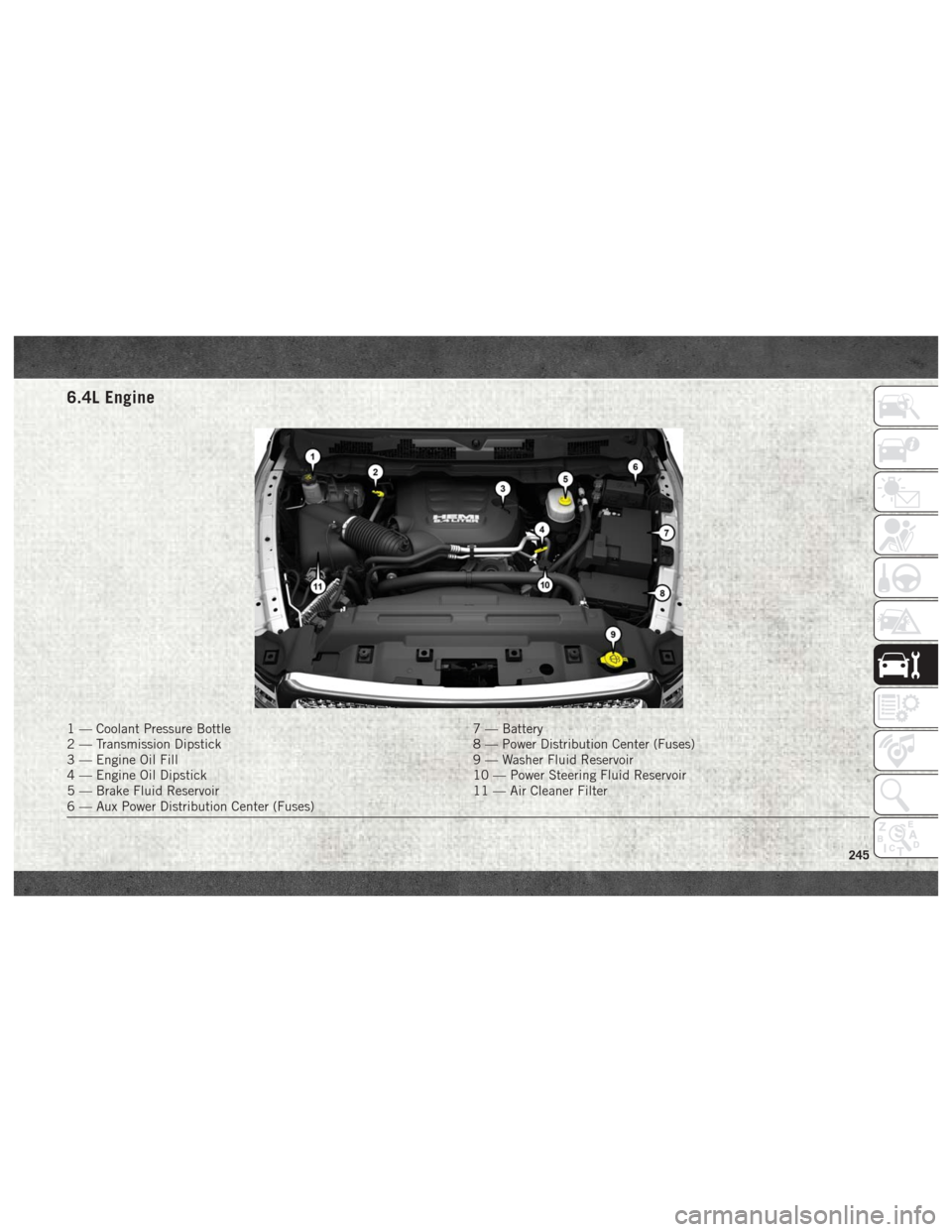

6.4L Engine

1 β Coolant Pressure Bottle7 β Battery

2 β Transmission Dipstick 8 β Power Distribution Center (Fuses)

3 β Engine Oil Fill 9 β Washer Fluid Reservoir

4 β Engine Oil Dipstick 10 β Power Steering Fluid Reservoir

5 β Brake Fluid Reservoir 11 β Air Cleaner Filter

6 β Aux Power Distribution Center (Fuses)

245

Page 248 of 372

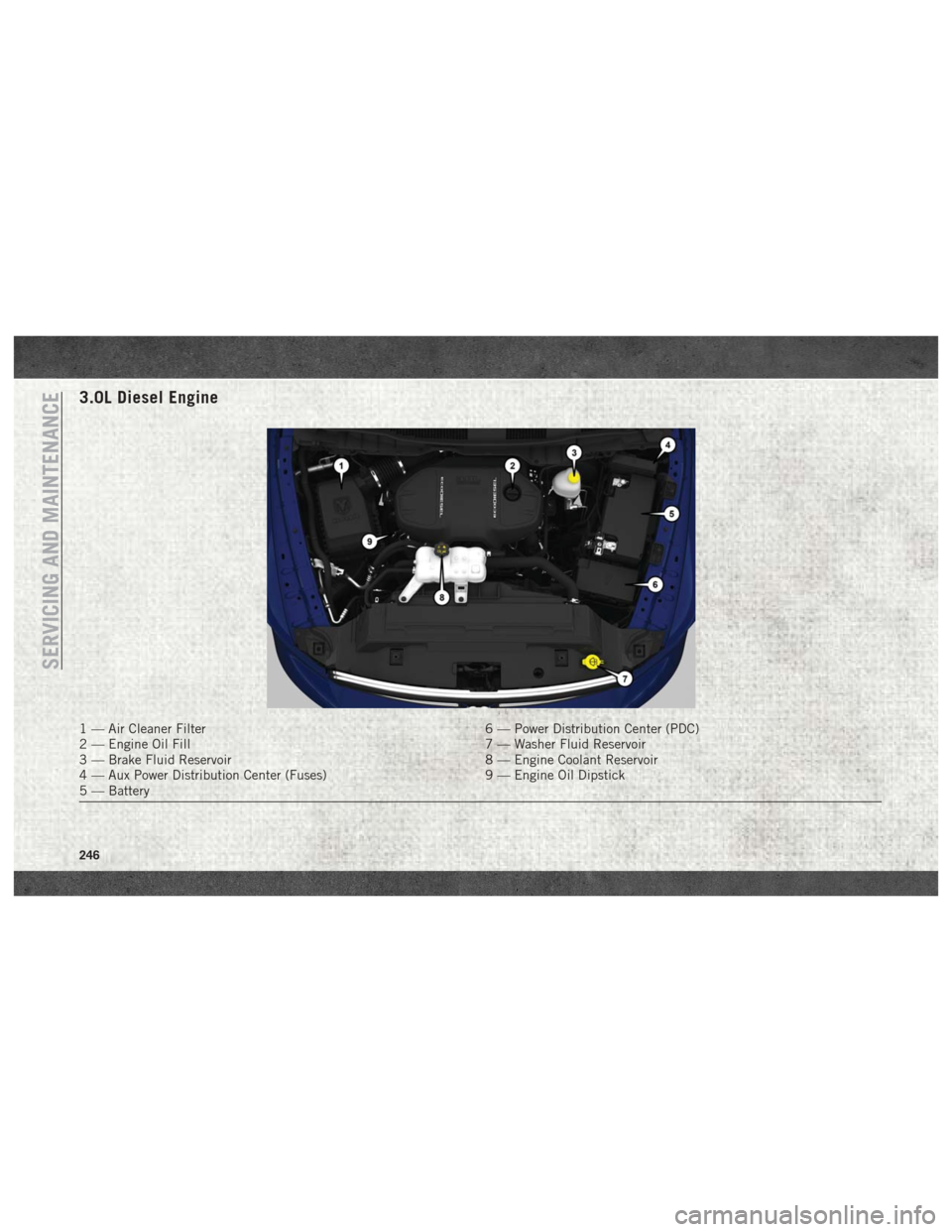

3.0L Diesel Engine

1 β Air Cleaner Filter6 β Power Distribution Center (PDC)

2 β Engine Oil Fill 7 β Washer Fluid Reservoir

3 β Brake Fluid Reservoir 8 β Engine Coolant Reservoir

4 β Aux Power Distribution Center (Fuses) 9 β Engine Oil Dipstick

5 β Battery

SERVICING AND MAINTENANCE

246

Page 249 of 372

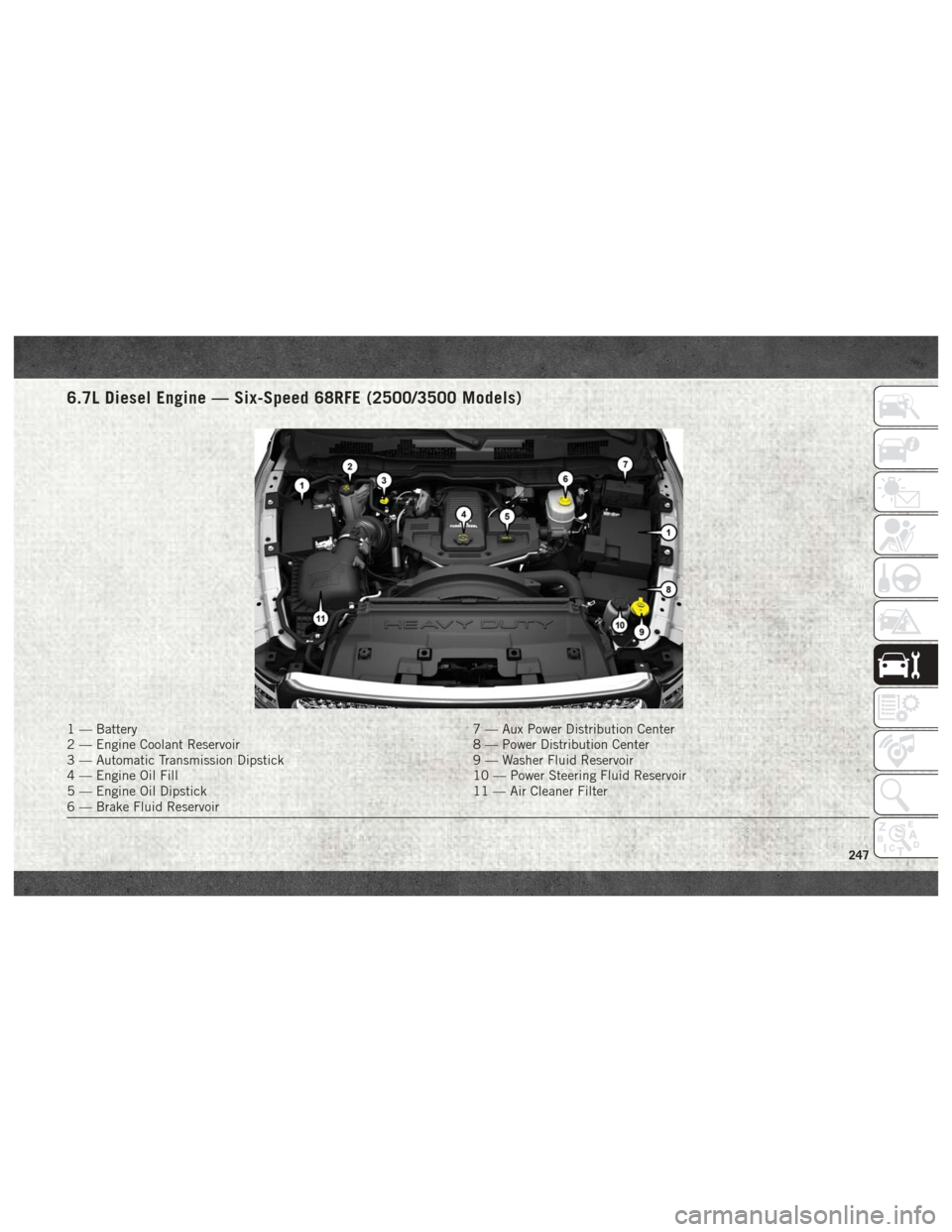

6.7L Diesel Engine β Six-Speed 68RFE (2500/3500 Models)

1 β Battery7 β Aux Power Distribution Center

2 β Engine Coolant Reservoir 8 β Power Distribution Center

3 β Automatic Transmission Dipstick 9 β Washer Fluid Reservoir

4 β Engine Oil Fill 10 β Power Steering Fluid Reservoir

5 β Engine Oil Dipstick 11 β Air Cleaner Filter

6 β Brake Fluid Reservoir

247