steering Ram 3500 Chassis Cab 2017 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2017, Model line: 3500 Chassis Cab, Model: Ram 3500 Chassis Cab 2017Pages: 542, PDF Size: 5.09 MB

Page 419 of 542

The trailer and the vehicle’s brake lamps will come on

when either vehicle braking or manual trailer brakes are

applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical connection status.

If no electrical connection is detected after the ignition is

turned on, pushing the GAIN adjustment button or sliding

the manual brake control lever will display the GAIN

setting for 10 seconds and the “Trailer Brake Status Indi-

cator Light” will not be displayed.

If a fault is detected in the trailer wiring or the Integrated

Trailer Brake Module (ITBM), the “Trailer Brake Status

Indicator Light” will flash.

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake control power

output to the trailer brakes in 0.5 increments. The GAIN

setting can be increased to a maximum of 10 or decreased

to a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer brake control for

the specific towing condition and should be changed astowing conditions change. Changes to towing conditions

include trailer load, vehicle load, road conditions and

weather.

Adjusting GAIN

NOTE:

This should only be performed in a traffic free

environment at speeds of approximately 20–25 mph

(30–40 km/h).

1. Make sure the trailer brakes are in good working condition, functioning normally and properly adjusted.

See your trailer dealer if necessary.

2. Hook up the trailer and make the electrical connections according to the trailer manufacturer’s instructions.

3. When a trailer with electric/EOH brakes is plugged in, the trailer connected message should appear in the

instrument cluster display (if the connection is not

recognized by the ITBM, braking functions will not be

available), the GAIN setting will illuminate and the

correct type of trailer must be selected from the instru-

ment cluster display options.

4. Push the UP or DOWN button on the steering wheel until “TRAILER TOW” appears on the screen.

5

STARTING AND OPERATING 417

Page 420 of 542

5. Push the RIGHT arrow on the steering wheel to enter“TRAILER TOW”.

6. Push the UP or DOWN buttons until Trailer Brake Type appears on the screen.

7. Push the RIGHT arrow and then push the UP or DOWN buttons until the proper Trailer Brake Type appears on

the screen. 8. In a traffic-free environment, tow the trailer on a dry,

level surface at a speed of 20–25 mph (30–40 km/h) and

squeeze the manual brake control lever completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting; if the trailer wheels turn

freely, increase the GAIN setting.

Repeat steps 8 and 9 until the GAIN setting is at a point just

below trailer wheel lockup. If towing a heavier trailer,

trailer wheel lockup may not be attainable even with the

maximum GAIN setting of 10.

Light Electric Heavy Electric Light EOH Heavy EOH

Type of Trailer Brakes Electric Trailer Brakes Electric Trailer Brakes Electric over Hydrau- lic Trailer BrakesElectric over Hydrau-

lic Trailer Brakes

Load *Under 10,000 lbs *Above 10,000 lbs *Under 10,000 lbs *Above 10,000 lbs

* The suggested selection depends and may change de-

pending on the customer preferences for braking perfor-

mance. Condition of the trailer brakes, driving and road

state may also affect the selection.

418 STARTING AND OPERATING

Page 445 of 542

5. Start the engine in the vehicle that has the boosterbattery, let the engine idle a few minutes, and then start

the engine in the vehicle with the discharged battery.

CAUTION!

Do not connect jumper cable to any of the fuses on the

positive battery terminal. The resulting electrical cur-

rent will blow the fuse.

6. Once the engine is started, remove the jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative (-)end of the jumper cable from

the engine ground of the vehicle with the discharged

battery.

2. Disconnect the opposite end of the negative (-)jumper

cable from the negative (-)post of the booster battery.

3. Disconnect the positive (+)end of the jumper cable from

the positive (+)post of the booster battery.

4. Disconnect the opposite end of the positive (+)jumper

cable from the positive (+)post of the vehicle with the

discharged battery. If frequent jump-starting is required to start your vehicle

you should have the battery and charging system in-

spected at your authorized dealer.

CAUTION!

Accessories plugged into the vehicle power outlets

draw power from the vehicle’s battery, even when not

in use (i.e., cellular devices, etc.). Eventually, if plugged

in long enough without engine operation, the vehicle’s

battery will discharge sufficiently to degrade battery

life and/or prevent the engine from starting.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or snow, it can

often be moved using a rocking motion. Turn the steering

wheel right and left to clear the area around the front

wheels. Next, shift back and forth between DRIVE and

REVERSE (with automatic transmission) or SECOND

GEAR and REVERSE (with manual transmission) while

gently pressing the accelerator. Use the least amount of

accelerator pedal pressure that will maintain the rocking

motion, without spinning the wheels or racing the engine.

6

WHAT TO DO IN EMERGENCIES 443

Page 447 of 542

WARNING!

•Do not use a chain for freeing a stuck vehicle. Chains

may break, causing serious injury or death.

• Stand clear of vehicles when pulling with tow hooks.

Tow straps may become disengaged, causing serious

injury.

CAUTION!

Tow hooks are for emergency use only to rescue a

vehicle stranded off-road. Do not use tow hooks for

tow truck hookup or highway towing. You could

damage your vehicle.

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector cannot be

moved out of the PARK position, you can use the following

procedure to temporarily move the gear selector:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Tilt the steering wheel to the full up position. 4. Press and maintain firm pressure on the brake pedal.

5. Insert a screwdriver or similar tool into the access port

(ringed circle) on the bottom of the steering column, and

push and hold the override release lever up.

6. Move the gear selector to the NEUTRAL position.

7. The vehicle may then be started in NEUTRAL.Gear Selector Override Access Port

6

WHAT TO DO IN EMERGENCIES 445

Page 449 of 542

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use only tow bars and other

equipment designed for this purpose, following equipment

manufacturer ’s instructions. Use of safety chains is man-

datory. Attach a tow bar or other towing device to main

structural members of the vehicle, not to bumpers or

associated brackets. State and local laws regarding vehicles

under tow must be observed.

If you must use the accessories (wipers, defrosters, etc.)

while being towed, the ignition must be in the ON/RUN

mode, not the ACC mode.

If the key fob is unavailable or the vehicle’s battery is

discharged, refer to “Gear Selector Override” in this section

for instructions on shifting the automatic transmission out

of PARK for towing.

CAUTION!

•Do not use sling type equipment when towing.

Vehicle damage may occur.

• When securing the vehicle to a flat bed truck, do not

attach to front or rear suspension components. Dam-

age to your vehicle may result from improper towing.

Two-Wheel Drive Models

The manufacturer recommends towing your vehicle with

all four wheels OFFthe ground using a flatbed.

If flatbed equipment is not available, and the transmission

is operable, the vehicle may be towed (with the rear wheels

on the ground) under the following conditions:

• The transmission must be in NEUTRAL.

• The towing speed must not exceed 30 mph (48 km/h).

• The towing distance must not exceed 15 miles (24 km).

If the transmission is not operable, or the vehicle must be

towed faster than 30 mph (48 km/h) or farther than

15 miles (24 km), tow with the rear wheels OFFthe ground.

Acceptable methods are to tow the vehicle on a flatbed, or

with the front wheels raised and the rear wheels on a

towing dolly, or (when using a suitable steering wheel

stabilizer to hold the front wheels in the straight position)

with rear wheels raised and the front wheels on the

ground.

6

WHAT TO DO IN EMERGENCIES 447

Page 455 of 542

ENGINE COMPARTMENT — 6.4L

1 — Coolant Pressure Bottle6 — Battery

2 — Transmission Dipstick 7 — Power Distribution Center (Fuses)

3 — Engine Oil Fill 8 — Washer Solvent

4 — Engine Oil Dipstick 9 — Power Steering Fluid Reservoir

5 — Brake Fluid Reservoir 10 — Air Cleaner Filter

7

MAINTAINING YOUR VEHICLE 453

Page 494 of 542

Seat Belt Maintenance

Do not bleach, dye or clean the belts with chemical solvents

or abrasive cleaners. This will weaken the fabric. Sun

damage can also weaken the fabric.

If the belts need cleaning, use a mild soap solution or

lukewarm water. Do not remove the belts from the vehicle

to wash them. Dry with a soft cloth.

Replace the belts if they appear frayed or worn or if the

buckles do not work properly.

NOTE:If the belts retract slowly, inspect the upper turning

loop for soiling. If soiling is present, clean with a wet soft

cloth until all residue is removed.

WARNING!

A frayed or torn belt could rip apart in a collision and

leave you with no protection. Inspect the belt system

periodically, checking for cuts, frays, or loose parts.

Damaged parts must be replaced immediately. Do not

disassemble or modify the system. Seat belt assemblies

must be replaced after a collision if they have been

damaged (i.e., bent retractor, torn webbing, etc.).

FUSES

WARNING!

• When replacing a blown fuse, always use an appro-

priate replacement fuse with the same amp rating as

the original fuse. Never replace a fuse with another

fuse of higher amp rating. Never replace a blown

fuse with metal wires or any other material. Failure

to use proper fuses may result in serious personal

injury, fire and/or property damage.

• Before replacing a fuse, make sure that the ignition is

off and that all the other services are switched off

and/or disengaged.

• If the replaced fuse blows again, contact an autho-

rized dealer.

• If a general protection fuse for safety systems (air

bag system, braking system), power unit systems

(engine system, gearbox system) or steering system

blows, contact an authorized dealer.

492 MAINTAINING YOUR VEHICLE

Page 500 of 542

CavityCartridge Fuse Micro Fuse Description

F74 –20 Amp Yellow (Gas

Engine & 1500 LD Diesel) Brake Vacuum Pump Gas/Diesel – If

Equipped

F75 –10 Amp Red Coolant Temperature Valve Actuator

F76 –10 Amp Red Antilock Brakes / Electronic Stability Control

F77 –10 Amp Red Drivetrain Control Module/Front Axle

Disconnect Module

F78 –10 Amp Red Engine Control Module / Electric Power

Steering

F79 –15 Amp Blue Clearance Lights

F80 –10 Amp Red Universal Garage Door Opener / Compass

F81 –20 Amp Yellow Trailer Tow Right Turn / Stop Lights

F82 –10 Amp Red Steering Column Control Module /

Cruise Control

F84 –15 Amp Blue Switch Bank / Instrument Cluster

F85 –10 Amp Red Airbag Module

F86 –10 Amp Red Airbag Module

F87 –10 Amp Red Air Suspension – If Equipped / Trailer Tow

/ Steering Column Control Module

F88 –15 Amp Blue Instrument Panel Cluster

498 MAINTAINING YOUR VEHICLE

Page 501 of 542

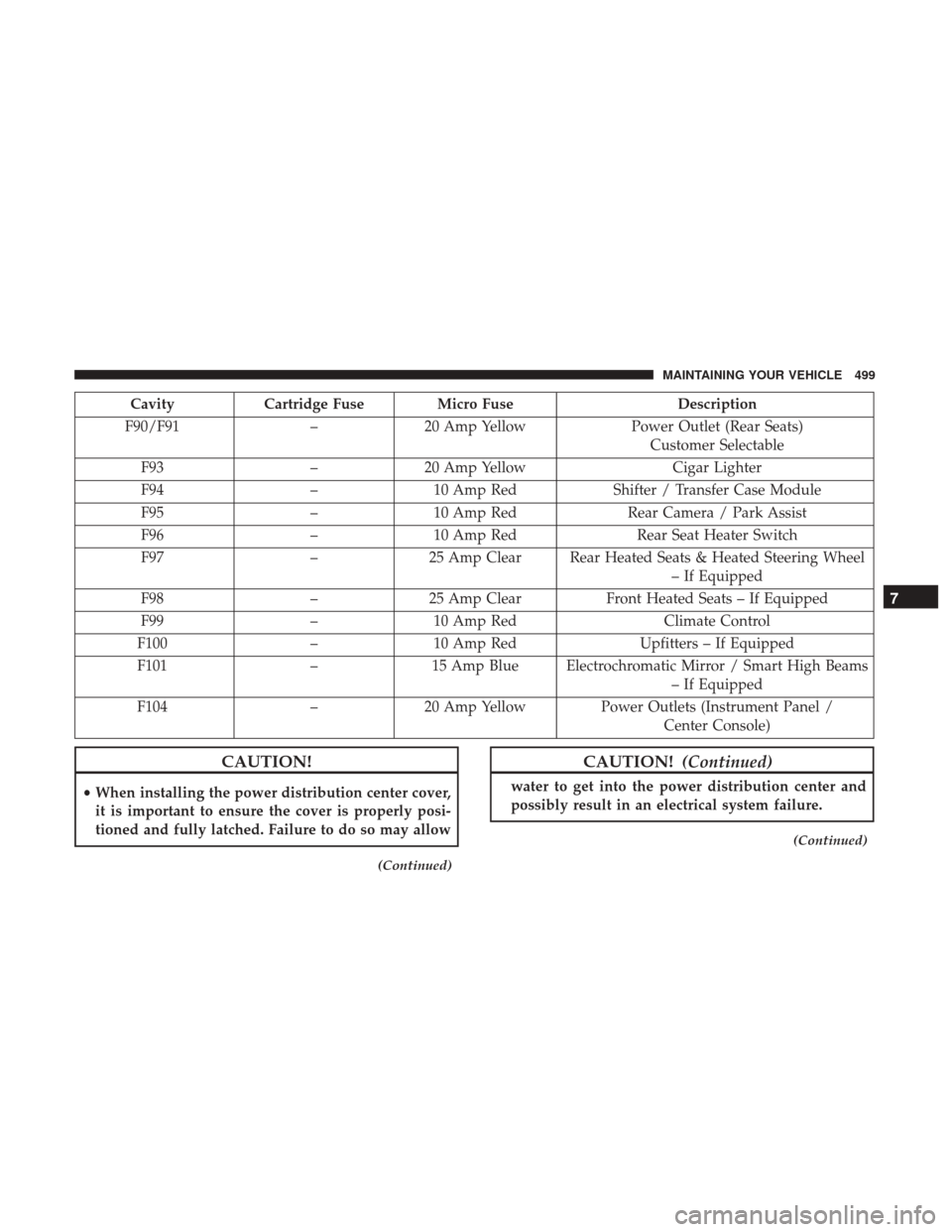

CavityCartridge Fuse Micro Fuse Description

F90/F91 –20 Amp Yellow Power Outlet (Rear Seats)

Customer Selectable

F93 –20 Amp Yellow Cigar Lighter

F94 –10 Amp Red Shifter / Transfer Case Module

F95 –10 Amp Red Rear Camera / Park Assist

F96 –10 Amp Red Rear Seat Heater Switch

F97 –25 Amp Clear Rear Heated Seats & Heated Steering Wheel

– If Equipped

F98 –25 Amp Clear Front Heated Seats – If Equipped

F99 –10 Amp Red Climate Control

F100 –10 Amp Red Upfitters – If Equipped

F101 –15 Amp Blue Electrochromatic Mirror / Smart High Beams

– If Equipped

F104 –20 Amp Yellow Power Outlets (Instrument Panel /

Center Console)

CAUTION!

•When installing the power distribution center cover,

it is important to ensure the cover is properly posi-

tioned and fully latched. Failure to do so may allow

(Continued)

CAUTION! (Continued)

water to get into the power distribution center and

possibly result in an electrical system failure.

(Continued)

7

MAINTAINING YOUR VEHICLE 499

Page 512 of 542

Chassis

ComponentFluid, Lubricant, or Genuine Part

Automatic Transmission (6.4L Engine with 66RFE Trans-

mission) (For Diesel Engine See Diesel Supplement) Use only ATF+4 Automatic Transmission Fluid. Failure to

use ATF+4 fluid may affect the function or performance of

your transmission. We recommend Mopar ATF+4 fluid.

Automatic Transmission (6.4L Engine with AS66RC Trans-

mission) Use only Mopar ASRC Automatic Transmission Fluid or

equivalent. Failure to use the proper fluid may affect the

function or performance of your transmission.

Transfer Case We recommend you use Mopar BW44-44 Transfer Case

Fluid.

Front and Rear Axle Fluid (4500/5500) We recommend you use GL-5 SAE 75W-90 Synthetic

(MS-9763). Limited slip additive is not required for

Limited-Slip Rear Axles.

Brake Master Cylinder We recommend you use Mopar DOT 3 and SAE J1703.

If DOT 3 brake fluid is not available, then DOT 4 is

acceptable.

Power Steering Reservoir We recommend you use Mopar Power Steering Fluid +4,

Mopar ATF+4 Automatic Transmission Fluid.

510 MAINTAINING YOUR VEHICLE