technical specifications Ram 4500 Chassis Cab 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2020Pages: 516, PDF Size: 29.24 MB

Page 3 of 516

TABLE OF CONTENTS

1

2

3

4

5

6

7

8

9

10

11

1 INTRODUCTION ............................................................................................................................ 10

2 GETTING TO KNOW YOUR VEHICLE ..................................................................................12

3 GETTING TO KNOW YOUR INSTRUMENT PANEL ........................................................82

4 SAFETY ......................................................................................................................................... 120 5 STARTING AND OPERATING ............................................................................................... 183

6 IN CASE OF EMERGENCY .................................................................................................... 294 7 SERVICING AND MAINTENANCE ...................................................................................... 329

8 TECHNICAL SPECIFICATIONS ............................................................................................ 397

9 MULTIMEDIA ...............................................................................................................................414

10 CUSTOMER ASSISTANCE .................................................................................................... 500

11 INDEX ............................................................................................................................................ 504

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 1

Page 9 of 516

7

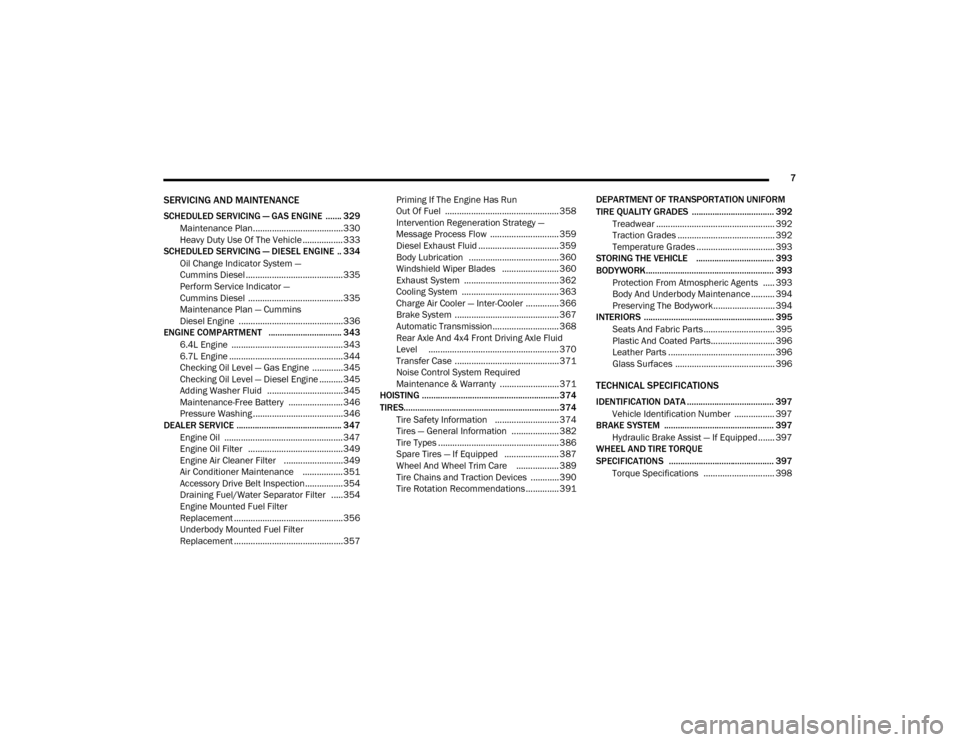

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GAS ENGINE ....... 329Maintenance Plan......................................330

Heavy Duty Use Of The Vehicle ................. 333

SCHEDULED SERVICING — DIESEL ENGINE .. 334

Oil Change Indicator System —

Cummins Diesel .........................................335 Perform Service Indicator —

Cummins Diesel ........................................335 Maintenance Plan — Cummins

Diesel Engine ............................................336

ENGINE COMPARTMENT ................................ 343

6.4L Engine ...............................................3436.7L Engine ................................................344

Checking Oil Level — Gas Engine .............345

Checking Oil Level — Diesel Engine ..........345

Adding Washer Fluid ................................345Maintenance-Free Battery .......................346

Pressure Washing ......................................346

DEALER SERVICE .............................................. 347

Engine Oil .................................................. 347Engine Oil Filter ........................................349

Engine Air Cleaner Filter .........................349

Air Conditioner Maintenance ................. 351

Accessory Drive Belt Inspection................354Draining Fuel/Water Separator Filter .....354

Engine Mounted Fuel Filter

Replacement ..............................................356 Underbody Mounted Fuel Filter

Replacement ..............................................357 Priming If The Engine Has Run

Out Of Fuel ................................................ 358 Intervention Regeneration Strategy —

Message Process Flow ............................. 359 Diesel Exhaust Fluid .................................. 359Body Lubrication ...................................... 360

Windshield Wiper Blades ........................ 360

Exhaust System ........................................ 362

Cooling System ......................................... 363

Charge Air Cooler — Inter-Cooler .............. 366

Brake System ............................................ 367Automatic Transmission............................ 368

Rear Axle And 4x4 Front Driving Axle Fluid

Level ....................................................... 370 Transfer Case ............................................ 371Noise Control System Required

Maintenance & Warranty ......................... 371

HOISTING ............................................................374

TIRES....................................................................374

Tire Safety Information ........................... 374

Tires — General Information .................... 382

Tire Types ................................................... 386

Spare Tires — If Equipped ....................... 387

Wheel And Wheel Trim Care .................. 389Tire Chains and Traction Devices ............ 390

Tire Rotation Recommendations .............. 391 DEPARTMENT OF TRANSPORTATION UNIFORM

TIRE QUALITY GRADES .................................... 392

Treadwear .................................................. 392

Traction Grades ......................................... 392Temperature Grades ................................. 393

STORING THE VEHICLE .................................. 393

BODYWORK ........................................................ 393 Protection From Atmospheric Agents ..... 393

Body And Underbody Maintenance .......... 394Preserving The Bodywork.......................... 394

INTERIORS ......................................................... 395

Seats And Fabric Parts .............................. 395

Plastic And Coated Parts........................... 396

Leather Parts ............................................. 396

Glass Surfaces .......................................... 396

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA ...................................... 397Vehicle Identification Number ................. 397

BRAKE SYSTEM ................................................ 397

Hydraulic Brake Assist — If Equipped....... 397

WHEEL AND TIRE TORQUE

SPECIFICATIONS .............................................. 397

Torque Specifications .............................. 398

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 7

Page 198 of 516

196STARTING AND OPERATING

NOTE:

Use of Climatized ULSD or Number 1 ULSD

Fuel results in a noticeable decrease in fuel

economy.

Climatized ULSD Fuel is a blend of Number 2

ULSD and Number 1 ULSD Fuels which

reduces the temperature at which wax crystals

form in fuel.

The fuel grade should be clearly marked on the

pump at the fuel station.

The engine requires the use of “ULSD Fuel”.

Use of incorrect fuel could result in engine and

exhaust system damage. Refer to “Fuel

Requirements” in “Technical Specifications”

for further information.

If climatized or diesel Number 1 ULSD fuel is

not available, and you are operating below

(20°F/-6°C), in sustained arctic conditions,

Mopar Premium Diesel Fuel Treatment (or

equivalent) is recommended to avoid gelling

(see Fuel Operating Range Chart).

Under some circumstances increased engine

noise may be audible in the seconds following

a cold start. This is most likely to occur when

using fuel that isnt blended for the ambient

temperature present. This may occur on an

unseasonably cold day or when a truck is fueled in a warmer climate and driven to a

colder climate. The noise can typically be

prevented by using Mopar Premium Diesel

Fuel Treatment as recommended (see Fuel

Operating Range Chart)..

Engine Oil Usage

Refer to “Dealer Service” in “Servicing And

Maintenance” for the correct engine oil

viscosity.

Winter Front Cover Usage

A winter front or cold weather cover is to be used in

ambient temperatures below 32°F (0°C), espe

-

cially during extended idle conditions. This cover is

equipped with four flaps for managing total grille

opening in varying ambient temperatures. If a

winter front or cold weather cover is to be used the

flaps should be left in the full open position to allow

air flow to the charge air cooler and automatic

transmission oil cooler. When ambient tempera -

tures drop below 0°F (-17°C) the four flaps need

to be closed. A suitable cold weather cover is avail -

able from your Mopar dealer.

Battery Blanket Usage

A battery loses 60% of its cranking power as the

battery temperature decreases to 0°F (-18°C). For

the same decrease in temperature, the engine

requires twice as much power to crank at the same RPM. The use of 120 Volts AC powered battery

blankets will greatly increase starting capability at

low temperatures. Suitable battery blankets are

available from an authorized Mopar dealer.

Engine Warm-Up

Avoid full throttle operation when the engine is

cold. When starting a cold engine, bring the

engine up to operating speed slowly to allow the

oil pressure to stabilize as the engine warms up.

NOTE:

High-speed, no-load running of a cold engine

can result in excessive white smoke and poor

engine performance. No-load engine speeds

should be kept under 1,000 RPM during the

warm-up period, especially in cold ambient

temperature conditions.

Your vehicle is equipped with an engine warm

up protection feature that may limit engine

performance after cold starting at low ambient

temperatures. The length of time engine speed

is limited is dependent upon engine coolant

temperature. Engine speed may be briefly

limited to 1,000 RPM after starting with coolant

temperature below freezing conditions, and

may be limited to 1,000 RPM for up to approxi

-

mately 2 minutes under more severe cold

conditions.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 196

Page 231 of 516

STARTING AND OPERATING229

POWER STEERING

Hydraulic Power Steering

The standard power steering system will give

you good vehicle response and increased ease

of maneuverability in tight spaces. The system

will provide mechanical steering capability if

power assist is lost.

If for some reason the power assist is inter -

rupted, it will still be possible to steer your

vehicle. Under these conditions, you will

observe a substantial increase in steering

effort, especially at very low vehicle speeds and

during parking maneuvers.

NOTE:

Increased noise levels at the end of the

steering wheel travel are considered normal

and do not indicate that there is a problem

with the power steering system.

Upon initial start-up in cold weather, the

power steering pump may make noise for a

short amount of time. This is due to the cold,

thick fluid in the steering system. This noise

should be considered normal, and it does not

in any way damage the steering system.

Power Steering Fluid Check

Checking the power steering fluid level at a

defined service interval is not required. The fluid

should only be checked if a leak is suspected,

abnormal noises are apparent, and/or the

system is not functioning as anticipated. Check

fluid level when the engine is cold and off. Coor -

dinate inspection efforts through an authorized

dealer. If necessary, add fluid to restore to the proper

indicated level. With a clean cloth, wipe any

spilled fluid from all surfaces. Refer to “Fluids

And Lubricants” in “Technical Specifications”

for further information.

CAUTION!

Prolonged operation of the steering system at

the end of the steering wheel travel will

increase the steering fluid temperature and it

should be avoided when possible. Damage to

the power steering pump may occur.

WARNING!

Fluid level should be checked on a level

surface and with the engine off to prevent

injury from moving parts and to ensure

accurate fluid level reading. Do not overfill.

Use only manufacturer's recommended

power steering fluid.

CAUTION!

Do not use chemical flushes in your power

steering system as the chemicals can

damage your power steering components.

Such damage is not covered by the New

Vehicle Limited Warranty.5

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 229

Page 273 of 516

STARTING AND OPERATING271

Adding Diesel Exhaust Fluid (DEF)

The DEF gauge (located on the instrument

cluster) will display the level of DEF remaining in

the tank. Refer to “Instrument Cluster” and

“Instrument Cluster Descriptions” in “Getting To

Know Your Instrument Panel” for further infor -

mation.

NOTE:

Driving conditions (altitude, vehicle speed,

load, etc.) will effect the amount of DEF that

is used in your vehicle.

Another factor is that outside temperature

can affect DEF consumption. In cold condi -

tions, 12°F (-11°C) and below, the DEF

gauge needle can stay on a fixed position and

may not move for extended periods of time.

This is a normal function of the system.

There is an electric heater inside the DEF

tank that automatically works when neces -

sary. And if the DEF supply does freeze, the

truck will operate normally until it thaws.

DEF Fill Procedure

NOTE:

Refer to “Fluids And Lubricants” in “Technical

Specifications” for the correct fluid type.

1. Remove cap from DEF tank (located on

drivers side of the vehicle or in fuel door).

DEF Filler Cap And Fuel Fill Chassis Cab Models

2. Insert DEF fill adapter/nozzle into DEF tank filler neck. NOTE:The DEF gauge may take up to five seconds

to update after adding a gallon or more of

Diesel Exhaust Fluid (DEF) to the DEF tank.

If you have a fault related to the DEF

system, the gauge may not update to the

new level. See an authorized dealer for

service.

The DEF gauge may also not immediately

update after a refill if the temperature of the

DEF fluid is below 39°F (4°C). The DEF line

heater will possibly warm up the DEF fluid

and allow the gauge to update after a period

of run time. Under very cold conditions, it is

possible that the gauge may not reflect the

new fill level for several drives.

Excessive overfilling of the DEF tank can

result in a MIL lamp/fault code and inaccu

-

rate level readings.1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Diesel Fuel Fill Location

5

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 271

Page 319 of 516

IN CASE OF EMERGENCY317

5. Remove the lug nuts and pull the wheel off.

Install the spare wheel and lug nuts with the

cone shaped end of the nuts toward the

wheel on Single Rear-Wheel (SRW) models.

On Dual Rear-Wheel models (DRW) the lug

nuts are a two-piece assembly with a flat

face. Lightly tighten the nuts. To avoid risk

of forcing the vehicle off the jack, do not

fully tighten the nuts until the vehicle has

been lowered.

6. Using the lug wrench, finish tightening the nuts using a crisscross pattern. For the

proper lug nut torque specifications refer to

“Wheel And Tire Torque Specifications” in

“Technical Specifications.” If in doubt about

the correct tightness, have them checked

with a torque wrench by an authorized

dealer or at a service station. 7. Install wheel center cap (if equipped) and

remove wheel blocks. Do not install chrome

or aluminum wheel center caps on the

spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. If the jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary

to use the jack driver in order to lower the

jack. Stow the replaced tire, jack, and tools

as previously described.

9. Adjust the tire pressure when possible.

10. After 25 miles (40 km), check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Dual Rear Wheels

Slots in the wheels will assist in properly

orienting the inner and outer wheels. Align

these slots when assembling the wheels for

best access to the tire valve on the inner wheel.

The tires of both dual wheels must be

completely off the ground when tightening to

insure wheel centering and maximum wheel

clamping.

Dual wheel models require a special heavy-duty

lug nut tightening adapter (included with the

vehicle) to correctly tighten the lug nuts. Also,

when it is necessary to remove and install dual

rear wheels, use a proper vehicle lifting device.

NOTE:

When installing a spare tire (if equipped) as part

of a dual rear wheel end combination, the tire

diameter of the two individual tires must be

compared. If there is a significant difference,

the larger tire should be installed in a front loca-

tion. The correct direction of rotation for dual

tire installations must also be observed.WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided.

6

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 317

Page 320 of 516

318IN CASE OF EMERGENCY

It is recommended that wheel stud nuts be kept

torqued to specifications at all times. Torque

wheel stud nuts to specifications at each lubri -

cation interval.

Refer to “Wheel And Tire Torque Specifications”

in “Technical Specifications” for further infor -

mation.

Wheel Nuts

All wheel nuts should be tightened occasionally

to eliminate the possibility of wheel studs being

sheared or the bolt holes in the wheels

becoming elongated. This is especially

important during the first few hundred miles/

kilometers of operation to allow the wheel nuts

to become properly set. All wheel nuts should

first be firmly seated against the wheel. The

wheel nuts should then be tightened to recom -

mended torque. Tighten the wheel nuts to final

torque in increments. Progress around the bolt

circle, tightening the wheel nut opposite to the

wheel nut just previously tightened until final

torque is achieved. Refer to “Wheel And Tire Torque Specifications”

in “Technical Specifications” for further infor

-

mation.

To Stow The Flat Or Spare — If Equipped

Refer to Upfitters Body Builder’s Guide for infor -

mation on stowing your spare tire (if equipped).

Hub Caps/Wheel Covers — If Equipped

The hub caps must be removed before raising

the vehicle off the ground. For 3500 Single Rear-Wheel (SRW) models, use

the flat end of the lug wrench to hook and pull

off the hub cap. Find the opening in the hub cap,

insert the lug wrench, and pull off the cap. If you

need to pry against the wheel, protect the wheel

surface.

Lug Wrench Insertion Location — Hub Cap

CAUTION!

Use extreme caution when removing the front

and rear wheel covers. Damage can occur to

the center cap and/or the wheel if

screwdriver type tools are used. A pulling

motion, not a pry off motion, is recommended

to remove the caps.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 318

Page 366 of 516

364SERVICING AND MAINTENANCE

Cooling System — Drain, Flush And Refill

NOTE:

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system please contact an authorized

dealer.

If the engine coolant (antifreeze) is dirty or

contains visible sediment, have an authorized

dealer clean and flush with OAT coolant (anti -

freeze) (conforming to MS.90032).

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

Selection Of Coolant

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. NOTE:

Mixing of engine coolant (antifreeze) other

than specified Organic Additive Technology

(OAT) engine coolant (antifreeze), may result

in engine damage and may decrease corro

-

sion protection. Organic Additive Technology

(OAT) engine coolant is different and should

not be mixed with Hybrid Organic Additive

Technology (HOAT) engine coolant (anti -

freeze) or any “globally compatible” coolant

(antifreeze). If a non-OAT engine coolant

(antifreeze) is introduced into the cooling

system in an emergency, the cooling system

will need to be drained, flushed, and refilled

with fresh OAT coolant (conforming to

MS.90032), by an authorized dealer as soon

as possible.

Do not use water alone or alcohol-based

engine coolant (antifreeze) products. Do not

use additional rust inhibitors or antirust prod -

ucts, as they may not be compatible with the

radiator engine coolant and may plug the

radiator.

This vehicle has not been designed for use

with propylene glycol-based engine coolant

(antifreeze). Use of propylene glycol-based

engine coolant (antifreeze) is not recom -

mended.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added

to the system please contact an authorized

dealer.

Adding Coolant

Your vehicle has been built with an improved

engine coolant (OAT coolant conforming to

MS.90032) that allows extended maintenance

intervals. This engine coolant (antifreeze) can

be used up to ten years or 150,000 miles

(240,000 km) before replacement. To prevent

reducing this extended maintenance period, it

is important that you use the same engine

coolant (OAT coolant conforming to MS.90032)

throughout the life of your vehicle.

Please review these recommendations for

using Organic Additive Technology (OAT) engine

coolant (antifreeze) that meets the require-

ments of FCA Material Standard MS.90032.

When adding engine coolant (antifreeze):

We recommend using Mopar Antifreeze/

Coolant 10 Year/150,000 Mile

(240,000 km) Formula OAT (Organic Additive

Technology) that meets the requirements of

FCA Material Standard MS.90032.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 364

Page 369 of 516

SERVICING AND MAINTENANCE367

(Continued)

Brake System

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the “Mainte -

nance Plan” in this section for the proper main -

tenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood

service or immediately if the brake system

warning lamp indicates system failure.

If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the

top of the master cylinder area before removing

cap. With disc brakes the fluid level can be expected

to fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by

a leak and a system check should be

conducted.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder reser -

voir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 367

Page 370 of 516

368SERVICING AND MAINTENANCE

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission perfor-

mance and life. Use only the manufacturer’s

specified transmission fluid. Refer to “Fluids

And Lubricants” in “Technical Specifications”. It

is important to maintain the transmission fluid

at the correct level using the recommended

fluid. No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

Special Additives

The manufacturer strongly recommends

against using any special additives in the trans -

mission. Automatic Transmission Fluid (ATF) is

an engineered product and its performance

may be impaired by supplemental additives.

Therefore, do not add any fluid additives to the

transmission. The only exception to this policy is

the use of special dyes for diagnosing fluid

leaks in six-speed transmissions. Avoid using

transmission sealers as they may adversely

affect seals.

Fluid Level Check — Eight-Speed

Transmission

The fluid level is preset at the factory and does

not require adjustment under normal operating

conditions. Routine fluid level checks are not

required, therefore the transmission has no dipstick. An authorized dealer can check your

transmission fluid level using special service

tools.

If you notice fluid leakage or transmission

malfunction, visit an authorized dealer immedi

-

ately to have the transmission fluid level

checked. Operating the vehicle with an

improper fluid level can cause severe transmis -

sion damage.

Fluid Level Check — Six-Speed Transmission

It is best to check the fluid level when the trans -

mission is at normal operating temperature

(158-176°F / 70-80°C). This normally occurs

after at least 15 miles (25 km) of driving. At

normal operating temperature the fluid cannot

be held comfortably between the fingertips. You

can read the transmission sump temperature in

the instrument cluster screen (refer to “Instru -

ment Cluster Display” in “Getting To Know Your

Instrument Panel” for further information).

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder, and

(for six-speed transmissions) will require

more frequent fluid and filter changes. Refer

to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An

authorized dealer has the proper tools to

adjust the fluid level accurately.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 368