wheel torque RAM CHASSIS CAB 2022 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2022Pages: 428, PDF Size: 20.18 MB

Page 161 of 428

STARTING AND OPERATING159

Use of the turn signal suppresses the warnings.

The system will not apply torque to the steering

wheel whenever a safety system engages

(Anti-Lock Brakes, Traction Control System,

Electronic Stability Control, Forward Collision

Warning, etc.).

PARKVIEW REAR BACK UP CAMERA

The ParkView Rear Back Up Camera allows you to

see an on-screen image of the rear surroundings of

your vehicle whenever the gear selector is put into

REVERSE. The image will be displayed on the

Uconnect display along with a caution note to

“Check Entire Surroundings” across the top of the

screen. After five seconds this note will disappear.

The ParkView Camera is located in the center of

the tailgate handle.

NOTE:For the 3500, 4500, and 5500 Chassis Cab

vehicles, the Rear Backup Camera is shipped

loose and not installed. Please refer to the Ram

Body Builder’s Guide for more information.

Manual Activation Of The Rear View

Camera:

1. Press the "Controls" button located on the bottom of the Uconnect display.

2. Press the "Back Up Camera" icon to turn the Rear View Camera system on. When the vehicle is shifted out of REVERSE (with

camera delay turned off), the rear camera mode is

exited and the previous screen appears. When the

vehicle is shifted out of REVERSE (with camera

delay turned on), the camera image will continue to

be displayed for up to 10 seconds unless the

following conditions occur: The vehicle speed

exceeds 8 mph (13 km/h), the vehicle is shifted

into PARK, the vehicle’s ignition is placed in the

OFF position, or the user presses image defeat “X”

to exit out of the camera video display.

Whenever the Rear View Camera image is

activated through the "Backup Camera" button in

the Controls menu, and the vehicle speed is

greater than, or equal to, 8 mph (13 km/h), a

display timer for the image is initiated. The image

will continue to be displayed until the display timer

exceeds 10 seconds.NOTE:

If the vehicle speed remains below 8 mph

(13 km/h), the Rear View Camera image will be

displayed continuously until deactivated via the

touchscreen button "X", the transmission is

shifted into PARK, or the ignition is placed in the

OFF position.

The touchscreen button "X" to disable display of

the camera image is made available ONLY when

the vehicle is not in REVERSE.

Cargo Camera Icons — If Equipped

If equipped with a Cargo Camera, a touchscreen

button is made available to indicate the current

active Camera image being displayed whenever

the Rear View Camera image is displayed.

If equipped with a Cargo Camera, a touchscreen

button to switch the display to Cargo Camera

image is made available whenever the Rear View

Camera image is displayed.

A touchscreen button "X" to disable display of the

camera image is made available when the vehicle

is not in REVERSE gear.

When enabled, active guidelines are overlaid on

the backup camera image to illustrate the width of

the vehicle and its projected backup path based on

the steering wheel position. The active guidelines

will show separate zones that will help indicate the

Backup Camera Touchscreen Button

Cargo Camera Touchscreen Button

AUX Camera Touchscreen Button

4

22_DPF_OM_EN_USC_t.book Page 159

Page 262 of 428

260SAFETY

Anti-Lock Brake System (ABS) Warning

Light

The yellow ABS Warning Light will turn on when the

ignition is placed in the ON/RUN mode and may

stay on for as long as four seconds.

If the ABS Warning Light remains on or comes on

while driving, it indicates that the anti-lock portion

of the brake system is not functioning and that

service is required. However, the conventional

brake system will continue to operate normally if

the ABS Warning Light is on.

If the ABS Warning Light is on, the brake system

should be serviced as soon as possible to restore

the benefits of anti-lock brakes. If the ABS Warning

Light does not come on when the ignition is placed

in the ON/RUN mode, have the light repaired as

soon as possible.

ELECTRONIC BRAKE CONTROL (EBC)

S

YSTEM

Your vehicle is equipped with an advanced

Electronic Brake Control (EBC) system. This system

includes Anti-Lock Brake System (ABS), Brake

Assist System (BAS), Electronic Brake Force

Distribution (EBD), Hill Start Assist (HSA),

Electronic Roll Mitigation (ERM), Electronic

Stability Control (ESC), and Traction Control

System (TCS). These systems work together to

enhance both vehicle stability and control in

various driving conditions. Your vehicle may also be equipped with Trailer

Sway Control (TSC) and Hill Descent Control (HDC).

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s

braking capability during emergency braking

maneuvers. The system detects an emergency

braking situation by sensing the rate and amount

of brake application and then applies optimum

pressure to the brakes. This can help reduce

braking distances. The BAS complements the

Anti-Lock Brake System (ABS). Applying the brakes

very quickly results in the best BAS assistance. To

receive the benefit of the system, you must apply

continuous braking pressure during the stopping

sequence (do not “pump” the brakes). Do not

reduce brake pedal pressure unless braking is no

longer desired. Once the brake pedal is released,

the BAS is deactivated.

Brake System Warning Light

The red Brake System Warning Light will turn on

when the ignition is placed in the ON/RUN mode

and may stay on for as long as four seconds.

If the Brake System Warning Light remains on or

comes on while driving, it indicates that the brake

system is not functioning properly and that

immediate service is required. If the Brake System

Warning Light does not come on when the ignition

is placed in the ON/RUN mode, have the light

repaired as soon as possible.

Electronic Brake Force Distribution (EBD)

EBD manages the distribution of the braking

torque between the front and rear axles by limiting

braking pressure to the rear axle. This is done to

prevent overslip of the rear wheels to avoid vehicle

instability, and to prevent the rear axle from

entering ABS before the front axle.

Electronic Roll Mitigation (ERM)

ERM anticipates the potential for wheel lift by

monitoring the driver’s steering wheel input and

the speed of the vehicle. When ERM determines

that the rate of change of the steering wheel angle

and vehicle’s speed are sufficient to potentially

cause wheel lift, it then applies the appropriate

brake and may also reduce engine power to lessen

the chance that wheel lift will occur. ERM can only

reduce the chance of wheel lift occurring during

severe or evasive driving maneuvers; it cannot

WARNING!

The Brake Assist System (BAS) cannot prevent the

natural laws of physics from acting on the vehicle,

nor can it increase the traction afforded by pre

-

vailing road conditions. BAS cannot prevent colli -

sions, including those resulting from excessive

speed in turns, driving on very slippery surfaces,

or hydroplaning. The capabilities of a BAS-

equipped vehicle must never be exploited in a

reckless or dangerous manner, which could jeop -

ardize the user's safety or the safety of others.

22_DPF_OM_EN_USC_t.book Page 260

Page 264 of 428

262SAFETY

ESC Operating Modes

Depending upon model and mode of operation, the

ESC system may have multiple operating modes.

ESC On

This is the normal operating mode for the ESC

system. Whenever the vehicle is started, the ESC

system will be in this mode. This mode should be

used for most driving conditions. Alternate ESC

modes should only be used for specific reasons as

noted in the following paragraphs.

Partial Off

This mode may be useful if the vehicle becomes

stuck. This mode may modify TCS and ESC

thresholds for activation, which allows for more

wheel spin than normally allowed.

To enter the “Partial Off” mode, momentarily push

the ESC OFF button and the ESC OFF Indicator

Light will illuminate. To turn the ESC on again,

momentarily push the ESC OFF button and the ESC

OFF Indicator Light will turn off.

NOTE:For vehicles with multiple partial ESC modes, the

push and release of the button will toggle the ESC

modes. Multiple attempts may be required to

return to "ESC On" mode. Full Off — If Equipped

This mode is intended for off-highway or off-road

use only and should not be used on any public

roadways. In this mode, TCS and ESC features are

turned off. To enter the “Full Off” mode, push and

hold the ESC OFF button for five seconds while the

vehicle is stopped with the engine running. After

five seconds, a chime will sound, the ESC OFF

Indicator Light will illuminate, and the “ESC OFF”

message will display in the instrument cluster. To

turn ESC on again, momentarily push the ESC OFF

button.

NOTE:The system may switch from ESC “Full Off” to

“Partial Off” mode when the vehicle exceeds a

predetermined speed. When the vehicle speed

slows below the predetermined speed the system

will return to ESC “Full Off”.

ESC modes may also be affected by drive modes (if

equipped).WARNING!

When in “Partial Off” mode, the TCS function

-

ality of ESC, except for the limited slip feature

described in the TCS section, has been

disabled and the ESC OFF Indicator Light will

be illuminated. When in “Partial Off” mode,

the engine power reduction feature of TCS is

disabled, and the enhanced vehicle stability

offered by the ESC system is reduced.

Trailer Sway Control (TSC) is disabled when

the ESC system is in the “Partial Off” mode.

WARNING!

In the ESC “Full Off” mode, the engine torque

reduction and stability features are disabled.

Therefore, enhanced vehicle stability offered

by the ESC system is unavailable. In an emer -

gency evasive maneuver, the ESC system will

not engage to assist in maintaining stability.

ESC “Full Off” mode is intended for

off-highway or off-road use only.

The Electronic Stability Control (ESC) cannot

prevent the natural laws of physics from

acting on the vehicle, nor can it increase the

traction afforded by prevailing road condi -

tions. ESC cannot prevent all accidents,

including those resulting from excessive

speed in turns, driving on very slippery

surfaces, or hydroplaning. ESC also cannot

prevent collisions.

22_DPF_OM_EN_USC_t.book Page 262

Page 319 of 428

IN CASE OF EMERGENCY317

Jack Warning Label

1. If equipped, remove the spare wheel and tools from storage.

2. Using the lug wrench, loosen, but do not remove, the lug nuts by turning them counter -

clockwise one turn while the wheel is still on

the ground.

3. When changing the front wheel, place the jack under the axle as close to the tire as possible.

Front Jacking Locations

When changing a rear wheel, securely place

the jack under the sway bar bracket (unless

both tires are flat on one side, then place jack

under shock bracket) facing forward in vehicle.

Rear Jacking Location

Before raising the wheel off the ground, make

sure that the jack will not damage surrounding

truck parts and adjust the jack position as re

-

quired.

4. Raise the vehicle until the wheel just clears the surface.

5. Remove the lug nuts and pull the wheel off. For Single Rear-Wheel (SRW) models, Install the

spare wheel and lug nuts with the cone shaped

end of the nuts toward the wheel. For Dual

Rear-Wheel (DRW) models, the lug nuts are a

two-piece assembly with a flat face. Lightly

tighten the nuts. To avoid risk of forcing the

vehicle off the jack, do not fully tighten the

nuts until the vehicle has been lowered.

6. Using the lug wrench, finish tightening the nuts using a crisscross pattern Ú page 397. If in

doubt about the correct tightness, have them

checked with a torque wrench by an

authorized dealer or at a service station.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the

Jacking Instructions for this vehicle.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

7

22_DPF_OM_EN_USC_t.book Page 317

Page 320 of 428

318IN CASE OF EMERGENCY

7. Install wheel center cap (if equipped) and remove wheel blocks. Do not install chrome or

aluminum wheel center caps on the spare

wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. Stow the replaced tire and tools as previously

described.

9. Adjust the tire pressure when possible.

10. After 25 miles (40 km), check the lug nut torque Ú page 397 with a torque wrench to

ensure that all lug nuts are properly seated

against the wheel.

Dual Rear Wheels

Slots in the wheels will assist in properly orienting

the inner and outer wheels. Align these slots when

assembling the wheels for best access to the tire

valve on the inner wheel. The tires of both dual

wheels must be completely off the ground when

tightening to ensure wheel centering and

maximum wheel clamping. Dual wheel models require a special heavy-duty lug

nut tightening adapter (included with the vehicle)

to correctly tighten the lug nuts. Also, when it is

necessary to remove and install dual rear wheels,

use a proper vehicle lifting device.

NOTE:When installing a spare tire (if equipped) as part of

a dual rear wheel end combination, the tire

diameter of the two individual tires must be

compared. If there is a significant difference, the

larger tire should be installed in a front location.

The correct direction of rotation for dual tire instal

-

lations must also be observed.

It is recommended that wheel stud nuts be kept

torqued to specifications at all times. Torque wheel

stud nuts to specifications at each lubrication

interval Ú page 397.

Wheel Nuts

All wheel nuts should be tightened occasionally to

eliminate the possibility of wheel studs being

sheared or the bolt holes in the wheels becoming

elongated. This is especially important during the

first few hundred miles/kilometers of operation to

allow the wheel nuts to become properly set. All

wheel nuts should first be firmly seated against the

wheel. The wheel nuts should then be tightened to

recommended torque. Tighten the wheel nuts to

final torque in increments. Progress around the

bolt circle, tightening the wheel nut opposite to the wheel nut just previously tightened until final

torque is achieved Ú

page 397.

TO STOW THE FLAT OR SPARE —

I

F EQUIPPED

Refer to Upfitters Body Builder’s Guide for

information on stowing your spare tire (if

equipped).

HUB CAPS/WHEEL COVERS —

I

F EQUIPPED

The hub caps must be removed before raising the

vehicle off the ground.

For 3500 Single Rear-Wheel (SRW) models, use

the flat end of the lug wrench to hook and pull off

the hub cap. Find the opening in the hub cap,

insert the lug wrench, and pull off the cap. If you

need to pry against the wheel, protect the wheel

surface.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop, could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided.

CAUTION!

Use extreme caution when removing the front

and rear wheel covers. Damage can occur to the

center cap and/or the wheel if screwdriver type

tools are used. A pulling motion, not a pry off

motion, is recommended to remove the caps.

22_DPF_OM_EN_USC_t.book Page 318

Page 399 of 428

397

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the

instrument panel, visible through the windshield.

Vehicle Identification Number

NOTE:It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for example,

repeated brake applications with the engine off),

the brakes will still function. However, you will

experience a substantial increase in braking effort

to stop the vehicle. If either the front or rear hydraulic system loses

normal braking capability, the remaining system

will still function with some loss of overall braking

effectiveness. This will be evident by increased

pedal travel during application, greater pedal force

required to slow or stop, and activation of the

Brake Warning Light and/or the ABS Warning Light

during brake use.

HYDRAULIC BRAKE ASSIST —

I

F EQUIPPED

The brake system power assist is provided by a

hydro-boost unit which shares fluid with the power

steering system. You may experience some

clicking or hissing noises from the hydro-boost

system during hard braking conditions.

NOTE:Under cold temperatures, pedal effort will be

higher than normal until the power steering fluid

reaches operating temperature.

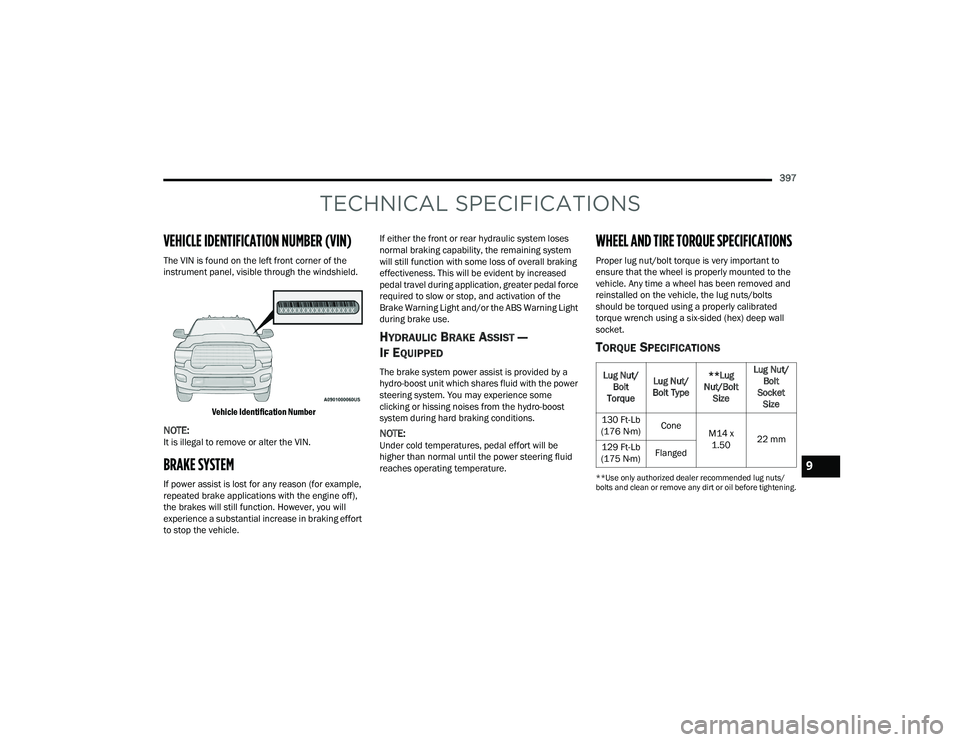

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Lug Nut/

Bolt

Torque Lug Nut/

Bolt Type **Lug

Nut/Bolt Size Lug Nut/

Bolt

Socket Size

130 Ft-Lb

(176 N·m) Cone

M14 x

1.50 22 mm

129 Ft-Lb

(175 N·m) Flanged

9

22_DPF_OM_EN_USC_t.book Page 397

Page 400 of 428

398TECHNICAL SPECIFICATIONS

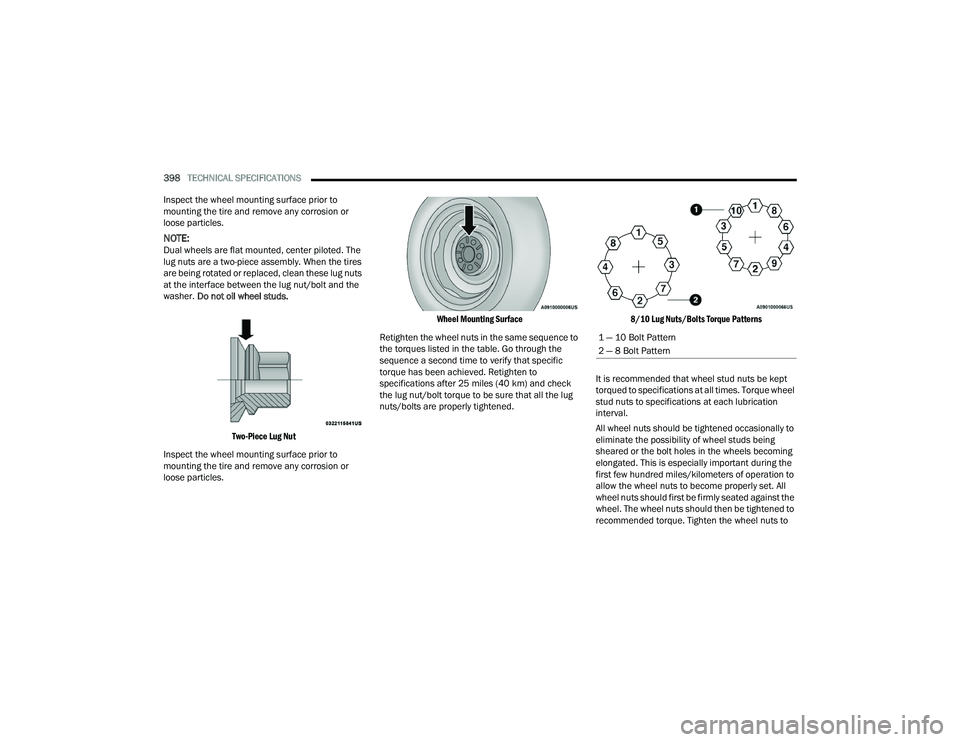

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

NOTE:Dual wheels are flat mounted, center piloted. The

lug nuts are a two-piece assembly. When the tires

are being rotated or replaced, clean these lug nuts

at the interface between the lug nut/bolt and the

washer. Do not oil wheel studs.

Two-Piece Lug Nut

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Retighten the wheel nuts in the same sequence to

the torques listed in the table. Go through the

sequence a second time to verify that specific

torque has been achieved. Retighten to

specifications after 25 miles (40 km) and check

the lug nut/bolt torque to be sure that all the lug

nuts/bolts are properly tightened.

8/10 Lug Nuts/Bolts Torque Patterns

It is recommended that wheel stud nuts be kept

torqued to specifications at all times. Torque wheel

stud nuts to specifications at each lubrication

interval.

All wheel nuts should be tightened occasionally to

eliminate the possibility of wheel studs being

sheared or the bolt holes in the wheels becoming

elongated. This is especially important during the

first few hundred miles/kilometers of operation to

allow the wheel nuts to become properly set. All

wheel nuts should first be firmly seated against the

wheel. The wheel nuts should then be tightened to

recommended torque. Tighten the wheel nuts to

1 — 10 Bolt Pattern

2 — 8 Bolt Pattern

22_DPF_OM_EN_USC_t.book Page 398

Page 401 of 428

TECHNICAL SPECIFICATIONS399

final torque in increments. Progress around the

bolt circle, tightening the wheel nut opposite to the

wheel nut just previously tightened until final

torque is achieved.

FUEL REQUIREMENTS— GASOLINE ENGINE

While operating on gasoline with the required

octane number, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see a dealer immediately. Use of

gasoline with a lower than recommended octane

number can cause engine failure and may void or

not be covered by the New Vehicle Limited

Warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand of

gasoline before considering service for the vehicle.

6.4L ENGINE

Do not use E-85 flex fuel or ethanol blends greater

than 15% in this engine. This engine is designed to meet all

emissions regulations and provide

satisfactory fuel economy and

performance when using high quality

unleaded gasoline having a posted octane number

of 87 as specified by the (R+M)/2 method.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner-burning gasoline referred to as

“reformulated gasoline”. Reformulated gasoline

contains oxygenates and are specifically blended

to reduce vehicle emissions and improve air

quality.

The use of reformulated gasoline is recommended.

Properly blended reformulated gasoline will

provide improved performance and durability of

engine and fuel system components.

MATERIALS ADDED TO FUEL

Besides using unleaded gasoline with the proper

octane rating, gasolines that contain detergents,

corrosion and stability additives are

recommended. Using gasolines that have these

additives will help improve fuel economy, reduce

emissions, and maintain vehicle performance. Designated TOP TIER Detergent Gasoline

contains a higher level of detergents to

further aide in minimizing engine and

fuel system deposits. When available,

the usage of TOP TIER Detergent Gasoline is

recommended. Visit www.toptiergas.com for a list

of TOP TIER Detergent Gasoline Retailers.

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials

intended for gum and varnish removal may contain

active solvents or similar ingredients. These can

harm fuel system gasket and diaphragm materials.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as ethanol.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully until

the vehicle has been lowered. Failure to follow

this warning may result in personal injury.

CAUTION!

DO NOT use E-85, gasoline containing methanol,

or gasoline containing more than 15% ethanol

(E-15). Use of these blends may result in starting

and drivability problems, damage critical fuel

system components, cause emissions to exceed

the applicable standard, and/or cause the

Malfunction Indicator Light to illuminate. Please

observe pump labels as they should clearly

communicate if a fuel contains greater than

15% ethanol (E-15).

9

22_DPF_OM_EN_USC_t.book Page 399

Page 423 of 428

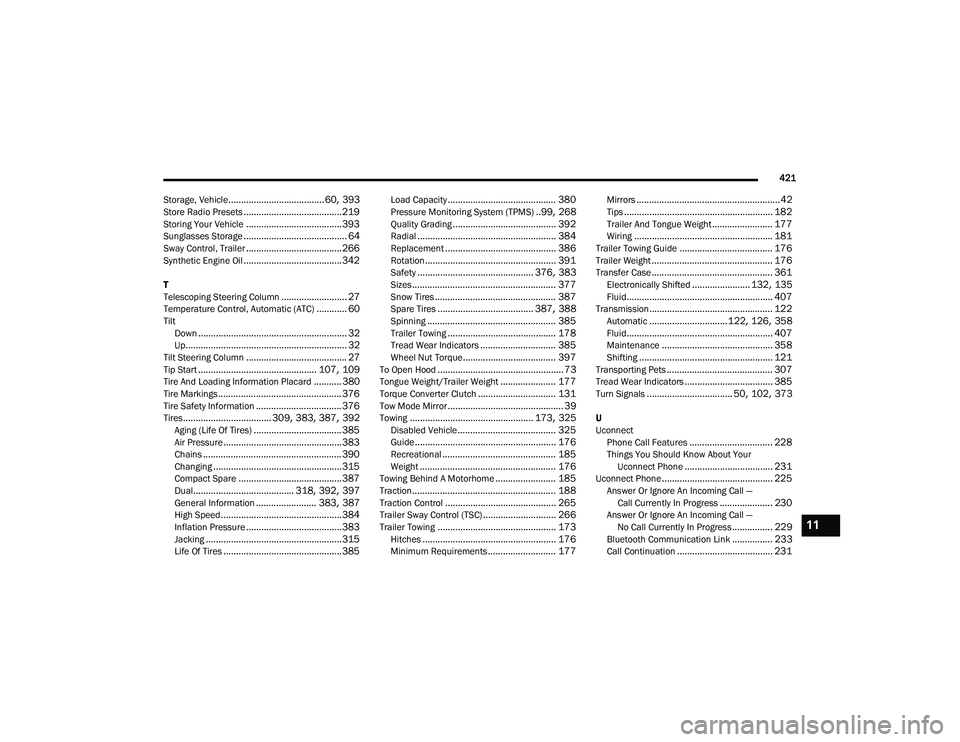

421

Storage, Vehicle

...................................... 60, 393Store Radio Presets....................................... 219Storing Your Vehicle...................................... 393Sunglasses Storage......................................... 64Sway Control, Trailer...................................... 266Synthetic Engine Oil....................................... 342

T

Telescoping Steering Column.......................... 27Temperature Control, Automatic (ATC)............ 60Tilt Down........................................................... 32Up................................................................ 32Tilt Steering Column........................................ 27Tip Start............................................... 107, 109Tire And Loading Information Placard........... 380Tire Markings................................................. 376Tire Safety Information.................................. 376Tires................................... 309, 383, 387, 392Aging (Life Of Tires)................................... 385Air Pressure............................................... 383Chains....................................................... 390Changing................................................... 315Compact Spare......................................... 387Dual........................................ 318, 392, 397General Information........................ 383, 387High Speed................................................ 384Inflation Pressure...................................... 383Jacking...................................................... 315Life Of Tires............................................... 385

Load Capacity........................................... 380Pressure Monitoring System (TPMS)..99, 268Quality Grading......................................... 392Radial....................................................... 384Replacement............................................ 386Rotation.................................................... 391Safety.............................................. 376, 383Sizes......................................................... 377Snow Tires................................................ 387Spare Tires...................................... 387, 388Spinning................................................... 385Trailer Towing........................................... 178Tread Wear Indicators.............................. 385Wheel Nut Torque..................................... 397To Open Hood.................................................. 73Tongue Weight/Trailer Weight...................... 177Torque Converter Clutch............................... 131Tow Mode Mirror.............................................. 39Towing................................................. 173, 325Disabled Vehicle....................................... 325Guide........................................................ 176Recreational............................................. 185Weight...................................................... 176Towing Behind A Motorhome........................ 185Traction......................................................... 188Traction Control............................................ 265Trailer Sway Control (TSC)............................. 266Trailer Towing............................................... 173Hitches..................................................... 176Minimum Requirements........................... 177

Mirrors.........................................................42Tips........................................................... 182Trailer And Tongue Weight........................ 177Wiring....................................................... 181Trailer Towing Guide..................................... 176Trailer Weight................................................ 176Transfer Case................................................ 361Electronically Shifted....................... 132, 135Fluid.......................................................... 407Transmission................................................. 122Automatic............................... 122, 126, 358Fluid.......................................................... 407Maintenance............................................ 358Shifting..................................................... 121Transporting Pets.......................................... 307Tread Wear Indicators................................... 385Turn Signals.................................. 50, 102, 373

U

UconnectPhone Call Features

................................. 228Things You Should Know About Your Uconnect Phone................................... 231Uconnect Phone............................................ 225Answer Or Ignore An Incoming Call — Call Currently In Progress..................... 230Answer Or Ignore An Incoming Call — No Call Currently In Progress................ 229Bluetooth Communication Link................ 233Call Continuation...................................... 231

11

22_DPF_OM_EN_USC_t.book Page 421