wheel bolt torque Ram ProMaster 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: ProMaster, Model: Ram ProMaster 2018Pages: 204, PDF Size: 4 MB

Page 117 of 204

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.NOTE:

Do not install the wheel cover on the spare

tire.

7. Lower the vehicle by turning the jack screw to the left.

8. Refer to “Wheel And Tire Torque Specifi- cations” in “Technical Specifications” for

proper wheel lug bolt torque.

9. Lower the jack to its fully-closed position.

10. Stow the damaged wheel/spare tire with the cable and wheel spacer before driv-

ing the vehicle.

11. Install the winch extension and rotate the

wrench handle clockwise until the winch

mechanism operator hears “3 clicks” from

the device to indicate the wheel is properly

stowed under the vehicle. 12. Stow the jack, jack handle and winch

handle tools back in the storage

compartment.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

13. Check the spare tire pressure as soon as possible. Correct the tire pressure, as

required.

For vehicles with aluminum wheels:

The center cap must be pushed out from the

rear to install the retainer and stow the tire.

Wheel Covers

CAUTION!

Use a back-and-forth motion to remove the

hub cap. Do not use a twisting motion when

removing the hub cap, damage to the hub

cap finish may occur.

The wheel covers on the vehicle are held in

place by the wheel lug bolts and can be

removed after the wheel lug bolts are taken

off.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so

please follow the procedures in this section

carefully.

NOTE:

When using a portable battery booster pack,

follow the manufacturer’s operating instruc-

tions and precautions.

115

Page 156 of 204

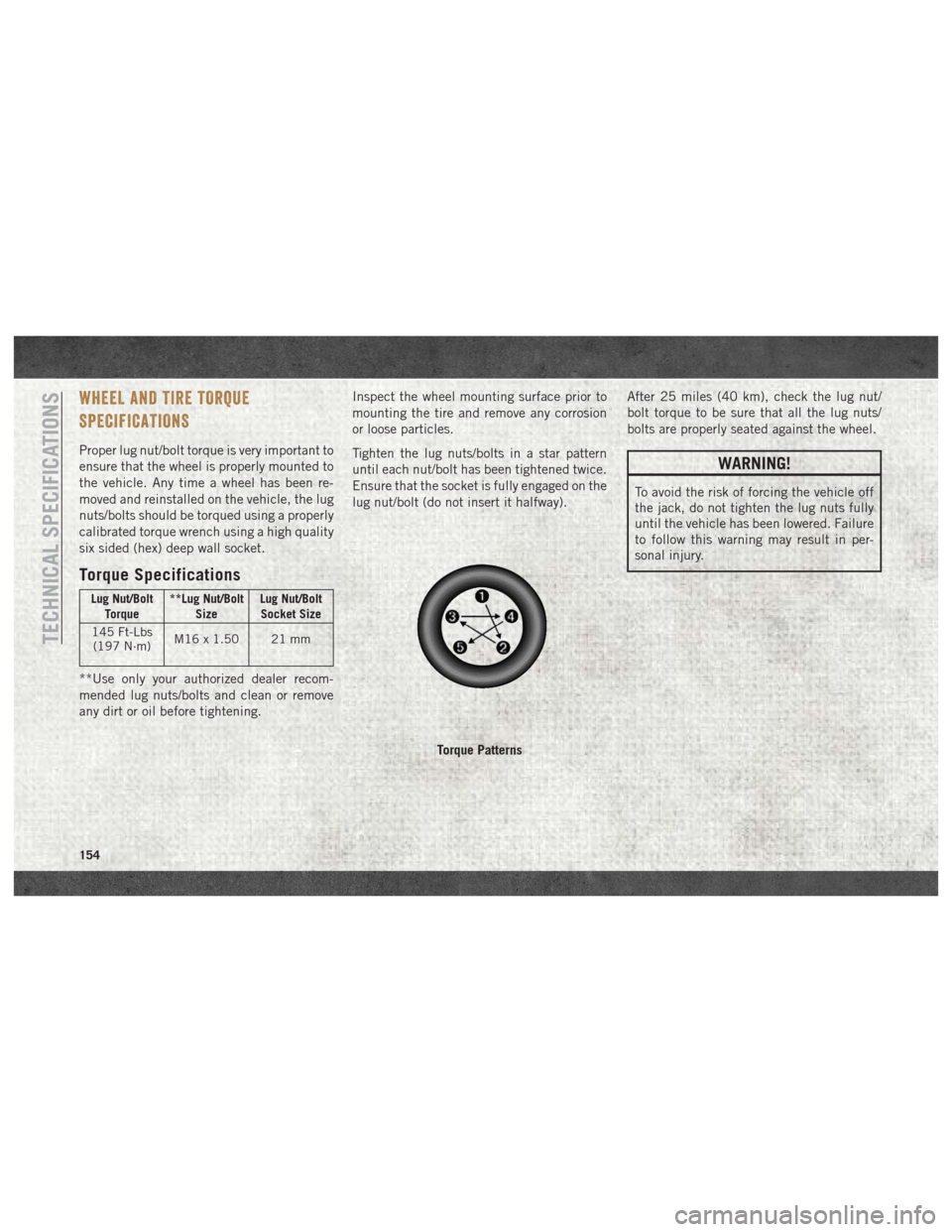

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lug

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/BoltTorque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

145 Ft-Lbs (197 N·m) M16x1.50 21mm

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening. Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it halfway).

After 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

Torque Patterns

TECHNICAL SPECIFICATIONS

154