tires RAM PROMASTER 2022 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: PROMASTER, Model: RAM PROMASTER 2022Pages: 268, PDF Size: 13.26 MB

Page 142 of 268

140SAFETY

ESC Activation/Malfunction Indicator Light

And ESC OFF Indicator Light

The ESC Activation/Malfunction Indicator

Light in the instrument cluster will come

on when the ignition is turned to the ON

mode. It should go out with the engine

running. If the ESC Activation/Malfunction Indicator

Light comes on continuously with the engine

running, a malfunction has been detected in the ESC

system. If this light remains on after several ignition

cycles, and the vehicle has been driven several

miles (kilometers) at speeds greater than 30 mph

(48 km/h), see an authorized dealer as soon as

possible to have the problem diagnosed and

corrected.

The ESC Activation/Malfunction Indicator Light

starts to flash as soon as the tires lose traction and

the ESC system becomes active. The ESC Activation/

Malfunction Indicator Light also flashes when TCS is

active. If the ESC Activation/Malfunction Indicator

Light begins to flash during acceleration, ease up

on the accelerator and apply as little throttle as

possible. Be sure to adapt your speed and driving to

the prevailing road conditions.

The ESC OFF Indicator Light indicates

that the Electronic Stability Control (ESC)

is in a reduced mode.

NOTE:

The ESC Activation/Malfunction Indicator Light

and the ESC OFF Indicator Light come on

momentarily each time the ignition switch is

placed in the ON position.

Each time the ignition is placed in the ON posi -

tion, the ESC system will be on even if it was

turned off previously.

The ESC system will make buzzing or clicking

sounds when it is active. This is normal; the

sounds will stop when ESC becomes inactive

following the maneuver that caused the ESC

activation.

Hill Start Assist (HSA)

The HSA system is designed to assist the driver

when starting a vehicle from a stop on a hill. HSA

will maintain the level of brake pressure the driver

applied for a short period of time after the driver

takes their foot off of the brake pedal. If the driver

does not apply the throttle during this short period

of time, the system will release brake pressure and

the vehicle will roll down the hill. The system will

release brake pressure in proportion to the

amount of throttle applied as the vehicle starts

to move in the intended direction of travel.

HSA Activation Criteria

The following criteria must be met in order for HSA

to activate:

The vehicle must be stopped.

The vehicle must be on a 6% (approximate)

grade or greater hill.

Gear selection matches vehicle uphill direction

(i.e., vehicle facing uphill is in forward gear;

vehicle backing uphill is in REVERSE gear).

HSA will work in REVERSE and all forward gears

when the activation criteria have been met.

The system will not activate if the vehicle is placed

in NEUTRAL or PARK.

WARNING!

There may be situations on minor hills with a

loaded vehicle, or while pulling a trailer, when

the system will not activate and slight rolling may

occur. This could cause a collision with another

vehicle or object. Always remember the driver is

responsible for braking the vehicle.

22_VF_OM_EN_USC_t.book Page 140

Page 143 of 268

SAFETY141

Towing With HSA

HSA will also provide assistance to mitigate roll

back while towing a trailer.

Traction Control System (TCS)

TCS monitors the amount of wheel spin of each of

the driven wheels. If wheel spin is detected, brake

pressure is applied to the slipping wheel(s) and

engine power is reduced, to provide enhanced

acceleration and stability. A feature of the TCS,

Brake Limited Differential (BLD) functions similarly to a limited slip differential and controls the wheel

spin across a driven axle. If one wheel on a driven

axle is spinning faster than the other, the system

will apply the brake of the spinning wheel. This will

allow more engine torque to be applied to the

wheel that is not spinning. This feature remains

active even if the ESC is in the “Partial Off” mode.

The ESC Activation/Malfunction Indicator Light (in

the instrument cluster) will start to flash as soon as

the tires lose traction and the wheels begin to spin.

This indicates that the TCS is active. If the indicator

light flashes during acceleration, ease up on the

accelerator and apply as little throttle as possible.

Be sure to adapt your speed and driving to the

prevailing road conditions, and do not switch off

the ESC or TCS.

Trailer Sway Control (TSC) — If Equipped

TSC uses sensors in the vehicle to recognize an

excessively swaying trailer and will take the

appropriate actions to attempt to stop the sway.

The system may reduce engine power and apply

the brake of the appropriate wheel(s) to counteract

the sway of the trailer.

NOTE:TSC cannot stop all trailers from swaying. Always

use caution when towing a trailer and follow the

trailer tongue weight recommendations

Ú

page 110.

When TSC is functioning, the ESC Activation/

Malfunction Indicator Light will flash, the engine

power may be reduced, and you may feel the

brakes being applied to individual wheels to

attempt to stop the trailer from swaying. TSC is

disabled when the ESC system is in the “Partial

Off” mode.

WARNING!

If you use a trailer brake controller with your

trailer, the trailer brakes may be activated and

deactivated with the brake switch. If so, there

may not be enough brake pressure to hold

both the vehicle and the trailer on a hill when

the brake pedal is released. In order to avoid

rolling down an incline while resuming accel -

eration, manually activate the trailer brake or

apply more vehicle brake pressure prior to

releasing the brake pedal.

HSA is not a parking brake. Always apply the

parking brake fully when exiting your vehicle. Also,

be certain to place the transmission in PARK.

Failure to follow these warnings can result in a

collision or serious personal injury.

WARNING!

The TCS cannot prevent the natural laws of

physics from acting on the vehicle, nor can it

increase the traction afforded.

The TCS cannot prevent collisions, including

those resulting from excessive speed in turns,

or hydroplaning.

The capabilities of a TCS-equipped vehicle

must never be exploited in a reckless or

dangerous manner, which could jeopardize

the user's safety or the safety of others.

WARNING!

If TSC activates while driving, slow the vehicle

down, stop at the nearest safe location, and

adjust the trailer load to eliminate trailer sway.

6

22_VF_OM_EN_USC_t.book Page 141

Page 148 of 268

146SAFETY

Trailer Merge Assist — If Equipped

Trailer Merge Assist is a function of the Blind Spot

Monitoring (BSM) system that extends the blind

spot zone to work while pulling a trailer.

NOTE:When Trailer Merge Assist is activated, Rear Cross

Path is disabled.

Trailer Merge Assist consists of three sub

functions:

Automatic Trailer Detection

Trailer Length Detection

Trailer Merge Warning

Blind Spot Zones With Trailer Merge Assist

Automatic Trailer Detection

There are two modes of operation for the detection

of the trailer length:

Automatic Mode

— When “Auto Mode” is

selected, the system will use the blind spot

sensors to automatically determine the pres -

ence and length of a trailer. The presence of a

trailer will be detected using the blind spot radar

within 90 seconds of forward movement of the

vehicle. The vehicle must be moving above

6 mph (10 km/h) to activate the feature. Once

the trailer has been detected, the system will

default to the maximum blind spot zone until the

length has been verified. You will see “Auto” in

the instrument panel cluster .

Maximum Mode — When “Max Mode” is

selected, the system will default to the maximum

blind spot zone regardless of what size trailer is

attached .

NOTE:Selected setting is stored when the ignition is

placed in the OFF position. To change this setting,

it must be selected through the Uconnect Settings

Ú page 120. Trailer Length Detection

Once the trailer presence has been established,

the trailer length will be established (by making

a 90 degree turn) and then the trailer length

category (example 10-20 ft (3 m to 6 m)) will be

displayed. This can take up to 30 seconds after

completing the turn.

NOTE:During the same ignition cycle, if the vehicle is at a

standstill for a minimum of 90 seconds, a new

“trailer detection request” is enabled by the

system once the vehicle resumes motion.

The maximum trailer length supported by the

Trailer Merge Assist feature is 39.5 ft (12 m).

Trailer length is considered the forward most

portion of the trailer hitch to the rearward most

portion of the body, fascia/bumper, or ramp of the

trailer.

The maximum width supported by the Trailer

Merge Assist feature is 8.5 ft (2.59 m). Trailer

width is measured at the widest portion of the

trailer and may include wheels, tires, finders,

or rails.

1 — Vehicle

2 — Trailer

22_VF_OM_EN_USC_t.book Page 146

Page 153 of 268

SAFETY151

Small Vehicles And/Or Not Aligned To The Lane

The system is not able to detect the presence of

vehicles that are in front of the vehicle but placed

outside the field of action of the camera and could

therefore not react in the presence of small

vehicles such as bicycles or motorcycles.

Small Vehicles And/Or Not Aligned To The Lane

Lane Changing Of Other Vehicles

Vehicles that suddenly change lanes, while staying

in the traffic lane of their vehicle and inside the

field of action of the camera, may cause the

intervention of the system.

Lane Changing Of Other Vehicles

Passing Of Vehicles In An Oncoming Intersection

The system could temporarily react to a vehicle

that crossed the range of the camera in an

oncoming intersection.

Passing Of Vehicles In An Oncoming Intersection

TIRE PRESSURE MONITORING SYSTEM

(TPMS)

The Tire Pressure Monitoring System (TPMS) will

warn the driver of a low tire pressure based on the

vehicle recommended cold placard pressure.

The tire pressure will vary with temperature by

about 1 psi (7 kPa) for every 12°F (6.5°C).

This means that when the outside temperature

decreases, the tire pressure will decrease. Tire

pressure should always be set based on cold

inflation tire pressure. This is defined as the tire

pressure after the vehicle has not been driven for

at least three hours, or driven less than 1 mile

(1.6 km) after a three hour period. The cold tire

inflation pressure must not exceed the maximum

inflation pressure molded into the tire sidewall.

The tire pressure will also increase as the vehicle

is driven — this is normal and there should be no

adjustment for this increased pressure.

See Ú page 225 on how to properly inflate the

vehicle’s tires.

The TPMS will warn the driver of a low tire pressure

if the tire pressure falls below the low-pressure

warning limit for any reason, including low

temperature effects and natural pressure loss

through the tire.

6

22_VF_OM_EN_USC_t.book Page 151

Page 154 of 268

152SAFETY

The TPMS will continue to warn the driver of low

tire pressure as long as the condition exists, and

will not turn off until the tire pressure is at or above

the recommended cold placard pressure. Once the

low tire pressure warning (TPMS Warning Light)

illuminates, you must increase the tire pressure to

the recommended cold placard pressure in order

for the TPMS Warning Light to turn off. The system

will automatically update and the TPMS Warning

Light will turn off once the system receives the

updated tire pressures. The vehicle may need to

be driven for up to 20 minutes above 15 mph

(24 km/h) in order for the TPMS to receive this

information.

NOTE:When filling warm tires, the tire pressure may need

to be increased up to an additional 4 psi (28 kPa)

above the recommended cold placard pressure in

order to turn the TPMS Warning Light off.

For example, your vehicle may have a recommended

cold (parked for more than three hours) placard

pressure of 30 psi (207 kPa). If the ambient

temperature is 68°F (20°C) and the measured tire

pressure is 27 psi (186 kPa), a temperature drop to

20°F (-7°C) will decrease the tire pressure to

approximately 23 psi (158 kPa). This tire pressure is

sufficiently low enough to turn on the TPMS Warning

Light. Driving the vehicle may cause the tire pressure

to rise to approximately 27 psi (186 kPa), but the TPMS Warning Light will still be on. In this situation,

the TPMS Warning Light will turn off only after the

tires are inflated to the vehicle’s recommended cold

placard pressure value.

NOTE:

The TPMS is not intended to replace normal tire

care and maintenance or to provide warning of

a tire failure or condition.

The TPMS should not be used as a tire pressure

gauge while adjusting your tire pressure.

Driving on a significantly underinflated tire

causes the tire to overheat and can lead to tire

failure. Underinflation also reduces fuel effi

-

ciency and tire tread life, and may affect the

vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsibility

to maintain correct tire pressure using an accu -

rate tire pressure gauge, even if underinflation

has not reached the level to trigger illumination

of the TPMS Warning Light.

Seasonal temperature changes will affect tire

pressure, and the TPMS will monitor the actual

tire pressure in the tire Ú page 256.

Base System

This is the TPMS warning indicator

located in the instrument cluster.

The TPMS uses wireless technology with wheel rim

mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each wheel

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures

and warning have been established for the tire

size equipped on your vehicle. Undesirable

system operation or sensor damage may result

when using replacement equipment that is not

of the same size, type, and/or style. After -

market wheels can cause sensor damage.

Using aftermarket tire sealants may cause the

Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended

that you take your vehicle to an authorized

dealership to have your sensor function

checked.

After inspecting or adjusting the tire pressure

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the TPMS

sensor.

22_VF_OM_EN_USC_t.book Page 152

Page 155 of 268

SAFETY153

as part of the valve stem, transmit tire pressure

readings to the receiver module.

NOTE:It is particularly important for you to check the tire

pressure in all of the tires on your vehicle regularly

and to maintain the proper pressure.

The TPMS consists of the following components:

Receiver module

Four Tire Pressure Monitoring System sensors

Tire Pressure Monitoring System Warning Light

Tire Pressure Monitoring System Low

Pressure Warnings

The Tire Pressure Monitoring System Warning Light

will illuminate in the instrument cluster, an audible

chime will be activated, and the “Check tire

pressure” message will display when one or more of

the four active road tire pressures are low. Should

this occur, you should stop as soon as possible,

check the inflation pressure of each tire on your

vehicle, and inflate each tire to the vehicle’s

recommended cold placard pressure value. The

system will automatically update and the Tire

Pressure Monitoring System Warning Light will

extinguish once the updated tire pressures have

been received. The vehicle may need to be driven

for up to 20 minutes above 15 mph (24 km/h) to

receive this information.

Check TPMS Warnings

The Tire Pressure Monitoring System Warning Light

will flash on and off for 75 seconds and remain on

solid when a system fault is detected, an audible

chime will be activated and the “Tire Pressure

Monitoring Unavailable” message will display.

If the ignition key is cycled, this sequence will

repeat providing the system fault still exists. The

TPMS Warning Light will turn off when the fault

condition no longer exists. A system fault can occur

with any of the following scenarios:

Jamming due to electronic devices or driving

next to facilities emitting the same radio

frequencies as the TPMS sensors

Installing some form of aftermarket window

tinting that affects radio wave signals

Snow or ice around the wheels or wheel housings

Using tire chains on the vehicle

Using wheels/tires not equipped with TPMS

sensors

NOTE:Your vehicle is equipped with a regular size spare

wheel.

1. The spare tire does not have a TPMS sensor.

Therefore, the TPMS will not monitor the

pressure in the spare tire.

2. If a spare tire not equipped with the Tire Pressure Monitoring System sensor is used,

the TPMS Warning Light will turn on, flashing

for 75 seconds and then remaining solid for

each subsequent ignition key cycle.

3. Once you repair or replace the original road tire and reinstall it on the vehicle in place of the

spare tire, the TPMS will update automatically

and the Tire Pressure Monitoring System

Warning Light will extinguish once the updated

tire pressures have been received. The vehicle

may need to be driven for up to 20 minutes

above 15 mph (24 km/h) to receive this

information.

NOTE:For correct Tire Pressure Monitoring System

behavior, please wait for about 20 minutes in

key-off during each tire substitution.

6

22_VF_OM_EN_USC_t.book Page 153

Page 176 of 268

174SAFETY

(Continued)

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven

wear patterns. Check for stones, nails, glass, or

other objects lodged in the tread or sidewall.

Inspect the tread for cuts and cracks. Inspect

sidewalls for cuts, cracks, and bulges. Check the

lug nut/bolt torque for tightness. Check the tires

(including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel or

brake fluid leaks are suspected, the cause should

be located and corrected immediately.

ALWAYS REMOVE THE EXISTING

FLOOR MAT FROM THE VEHICLE

before installing any other floor mat.

NEVER install or stack an additional

floor mat on top of an existing floor mat.

ONLY install floor mats designed to fit your vehicle.

NEVER install a floor mat that cannot be properly

attached and secured to your vehicle. If a floor mat

needs to be replaced, only use a FCA approved

floor mat for the specific make, model, and year of

your vehicle.

ONLY use the driver’s side floor mat on the driver’s

side floor area. To check for interference, with the

vehicle properly parked with the engine off, fully

depress the accelerator, the brake, and the clutch

pedal (if present) to check for interference. If your

floor mat interferes with the operation of any

pedal, or is not secure to the floor, remove the

floor mat from the vehicle and place the floor mat

in your trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

WARNING!

ALWAYS make sure objects cannot fall or slide into

the driver’s side floor area when the vehicle is

moving. Objects can become trapped under accel -

erator, brake, or clutch pedals and could cause a

loss of vehicle control.

NEVER place any objects under the floor mat

(e.g., towels, keys, etc.). These objects could

change the position of the floor mat and may

cause interference with the accelerator,

brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to

the floor and check the floor mat fasteners are

secure to the vehicle carpet. Fully depress

each pedal to check for interference with the

accelerator, brake, or clutch pedals then

re-install the floor mats.

It is recommended to only use mild soap and

water to clean your floor mats. After cleaning,

always check your floor mat has been properly

installed and is secured to your vehicle using

the floor mat fasteners by lightly pulling mat.

WARNING!

22_VF_OM_EN_USC_t.book Page 174

Page 182 of 268

180IN CASE OF EMERGENCY

Automatic SOS — If Equipped

Automatic SOS is a hands-free safety service that

can immediately connect you with help in the event

that your vehicle’s airbags deploy. Please refer to

your provided radio supplement for complete

information.

ASSIST Call

The ASSIST Button is used to automatically

connect you to any one of the following support

centers:

Roadside Assistance – If you get a flat tire, or

need a tow, just push the ASSIST button and

you’ll be connected to someone who can help.

Roadside Assistance will know what vehicle

you’re driving and its location. Additional fees

may apply for roadside assistance.

SiriusXM Guardian™ Customer Care – In-vehicle

support for SiriusXM Guardian™.

Vehicle Customer Care – Total support for all

other vehicle issues.

Uconnect Customer Care - Total support for

Radio, Phone and NAV issues.

JACKING AND TIRE CHANGING PREPARATIONS FOR JACKING

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake firmly.

4. Place the transmission in PARK (P) or REVERSE (R) for manual transmission.

5. Turn the ignition OFF.

6. Block both front and rear of the wheel diagonally opposite of the jacking position.

For example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid the danger of

being hit when operating the jack or changing

the wheel.

Being under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on

you. You could be crushed. Never put any part

of your body under a vehicle that is on a jack.

If you need to get under a raised vehicle, take

it to a service center where it can be raised on

a lift.

Never start or run the engine while the vehicle

is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

22_VF_OM_EN_USC_t.book Page 180

Page 186 of 268

184IN CASE OF EMERGENCY

(Continued)

5. Pull the retainer through the center of the

wheel.

Retainer

JACKING INSTRUCTIONS

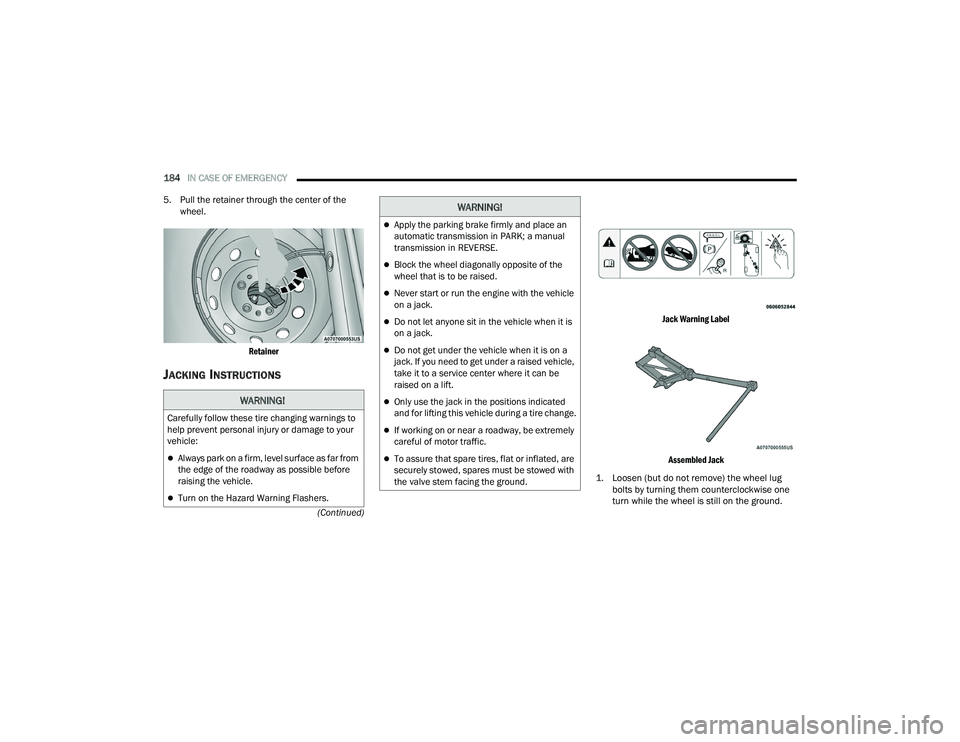

Jack Warning Label

Assembled Jack

1. Loosen (but do not remove) the wheel lug bolts by turning them counterclockwise one

turn while the wheel is still on the ground.

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and place an

automatic transmission in PARK; a manual

transmission in REVERSE.

Block the wheel diagonally opposite of the

wheel that is to be raised.

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with

the valve stem facing the ground.

WARNING!

22_VF_OM_EN_USC_t.book Page 184

Page 190 of 268

188IN CASE OF EMERGENCY

(Continued)

Using The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the following

symbols to indicate the air or sealant mode.

Selecting Air Mode Push in the Mode Select Knob (2) and

turn to this position for air pump oper -

ation only. Use the Black Air Pump

Hose (5) when selecting this mode.

Selecting Sealant Mode

Push in the Mode Select Knob (2) and

turn to this position to inject the Tire

Service Kit Sealant and to inflate the

tire. Use the Sealant Hose (3) when

selecting this mode.

Using The Power Button

Push and release the Power Button (1)

once to turn on the Tire Service Kit.

Push and release the Power Button (1)

again to turn Off the Tire Service Kit.

Using The Deflation Button Push the Deflation Button (9) to

reduce the air pressure in the tire if it

becomes overinflated.

TIRE SERVICE KIT USAGE PRECAUTIONS

Replace the Tire Service Kit Sealant Bottle (4)

and Sealant Hose (3) prior to the expiration date

(printed at the upper right hand corner on the

bottle label) to assure optimum operation of the

system Ú page 191.

Tire Service Kit Sealant Expiration Date Location

The Sealant Bottle (4) and Sealant Hose (3) are

a one tire application use and need to be

replaced after each use. Always replace these

components immediately at your original equip -

ment vehicle dealer.

When the Tire Service Kit sealant is in a liquid

form, clean water and a damp cloth will remove

the material from the vehicle or tire and wheel

components. Once the sealant dries, it can

easily be peeled off and properly discarded.

For optimum performance, make sure the valve

stem on the wheel is free of debris before

connecting the Tire Service Kit.

You can use the Tire Service Kit air pump to

inflate bicycle tires. The kit also comes with two

needles, located in the Accessory Storage

Compartment (on the bottom of the air pump)

for inflating sport balls, rafts, or similar inflat -

able items. However, use only the Air Pump

Hose (5) and make sure the Mode Select Knob

(2) is in the Air Mode when inflating such items

to avoid injecting sealant into them. The Tire

Service Kit Sealant is only intended to seal

punctures less than 1/4 inch (6 mm) diameter

in the tread of your tire.

Do not lift or carry the Tire Service Kit by the

hoses.

WARNING!

Do not attempt to seal a tire on the side of the

vehicle closest to traffic. Pull far enough off

the road to avoid the danger of being hit when

using the Tire Service Kit.

Do not use Tire Service Kit or drive the vehicle

under the following circumstances:

If the puncture in the tire tread is approxi -

mately 1/4 inch (6 mm) or larger.

If the tire has any sidewall damage.

22_VF_OM_EN_USC_t.book Page 188