battery Ram ProMaster City 2015 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: ProMaster City, Model: Ram ProMaster City 2015Pages: 414, PDF Size: 2.86 MB

Page 332 of 414

Your vehicle has a simple ignition actuated test, which

you can use prior to going to the test station. To check if

your vehicle’s OBD II system is ready, you must do the

following:

1. Cycle the ignition switch to the ON position, but donot crank or start the engine.

NOTE: If you crank or start the engine, you will have to

start this test over.

2. As soon as you cycle the ignition switch to the ON position, you will see the Malfunction Indicator Light

(MIL) symbol come on as part of a normal bulb check.

3. Approximately 15 seconds later, one of two things will happen:

• The MIL will flash for about 10 seconds and then

return to being fully illuminated until you turn OFF the ignition or start the engine. This means that your

vehicle’s OBD II system is

not readyand you should

not proceed to the I/M station.

• The MIL will not flash at all and will remain fully

illuminated until you place the ignition in the off

position or start the engine. This means that your

vehicle’s OBD II system is readyand you can proceed

to the I/M station.

If your OBD II system is not ready,you should see your

authorized dealer or repair facility. If your vehicle was

recently serviced or had a battery failure or replacement,

you may need to do nothing more than drive your

vehicle as you normally would in order for your OBD II

system to update. A recheck with the above test routine

may then indicate that the system is now ready.

Regardless of whether your vehicle’s OBD II system is

ready or not, if the MIL is illuminated during normal

vehicle operation you should have your vehicle serviced

330 MAINTAINING YOUR VEHICLE

Page 338 of 414

used to assure most efficient service. MOPAR® engine air

cleaner filters are a high quality filter and are recom-

mended.

Maintenance-Free Battery

Your vehicle is equipped with a maintenance-free battery.

You will never have to add water, nor is periodic main-

tenance required.

WARNING!

•Battery fluid is a corrosive acid solution and can

burn or even blind you. Do not allow battery fluid

to contact your eyes, skin, or clothing. Do not lean

over a battery when attaching clamps. If acid

splashes in eyes or on skin, flush the area imme-

diately with large amounts of water. Refer to

“Jump-Starting Procedures” in “What To Do In

(Continued)

WARNING! (Continued)

Emergencies” for further information.

• Battery gas is flammable and explosive. Keep

flame or sparks away from the battery. Do not use

a booster battery or any other booster source with

an output greater than 12 Volts. Do not allow cable

clamps to touch each other.

• Battery posts, terminals, and related accessories

contain lead and lead compounds. Wash hands

after handling.

CAUTION!

• It is essential when replacing the cables on the

battery that the positive cable is attached to the

positive post and the negative cable is attached to

the negative post. Battery posts are marked positive

(Continued)

336 MAINTAINING YOUR VEHICLE

Page 339 of 414

CAUTION!(Continued)

(+) and negative (-) and are identified on the

battery case. Cable clamps should be tight on the

terminal posts and free of corrosion.

• If a “fast charger” is used while the battery is in the

vehicle, disconnect both vehicle battery cables be-

fore connecting the charger to the battery. Do not

use a “fast charger” to provide starting voltage.

Air Conditioner Maintenance

For best possible performance, your air conditioner

should be checked and serviced by an authorized dealer

at the start of each warm season. This service should

include cleaning of the condenser fins and a performance

test. Drive belt tension should also be checked at this

time.

WARNING!

• Use only refrigerants and compressor lubricants

approved by the manufacturer for your air condi-

tioning system. Some unapproved refrigerants are

flammable and can explode, injuring you. Other

unapproved refrigerants or lubricants can cause the

system to fail, requiring costly repairs. Refer to

Warranty Information Book, located on the DVD,

for further warranty information.

• The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal

injury or damage to the system, adding refrigerant

or any repair requiring lines to be disconnected

should be done by an experienced technician.

7

MAINTAINING YOUR VEHICLE 337

Page 363 of 414

Underhood Fuses

The Front Distribution Unit is located on the right side of

the engine compartment, next to the battery. To access the

fuses, remove fasteners and remove the cover.The ID number of the electrical component correspond-

ing to each fuse can be found on the back of the cover.

Front Distribution Unit

7

MAINTAINING YOUR VEHICLE 361

Page 371 of 414

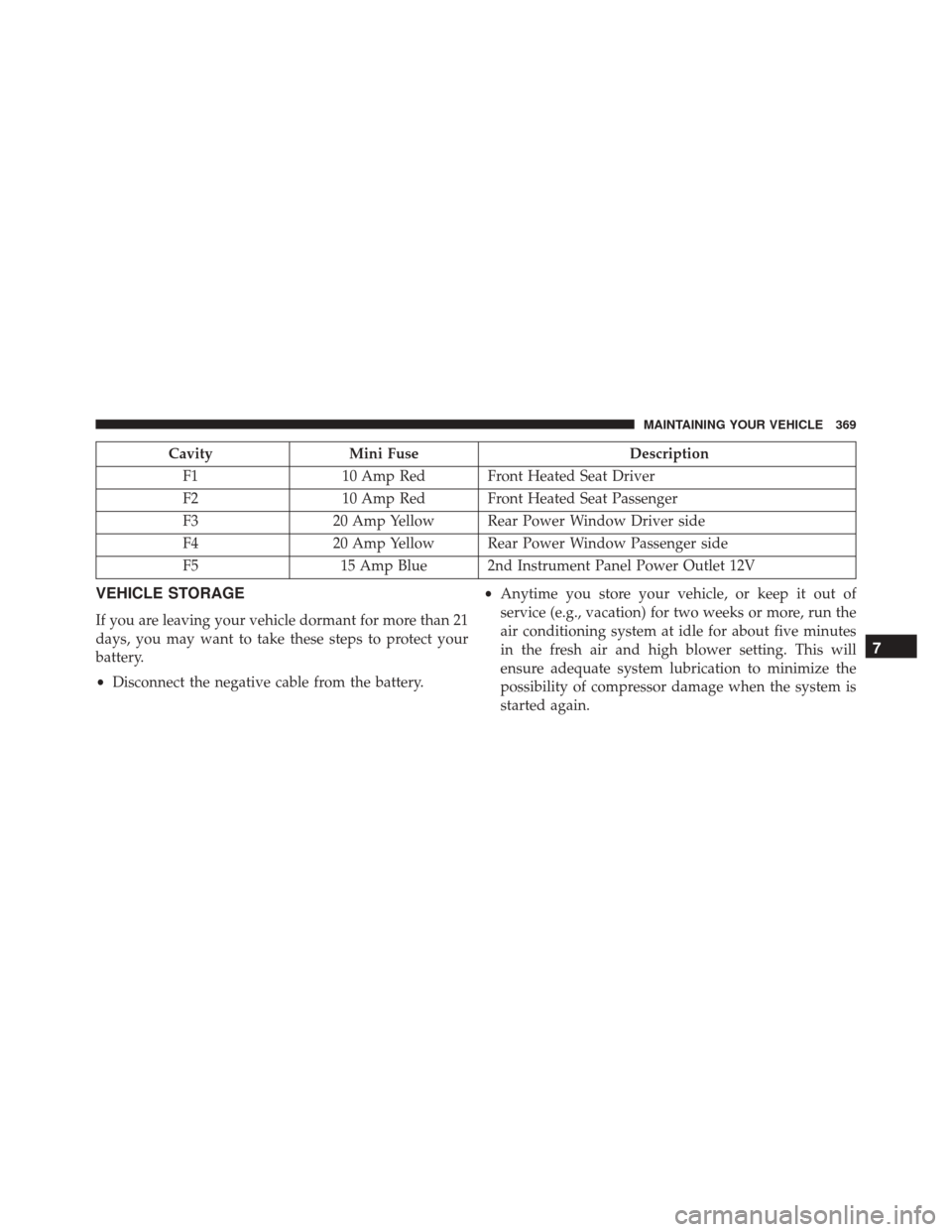

CavityMini Fuse Description

F1 10 Amp Red Front Heated Seat Driver

F2 10 Amp Red Front Heated Seat Passenger

F3 20 Amp Yellow Rear Power Window Driver side

F4 20 Amp Yellow Rear Power Window Passenger side

F5 15 Amp Blue 2nd Instrument Panel Power Outlet 12V

VEHICLE STORAGE

If you are leaving your vehicle dormant for more than 21

days, you may want to take these steps to protect your

battery.

•Disconnect the negative cable from the battery. •

Anytime you store your vehicle, or keep it out of

service (e.g., vacation) for two weeks or more, run the

air conditioning system at idle for about five minutes

in the fresh air and high blower setting. This will

ensure adequate system lubrication to minimize the

possibility of compressor damage when the system is

started again.

7

MAINTAINING YOUR VEHICLE 369

Page 383 of 414

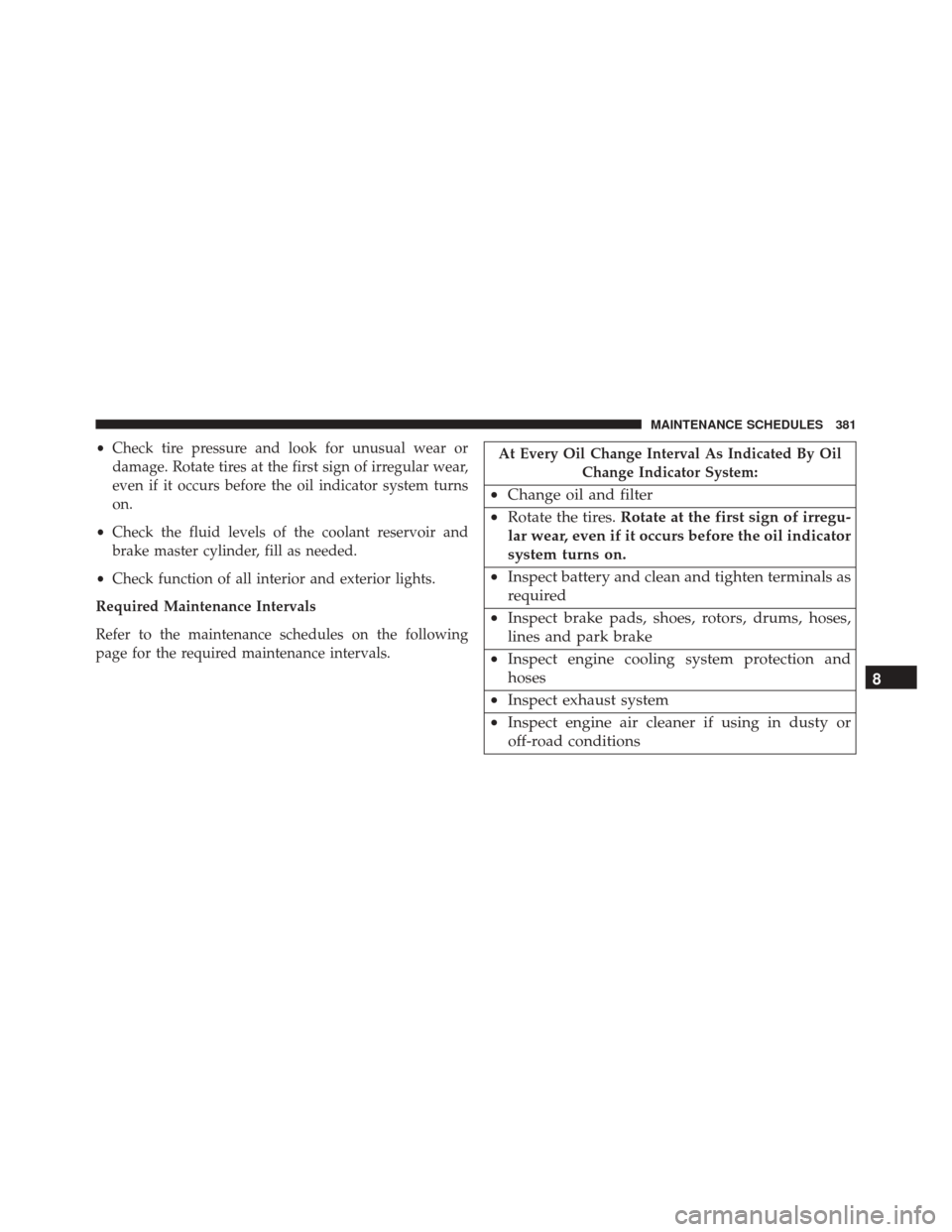

•Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before the oil indicator system turns

on.

• Check the fluid levels of the coolant reservoir and

brake master cylinder, fill as needed.

• Check function of all interior and exterior lights.

Required Maintenance Intervals

Refer to the maintenance schedules on the following

page for the required maintenance intervals.At Every Oil Change Interval As Indicated By Oil Change Indicator System:

•Change oil and filter

• Rotate the tires. Rotate at the first sign of irregu-

lar wear, even if it occurs before the oil indicator

system turns on.

• Inspect battery and clean and tighten terminals as

required

• Inspect brake pads, shoes, rotors, drums, hoses,

lines and park brake

• Inspect engine cooling system protection and

hoses

• Inspect exhaust system

• Inspect engine air cleaner if using in dusty or

off-road conditions 8

MAINTENANCE SCHEDULES 381

Page 399 of 414

Adding Fluid...................... .353, 377

Fluid and Filter Changes ..................353

Fluid Change ......................... .353

Fluid Level Check ...................352, 353

Fluid Type ........................ .352, 377

Special Additives ...................... .352

Auto Up Power Windows ....................27

Auxiliary Electrical Outlet (Power Outlet) ........131

Axle Lubrication ......................... .377

Battery ................................ .336

Keyless Transmitter Replacement (RKE) ........19

Belts, Seat ...............................88

Body Builders Guide ........................6

Body Mechanism Lubrication .................338

B-Pillar Location ......................... .236

Brake Assist System ...................... .222

Brake Fluid ............................ .377

Brake, Parking .......................... .218Brake System

........................ .220, 349

Anti-Lock (ABS) ....................... .221

Fluid Check ....................... .350, 377

Master Cylinder ....................... .350

Parking ............................. .218

Warning Light ........................ .147

Brake/Transmission Interlock .................204

Bulb Replacement ..................... .370, 371

Bulbs, Light .......................... .90, 370

Camera, Rear ........................... .129

Capacities, Fluid ......................... .374

Caps, Filler Fuel ................................ .265

Oil (Engine) ....................... .327, 334

Power Steering ........................ .217

Radiator (Coolant Pressure) ................347

Carbon Monoxide Warning ................87, 264

Cargo Tie-Downs ........................ .137

10

INDEX 397

Page 406 of 414

Tire Pressure Monitoring (TPMS)............147

Traction Control ....................... .226

Turn Signal ............................90

Wait to Start .......................... .147

Warning (Instrument Cluster Description) ......147

Loading Vehicle ...................... .267, 269

Capacities ........................... .269

Tires ............................... .236

Locks ..................................21

Door .................................21

Lubrication, Body ........................ .338

Lug Nuts .............................. .288

Maintenance Free Battery ....................336

Maintenance Procedures ....................331

Maintenance Schedule ..................... .380

Malfunction Indicator Light (Check Engine) .......329

Manual, Service ......................... .392

Master Cylinder (Brakes) ....................350 Methanol

.............................. .261

Mirrors .................................94

Electric Powered .........................96

Electric Remote .........................96

Exterior Folding .........................95

Outside ...............................94

Rearview ..............................94

Modifications/Alterations, Vehicle ...............7

Monitor, Tire Pressure System ................254

MOPAR® Parts ...................... .331, 391

MTBE/ETBE ........................... .261

Multi-Function Control Lever .................110

New Vehicle Break-In Period ..................85

Occupant Restraints ........................32

Octane Rating, Gasoline (Fuel) .............260, 375

Oil Change Indicator ...................... .163

Oil Change Indicator, Reset ..................163

404 INDEX

Page 411 of 414

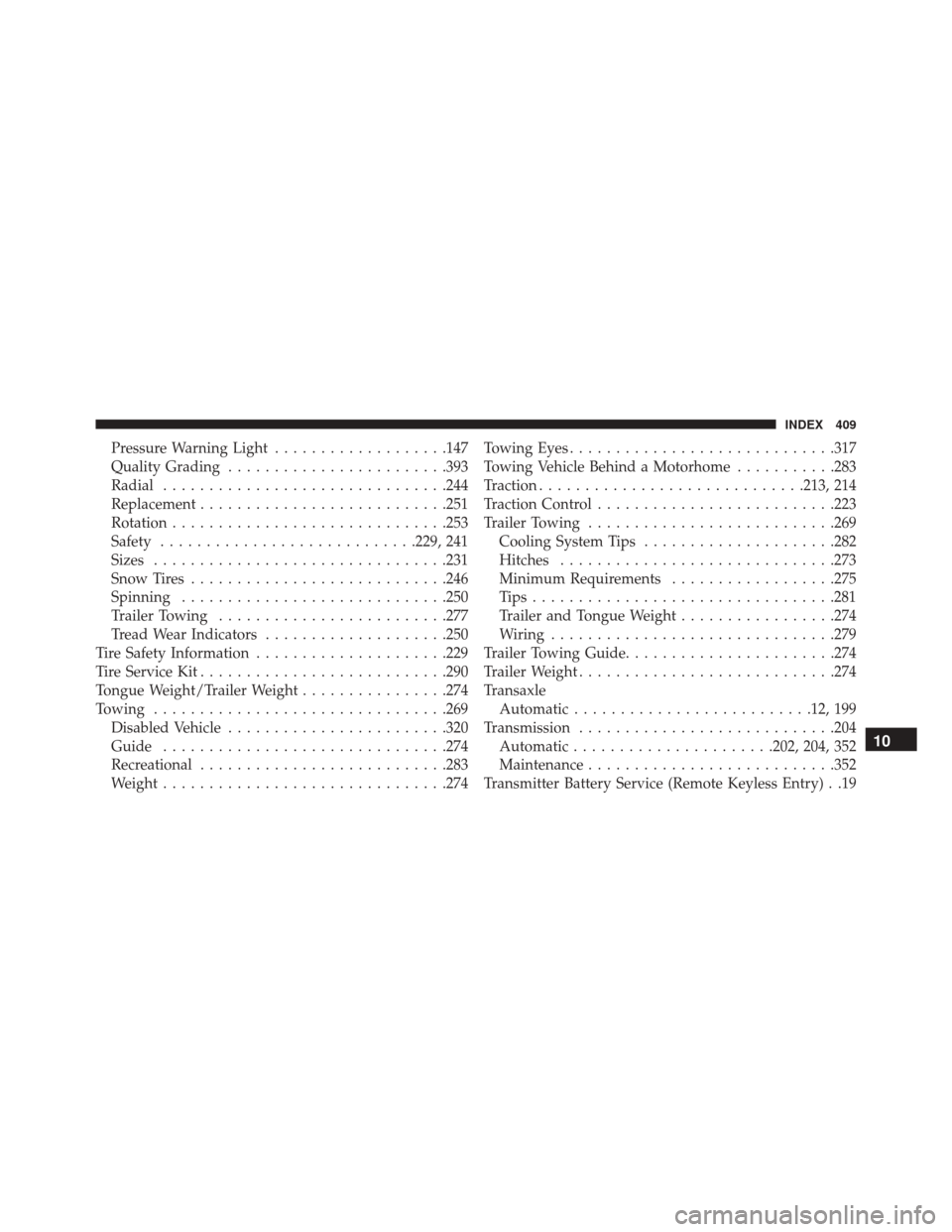

Pressure Warning Light...................147

Quality Grading ....................... .393

Radial .............................. .244

Replacement .......................... .251

Rotation ............................. .253

Safety ........................... .229, 241

Sizes ............................... .231

Snow Tires ........................... .246

Spinning ............................ .250

Trailer Towing ........................ .277

Tread Wear Indicators ....................250

Tire Safety Information .....................229

Tire Service Kit .......................... .290

Tongue Weight/Trailer Weight ................274

Towing ............................... .269

Disabled Vehicle ....................... .320

Guide .............................. .274

Recreational .......................... .283

Weight .............................. .274Towing Eyes

............................ .317

Towing Vehicle Behind a Motorhome ...........283

Traction ............................ .213, 214

Traction Control ......................... .223

Trailer Towing .......................... .269

Cooling System Tips .....................282

Hitches ............................. .273

Minimum Requirements ..................275

Tips................................ .281

Trailer and Tongue Weight .................274

Wiring .............................. .279

Trailer Towing Guide ...................... .274

Trailer Weight ........................... .274

Transaxle Automatic ......................... .12, 199

Transmission ........................... .204

Automatic ..................... .202,

204, 352

Maintenance .......................... .352

Transmitter Battery Service (Remote Keyless Entry) . .1910

INDEX 409

Page 413 of 414

INSTALLATION OF RADIO TRANSMITTING

EQUIPMENTSpecial design considerations are incorporated into this

vehicle’s electronic system to provide immunity to radio

frequency signals. Mobile two-way radios and telephone

equipment must be installed properly by trained person-

nel. The following must be observed during installation.

The positive power connection should be made directly

to the battery and fused as close to the battery as possible.

The negative power connection should be made to body

sheet metal adjacent to the negative battery connection.

This connection should not be fused.

Antennas for two-way radios should be mounted on the

roof or the rear area of the vehicle. Care should be used

in mounting antennas with magnet bases. Magnets may

affect the accuracy or operation of the compass on

vehicles so equipped.The antenna cable should be as short as practical and

routed away from the vehicle wiring when possible. Use

only fully shielded coaxial cable.

Carefully match the antenna and cable to the radio to

ensure a low Standing Wave Ratio (SWR).

Mobile radio equipment with output power greater than

normal may require special precautions.

All installations should be checked for possible interfer-

ence between the communications equipment and the

vehicle’s electronic systems.