check engine Ram ProMaster City 2017 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2017, Model line: ProMaster City, Model: Ram ProMaster City 2017Pages: 345, PDF Size: 3.25 MB

Page 281 of 345

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If you

have any doubt about your ability to perform a service

job, take your vehicle to a competent mechanic.

MAINTENANCE PROCEDURES

The pages that follow contain therequiredmaintenance

services determined by the engineers who designed your

vehicle.

Besides those maintenance items specified in the fixed

“Maintenance Schedule”, there are other components

which may require servicing or replacement in the future.

CAUTION!

• Failure to properly maintain your vehicle or perform

repairs and service when necessary could result in

more costly repairs, damage to other components or

negatively impact vehicle performance. Immediately

(Continued)

CAUTION! (Continued)

have potential malfunctions examined by an autho-

rized dealer or qualified repair center.

• Your vehicle has been built with improved fluids

that protect the performance and durability of your

vehicle and also allow extended maintenance inter-

vals. Do not use chemical flushes in these compo-

nents as the chemicals can damage your engine,

transmission or air conditioning. Such damage is not

covered by the New Vehicle Limited Warranty. If a

flush is needed because of component malfunction,

use only the specified fluid for the flushing proce-

dure.

Engine Oil

Checking Oil Level

To assure proper engine lubrication, the engine oil must be

maintained at the correct level. Check the oil level at

regular intervals, such as every month. The best time to

check the engine oil level is about five minutes after a fully

warmed up engine is shut off.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings.

7

MAINTAINING YOUR VEHICLE 279

Page 288 of 345

3. After turning the ignition to the STOP, within twominutes move the right stalk upward, into the unstable

(“anti-panic”) position, for at least half of a second. The

windshield wiper then executes part of a stroke; at each

command, approximately 1/3 of a normal wiper stroke

is triggered.

NOTE: The previous operation can be repeated up to three

times. In order to move the blades to the most suitable

position.

4. Lift the blade from the windshield and proceed with the required operation.

5. Carefully lower the blade, bringing it back in contact with the windshield.

6. Bring the blade to the initial rest position, turning the ignition to MAR-ON.

NOTE: Do not operate the screen wiper with the blades

lifted from the windshield.

Adding Washer Fluid

The fluid reservoir is located in the front of the engine

compartment. Be sure to check the fluid level in the reservoir at regular intervals. Fill the reservoir with wind-

shield washer solvent (not radiator antifreeze) and operate

the system for a few seconds to flush out the residual

water.

When refilling the washer fluid reservoir, take some

washer fluid and apply it to a cloth or towel and wipe clean

the wiper blades, this will help blade performance.

To prevent freeze-up of your windshield washer system in

cold weather, select a solution or mixture that meets or

exceeds the temperature range of your climate. This rating

information can be found on most washer fluid containers.

WARNING!

Commercially available windshield washer solvents

are flammable. They could ignite and burn you. Care

must be exercised when filling or working around the

washer solution.

Exhaust System

The best protection against carbon monoxide entry into the

vehicle body is a properly maintained engine exhaust

system.

286 MAINTAINING YOUR VEHICLE

Page 290 of 345

In unusual situations involving grossly malfunctioning

engine operation, a scorching odor may suggest severe and

abnormal catalyst overheating. If this occurs, stop the

vehicle, turn off the engine and allow it to cool. Service,

including a tune-up to manufacturer’s specifications,

should be obtained immediately.

To minimize the possibility of catalytic converter damage:

•Do not shut off the engine or interrupt the ignition,

when the transmission is in gear and the vehicle is in

motion.

• Do not try to start the engine by pushing or towing the

vehicle.

• Do not idle the engine with any spark plug wires

disconnected or removed, such as when diagnostic

testing, or for prolonged periods during very rough idle

or malfunctioning operating conditions.Cooling System

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator. If you

see or hear steam coming from under the hood, do not

open the hood until the radiator has had time to cool.

Never try to open a cooling system pressure cap when

the radiator or coolant bottle is hot.

Engine Coolant Checks

Check the engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where appli-

cable). If the engine coolant (antifreeze) is dirty, the system

should be drained, flushed, and refilled with fresh OAT

coolant (conforming to MS.90032) by an authorized dealer.

Check the front of the A/C condenser for any accumula-

tion of bugs, leaves, etc. If dirty, clean by gently spraying

water from a garden hose vertically down the face of the

condenser.

Check the engine cooling system hoses for brittle rubber,

cracking, tears, cuts, and tightness of the connection at the

coolant recovery bottle and radiator. Inspect the entire

system for leaks.

288 MAINTAINING YOUR VEHICLE

Page 291 of 345

With the engine at normal operating temperature (but not

running), check the cooling system pressure cap for proper

vacuum sealing by draining a small amount of engine

coolant (antifreeze) from the radiator drain cock. If the cap

is sealing properly, the engine coolant (antifreeze) will

begin to drain from the coolant recovery bottle. DO NOT

REMOVE THE COOLANT PRESSURE CAP WHEN THE

COOLING SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could lead to

severe internal engine damage. If any coolant is needed to

be added to the system, please contact your local autho-

rized dealer.

If the engine coolant (antifreeze) is dirty or contains visible

sediment, have an authorized dealer clean and flush with

OAT coolant (antifreeze) (conforming to MS.90032).

Refer to the “Maintenance Schedule” for the proper main-

tenance intervals.

Selection Of Coolant

Refer to “Fluids, Lubricants, And Genuine Parts” in “Main-

taining Your Vehicle” for further information.

CAUTION!

• Mixing of engine coolant (antifreeze) other than

specified Organic Additive Technology (OAT) en-

gine coolant (antifreeze), may result in engine dam-

age and may decrease corrosion protection. Organic

Additive Technology (OAT) engine coolant is differ-

ent and should not be mixed with Hybrid Organic

Additive Technology (HOAT) engine coolant (anti-

freeze) or any “globally compatible” coolant (anti-

freeze). If a non-OAT engine coolant (antifreeze) is

introduced into the cooling system in an emergency,

the cooling system will need to be drained, flushed,

and refilled with fresh OAT coolant (conforming to

MS.90032), by an authorized dealer as soon as pos-

sible.

• Do not use water alone or alcohol-based engine

coolant (antifreeze) products. Do not use additional

rust inhibitors or antirust products, as they may not

be compatible with the engine coolant and may plug

the radiator.

• This vehicle has not been designed for use with

propylene glycol-based engine coolant (antifreeze).

Use of propylene glycol-based engine coolant (anti-

freeze) is not recommended.

7

MAINTAINING YOUR VEHICLE 289

Page 293 of 345

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of engine

coolant (antifreeze), and to ensure that engine coolant

(antifreeze) will return to the radiator from the coolant

recovery tank.

The cap should be inspected and cleaned if there is any

accumulation of foreign material on the sealing surfaces.The image on the coolant system pres-

sure cap is a reminder that the radiator

contains hot engine coolant under pres-

sure.

WARNING!

•Do not open hot engine cooling system. Never add

engine coolant (antifreeze) when the engine is over-

heated. Do not loosen or remove the cap to cool an

overheated engine. Heat causes pressure to build up

in the cooling system. To prevent scalding or injury,

do not remove the pressure cap while the system is

hot or under pressure.

(Continued)

WARNING! (Continued)

•Do not use a pressure cap other than the one speci-

fied for your vehicle. Personal injury or engine

damage may result.

Disposal Of Used Engine Coolant

Used ethylene glycol-based engine coolant (antifreeze) is a

regulated substance requiring proper disposal. Check with

your local authorities to determine the disposal rules for

your community. To prevent ingestion by animals or

children, do not store ethylene glycol-based engine coolant

in open containers or allow it to remain in puddles on the

ground. If ingested by a child or pet, seek emergency

assistance immediately. Clean up any ground spills imme-

diately.

Coolant Level

The coolant expansion bottle provides a quick visual

method for determining that the coolant level is adequate.

With the engine OFF and cold, the level of the engine

coolant (antifreeze) in the bottle should be between the

“MIN” and “MAX” marks.

7

MAINTAINING YOUR VEHICLE 291

Page 294 of 345

The radiator normally remains completely full, so there is

no need to remove the radiator/coolant pressure cap

unless checking for engine coolant (antifreeze) freeze point

or replacing coolant. Advise your service attendant of this.

As long as the engine operating temperature is satisfactory,

the coolant bottle need only be checked once a month.

When additional engine coolant (antifreeze) is needed to

maintain the proper level, only OAT coolant that meets the

requirements of FCA Material Standard MS.90032 should

be added to the coolant bottle. Do not overfill.

Points To Remember

NOTE:When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor coming

from the front of the engine compartment. This is normally

a result of moisture from rain, snow, or high humidity

accumulating on the radiator and being vaporized when

the thermostat opens, allowing hot engine coolant (anti-

freeze) to enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

• Do not overfill the coolant expansion bottle. •

Check the coolant freeze point in the radiator and in the

coolant expansion bottle. If engine coolant (antifreeze)

needs to be added, the contents of the coolant expansion

bottle must also be protected against freezing.

• If frequent engine coolant (antifreeze) additions are

required, the cooling system should be pressure tested

for leaks.

• Maintain engine coolant (antifreeze) concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corrosion pro-

tection of your engine which contains aluminum com-

ponents.

• Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

• Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

• Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install ONLY

the correct type thermostat. Other designs may result in

unsatisfactory engine coolant (antifreeze) performance,

poor gas mileage, and increased emissions.

292 MAINTAINING YOUR VEHICLE

Page 296 of 345

WARNING!(Continued)

•Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

• Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

Power Steering Fluid

Check the fluid level with the vehicle on flat ground and

engine cold. Fluid should be between MIN and MAX

references on the reservoir body.

The level may go over the MAX line when oil is hot.

If topping off is required, make sure the oil you use is

approved. Refer to “Fluids, Lubricants and Genuine Parts”

in the section for further information.

WARNING!

Because it is flammable, do not allow the power

steering fluid to come into contact with hot engine

parts

NOTE: Power steering fluid consumption is very low. If

you need to top off your fluid often and multiple times

have your system inspected by your authorized dealer.

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission fluid to

ensure optimum transmission performance and life. Use

only the manufacturer’s specified transmission fluid. Refer

to “Fluids, Lubricants, And Genuine Parts” in this section

for fluid specifications. It is important to maintain the

transmission fluid at the correct level using the recom-

mended fluid.

NOTE: No chemical flushes should be used in any trans-

mission; only the approved lubricant should be used.

294 MAINTAINING YOUR VEHICLE

Page 297 of 345

CAUTION!

Using a transmission fluid other than the manufactur-

er ’s recommended fluid may cause deterioration in

transmission shift quality and/or torque converter

shudder. Refer to “Fluids, Lubricants, And Genuine

Parts” in this section for fluid specifications.

Special Additives

The manufacturer strongly recommends against using any

special additives in the transmission. Automatic Transmis-

sion Fluid (ATF) is an engineered product and its perfor-

mance may be impaired by supplemental additives. There-

fore, do not add any fluid additives to the transmission.

Avoid using transmission sealers as they may adversely

affect seals.

CAUTION!

Do not use chemical flushes in your transmission as

the chemicals can damage your transmission compo-

nents. Such damage is not covered by the New Vehicle

Limited Warranty.

Fluid Level Check

The fluid level is preset at the factory and does not require

adjustment under normal operating conditions. Routine

fluid level checks are not required, therefore the transmis-

sion has no dipstick. Your authorized dealer can check

your transmission fluid level using special service tools. If

you notice fluid leakage or transmission malfunction, visit

your authorized dealer immediately to have the transmis-

sion fluid level checked. Operating the vehicle with an

improper fluid level can cause severe transmission dam-

age.

CAUTION!

If a transmission fluid leak occurs, visit your autho-

rized dealer immediately. Severe transmission damage

may occur. Your authorized dealer has the proper tools

to adjust the fluid level accurately.

Fluid And Filter Changes

Under normal operating conditions, the fluid installed at

the factory will provide satisfactory lubrication for the life

of the vehicle.

7

MAINTAINING YOUR VEHICLE 295

Page 321 of 345

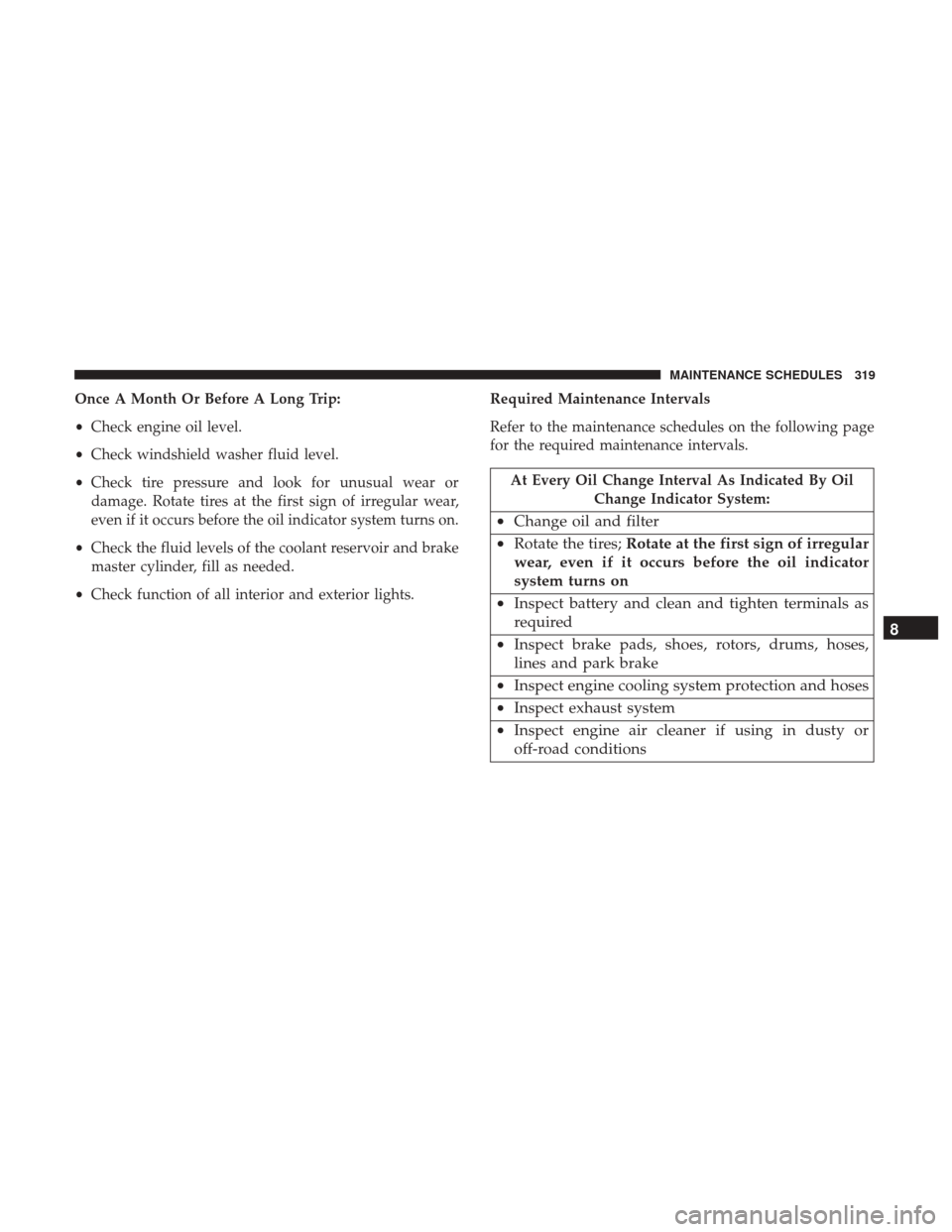

Once A Month Or Before A Long Trip:

•Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before the oil indicator system turns on.

• Check the fluid levels of the coolant reservoir and brake

master cylinder, fill as needed.

• Check function of all interior and exterior lights. Required Maintenance Intervals

Refer to the maintenance schedules on the following page

for the required maintenance intervals.

At Every Oil Change Interval As Indicated By Oil

Change Indicator System:

•Change oil and filter

• Rotate the tires; Rotate at the first sign of irregular

wear, even if it occurs before the oil indicator

system turns on

• Inspect battery and clean and tighten terminals as

required

• Inspect brake pads, shoes, rotors, drums, hoses,

lines and park brake

• Inspect engine cooling system protection and hoses

• Inspect exhaust system

• Inspect engine air cleaner if using in dusty or

off-road conditions 8

MAINTENANCE SCHEDULES 319

Page 332 of 345

Adding Engine Coolant (Antifreeze).............290

Additives, Fuel ........................... .228

AirBag ..................................38 Air Bag Operation .........................40

Driver Knee Air Bag .......................40

Enhanced Accident Response ................271

Event Data Recorder (EDR) .................271

If A Deployment Occurs ....................44

Knee Impact Bolsters .......................40

Maintaining Your Air Bag System ..............47

Transporting Pets .........................66

Air Bag Light .......................... .68, 132

Air Bag Maintenance .........................47

Air Cleaner, Engine (Engine Air Cleaner Filter) ......282

Air Conditioner Maintenance ..................283

Air Conditioning Filter ...................... .167

Air Conditioning, Operating Tips ............166, 168

Air Conditioning Refrigerant ...............283, 284

Air Conditioning System .....................283

Air Filter ............................... .282

Air Pressure, Tires ..........................211

Alarm (Security Alarm) .......................14

Alarm System (Security Alarm) .................14

Alterations/Modifications, Vehicle ................7

Antifreeze (Engine Coolant) ................289, 313 Disposal

.............................. .291

Anti-Lock Brake System (ABS) .................194

Appearance Care .......................... .296

Ashtray ................................ .106

Audio Systems (Radio) ...................... .159

Auto Down Power Windows ...................22

Automatic Transaxle ......................11,178

Automatic Transmission ...............181, 182, 295

Adding Fluid ....................... .295, 316

Fluid And Filter Changes ...................295

Fluid Change .......................... .295

Fluid Level Check .....................294, 295

Fluid Type ......................... .294, 316

Special Additives ........................ .295

Auto

Up Power Windows .....................22

Auxiliary Electrical Outlet (Power Outlet) .........104

Axle Lubrication .......................... .316

Battery .............................. .133, 282

Charging System Light ....................133

Keyless Key Fob Replacement ................16

Belts, Seat .................................68

Body Builders Guide ..........................6

Body Mechanism Lubrication ..................285

B-Pillar Location .......................... .206

330 INDEX