lock RENAULT CAPTUR 2014 1.G Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2014, Model line: CAPTUR, Model: RENAULT CAPTUR 2014 1.GPages: 244, PDF Size: 5.64 MB

Page 152 of 244

3.26

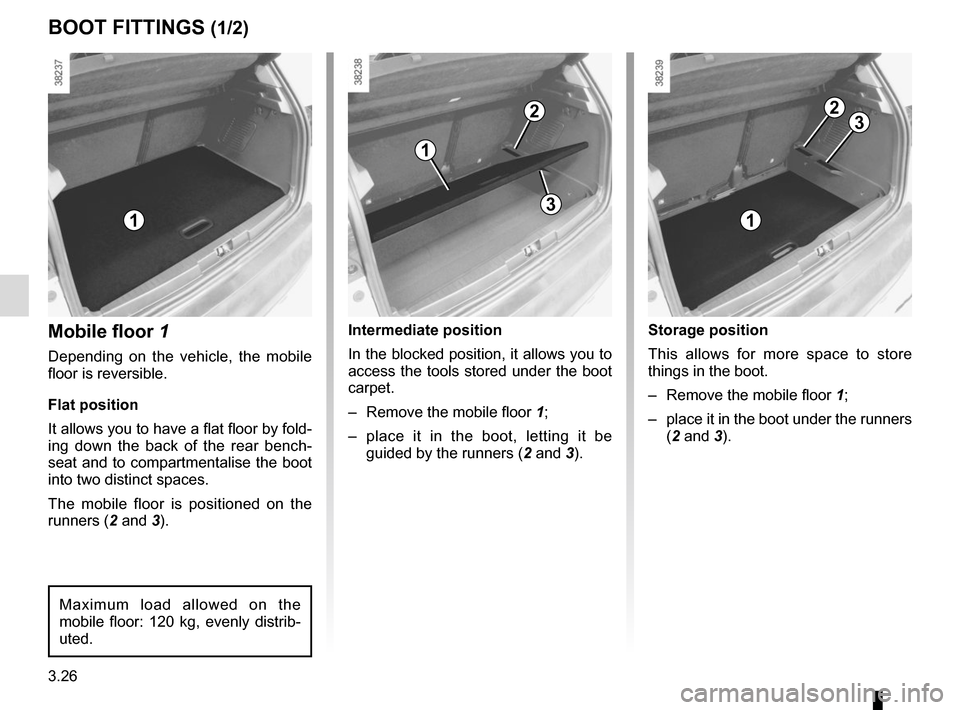

BOOT FITTINGS (1/2)

1

Mobile floor 1

Depending on the vehicle, the mobile

floor is reversible.

Flat position

It allows you to have a flat floor by fold-

ing down the back of the rear bench-

seat and to compartmentalise the boot

into two distinct spaces.

The mobile floor is positioned on the

runners (2 and 3).

Maximum load allowed on the

mobile floor: 120 kg, evenly distrib-

uted.

Storage position

This allows for more space to store

things in the boot.

– Remove the mobile floor 1;

– place it in the boot under the runners (2 and 3).

2

Intermediate position

In the blocked position, it allows you to

access the tools stored under the boot

carpet.

– Remove the mobile floor 1;

– place it in the boot, letting it be guided by the runners ( 2 and 3).

1

2

1

3

3

Page 160 of 244

4.2

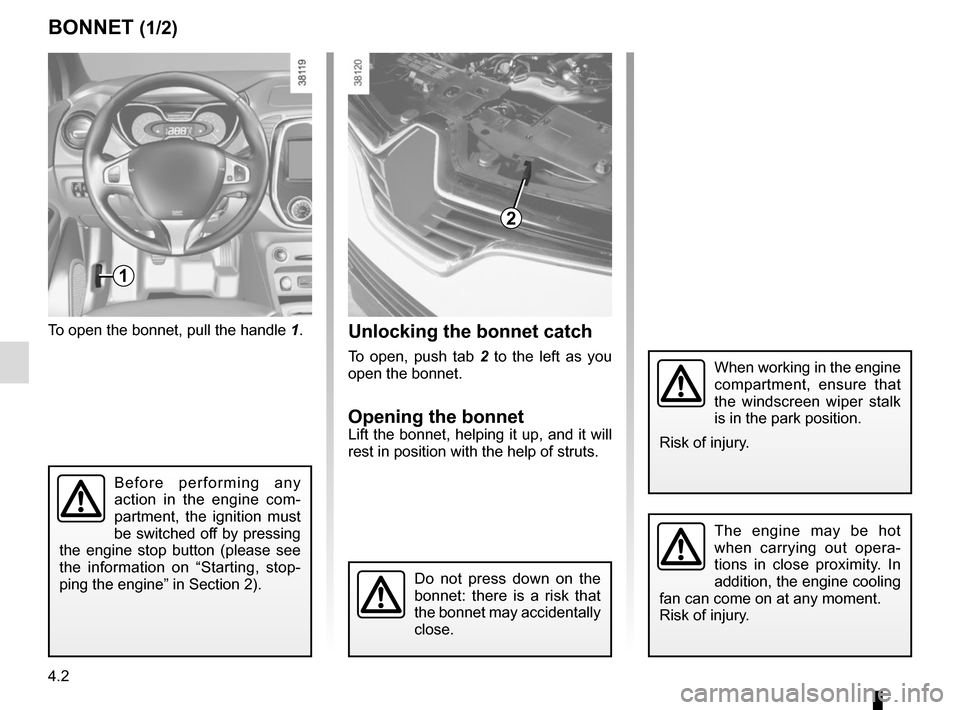

To open the bonnet, pull the handle 1.

BONNET (1/2)

1

The engine may be hot

when carrying out opera-

tions in close proximity. In

addition, the engine cooling

fan can come on at any moment.

Risk of injury.

Unlocking the bonnet catch

To open, push tab 2 to the left as you

open the bonnet.

Opening the bonnetLift the bonnet, helping it up, and it will

rest in position with the help of struts.

2

Do not press down on the

bonnet: there is a risk that

the bonnet may accidentally

close.

When working in the engine

compartment, ensure that

the windscreen wiper stalk

is in the park position.

Risk of injury.

Before performing any

action in the engine com-

partment, the ignition must

be switched off by pressing

the engine stop button (please see

the information on “Starting, stop-

ping the engine” in Section 2).

Page 161 of 244

4.3

BONNET (2/2)

Closing the bonnet

Check that nothing has been left in the

engine compartment.

To close the bonnet again, hold the

bonnet in the middle and lower it to

30 cm above the closed position, then

release it. It will latch automatically

under its own weight.

After carrying out any work

in the engine compart-

ment, check that nothing

has been left behind (cloth,

tools, etc.).

These may damage the engine or

cause a fire.

Ensure that the bonnet is

properly locked.

Check that nothing is pre-

venting the catch from lock-

ing (gravel, cloth, etc.).

In the event of even a slight

impact involving the radia-

tor grille or bonnet, have

the bonnet lock checked by

an approved dealer as soon as pos-

sible.

Page 173 of 244

4.15

Glass instrument panel(e.g.: instrument panel, clock, exterior

temperature display, radio display, mul-

timedia or multifunction display etc.)

Use a soft cloth (or cotton wool).

If this does not clean them properly,

use a soft cloth (or cotton wool) slightly

moistened with soapy water and then

wipe clean with another soft damp cloth

or cotton wool.

Finally, carefully dry off with a soft dry

cloth.

Do not use products containing alco-

hol and/or spray fluids on the area.

Seat belts

These must be kept clean.

Use products selected by our Technical

Department (Approved outlets) or

warm, soapy water and a sponge and

wipe with a dry cloth.

Detergents or dyes must not be used

under any circumstances.

INTERIOR TRIM MAINTENANCE (1/2)

Textiles (seats, door trim, etc)

For vehicles fitted with removable seat

covers, refer to the information on “Seat

covers” in Section 4.

Vacuum-clean the textiles regularly.

Liquid stain

Use soapy water.

Dab lightly (never rub) with a soft cloth,

rinse and remove the excess.

Solid or pasty stain

Carefully remove the excess solid or

pasty material immediately with a

spatula (working from the edges to the

centre to avoid spreading the stain).

Clean as for a liquid stain.

Special instructions for sweets or

chewing gum

Put an ice cube on the stain to solidify

it, then proceed as for a solid stain.

A well-maintained vehicle will last

longer. It is therefore recommended to

maintain the interior of the vehicle regu-

larly.

A stain should always be dealt with

swiftly.

Whatever type of stain is on the trim,

use

cold (or warm) soapy water with

natural soap.

Detergents (washing-up liquid, pow-

dered products, alcohol-based prod-

ucts) should not be used.

Use a soft cloth.

Rinse and soak up the excess.

For further recommendations for

maintaining the interior, and/or for

any unsatisfactory results, please

see an authorised dealer.

Page 178 of 244

4.20

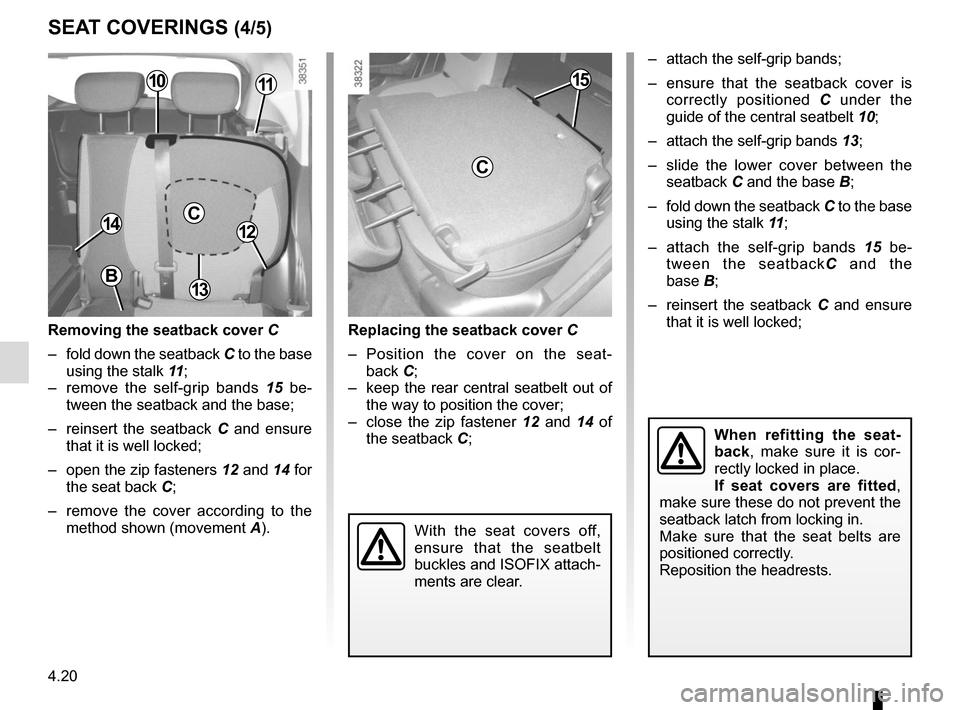

SEAT COVERINGS (4/5)

Removing the seatback cover C

– fold down the seatback C to the base

using the stalk 11 ;

– remove the self-grip bands 15 be-

tween the seatback and the base;

– reinsert the seatback C and ensure

that it is well locked;

– open the zip fasteners 12 and 14 for

the seat back C;

– remove the cover according to the method shown (movement A).

C1412

1115

C

Replacing the seatback cover C

– Position the cover on the seat- back C;

– keep the rear central seatbelt out of the way to position the cover;

– close the zip fastener 12 and 14 of the seatback C; – attach the self-grip bands;

– ensure that the seatback cover is

correctly positioned C under the

guide of the central seatbelt 10;

– attach the self-grip bands 13;

– slide the lower cover between the seatback C and the base B;

– fold down the seatback C to the base

using the stalk 11 ;

– attach the self-grip bands 15 be-

tween the seatback C and the

base B;

– reinsert the seatback C and ensure

that it is well locked;

10

13

When refitting the seat-

back, make sure it is cor-

rectly locked in place.

If seat covers are fitted ,

make sure these do not prevent the

seatback latch from locking in.

Make sure that the seat belts are

positioned correctly.

Reposition the headrests.

B

With the seat covers off,

ensure that the seatbelt

buckles and ISOFIX attach-

ments are clear.

Page 179 of 244

4.21

Replacing the seatback cover D

– Position the cover on the seat- back D;

– close the zip fastener 20;

– attach the self-grip bands 19;

– slide the lower cover between the seatback D and the base;

– move the seatback D onto the base using the stalk 16;

– close the zip fastener 18 of the seat

back D;

– attach the self-grip bands 17 be-

tween the seatback and the base;

– raise the seatback D completely and ensure that it is well locked.

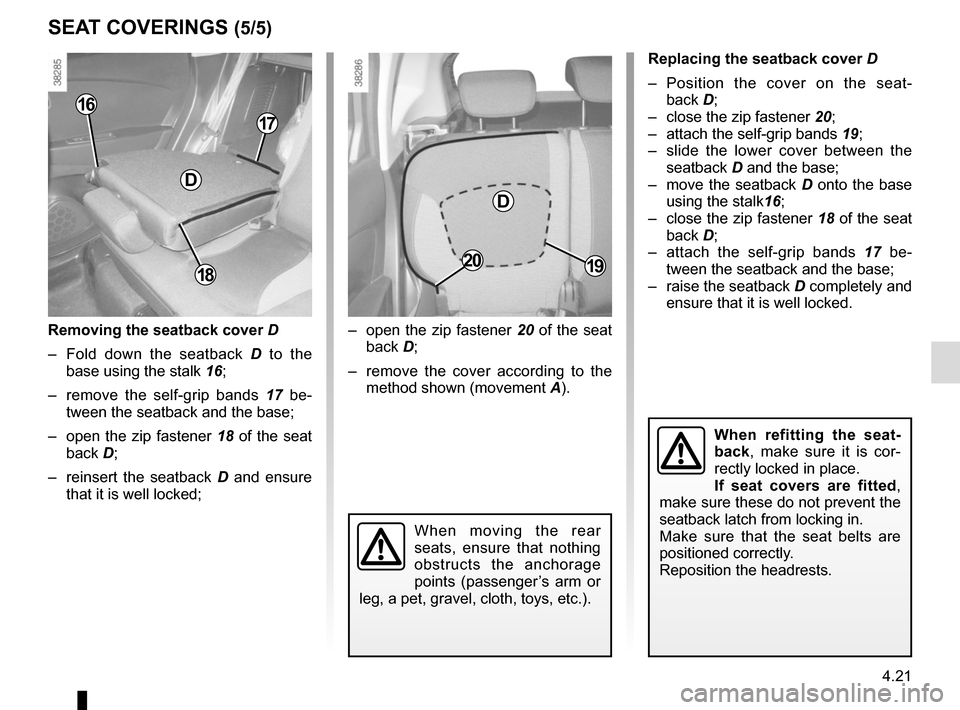

SEAT COVERINGS (5/5)

– open the zip fastener 20 of the seat

back D;

– remove the cover according to the method shown (movement A).

20

D

18

17

D

16

Removing the seatback cover D

– Fold down the seatback D to the

base using the stalk 16;

– remove the self-grip bands 17 be-

tween the seatback and the base;

– open the zip fastener 18 of the seat

back D;

– reinsert the seatback D and ensure

that it is well locked;

19

When moving the rear

seats, ensure that nothing

obstructs the anchorage

points (passenger’s arm or

leg, a pet, gravel, cloth, toys, etc.).

When refitting the seat-

back, make sure it is cor-

rectly locked in place.

If seat covers are fitted ,

make sure these do not prevent the

seatback latch from locking in.

Make sure that the seat belts are

positioned correctly.

Reposition the headrests.

Page 186 of 244

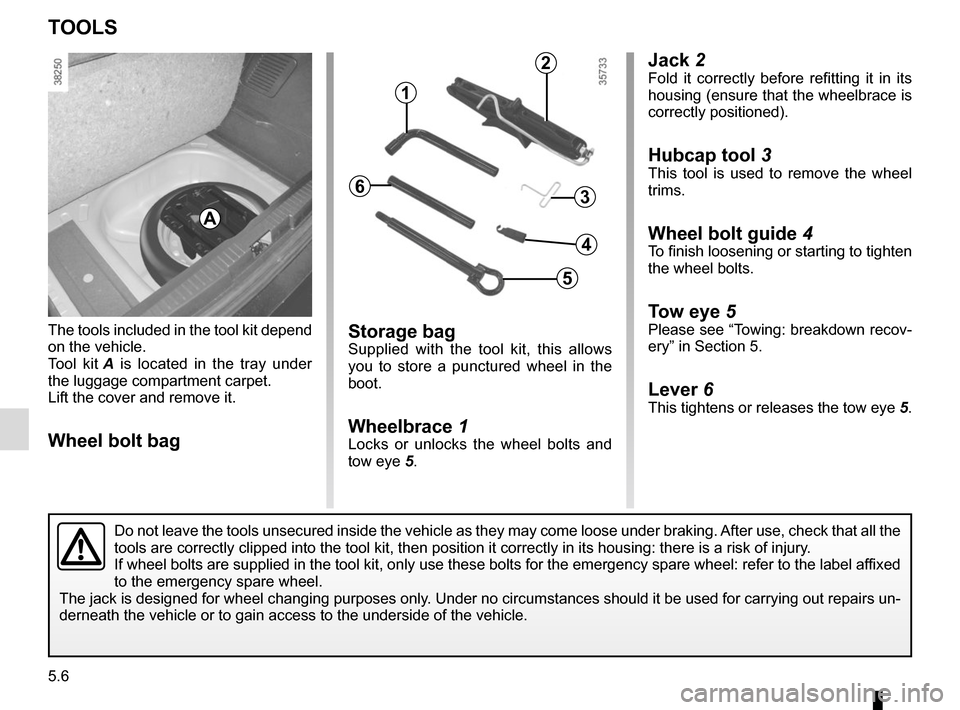

5.6

Jack 2Fold it correctly before refitting it in its

housing (ensure that the wheelbrace is

correctly positioned).

Hubcap tool 3

This tool is used to remove the wheel

trims.

Wheel bolt guide 4To finish loosening or starting to tighten

the wheel bolts.

Tow eye 5Please see “Towing: breakdown recov-

ery” in Section 5.

Lever 6This tightens or releases the tow eye 5.

Storage bagSupplied with the tool kit, this allows

you to store a punctured wheel in the

boot.

Wheelbrace 1Locks or unlocks the wheel bolts and

tow eye 5.

The tools included in the tool kit depend

on the vehicle.

Tool kit

A is located in the tray under

the luggage compartment carpet.

Lift the cover and remove it.Wheel bolt bag

TOOLS

A

Do not leave the tools unsecured inside the vehicle as they may come loo\

se under braking. After use, check that all the

tools are correctly clipped into the tool kit, then position it correctl\

y in its housing: there is a risk of injury.

If wheel bolts are supplied in the tool kit, only use these bolts for th\

e emergency spare wheel: refer to the label affixed

to the emergency spare wheel.

The jack is designed for wheel changing purposes only. Under no circumstances should it be used for carrying out repairs un-

derneath the vehicle or to gain access to the underside of the vehicle.

2

1

3

5

4

6

Page 196 of 244

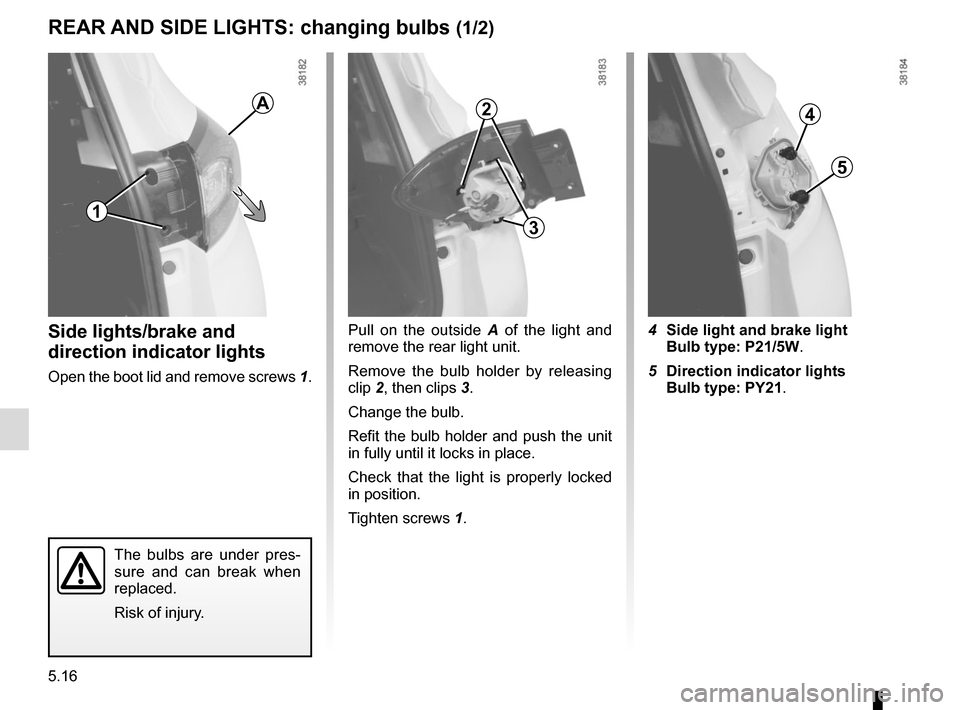

5.16

Pull on the outside A of the light and

remove the rear light unit.

Remove the bulb holder by releasing

clip 2, then clips 3.

Change the bulb.

Refit the bulb holder and push the unit

in fully until it locks in place.

Check that the light is properly locked

in position.

Tighten screws 1.

The bulbs are under pres-

sure and can break when

replaced.

Risk of injury.

4 Side light and brake light

Bulb type: P21/5W.

5 Direction indicator lights

Bulb type: PY21.Side lights/brake and

direction indicator lights

Open the boot lid and remove screws 1.

REAR AND SIDE LIGHTS: changing bulbs (1/2)

4

5

1

A2

3

Page 200 of 244

5.20

Operating faultsIf the battery is too weak to ensure cor-

rect operation, you may start (insert the

RENAULT card in the card reader) and

lock/unlock the vehicle (refer to the in-

formation on “Locking/unlocking the

doors” in Section 1).

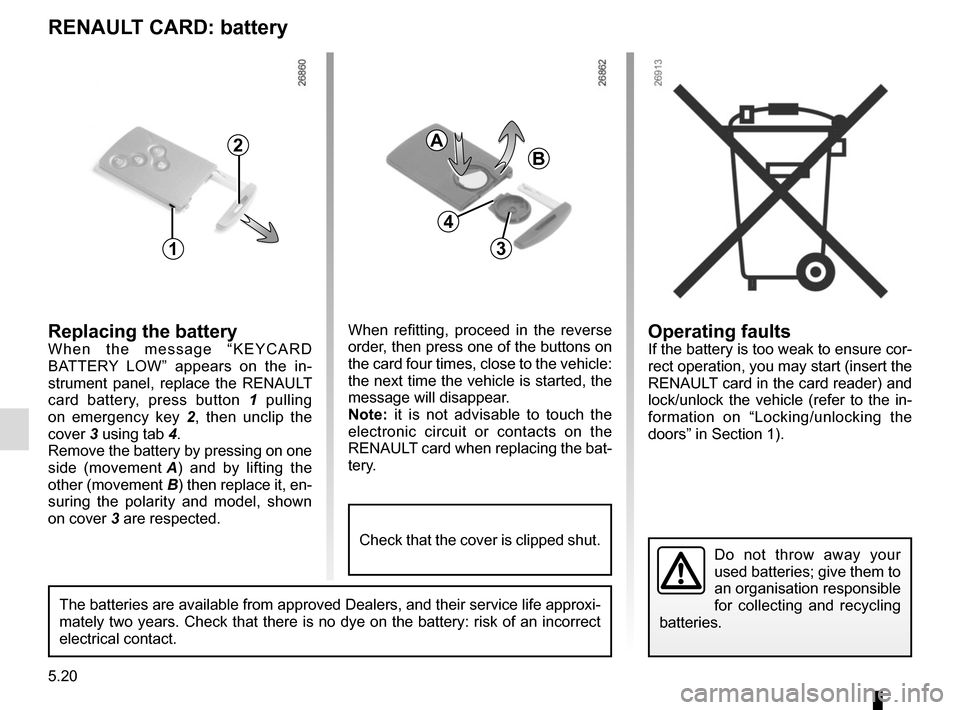

RENAULT CARD: battery

Replacing the batteryWhen the message “KEYCARD

BATTERY LOW” appears on the in-

strument panel, replace the RENAULT

card battery, press button 1 pulling

on emergency key 2 , then unclip the

cover 3 using tab 4.

Remove the battery by pressing on one

side (movement A) and by lifting the

other (movement B) then replace it, en-

suring the polarity and model, shown

on cover 3 are respected.

Do not throw away your

used batteries; give them to

an organisation responsible

for collecting and recycling

batteries.

1

2

When refitting, proceed in the reverse

order, then press one of the buttons on

the card four times, close to the vehicle:

the next time the vehicle is started, the

message will disappear.

Note: it is not advisable to touch the

electronic circuit or contacts on the

RENAULT card when replacing the bat-

tery.

A

B

3

The batteries are available from approved Dealers, and their service lif\

e approxi-

mately two years. Check that there is no dye on the battery: risk of an \

incorrect

electrical contact.

4

Check that the cover is clipped shut.

Page 203 of 244

5.23

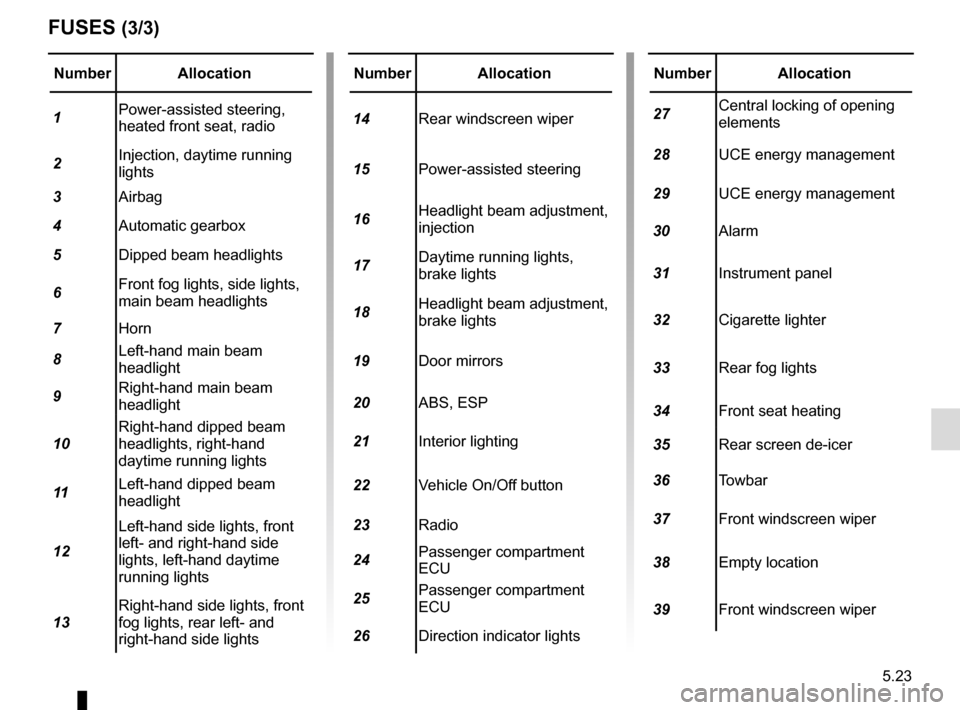

Number Allocation

1 Power-assisted steering,

heated front seat, radio

2 Injection, daytime running

lights

3 Airbag

4 Automatic gearbox

5 Dipped beam headlights

6 Front fog lights, side lights,

main beam headlights

7 Horn

8 Left-hand main beam

headlight

9 Right-hand main beam

headlight

10 Right-hand dipped beam

headlights, right-hand

daytime running lights

11 Left-hand dipped beam

headlight

12 Left-hand side lights, front

left- and right-hand side

lights, left-hand daytime

running lights

13 Right-hand side lights, front

fog lights, rear left- and

right-hand side lights

FUSES (3/3)

Number Allocation

14 Rear windscreen wiper

15 Power-assisted steering

16 Headlight beam adjustment,

injection

17 Daytime running lights,

brake lights

18 Headlight beam adjustment,

brake lights

19 Door mirrors

20 ABS, ESP

21 Interior lighting

22 Vehicle On/Off button

23 Radio

24 Passenger compartment

ECU

25 Passenger compartment

ECU

26 Direction indicator lightsNumber Allocation

27 Central locking of opening

elements

28 UCE energy management

29 UCE energy management

30 Alarm

31 Instrument panel

32 Cigarette lighter

33 Rear fog lights

34 Front seat heating

35 Rear screen de-icer

36 Towbar

37 Front windscreen wiper

38 Empty location

39 Front windscreen wiper