transmission RENAULT ESPACE 2000 J66 / 3.G Technical Note 3426A User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: ESPACE, Model: RENAULT ESPACE 2000 J66 / 3.GPages: 52, PDF Size: 0.98 MB

Page 16 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 2

Timing belt

REMOVAL

Disconnect the battery.

If necessary, place the vehicle on a two-post lift.

Remove the right-hand side member soundproofing.

Remove the travel limiter linkage.

Turn the steering to full right-hand lock.

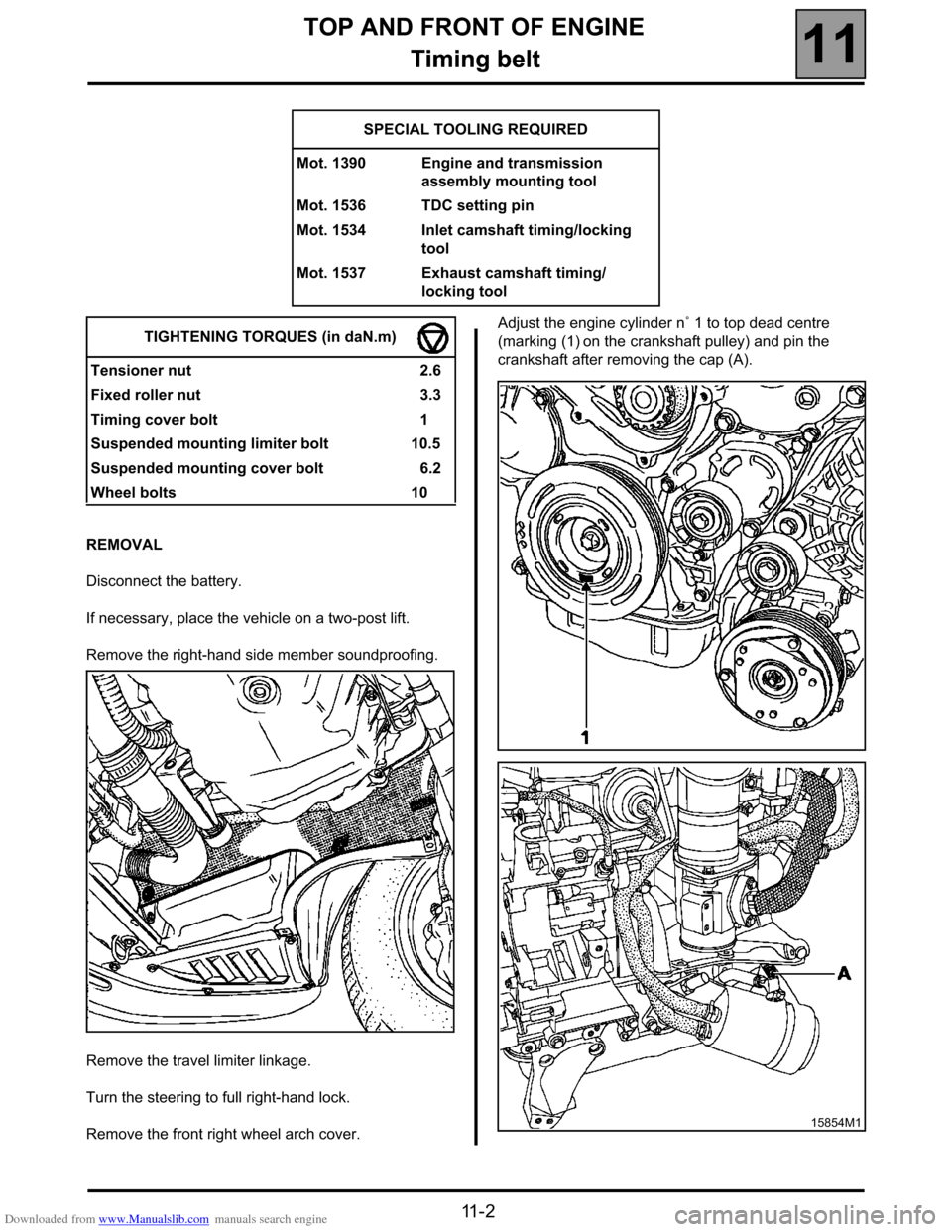

Remove the front right wheel arch cover. Adjust the engine cylinder n˚ 1 to top dead centre

(marking (1) on the crankshaft pulley) and pin the

crankshaft after removing the cap (A). SPECIAL TOOLING REQUIRED

Mot. 1390 Engine and transmission

assembly mounting tool

Mot. 1536 TDC setting pin

Mot. 1534 Inlet camshaft timing/locking

tool

Mot. 1537 Exhaust camshaft timing/

locking tool

TIGHTENING TORQUES (in daN.m)

Tensioner nut 2.6

Fixed roller nut 3.3

Timing cover bolt 1

Suspended mounting limiter bolt 10.5

Suspended mounting cover bolt 6.2

Wheel bolts 10

15854M1

Page 17 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 3

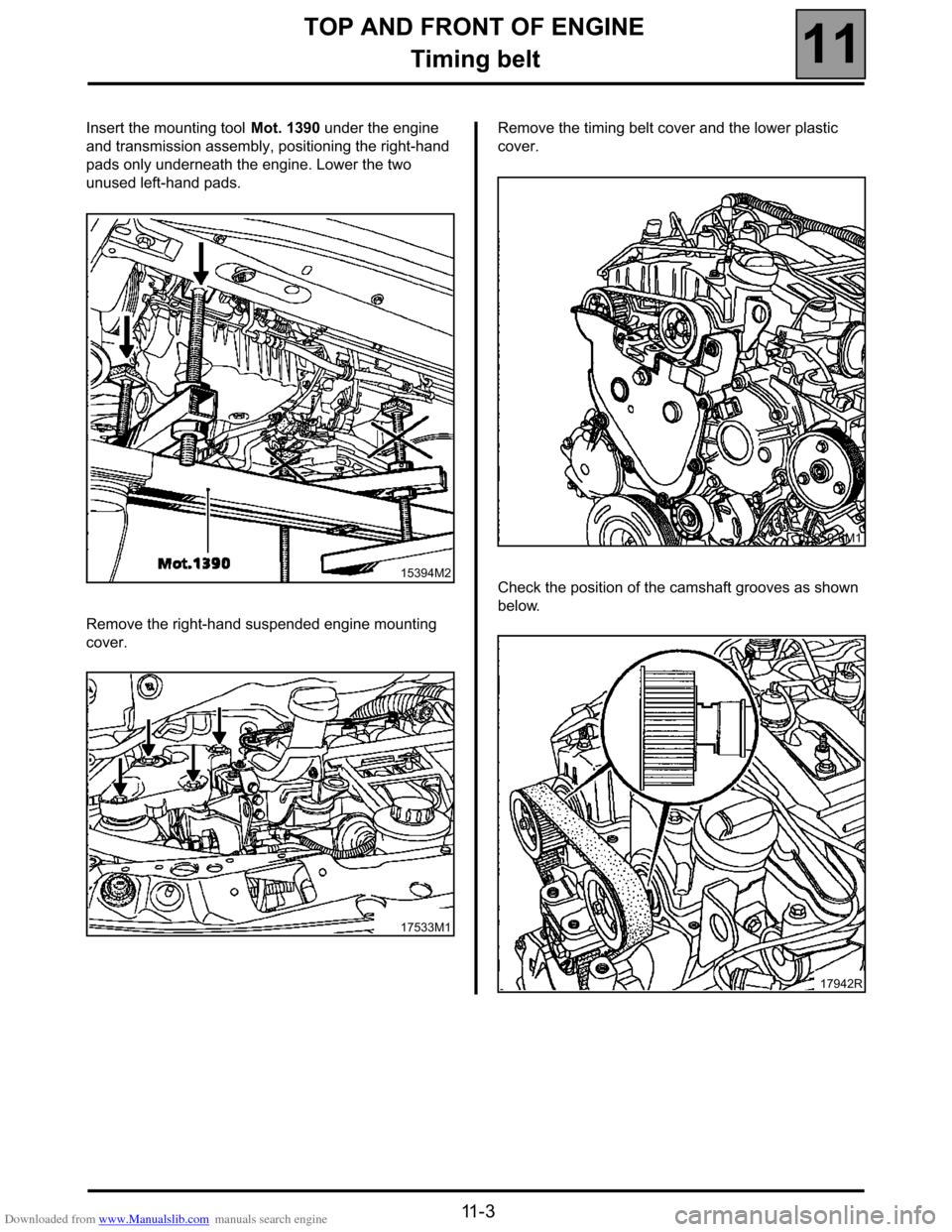

Insert the mounting tool Mot. 1390 under the engine

and transmission assembly, positioning the right-hand

pads only underneath the engine. Lower the two

unused left-hand pads.

Remove the right-hand suspended engine mounting

cover.Remove the timing belt cover and the lower plastic

cover.

Check the position of the camshaft grooves as shown

below.

15394M2

17533M1

15850-6M1

17942R

Page 22 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Cylinder head gasket

11

11 - 8

Cylinder head gasket

Consult manual Mot. G9 for the details of this

operation.You must remove the engine and transmission

assembly to remove the cylinder head

Page 23 of 52

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

112TURBOCHARGING

Turbocharger

THE TURBOCHARGING PRESSURE ON THE

TURBOCHARGER FITTED ON THE G9T 710

ENGINE IS NOT ADJUSTABLE.

In operation, the pressure should stabilise at

210 ± 3.5 mbar.

REMOVAL

Removal or refitting of the turbocharger requires the

removal of the engine and transmission assembly.TIGHTENING TORQUES (in daN.m)

Turbocharger mounting nuts 2.6

Oil inlet union bolt 2

Oil return union bolt 0.9

Turbo mounting nut on the intermediate

exhaust downpipe 2.6

12-1

Page 29 of 52

Downloaded from www.Manualslib.com manuals search engine FUEL MIXTURE

Exhaust manifold

12

12-7

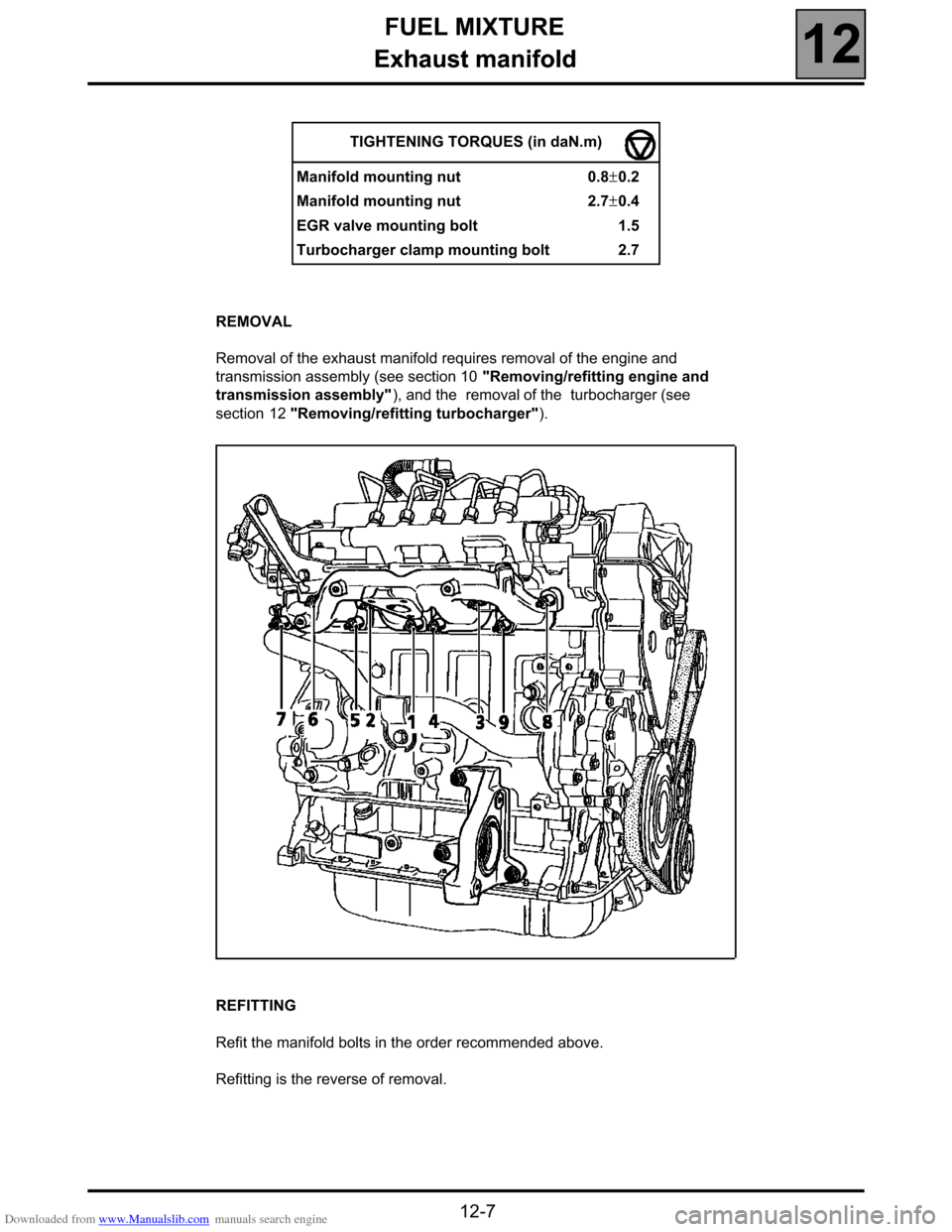

Exhaust manifold

REMOVAL

Removal of the exhaust manifold requires removal of the engine and

transmission assembly (see section 10 "Removing/refitting engine and

transmission assembly"), and the removal of the turbocharger (see

section 12 "Removing/refitting turbocharger").

REFITTING

Refit the manifold bolts in the order recommended above.

Refitting is the reverse of removal.TIGHTENING TORQUES (in daN.m)

Manifold mounting nut 0.8±0.2

Manifold mounting nut 2.7±0.4

EGR valve mounting bolt 1.5

Turbocharger clamp mounting bolt 2.7

Page 30 of 52

Downloaded from www.Manualslib.com manuals search engine FUEL MIXTURE

Inlet manifold

12

12-8

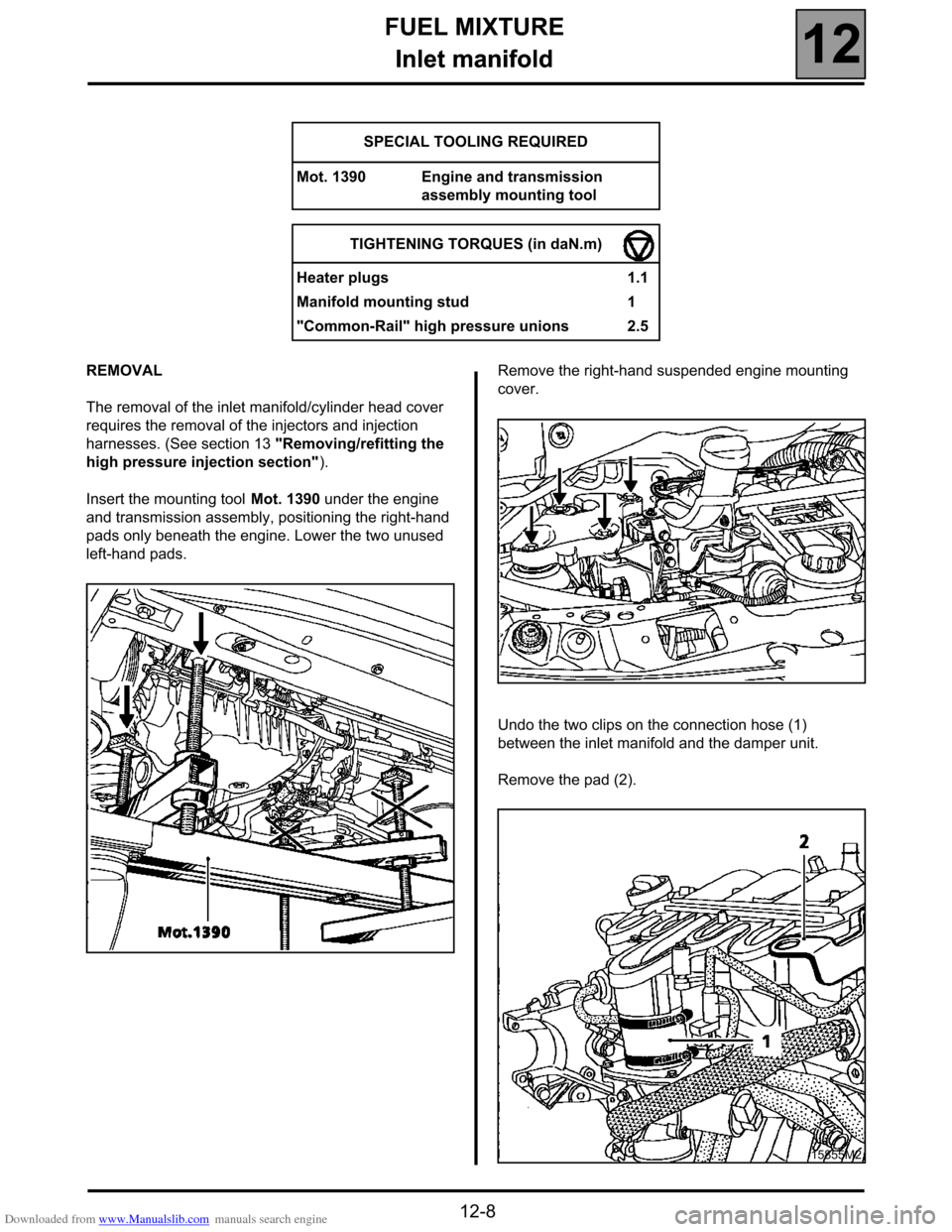

Inlet manifold

REMOVAL

The removal of the inlet manifold/cylinder head cover

requires the removal of the injectors and injection

harnesses. (See section 13 "Removing/refitting the

high pressure injection section").

Insert the mounting tool Mot. 1390 under the engine

and transmission assembly, positioning the right-hand

pads only beneath the engine. Lower the two unused

left-hand pads.Remove the right-hand suspended engine mounting

cover.

Undo the two clips on the connection hose (1)

between the inlet manifold and the damper unit.

Remove the pad (2). SPECIAL TOOLING REQUIRED

Mot. 1390 Engine and transmission

assembly mounting tool

TIGHTENING TORQUES (in daN.m)

Heater plugs 1.1

Manifold mounting stud 1

"Common-Rail" high pressure unions 2.5

15855M2

Page 34 of 52

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-3

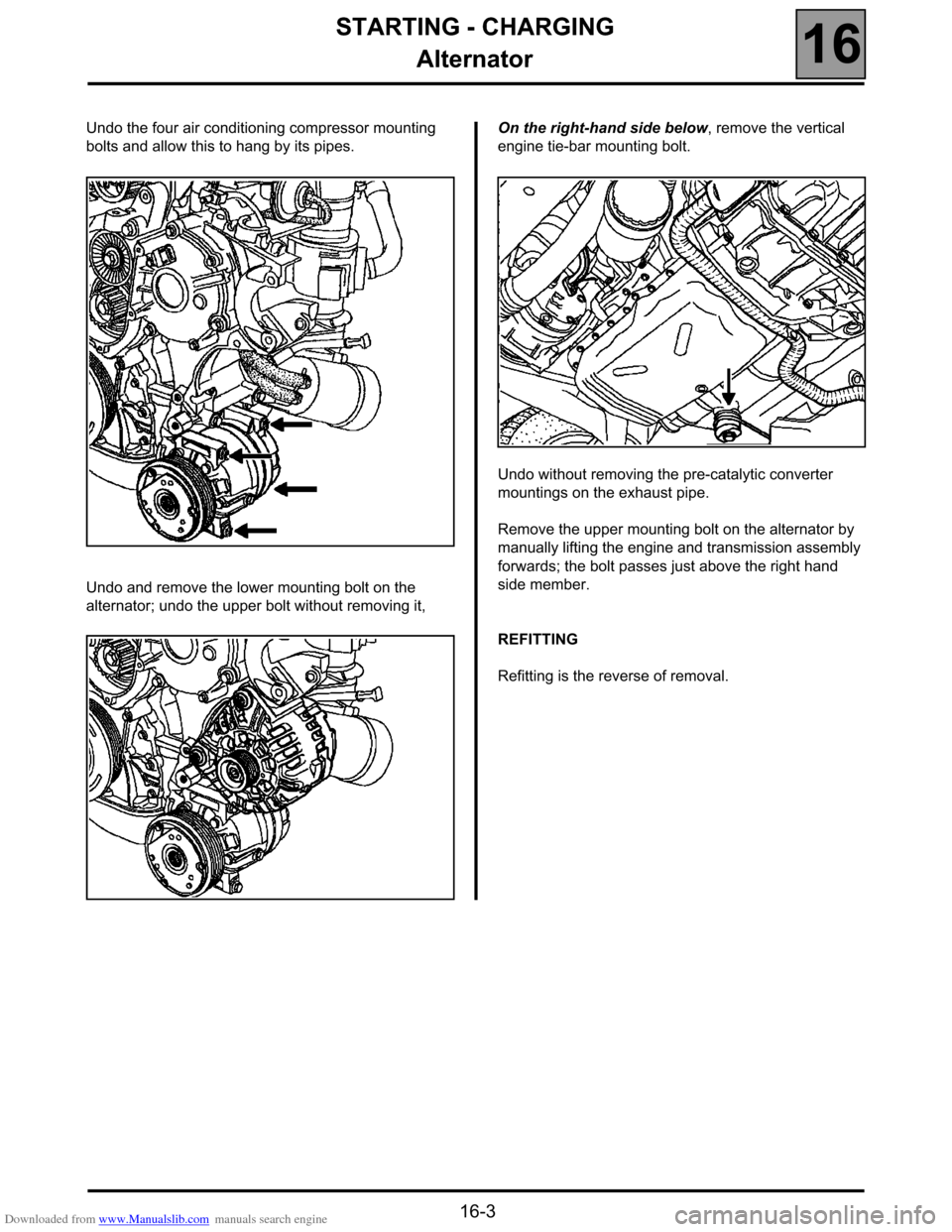

Undo the four air conditioning compressor mounting

bolts and allow this to hang by its pipes.

Undo and remove the lower mounting bolt on the

alternator; undo the upper bolt without removing it,On the right-hand side below, remove the vertical

engine tie-bar mounting bolt.

Undo without removing the pre-catalytic converter

mountings on the exhaust pipe.

Remove the upper mounting bolt on the alternator by

manually lifting the engine and transmission assembly

forwards; the bolt passes just above the right hand

side member.

REFITTING

Refitting is the reverse of removal.

Page 45 of 52

Downloaded from www.Manualslib.com manuals search engine MANUAL GEARBOX

Removal - refitting

21

21-4

Removal - refitting

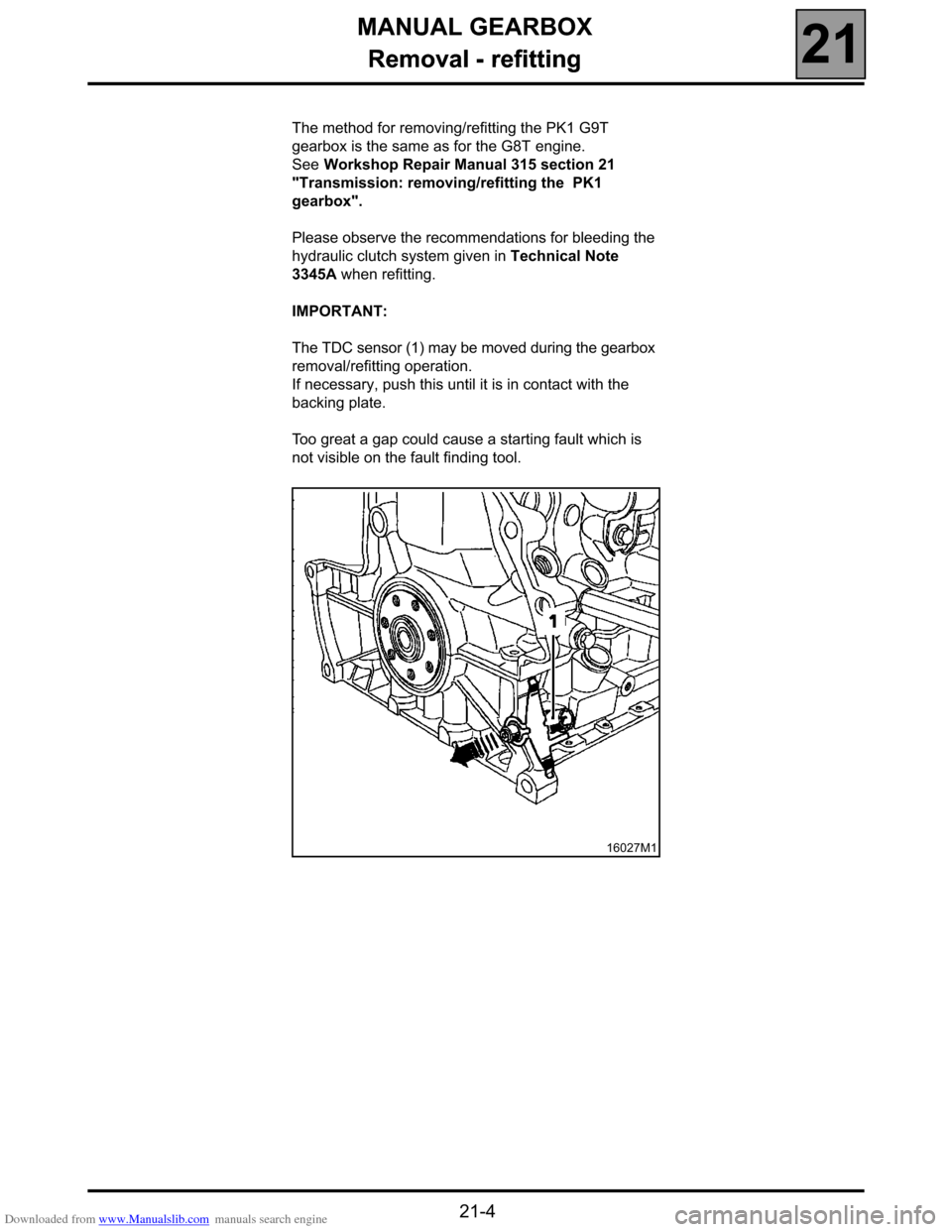

The method for removing/refitting the PK1 G9T

gearbox is the same as for the G8T engine.

See Workshop Repair Manual 315 section 21

"Transmission: removing/refitting the PK1

gearbox".

Please observe the recommendations for bleeding the

hydraulic clutch system given in Technical Note

3345A when refitting.

IMPORTANT:

The TDC sensor (1) may be moved during the gearbox

removal/refitting operation.

If necessary, push this until it is in contact with the

backing plate.

Too great a gap could cause a starting fault which is

not visible on the fault finding tool.

16027M1