check engine RENAULT ESPACE 2000 J66 / 3.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: ESPACE, Model: RENAULT ESPACE 2000 J66 / 3.GPages: 52, PDF Size: 0.98 MB

Page 6 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Oil pressure

10

10-2

Oil pressure

CHECKING

The oil pressure should be checked when the engine

is warm (approximately 80°C).

USE

Connect the pressure gauge in place of the oil

pressure switch.

Oil pressure

1 000 rpm 1.2 bar

3 000 rpm 3.5 bars SPECIAL TOOLING REQUIRED

Mot. 836-05 Boxed kit for measuring oil

pressure

ESSENTIAL SPECIAL TOOLING

22 mm long socket

Page 13 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-9

REFITTING - Special points

Pre-position the gearbox control cables.

Position the engine/gearbox assembly in its

compartment. Check the rear of the gearbox in relation

to the sub-frame.

Fitting suspended mountings: see section 19

"Suspended mountings".

Tighten all the bolts, nuts and studs to the

recommended torques.

Refitting is the reverse of removal.

Press the brake pedal several times to bring the

pistons into contact with the brake pads.

Reprogram all the components deprogrammed by

disconnecting the battery.

Fill the refrigerant circuit using the filling station (see

section 62 "Air conditioning").

Refrigerant fluid R134a: 800 ± 20 g.

Carry out:

–filling and bleeding of the cooling circuit (see

section 19),

–filling and bleeding of the power assisted steering

circuit,–bleed the hydraulic clutch circuit.

Damage to the union leads to replacement of the

master cylinder, and thus removal/refitting of the

gearbox.IT IS ESSENTIAL THAT YOU FOLLOW THE

BLEEDING METHOD GIVEN BELOW

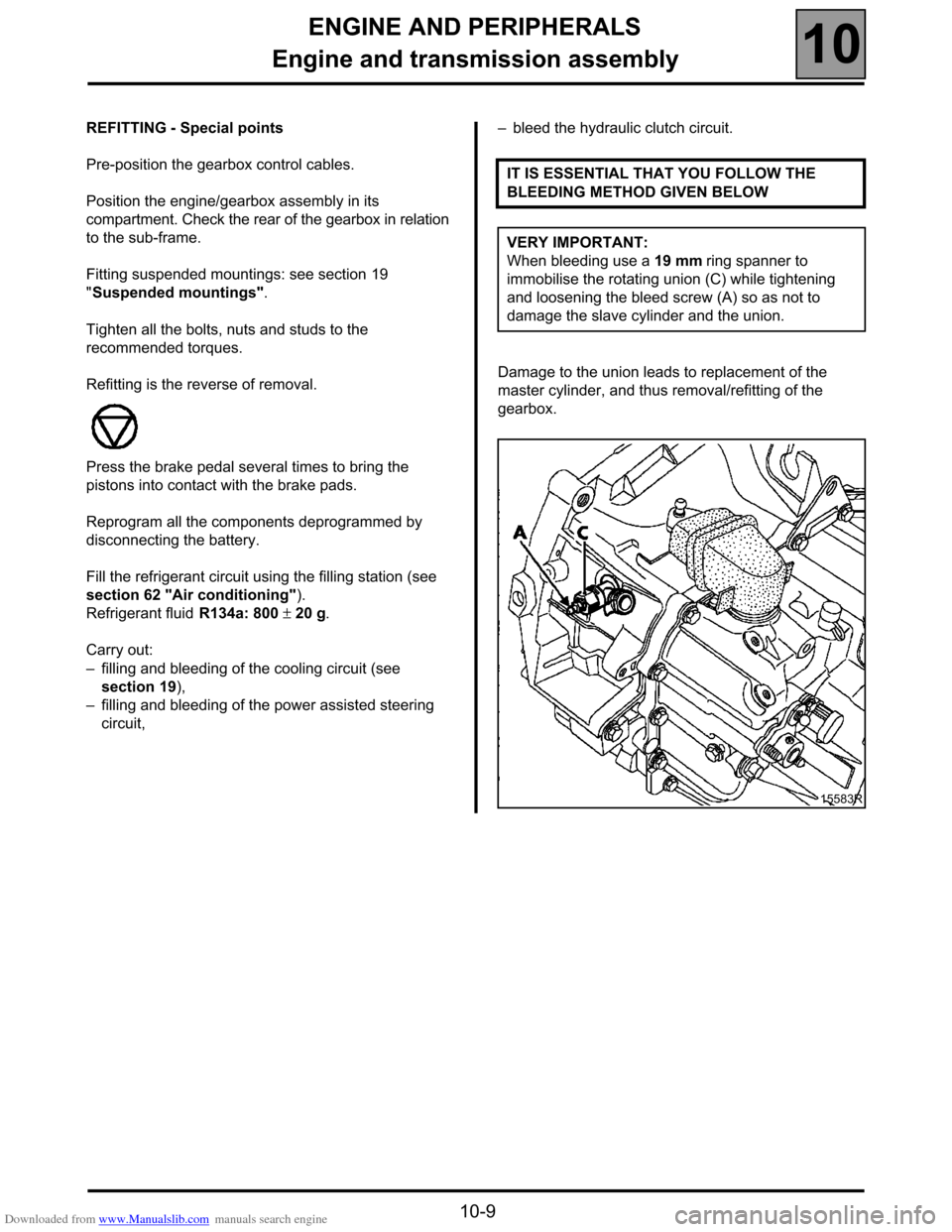

VERY IMPORTANT:

When bleeding use a 19 mm ring spanner to

immobilise the rotating union (C) while tightening

and loosening the bleed screw (A) so as not to

damage the slave cylinder and the union.

15583R

Page 14 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-10

BLEEDING METHOD TO BE USED:

(for two people).

1) Filling the circuit:

Check that the clutch pedal is in the top position; put

it in this position and hold it by hand if necessary.

Fill the hydraulic circuit by connecting a filling system

and applying pressure to the tank, open the bleed

screw (A) (always compensate for the force using a

counter-spanner) and allow a little fluid to escape

(approximately 0.5 l) through a transparent tube

connected to the bleed screw. Close the bleed

screw.

2) Final bleeding of the circuit:

One operator slowly disengages fully and keeps the

pedal depressed. Wait approximately ten seconds in

this situation. With the pedal still depressed, a

second operator opens the bleed screw briefly (A).

With the bleed screw closed again, the operator

inside the vehicle releases the clutch pedal and

slowly lifts it to top position by hand (It is normal that

the pedal does not return independently in this

configuration).

After a few seconds repeat the operations described

above in 2) as often as required until no more

bubbles escape when bleeding. Then repeat these

operations five times to ensure that the system has

been bled correctly.

These repeated bleedings allow the slave cylinder to

eject all the air trapped in any section between the

stop and the bleed screw and which has not been

"cleaned" by the flow of liquid when refilling using the

traditional pressurisation system.

An air bubble in the circuit, no matter how small, may

lead to operating faults such as: incorrect pedal

return, crashing of the gears,..., which may lead to

incorrect fault finding and unnecessary replacement

of a component in the clutch circuit.

Page 17 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 3

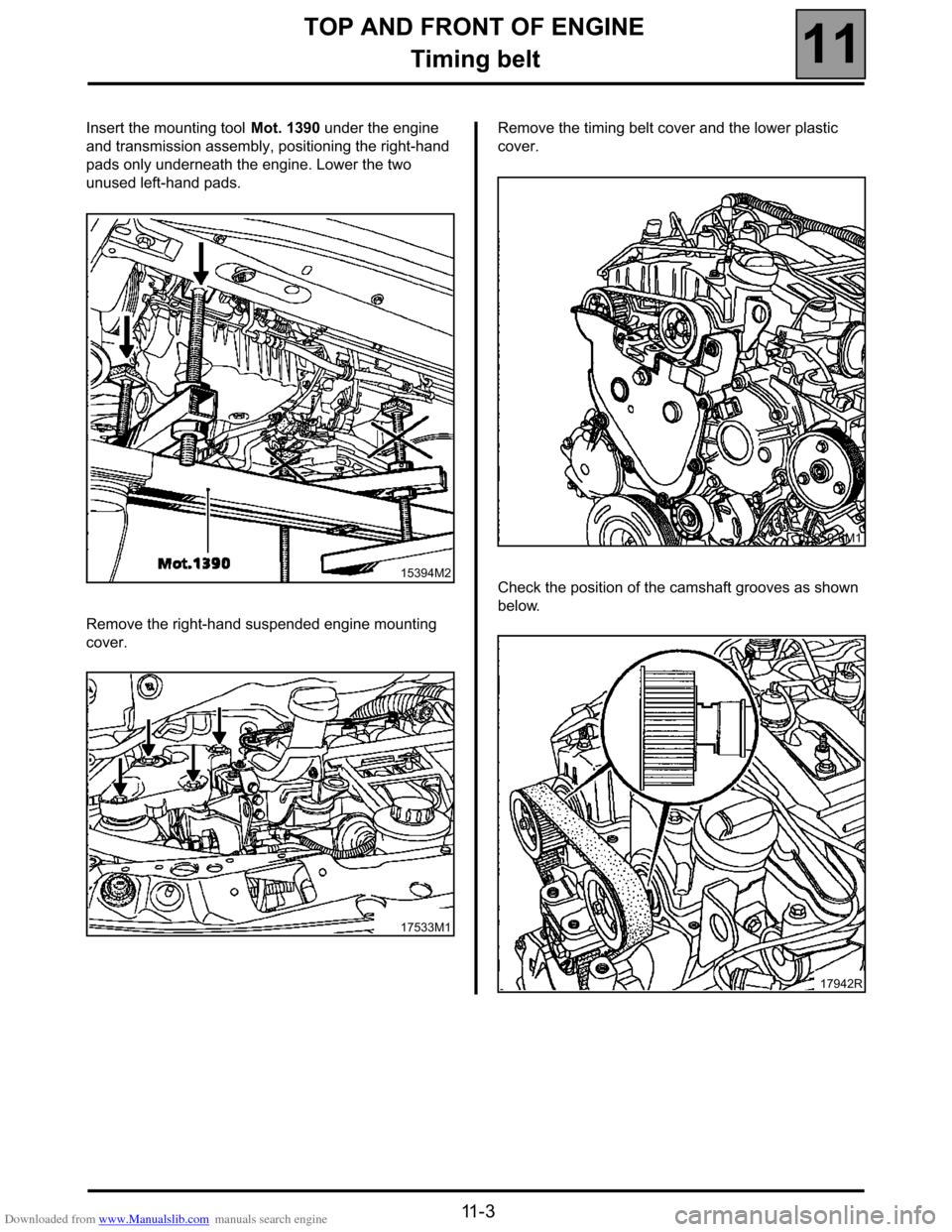

Insert the mounting tool Mot. 1390 under the engine

and transmission assembly, positioning the right-hand

pads only underneath the engine. Lower the two

unused left-hand pads.

Remove the right-hand suspended engine mounting

cover.Remove the timing belt cover and the lower plastic

cover.

Check the position of the camshaft grooves as shown

below.

15394M2

17533M1

15850-6M1

17942R

Page 19 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 5

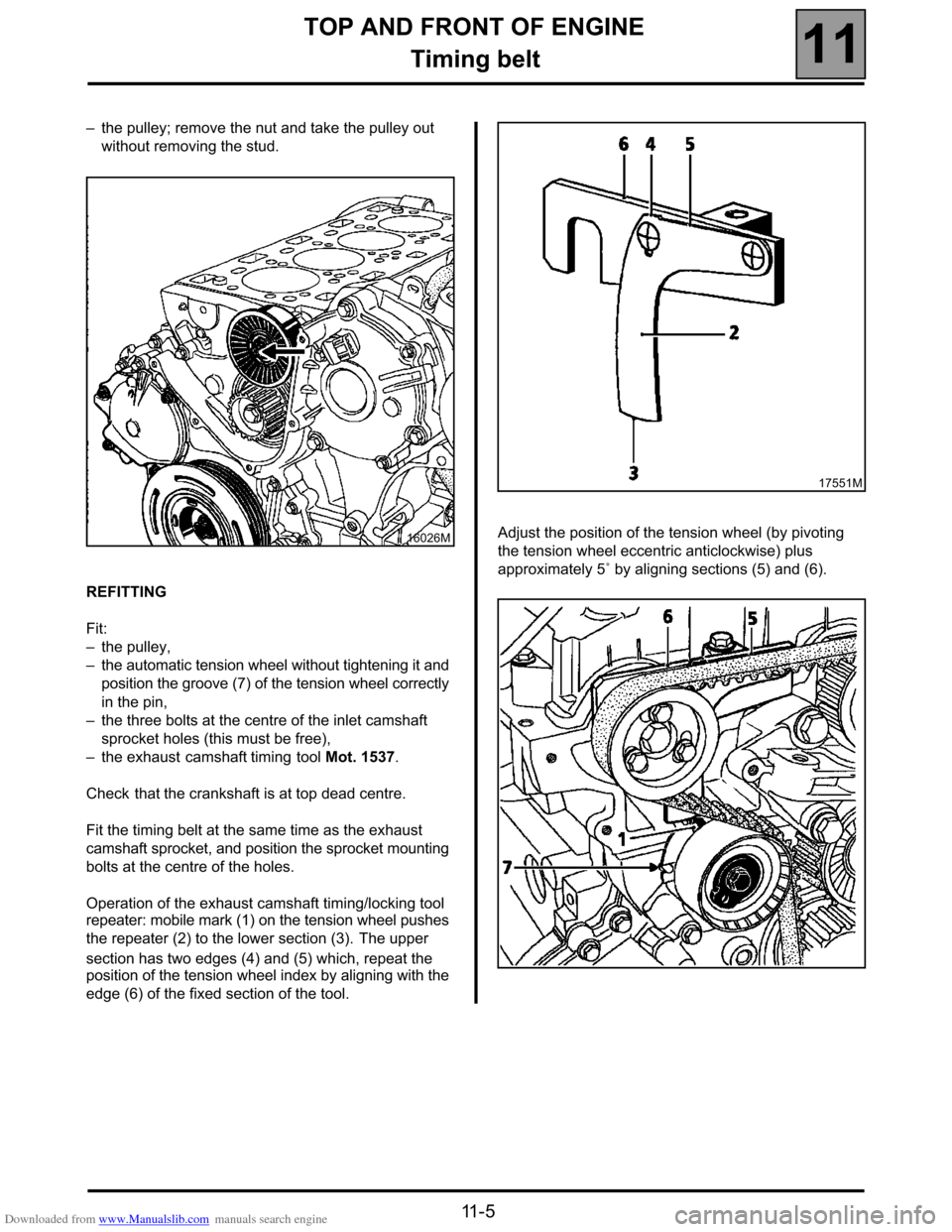

–the pulley; remove the nut and take the pulley out

without removing the stud.

REFITTING

Fit:

–the pulley,

–the automatic tension wheel without tightening it and

position the groove (7) of the tension wheel correctly

in the pin,

–the three bolts at the centre of the inlet camshaft

sprocket holes (this must be free),

–the exhaust camshaft timing tool Mot. 1537.

Check that the crankshaft is at top dead centre.

Fit the timing belt at the same time as the exhaust

camshaft sprocket, and position the sprocket mounting

bolts at the centre of the holes.

Operation of the exhaust camshaft timing/locking tool

repeater: mobile mark (1) on the tension wheel pushes

the repeater (2) to the lower section (3). The upper

section has two edges (4) and (5) which, repeat the

position of the tension wheel index by aligning with the

edge (6) of the fixed section of the tool.Adjust the position of the tension wheel (by pivoting

the tension wheel eccentric anticlockwise) plus

approximately 5˚ by aligning sections (5) and (6).

16026M

17551M

Page 20 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 6

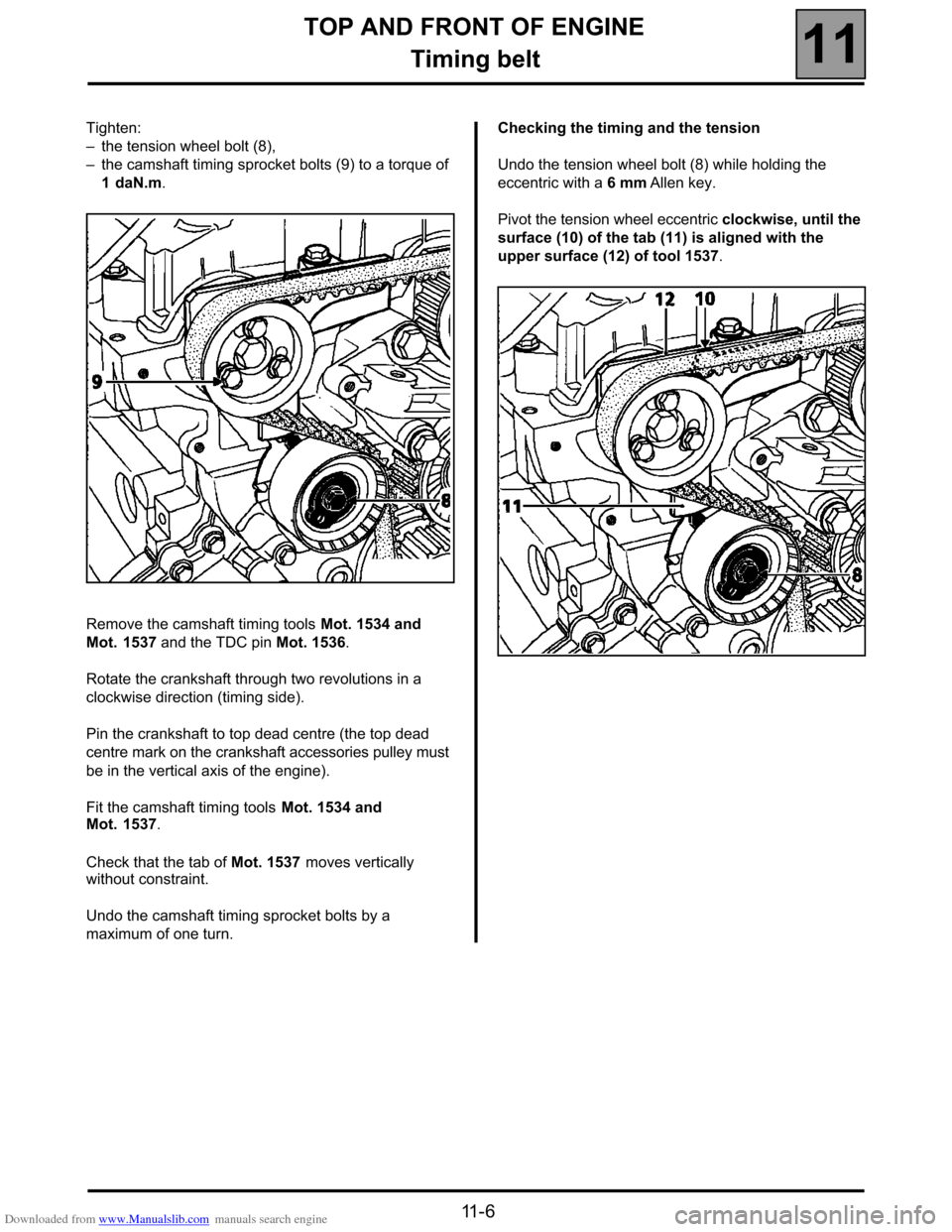

Tighten:

–the tension wheel bolt (8),

–the camshaft timing sprocket bolts (9) to a torque of

1 daN.m.

Remove the camshaft timing tools Mot. 1534 and

Mot. 1537 and the TDC pin Mot. 1536.

Rotate the crankshaft through two revolutions in a

clockwise direction (timing side).

Pin the crankshaft to top dead centre (the top dead

centre mark on the crankshaft accessories pulley must

be in the vertical axis of the engine).

Fit the camshaft timing tools Mot. 1534 and

Mot. 1537.

Check that the tab of Mot. 1537 moves vertically

without constraint.

Undo the camshaft timing sprocket bolts by a

maximum of one turn. Checking the timing and the tension

Undo the tension wheel bolt (8) while holding the

eccentric with a 6 mm Allen key.

Pivot the tension wheel eccentric clockwise, until the

surface (10) of the tab (11) is aligned with the

upper surface (12) of tool 1537.

Page 24 of 52

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

12-2

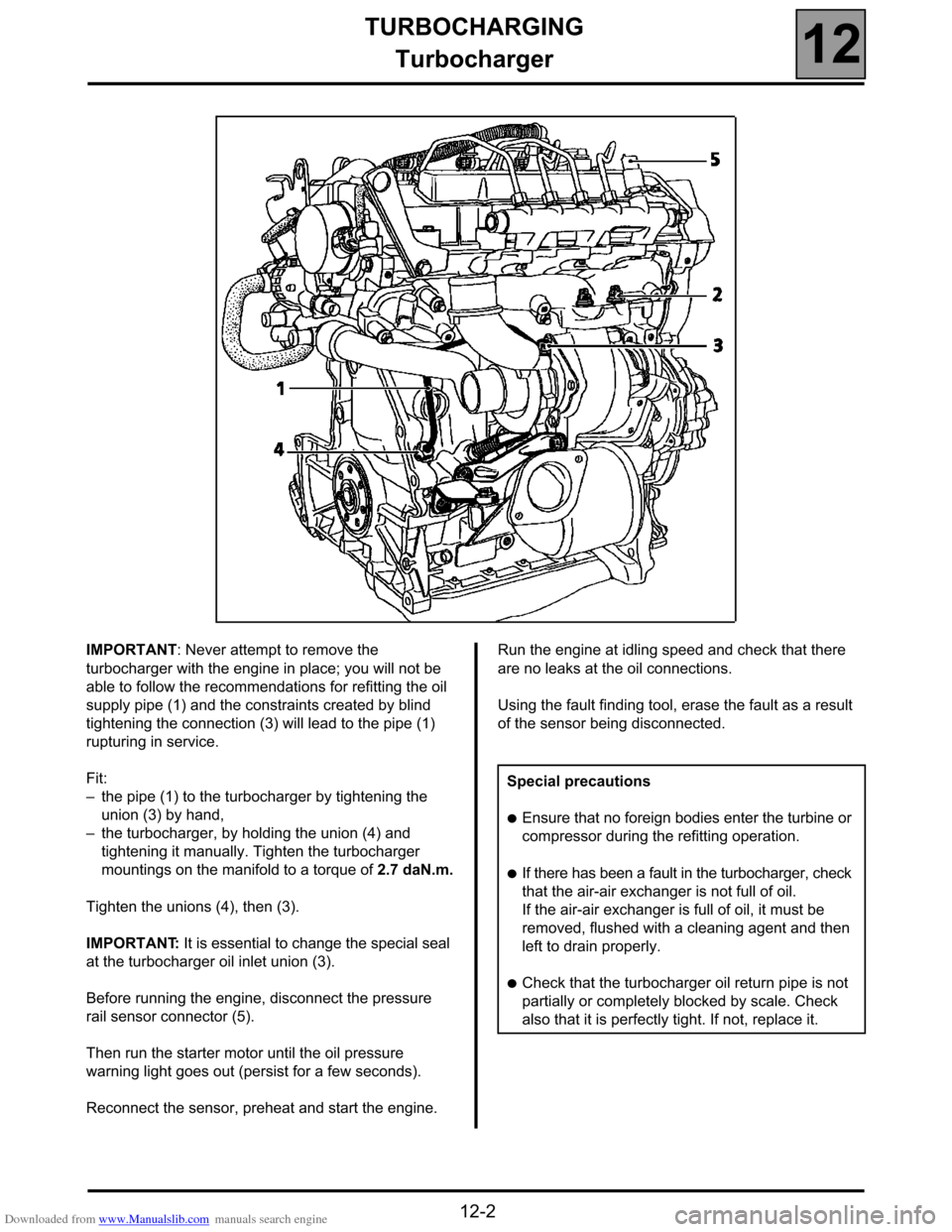

IMPORTANT: Never attempt to remove the

turbocharger with the engine in place; you will not be

able to follow the recommendations for refitting the oil

supply pipe (1) and the constraints created by blind

tightening the connection (3) will lead to the pipe (1)

rupturing in service.

Fit:

–the pipe (1) to the turbocharger by tightening the

union (3) by hand,

–the turbocharger, by holding the union (4) and

tightening it manually. Tighten the turbocharger

mountings on the manifold to a torque of 2.7 daN.m.

Tighten the unions (4), then (3).

IMPORTANT: It is essential to change the special seal

at the turbocharger oil inlet union (3).

Before running the engine, disconnect the pressure

rail sensor connector (5).

Then run the starter motor until the oil pressure

warning light goes out (persist for a few seconds).

Reconnect the sensor, preheat and start the engine.Run the engine at idling speed and check that there

are no leaks at the oil connections.

Using the fault finding tool, erase the fault as a result

of the sensor being disconnected.

Special precautions

●Ensure that no foreign bodies enter the turbine or

compressor during the refitting operation.

●If there has been a fault in the turbocharger, check

that the air-air exchanger is not full of oil.

If the air-air exchanger is full of oil, it must be

removed, flushed with a cleaning agent and then

left to drain properly.

●Check that the turbocharger oil return pipe is not

partially or completely blocked by scale. Check

also that it is perfectly tight. If not, replace it.

Page 28 of 52

Downloaded from www.Manualslib.com manuals search engine FUEL MIXTURE

Air intake

12

12-6

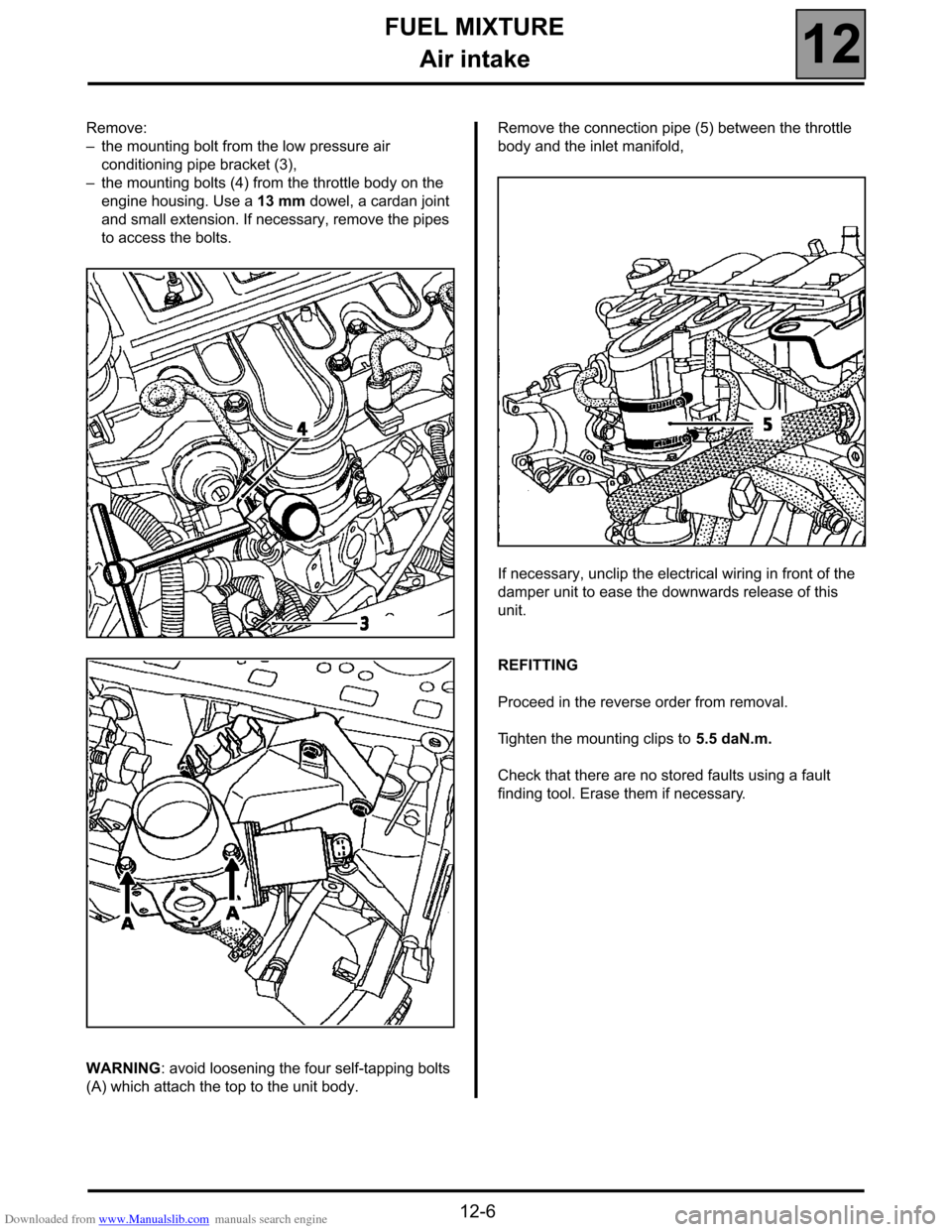

Remove:

–the mounting bolt from the low pressure air

conditioning pipe bracket (3),

–the mounting bolts (4) from the throttle body on the

engine housing. Use a 13 mm dowel, a cardan joint

and small extension. If necessary, remove the pipes

to access the bolts.

WARNING: avoid loosening the four self-tapping bolts

(A) which attach the top to the unit body.Remove the connection pipe (5) between the throttle

body and the inlet manifold,

If necessary, unclip the electrical wiring in front of the

damper unit to ease the downwards release of this

unit.

REFITTING

Proceed in the reverse order from removal.

Tighten the mounting clips to 5.5 daN.m.

Check that there are no stored faults using a fault

finding tool. Erase them if necessary.

Page 32 of 52

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

116STARTING - CHARGING

Alternator

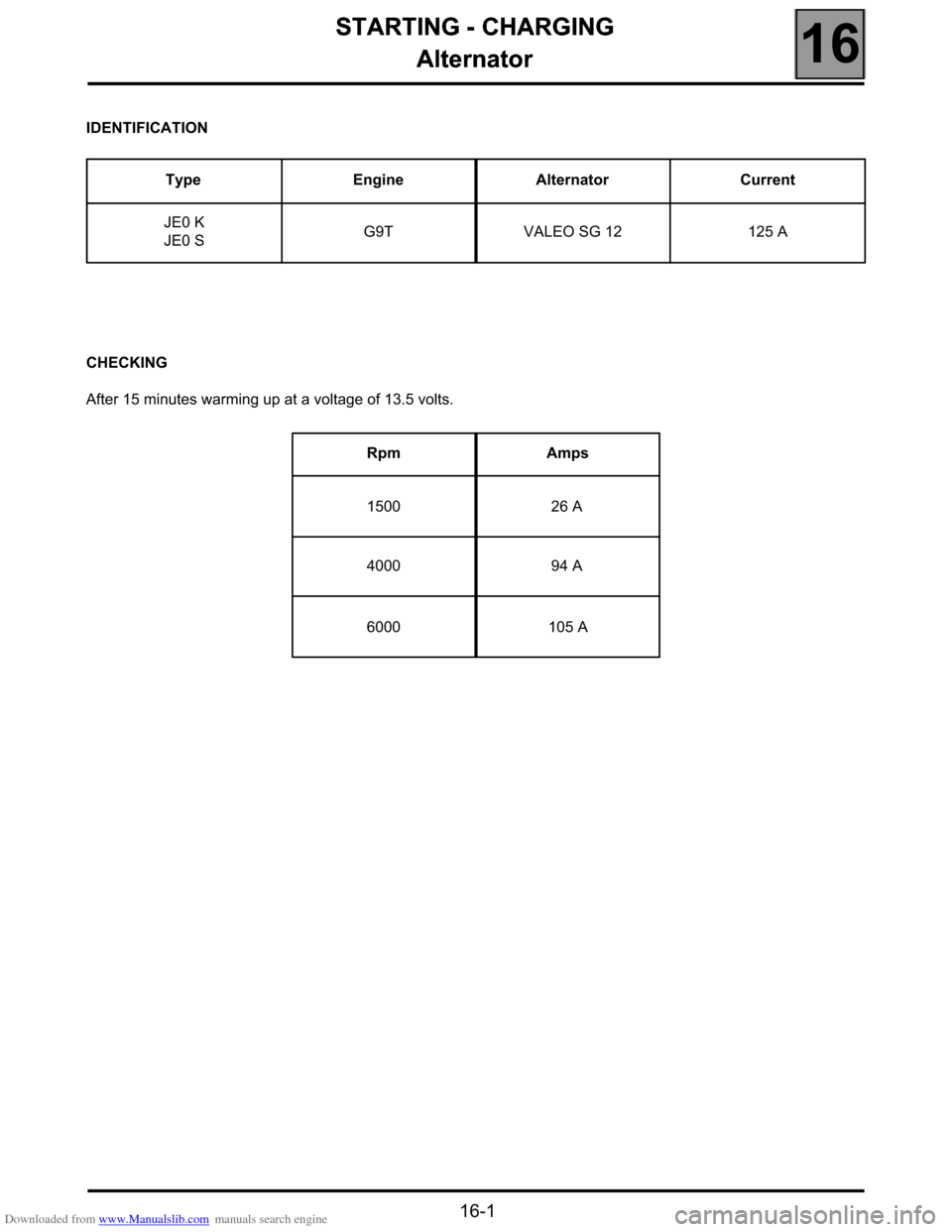

IDENTIFICATION

CHECKING

After 15 minutes warming up at a voltage of 13.5 volts.Type Engine Alternator Current

JE0 K

JE0 SG9T VALEO SG 12 125 A

Rpm Amps

1500 26 A

4000 94 A

6000 105 A

16-1

Page 37 of 52

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Filling and bleeding

19

119COOLING SYSTEM

Filling and bleeding

There is continuous circulation in the heater matrices.

FILLING

It is essential to open the two bleed screws at the

top of the radiator and the cylinder head coolant

pipe housing outlet.

Fill the circuit through the expansion bottle opening.

Close the bleed screws as soon as the liquid starts to

flow in a continuous stream.

Start the engine (2 500 rpm).

Adjust the level by overflow for a period of about

4 minutes.

Close the bottle.

BLEEDING

Allow the engine to run for about 20 minutes at

2 500 rpm, until the engine fans(s) operate (time

necessary for automatic degassing).

Check the liquid level is at the "Maximum" marker.

DO NOT OPEN THE BLEED SCREWS WHILST THE

ENGINE IS RUNNING.

REFIT THE EXPANSION BOTTLE CAP WHILE THE

ENGINE IS WARM.

19-1